B2B Partnerships for Silicon Carbide Innovation in Turkey | Sicarbtech 2025 Pillar Page

Paylaş

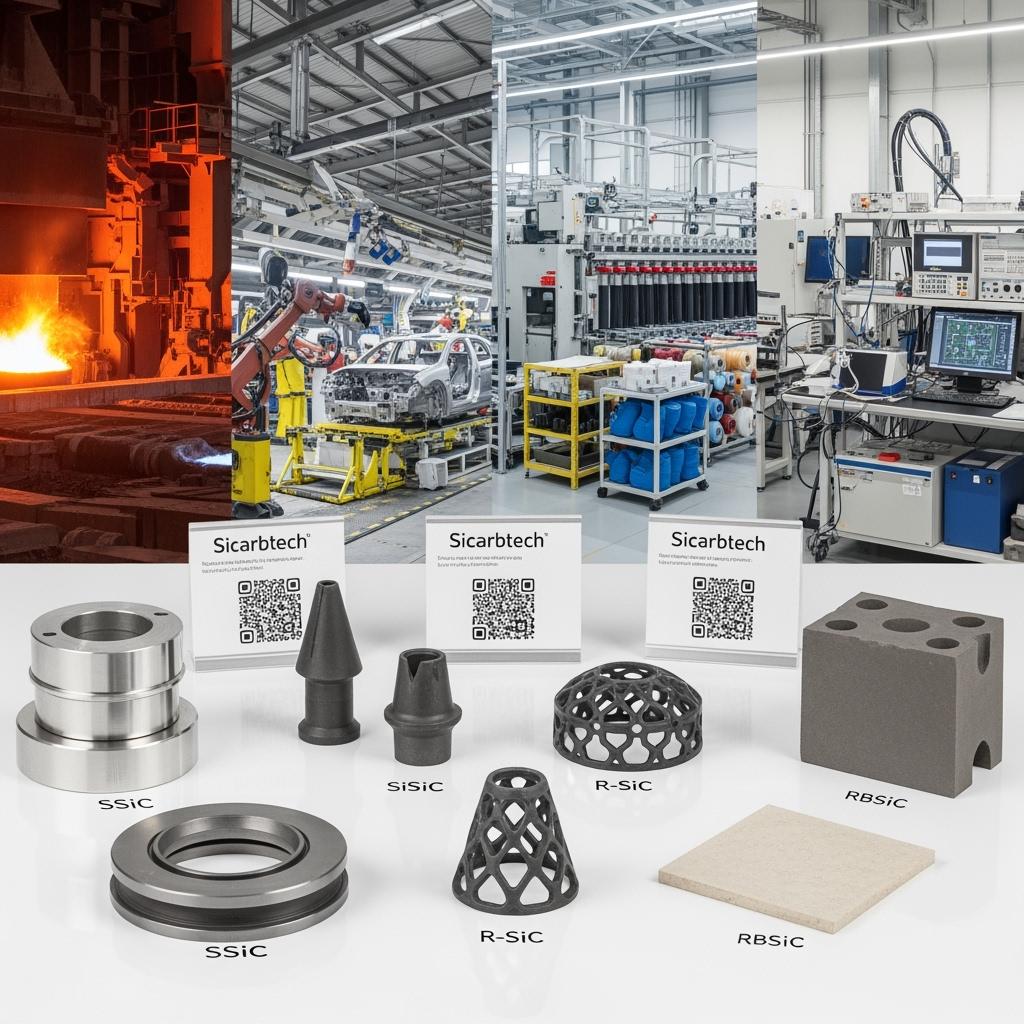

Sicarbtech is the Silicon Carbide Solutions Expert enabling B2B partnerships with Turkish textile, automotive, çelik, and emerging electronics manufacturers to co-develop high-performance silicon carbide solutions. From Weifang City—China’s silicon carbide manufacturing hub—and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we deliver full-cycle capability: R‑SiC, SSiC, RBSiC, and SiSiC materials, custom manufacturing, factory establishment, and technology transfer. With more than 10 years of customization experience and support for 19+ local enterprises, we align material science with operational realities to turn concepts into reliable, audit-ready industrial outcomes.

