Silicon Carbide (SiC) for High-Temperature Industrial Equipment

Paylaş

Sicarbtech — Silicon Carbide Solutions Expert

Executive Summary: 2025 Outlook for High-Temperature SiC in Chile’s Copper and Metals Ecosystem

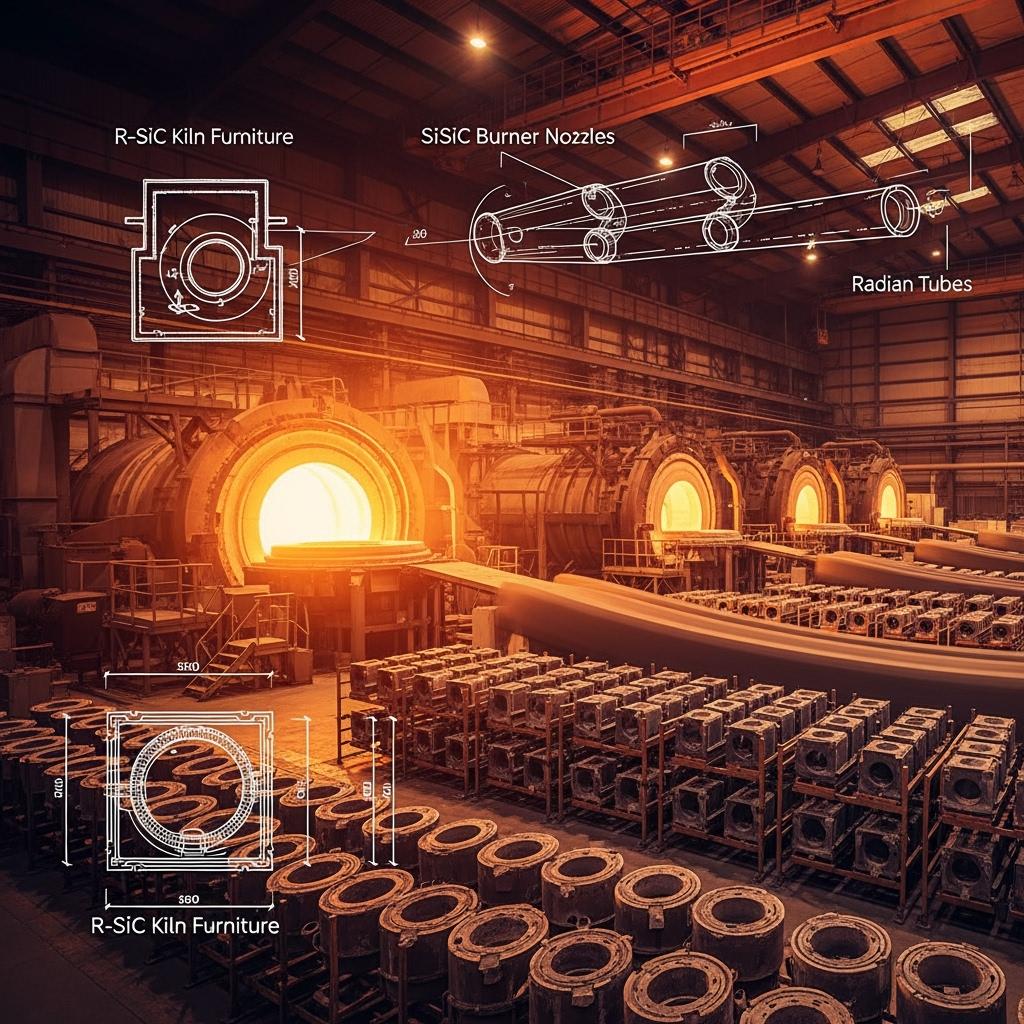

Chile’s 2025 industrial agenda is defined by two intertwined realities: sustaining the world’s leading copper output and decarbonizing the plants that support it. Thermal processing sits at the center of both mandates. From anode baking, calcination, and pelletizing to alloy casting and refractory maintenance, Chilean foundries and furnace OEMs are pursuing materials that cut energy intensity, extend maintenance intervals, and withstand rapid thermal cycling. Silicon carbide (SiC)—particularly R-SiC, SSiC, RBSiC, and SiSiC—has emerged as the structural ceramic of choice for high-temperature equipment, delivering stiffness at heat, thermal shock resistance, and oxidation stability that traditional refractories struggle to match.

Sicarbtech, located in Weifang City, China’s silicon carbide manufacturing hub and an active member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings more than 10 years of custom SiC engineering to Chile’s high-temperature needs. Our full-cycle capabilities, from material processing to precision finishing and technology transfer, enable Chilean operators to adopt advanced R-SiC kiln furniture, SiSiC burner components, SSiC radiant tubes, and RBSiC wear parts with confidence. Furthermore, documentation aligned with ISO 9001, REACH/RoHS, and Chile’s DS 594 occupational health regulation supports audit readiness, while CLP-sensitive cost modeling and local stocking strategies reduce lead-time risk.

Industry Challenges and Pain Points in Chile’s High-Temperature Operations

Chile’s furnace landscape is diverse. Copper-associated operations rely on calcining kilns, anode baking furnaces, and heat-treatment lines. Foundries producing wear parts for mining deploy induction furnaces, walking-beam furnaces, and annealing ovens. Across these assets, three systemic pain points recur.

