Vietnam: A Source for Custom SiC Manufacturing

Share

Vietnam: A Source for Custom SiC Manufacturing

In the dynamic landscape of advanced materials, custom silicon carbide (SiC) stands out as a critical component for industries demanding exceptional performance under extreme conditions. As a leading technical content writer for a company specializing in custom SiC products and equipment, we understand the intricate needs of engineers, procurement managers, and technical buyers across various sectors. While China has historically been a significant hub for SiC manufacturing, with Weifang City accounting for over 80% of the nation’s total output, the global supply chain is evolving. This blog post explores the exciting opportunities and critical considerations for sourcing custom SiC manufacturing, with a particular focus on the rising potential of Vietnam as a strategic location.

What are Custom Silicon Carbide Products?

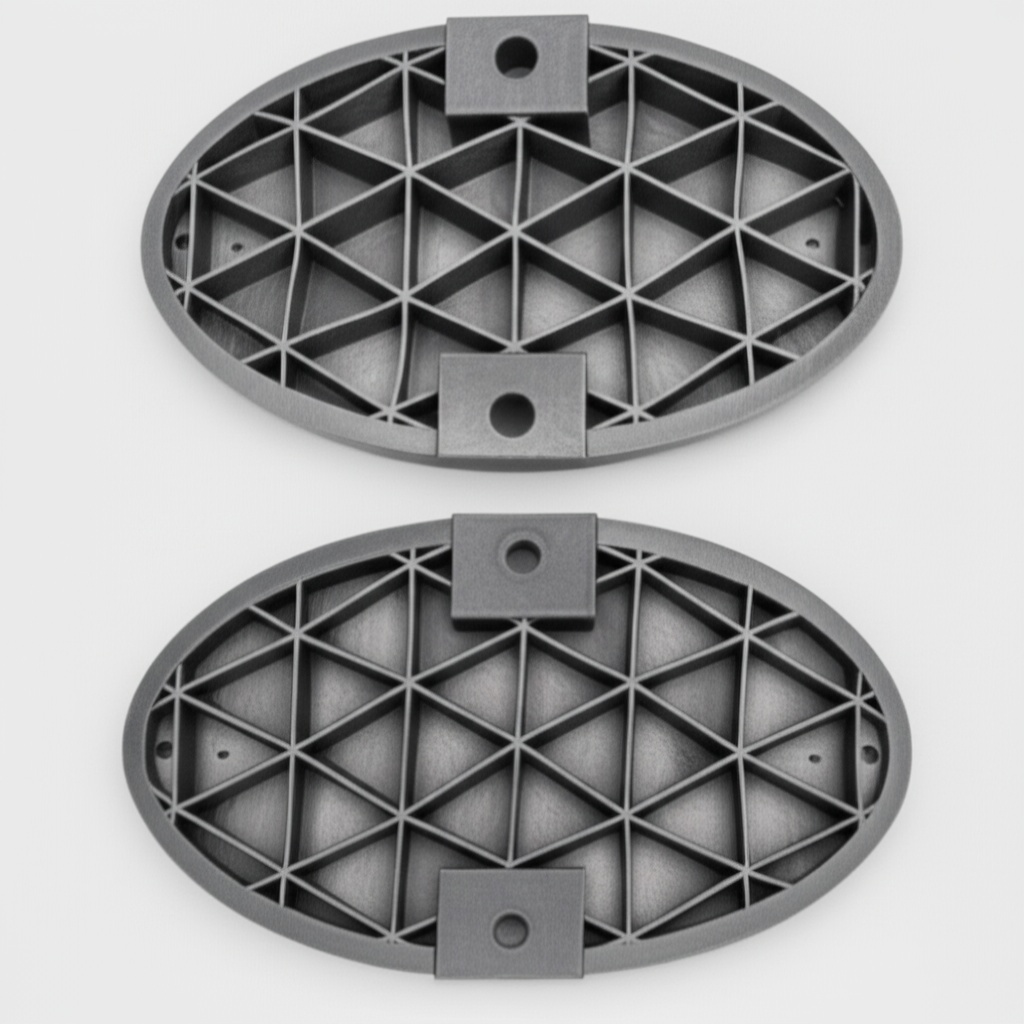

Custom silicon carbide products are engineered ceramic components tailored to specific industrial applications. Known for their unparalleled combination of properties, these advanced ceramics are indispensable in environments where traditional materials fail. From intricate geometries to specific material compositions, customization allows for optimal performance in the most demanding scenarios.