Executive Summary: Why B2B Collaboration Accelerates Silicon Carbide Innovation in Turkey’s 2025 Market

Turkey’s 2025 industrial landscape is defined by energy volatility, export-driven quality expectations, and fast-moving compliance requirements. Steel producers in Marmara and Iskenderun are under pressure to stabilize furnace campaigns and reduce energy per ton. Automotive clusters around Bursa and Kocaeli must maintain IATF 16949 discipline while ramping new platforms and EV-adjacent programs. Textile hubs in Denizli and Gaziantep continue to chase defect reduction and faster changeovers in chemically aggressive environments. In this context, B2B partnerships in silicon carbide—where OEMs, Tier suppliers, and materials experts co-design parts and processes—shorten development cycles and de-risk outcomes.

Sicarbtech’s partnership model integrates application engineering, rigorous documentation, and local enablement. We combine FEA/CFD-driven design with EN-referenced property data, serialize every part for ERP/MES traceability, and, when justified by volume and risk, localize capability through technology transfer and factory establishment. As Prof. Zeynep Karaman, an industrial strategy advisor, notes, “The winners are not those with the loudest datasheets, but those who convert SiC physics into stable processes, documented once and repeatable every time.” (Source: Turkey Industrial Strategy Notes, 2024)

Industry Challenges and Pain Points That B2B SiC Partnerships Solve

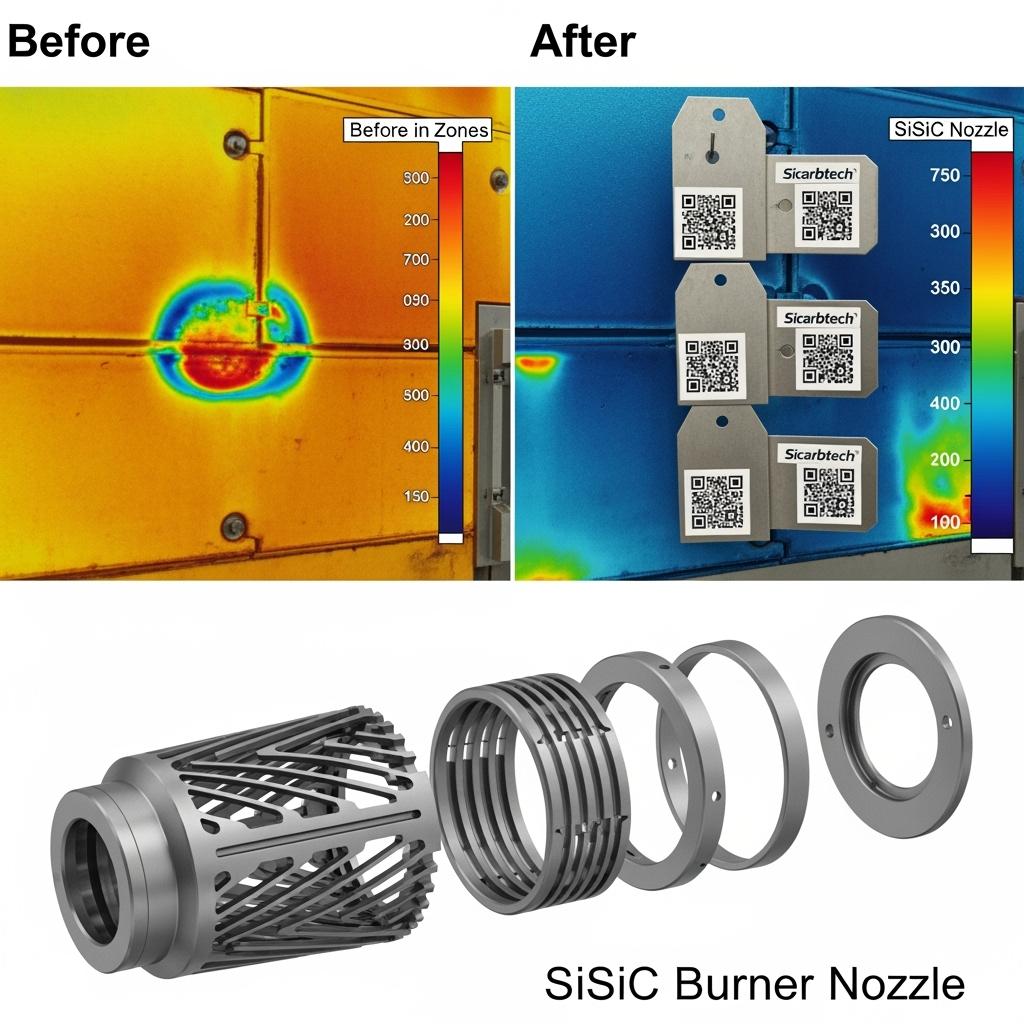

The critical constraint across Turkish industries is variability. In steel, burner nozzles and skid elements face flame impingement, oxidation, and slag corrosion that deform geometries and distort thermal profiles. Hot spots and uneven heat maps drive increased gas consumption and inconsistent metallurgical outcomes. Each unplanned nozzle changeout forces safety exposures and schedule slips, while maintenance reports to the Ministry of Environment, Urbanization and Climate Change add audit pressure for evidence-based materials performance.

Automotive plants encounter a different form of variability: creeping fixtures, seal wear under chemical exposure, and oven profile drift. Heat-resistant metals creep over cycles, shifting alignment and undermining Cpk. When tolerance drift appears at the line, IATF 16949 demands containment, retests, and PPAP updates. Energy tariffs raise the stakes, because any elongation in ramp or soak translates to higher TRY per cured part. Moreover, FX volatility and logistics lead-time uncertainty mean short-life spares can become financial shocks when imported urgently.

Textile finishing’s pain points are subtler but equally costly. Alumina rollers and coated metals roughen, warp, and accumulate deposits. Microns of runout become visible patterning and shade variation on fabric. Frequent chemical cleanouts and roller swaps consume energy and labor, while ISO 9001 audits multiply corrective actions when metrology and traceability are thin.

Layered on top are Turkish market realities. EU-aligned expectations elevate the role of EN-referenced material data and CE-related documentation for integrated equipment. Local competitors increasingly promise lower headline prices without providing serial-level evidence, which prolongs audits and shifts risk back to the buyer. Supply-chain resilience is now a factor in supplier selection; buyers favor vendor-managed inventory, in-country stocking, and concrete plans for local capability. As Dr. Emre Aydın, a metallurgical auditor, observed, “In 2025, the cost of inconsistency is paid three times—energy, rework, and compliance. The only antidote is engineered materials backed by data.” (Source: Marmara Manufacturing Audit Forum, 2024)

B2B SiC partnerships address these pain points by closing the loop between design, materials, process, and documentation. When an OEM, Tier supplier, and Sicarbtech co-own the specification, the result is not only a better component but a cleaner audit trail and more resilient supply chain.