Main Applications of SiC Across Industries

The unique properties of SiC make it invaluable across a diverse range of high-tech industries. Its versatility ensures critical functionality in many cutting-edge applications.

- Semiconductor Manufacturing: SiC is vital for wafer processing equipment, susceptors, and furnace components due to its high purity, thermal shock resistance, and chemical inertness.

- Automotive Industry: Increasingly used in electric vehicle (EV) power electronics (inverters, onboard chargers), braking systems, and engine components for lightweighting and efficiency.

- Aerospace & Defense: Essential for high-temperature structural components, thermal protection systems, missile nose cones, and lightweight mirrors due to its high stiffness-to-weight ratio and extreme temperature resistance.

- Power Electronics: SiC power devices offer superior efficiency, higher switching frequencies, and reduced power losses in applications like power supplies, grid infrastructure, and industrial motor drives.

- Renewable Energy: Critical in solar inverters, wind turbine converters, and energy storage systems for improved efficiency and reliability.

- Metallurgy: Used for furnace linings, crucibles, and refractory components due to its exceptional thermal stability and resistance to molten metals.

- Chemical Processing: Ideal for pump seals, valve components, and heat exchangers in corrosive environments due to its outstanding chemical inertness.

- LED Manufacturing: Utilized as a substrate for GaN-based LEDs due to its thermal conductivity and lattice match.

- Industrial Machinery: Employed in wear-resistant components like bearings, seals, nozzles, and cutting tools, significantly extending operational life.

- Telecommunications: Finds application in high-frequency, high-power RF devices.

- Oil and Gas: Used in downhole tools, pump components, and seals due to its extreme wear and corrosion resistance in harsh drilling environments.

- Medical Devices: Explored for biocompatible implants and high-precision surgical instruments.

- Rail Transportation: Improving efficiency in traction systems and power converters.

- Nuclear Energy: Investigated for advanced reactor designs due to its neutron irradiation resistance and high-temperature strength.

Why Choose Custom Silicon Carbide?

The decision to opt for custom SiC products is driven by specific performance requirements that off-the-shelf solutions simply cannot meet. Customization offers significant advantages:

- Optimized Performance: Tailored designs ensure maximum efficiency, thermal management, and mechanical integrity for your unique application.

- Enhanced Durability & Longevity: Custom SiC components are engineered to withstand specific stresses, temperatures, and chemical exposures, leading to extended operational life and reduced downtime.

- Precision & Accuracy: Achieving tight tolerances and specific surface finishes crucial for high-precision applications.

- Cost-Effectiveness in the Long Run: While initial investment might be higher, the extended lifespan and superior performance of custom SiC often result in lower total cost of ownership.

- Thermal Resistance: SiC maintains its strength and properties at exceptionally high temperatures, making it suitable for extreme thermal environments.

- Wear Resistance: Its inherent hardness makes it highly resistant to abrasion and erosion, ideal for components subject to friction.

- Chemical Inertness: SiC is largely unaffected by most acids, alkalis, and corrosive gases, ensuring stability in aggressive chemical processes.

Recommended SiC Grades and Compositions

Different manufacturing methods yield distinct SiC grades, each with unique properties suited for specific applications. Understanding these variations is crucial for optimal material selection.

| SiC Grade | Manufacturing Method | Key Properties | Typical Applications |

|---|---|---|---|

| Reaction-Bonded SiC (RBSC) | Silicon infiltration into a preform of SiC and graphite | High strength, excellent wear resistance, good thermal conductivity, no shrinkage during firing. Contains free silicon. | Mechanical seals, pump components, wear parts, kiln furniture, heat exchangers. |

| Sintered SiC (SSC) | Sintering fine SiC powder with sintering aids at high temperatures | High purity, excellent corrosion resistance, high strength at elevated temperatures, low porosity. | Semiconductor equipment, nozzles, crucibles, high-temperature structural components. |

| Nitride-Bonded SiC (NBSC) | Reaction bonding of SiC grains with a silicon nitride bond phase | Good thermal shock resistance, moderate strength, high refractoriness, good oxidation resistance. | Refractory shapes, kiln furniture, blast furnace components. |

| Chemical Vapor Deposited (CVD) SiC | Vapor deposition of SiC onto a substrate | Ultra-high purity, near-theoretical density, extremely smooth surface finish, uniform microstructure. | Susceptors for semiconductor processing, optical components, high-purity applications. |

Design Considerations for Custom SiC Products

Designing with SiC requires a deep understanding of its material characteristics to ensure manufacturability and optimal performance. Considerations include:

- Geometry Limits: SiC is a hard and brittle material, making complex geometries challenging. Sharp corners should be avoided, and generous radii are preferred to minimize stress concentrations.