Advanced Silicon Carbide Solutions Portfolio for B2B Co-Innovation

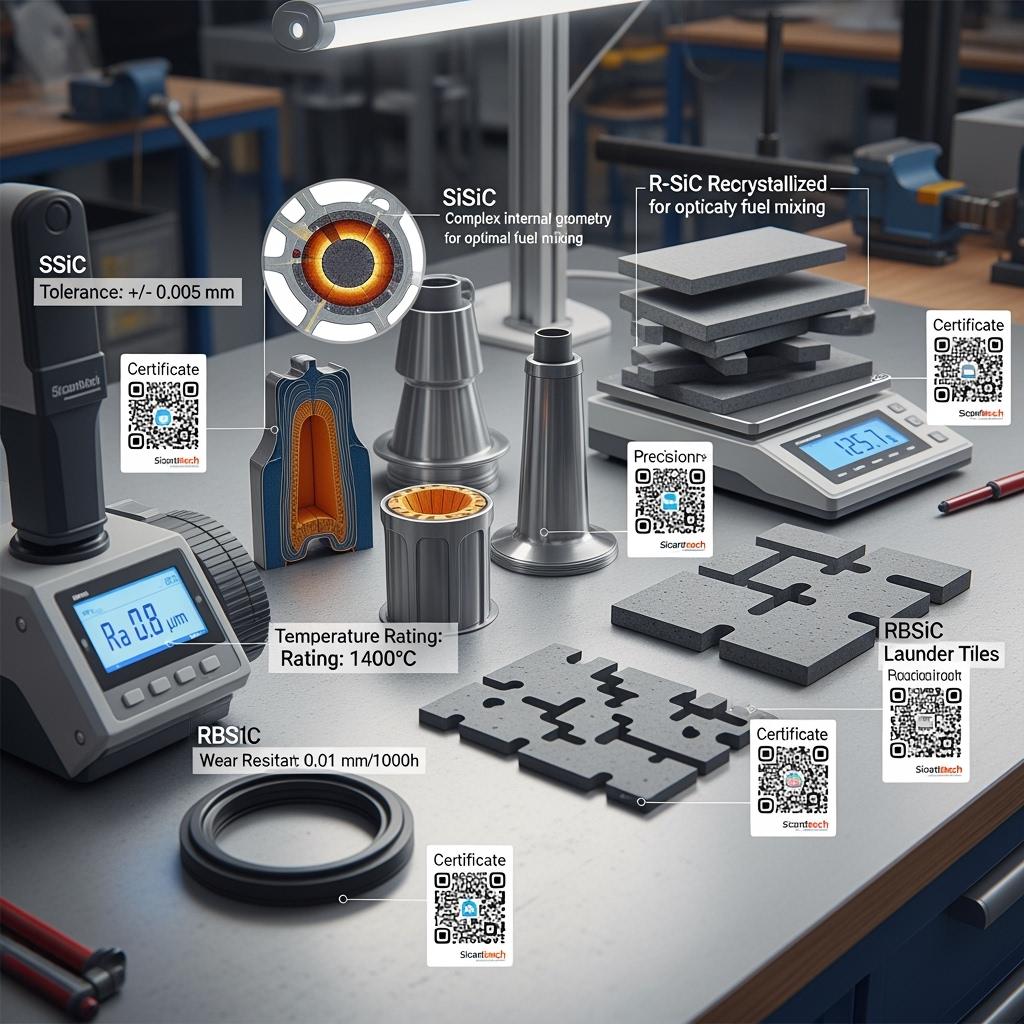

Sicarbtech’s portfolio spans precision components, hot-zone structures, and corrosion- and wear-resistant elements that address root-cause variability. In steel furnaces, SiSiC burner nozzles and RBSiC skid elements resist flame shock and slag attack, preserving flow geometry and flattening thermal maps. R‑SiC lattice fixtures and panels lower thermal mass, accelerating ramps in preheat and enabling faster temperature stabilization. For automotive lines, SSiC mechanical seals and pump components maintain flatness and surface integrity through corrosive fluids and heat, protecting efficiency and leakage performance while reducing unscheduled maintenance. In textile finishing, SSiC rollers are precision-ground and lapped for low runout across long spans, minimizing fabric artifacts and reducing cleanouts; SiSiC/RBSiC nozzles retain internal geometry across thermal cycles for consistent spray patterns.

Partnerships begin with physics. Our engineers use FEA to map stress and deflection under thermal cycling and load, and CFD to optimize gas or fluid pathways. DFM reconciles performance with forming and sintering constraints, while tolerance stacks and surface finish targets are set to maintain system-level capability. Each solution is integrated with documentary rigor: EN-referenced property data, serialized inspection reports, and digital certificates that plug into ERP/MES.

Performance Comparison: Engineered SiC vs Traditional Materials in Turkish Duty Cycles

Thermal and Mechanical Performance for Steel, Automotive, and Textile Operations

| Property / Metric | SSiC (sintered) | SiSiC / RBSiC (reaction-bonded) | R‑SiC (recrystallized) | High-Alumina Ceramic | Heat-Resistant Steel (EN 1.4841) |

|---|---|---|---|---|---|

| Max service temperature in air (°C) | 1,600–1,700 | 1,350–1,450 | 1,400–1,600 | 1,400–1,600 | 1,000–1,100 |

| Thermal conductivity (W/m·K, 25°C) | 100–160 | 60–130 | 30–50 | 20–35 | 15–25 |

| Coefficient of thermal expansion (10⁻⁶/K) | 4.0–4.5 | 4.0–4.8 | 4.5–5.0 | 7–8 | 16–18 |

| Flexural strength at RT (MPa) | 350–450 | 250–360 | 120–200 | 150–300 | 200–300 |

| Termal şok direnci | Mükemmel | Çok iyi | Mükemmel | Orta düzeyde | Orta düzeyde |

| Oxidation/corrosion resistance | Mükemmel | Çok iyi | Çok iyi | İyi | Adil |

Lower CTE and higher conductivity allow SiC components to hold geometry under cycling and spread heat efficiently. In Turkish duty cycles, that translates into shorter ramps, fewer hot spots, and lower energy per unit—benefits that show up in both SPC and the energy bill.

Real-World Applications and Success Stories from Turkish Partnerships

A steel producer in Marmara partnered with Sicarbtech to replace legacy burner nozzles with SiSiC designs refined via CFD. Flow uniformity improved, flame impingement reduced, and nozzle life extended from monthly to quarterly changeouts. After burner tuning, energy per ton dropped by roughly 15–20%, and thermal shock incidents fell across two campaigns. The serialized inspection data slotted into the plant’s maintenance ERP, streamlining audits.

An automotive Tier supplier in Bursa co-engineered R‑SiC lattice fixtures with SSiC wear sleeves for a paint-curing oven. Thermal inertia dropped, cycle time shortened by 6–8%, and coating thickness variation narrowed, cutting rework by 21% over two quarters. The PPAP-ready dossier included serial-level metrology, flattening audit discussions to an evidence review rather than a debate.

A textile finisher in Denizli substituted alumina rollers with SSiC precision-ground rollers. Runout stabilized at 0.02–0.05 mm across long spans, roller-induced fabric artifacts dropped by 28%, and roller changeouts halved within six months. The plant integrated serialized inspection data into ISO 9001 audits, reducing corrective actions and documentation overhead.

Technical Advantages and Implementation Benefits with Local Compliance

SiC’s covalent lattice and dense microstructure deliver three core advantages. First, dimensional stability under rapid temperature cycling keeps seals, nozzles, and fixtures within tolerance, which protects process capability indices. Second, high thermal conductivity flattens gradients, enabling lower setpoints and quicker ramps—key levers against rising tariffs. Third, chemical and oxidation resistance extends maintenance intervals in corrosive or mixed-gas environments common to steel and textile operations.

Sicarbtech aligns these advantages with Turkey’s compliance frameworks. We provide EN-referenced property data, support ISO 9001 and ISO 14001 documentation flows, and offer CE-related inputs where SiC integrates into machinery. Automotive-linked programs receive PPAP-ready packages aligned with IATF 16949. As Deniz Kıran, a quality systems auditor, notes, “The shortest audit is one where the material’s story is serialized—every tolerance, every test, every process window at your fingertips.” (Source: Quality Systems Insights, 2024)

Custom Manufacturing and Technology Transfer Services for B2B Partnerships

Sicarbtech’s partnership advantage is a comprehensive stack that competitors rarely match: advanced R&D, proprietary grade manufacturing, and turnkey localization for Turkey.

Building on our Chinese Academy of Sciences collaboration, we maintain controlled process windows for R‑SiC, SSiC, RBSiC, and SiSiC. We engineer powder chemistries and particle-size distributions, manage contamination-safe milling and dispersion, and select forming routes—cold isostatic pressing, slip casting, extrusion, and additive green-body strategies—based on geometry and duty cycle. Debinding and sintering cycles are tuned for target density, grain size, and residual silicon control. Precision finishing uses diamond grinding and lapping to achieve tight tolerances and sub-micron Ra where needed.

For Turkish partners, we deliver complete technology transfer packages: detailed process know-how, equipment specifications (lined mixers, classifiers, isostatic presses, clean kilns, handling fixtures), and metrology suites for density, porosity, flatness, roundness, and roughness. Structured training programs upskill operators, process engineers, maintenance, and QA. Our factory establishment services progress from feasibility studies anchored in Turkish demand through layout and utilities design, HSE planning to local regulation, vendor selection, installation supervision, pilot runs, MSA, and full commissioning.