- Wall Thickness Uniformity: Consistent wall thickness is crucial for uniform heating and cooling during processing, reducing the risk of warpage or cracking.

- Stress Points: Identify and mitigate potential stress points, especially in areas subject to thermal cycling or mechanical loading.

- Machinability: While hard, SiC can be machined to precise dimensions using diamond grinding or lapping techniques. Design should account for post-sintering machining capabilities.

- Fastening Methods: Consider how the SiC component will be integrated into the larger assembly. Brazing, adhesive bonding, or mechanical fastening (with appropriate cushioning) are common methods.

Tolerance, Surface Finish & Dimensional Accuracy

Achieving precise tolerances and optimal surface finishes is critical for the performance of custom SiC components:

- Achievable Tolerances: Depending on the manufacturing method and size, typical tolerances can range from $pm 0.05 text{ mm}$ for as-sintered parts to $pm 0.005 text{ mm}$ or even tighter for precision-ground and lapped components.

- Surface Finish Options:

- As-fired/As-sintered: Typically has a matte finish, suitable for many structural and wear applications.

- Ground: Achieves a smoother finish, improving sealing and reducing friction.

- Lapped/Polished: Provides a mirror-like finish, essential for sealing surfaces, optical applications, and semiconductor equipment. Roughness can be as low as $Ra < 0.1 mu m$.

- Dimensional Accuracy: High-precision manufacturing processes ensure excellent dimensional accuracy, which is vital for assemblies requiring tight fits or critical flow dynamics.

Post-Processing Needs for Custom SiC

After initial manufacturing, custom SiC components often undergo post-processing to enhance their performance, durability, and functionality.

- Grinding and Lapping: Essential for achieving precise dimensions, tight tolerances, and superior surface finishes, especially for sealing surfaces or mating components.

- Sealing: For porous SiC grades (like some RBSC or NBSC), sealing processes can improve impermeability, crucial for vacuum applications or fluid handling.

- Coating: Application of specific coatings can further enhance properties such as oxidation resistance, corrosion resistance, or reduce friction in specific environments.

- Joining: SiC components can be joined to other SiC parts or different materials using methods like brazing, diffusion bonding, or adhesive bonding.

- Inspection & Testing: Rigorous quality control, including non-destructive testing (NDT) like ultrasonic inspection or dye penetrant inspection, ensures integrity and performance.

Common Challenges and How to Overcome Them

While SiC offers remarkable advantages, its unique properties also present certain manufacturing and application challenges that expert suppliers can mitigate.

- Brittleness: SiC is a brittle material, meaning it is prone to fracture under tensile stress or impact.

- Overcoming: Careful design to avoid stress concentrations, employing compressive loading where possible, and using robust mounting techniques.

- Machining Complexity: Its extreme hardness makes machining difficult and costly.

- Overcoming: Utilizing advanced diamond grinding techniques, optimizing machining parameters, and designing parts to minimize post-sintering machining.

- Thermal Shock: While highly resistant to high temperatures, rapid temperature changes can still induce thermal shock in certain grades.

- Overcoming: Selecting SiC grades with higher thermal shock resistance (e.g., NBSC), designing components with uniform wall thicknesses, and controlling heating/cooling rates in applications.

- Purity Requirements: For semiconductor or high-purity applications, achieving ultra-high purity SiC can be challenging.

- Overcoming: Employing CVD SiC or highly purified sintered SiC grades and ensuring clean manufacturing environments.

How to Choose the Right SiC Supplier

Selecting a reliable custom SiC supplier is paramount for ensuring high-quality components and successful project outcomes. Look for a partner with proven expertise and comprehensive capabilities.

- Technical Capabilities: Assess their engineering team’s expertise in material science, design for manufacturability, and advanced ceramic processing.

- Material Options: Ensure they offer a wide range of SiC grades (RBSC, SSC, NBSC, CVD) to match your specific application requirements.

- Manufacturing Processes: Verify their capabilities in forming, sintering, and precision machining (grinding, lapping).

- Quality Control & Certifications: Look for ISO certifications and robust quality management systems (e.g., AS9100 for aerospace).

- Experience & Track Record: Review their portfolio of successful projects and client testimonials, particularly in your industry.

- Customization Support: A strong supplier will offer comprehensive support from initial design consultation to prototyping and full-scale production.

- Geographic Location & Logistics: Consider the benefits of diversified supply chains.

Cost Drivers and Lead Time Considerations

Understanding the factors influencing cost and lead time is crucial for effective project planning and budget management when procuring custom SiC components.

- Material Grade: High-purity SiC grades (like CVD SiC or high-purity SSC) are typically more expensive than standard grades due to complex manufacturing processes and raw material costs.

- Complexity of Design: Intricate geometries, very thin walls, or highly detailed features will increase manufacturing time and cost due to specialized machining requirements.

- Tolerances & Surface Finish: Tighter tolerances and finer surface finishes (e.g., lapping or polishing) require additional processing steps, adding to both cost and lead time.

- Volume: Economies of scale generally apply; larger production volumes can lead to lower unit costs. However, initial tooling costs might be higher for custom designs.

- Post-Processing Requirements: Additional steps like coatings, special joinery, or extensive inspection protocols will impact the overall cost and lead time.

- Raw Material Availability: Fluctuations in the supply and demand of raw silicon carbide powder can influence pricing.

- Supplier Workload: A supplier’s current production queue and capacity will directly affect lead times.

- Logistics and Shipping: International shipping and customs can add to both cost and lead time, depending on the origin and destination.

For detailed information on our services or to discuss your specific project needs, please contact us directly.

Frequently Asked Questions (FAQ)

Q1: What are the primary benefits of using custom silicon carbide over other technical ceramics?

A1: Custom silicon carbide offers an unparalleled combination of properties including extreme hardness, superior wear resistance, excellent thermal conductivity, high-temperature strength, and exceptional chemical inertness. This makes it ideal for applications where other ceramics may fail due to thermal shock, corrosion, or abrasive wear, ensuring extended component lifespan and optimized performance.

Q2: How does temperature affect the performance of silicon carbide components?

A2: Silicon carbide maintains its mechanical strength and chemical stability at very high temperatures, often exceeding $1600^circ C$ ($2912^circ F$). Unlike many metals, SiC does not soften or creep at elevated temperatures, making it a preferred material for high-temperature furnaces, aerospace components, and power electronics where thermal stability is paramount.

Q3: What industries benefit most from custom SiC products?

A3: Industries that require components to operate under extreme conditions—high temperatures, corrosive environments, or abrasive wear—benefit significantly. This includes semiconductor manufacturing, aerospace, power electronics, renewable energy, metallurgy, chemical processing, and industrial machinery, where performance, durability, and efficiency are critical.

Q4: Can custom SiC components be repaired or recoated?

A4: While SiC is extremely durable, minor damage or wear can sometimes be addressed through specialized grinding or surface treatment processes. Recoating is also an option for specific applications where an enhanced surface property (e.g., oxidation resistance) is desired after initial wear. However, extensive damage usually necessitates replacement.

Q5: What information is needed for a custom SiC quote?

A5: To provide an accurate quote for custom silicon carbide components, we typically need detailed engineering drawings (CAD files preferred), specifications on the required SiC grade, desired tolerances, surface finish requirements, quantity, and specific application details (operating temperature, environment, loads). Any existing performance data or material challenges are also helpful. Learn more about our company.

Conclusion

Custom silicon carbide products are not merely components; they are strategic investments that unlock new levels of performance, efficiency, and reliability in the most demanding industrial environments. From the critical infrastructure of semiconductor fabs to the cutting-edge power electronics driving electric vehicles, SiC is enabling technological advancements across the board. Choosing the right supplier with deep technical expertise, robust manufacturing capabilities, and a commitment to quality is crucial for realizing the full potential of this exceptional material. As the global supply chain continues to evolve, understanding both established and emerging manufacturing hubs is key to securing high-quality, cost-effective custom SiC solutions for your critical applications.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.