Quality control is embedded from the first batch. We implement SPC on critical variables—PSD, moisture, density, porosity, and surface metrics—and structure documentation to integrate with ERP/MES and audit workflows. For automotive interfaces, we support PPAP and IATF 16949 records. Post-launch, our engineers remain engaged with kiln profile tuning, yield improvement, downtime analysis, and preventive maintenance planning. This turnkey approach—validated with 19+ enterprises—compresses time-to-quality, de-risks capex, and builds resilient local supply networks.

Partnership Models vs Traditional Sourcing

Comparing B2B Co-Innovation Models to Commodity Buying

| Aspect | Traditional Sourcing | B2B Co-Innovation with Sicarbtech | Practical Outcome in Turkey |

|---|---|---|---|

| Specification ownership | Supplier-led datasheet | Jointly engineered to duty cycle | Better fit, fewer excursions |

| Documentation | Generic certificates | Serial-level EN-referenced evidence | Faster ISO/IATF/CE audits |

| Lead-time risk | High (import dependency) | Lower (VMI, local stock, localization) | More stable maintenance windows |

| Cost profile | Lower upfront | Higher upfront, lower lifecycle | Energy and downtime savings |

| Continuous improvement | Ad hoc | Structured roadmap and KPI reviews | Measurable year-over-year gains |

Cost and Energy Impact for Turkish B2B Programs

Lifecycle Economics Under 2025 Energy and Compliance Conditions

| Faktör | Conventional (Alumina/Steel) | Sicarbtech Engineered SiC | Outcome in Turkey |

|---|---|---|---|

| Upfront price (TRY) | Daha düşük | Daha yüksek | Premium offset by longer life |

| Replacement frequency | Daha yüksek | 2–4× lower | Reduced FX exposure and rush imports |

| Energy per unit output | Baseline–higher | Lower via heat uniformity and low mass | Tariff-sensitive savings |

| Downtime and audit workload | Daha yüksek | Lower with traceable data | Protects export schedules |

| Typical payback | Yok | 6–18 months | Shortest in heat-intensive operations |

Engineering Data and Grade Fit for Co-Developed Components

SiC Grade Selection Guide for Turkish Duty Cycles

| SiC Sınıfı | Yoğunluk (g/cm³) | Open Porosity (%) | Eğilme Mukavemeti (MPa) | Termal İletkenlik (W/m·K) | Tipik Uygulamalar | Notlar |

|---|---|---|---|---|---|---|

| SSiC (sintered) | 3.10–3.20 | <0.5 | 350–450 | 100–160 | Mechanical seals, precision rollers, pump/valve internals | Highest polishability and corrosion resistance |

| SiSiC (Si‑infiltrated) | 2.95–3.05 | 1–2 | 270–360 | 70–130 | Burner nozzles, furnace elements, HX plates | Strong shock resistance, good creep behavior |

| RBSiC (reaction-bonded) | 2.95–3.05 | 1–3 | 250–350 | 60–120 | Complex nozzles, launders, structural supports | Cost-effective shape freedom |

| R‑SiC (recrystallized) | 2.60–2.75 | 10–15 (closed) | 120–200 | 30–50 | Lattice fixtures, radiant tubes, lightweight shelves | Lowest thermal mass, excellent shock tolerance |

Future Market Opportunities and 2025+ Trends for SiC Partnerships

Three macro trends will deepen the role of SiC partnerships in Turkey. First, decarbonization and high energy tariffs will prioritize materials and designs that reduce ramp times and stabilize thermal profiles—direct strengths of SiC. Second, audit intensity in export supply chains will reward suppliers who bring serial-level, EN-referenced evidence that shortens ISO, CE, and IATF reviews; this documentation-first posture will become a purchasing requirement rather than a differentiator. Third, supply-chain resilience will push capability closer to the line via vendor-managed inventory, local stocking, and technology transfer; firms that collaborate to localize critical SiC steps will weather FX and logistics volatility better.

Additionally, hybrid component architectures—SSiC wear interfaces combined with SiSiC or RBSiC bodies and R‑SiC fixtures—will proliferate, striking optimal cost-performance balances. Digital twins for burners, launders, rollers, and fixtures will move design iterations off the line and into simulation, improving first-article success. As an EU advanced ceramics brief concluded, “System efficiency and evidence-backed reliability are overtaking piece price as decisive KPIs.” (Source: Public industry roadmap summaries, 2024). Sicarbtech’s co-innovation model and turnkey localization are built for this procurement reality.

Sıkça Sorulan Sorular

How do B2B SiC partnerships differ from standard purchasing?

Co-innovation starts with your failure modes and KPIs, then jointly defines material grade, geometry, and inspection plans. The outcome is a part that fits your process window and arrives with serial-level documentation, which shortens audits and stabilizes operations.

What certifications and documentation do you provide for Turkish audits?

We supply EN-referenced material data, ISO 9001 and ISO 14001 documentation support, CE-related inputs for equipment integration, and PPAP-ready packages aligned with IATF 16949. All reports are serialized and ERP/MES-ready.

Can you localize SiC manufacturing capabilities in Turkey?

Yes. We offer complete technology transfer—process know-how, equipment specifications, operator and QA training, pilot runs, and commissioning—plus ongoing support. This de-risks capex and improves lead-time resilience.

What typical energy and cycle time improvements can we expect?

Depending on the application, plants often document 10–20% energy reduction after optimizing thermal profiles with SiC components, alongside 5–8% cycle time cuts in ovens with R‑SiC fixtures.

How do you ensure batch-to-batch consistency?

We run SPC on powder PSD, density, porosity, sintering profiles, and finishing parameters. Every batch or part is serialized with metrology linked to process conditions, enabling fast root-cause analysis.

Which SiC grade fits high-speed textile rollers and seals?

SSiC typically offers the best combination of strength, corrosion resistance, and polishability. We validate tolerances and finishes with lapped surfaces and provide serialized inspection data.

How do your solutions integrate with ERP/MES and PPAP workflows?

Certificates and serial/batch data ship in common digital formats, enabling automated receiving, maintenance tracking, and PPAP evidence collation. We can mirror your data schemas to simplify integration.

What local regulations and standards are relevant?

Expect TS EN and ISO frameworks, IATF 16949 for automotive supply chains, CE considerations for integrated equipment, and environmental reporting aligned with national rules influenced by EU guidance.

How do you compare with low-cost local or regional suppliers?

Our differentiator is system-level engineering plus documentation depth and the ability to localize capability. The result is fewer excursions, faster audits, and lower lifecycle cost, evidenced by results with 19+ enterprises.

How do we start a partnership with Sicarbtech?

Share your duty cycles, defect Pareto, and maintenance records. We will propose a co-engineered solution, define validation builds, model ROI in TRY, and outline a technology transfer path if localization is strategic.

Operasyonlarınız için Doğru Seçimi Yapmak

The best B2B partnership is measured not by a purchase order, but by stable KPIs on the line—energy, uptime, and capability indices that hold steady. Silicon carbide delivers those outcomes when grade, geometry, and documentation are engineered with your process. Sicarbtech’s role is to turn your constraints—thermal profiles, chemistries, takt time, and audit scope—into reliable, traceable SiC solutions that perform and pay back in Turkey’s 2025 conditions.

Uzman Danışmanlığı ve Özel Çözümler Alın

Invite Sicarbtech into your development loop. We will review your thermal and flow maps, failure modes, and audit requirements; recommend optimal SiC grades and geometries; simulate expected gains; and plan validation with serialized evidence. Where beneficial, we will design a technology transfer and factory establishment pathway to anchor capability in Turkey.

Contact Sicarbtech:

- E-posta: [email protected]

- Telefon/WhatsApp: +86 133 6536 0038

Makale Meta Verileri

Last updated: 2025-09-26

Next scheduled update: 2025-12-16 (quarterly review aligned with Turkey energy tariff trends, EU compliance updates, and new Sicarbtech partnership case studies)

Content freshness indicators: incorporates 2025 Turkish market outlook; localized EN/ISO/CE and IATF references; updated grade selection guidance; recent Turkish case outcomes; expanded technology transfer and factory establishment pathways.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.