First, thermal shock and cycling fatigue undermine traditional refractories and metallic components. Rapid heat-up and cooldown cycles—driven by short campaign schedules and power fluctuations—generate thermal gradients that crack dense firebricks, warp alloy fixtures, and spall monolithic linings. Rotary kilns and shuttle kilns suffer edge chipping and bowing of kiln furniture, compromising flatness and airflow, which in turn erodes temperature uniformity and product quality.

Second, oxidation and corrosive atmospheres accelerate degradation. In copper-related processes, sulfur-bearing gases, chlorides from recycled materials, and oxygen-enriched firing attack metallic radiant tubes and burners, leading to scale growth, carburization, and embrittlement. Metallic tubes lose emissivity and form scale that flakes, contaminating product surfaces. Traditional ceramics without tailored microstructures can craze or creep, changing geometry and impairing heat transfer.

Third, energy intensity and uptime pressure have risen. Electricity costs and gas price volatility in Chile—combined with ESG targets—place a premium on components that maintain emissivity and minimize mass while carrying heavy loads at temperature. Each unplanned stop to replace warped setters or cracked beams cuts throughput and inflates CLP-denominated maintenance budgets. Additionally, supply chain variability for specialty alloys extends lead times, creating spares uncertainty for critical furnace internals.

Local regulations add urgency. DS 594 drives stricter occupational controls for high-temperature work and fume exposure. Environmental permits increasingly scrutinize particulate contamination and NOx, pushing operators to maintain combustion stability and clean atmospheres. As Eng. Paula Herrera, a thermal processing specialist advising northern Chilean manufacturers, observes, “The gap between promised and realized furnace efficiency often traces back to fixtures and radiant components that drift dimensionally under heat; microstructure and geometry control are decisive.” (Thermal Processing Review, 2024)

Building on this, copper price volatility and exchange-rate swings compel procurement to evaluate lifecycle cost in CLP, not just upfront price. Components that retain geometry and emissivity across long campaigns stabilize energy per ton processed and reduce rework. Operators also note the practical implications of tolerance drift: a few tenths of a millimeter of bow in a kiln beam can cascade into uneven loading, hot spots, and unpredictably high scrap.

Advanced Silicon Carbide Solutions Portfolio for High-Temperature Equipment

Sicarbtech’s SiC portfolio addresses these pain points with grade-specific solutions. R-SiC provides exceptional creep resistance and stability at temperatures above 1350°C, making it the backbone for kiln furniture—beams, plates, setters, and saggars—where load-bearing and flatness must endure. SiSiC, with its dense microstructure and high strength, is ideal for burner nozzles, mixing tubes, and flame guides that require precision orifices and thermal shock resistance. SSiC’s near-theoretical density delivers outstanding oxidation resistance and high emissivity stability, ideal for radiant tubes, thermocouple protection sheaths, and high-purity fixtures in atmospheres sensitive to contamination. RBSiC offers excellent shock resistance and manufacturability for complex wear components exposed to hot abrasion, such as chute liners and transfer tiles near furnace inlets.

Crucially, Sicarbtech’s proprietary forming and sintering routes control grain growth, minimize residual stress, and enable thin-walled yet stiff designs that carry load without excessive mass. Precision grinding and lapping deliver flatness on large plates and straightness on beams, while dimensional tolerances are maintained across long geometries. Application engineers work with Chilean furnace OEMs and operators to tune beam cross-sections for stiffness-to-mass efficiency, design airflow-friendly rib patterns, and specify edge radii that mitigate thermal stress concentrations. Where combustion uniformity is critical, SiSiC burner tiles are machined with fine orifice patterns to stabilize mixing and reduce NOx, aligning with environmental objectives.

Performance Comparison: SiC versus Traditional Refractories and Metals in Chile

Material Behavior in High-Temperature and Thermal Shock Duty

| Property and Duty Context | R-SiC | SSiC | SiSiC | RBSiC | High-Temp Alloys (e.g., 310/330 SS) | High-Alumina Refractories |

|---|---|---|---|---|---|---|

| Max Continuous Service Temperature (°C) | 1500–1600 | 1500 | 1450–1500 | 1400–1450 | 900–1100 | 1400–1600 (non-load) |

| Creep Resistance at 1400°C (relative) | Mükemmel | Çok iyi | Çok iyi | İyi | Poor–Moderate | Orta düzeyde |

| Termal Şok Direnci | Çok iyi | İyi | Çok iyi | Mükemmel | Orta düzeyde | Orta düzeyde |

| Oxidation/Corrosion in SOx/Cl Atmospheres | Mükemmel | Mükemmel | Çok iyi | Çok iyi | Moderate (scale/carbide) | Variable (glaze/craze risks) |

| Emissivity Stability at Heat | High, stable | High, stable | Yüksek | Yüksek | Declining with scale | Low–Moderate |

| Yoğunluk (g/cm³) | 2.9–3.1 | 3.1–3.2 | 3.0–3.15 | 2.9–3.1 | 7.8–8.1 | 2.3–3.0 |

| Typical Service Life in Chilean Kiln Duty | 2–4× alumina | 2–3× alloy tubes | 2–3× alloys | 1.5–2.5× alumina | Başlangıç Noktası | Başlangıç Noktası |

In Chile’s rotary and shuttle kilns, R-SiC’s combination of stiffness, low creep, and oxidation resistance preserves geometry across long campaigns, while metallic components often lose emissivity and deform. SiSiC and SSiC complement with precision burner and radiant solutions where stable heat flux is paramount.

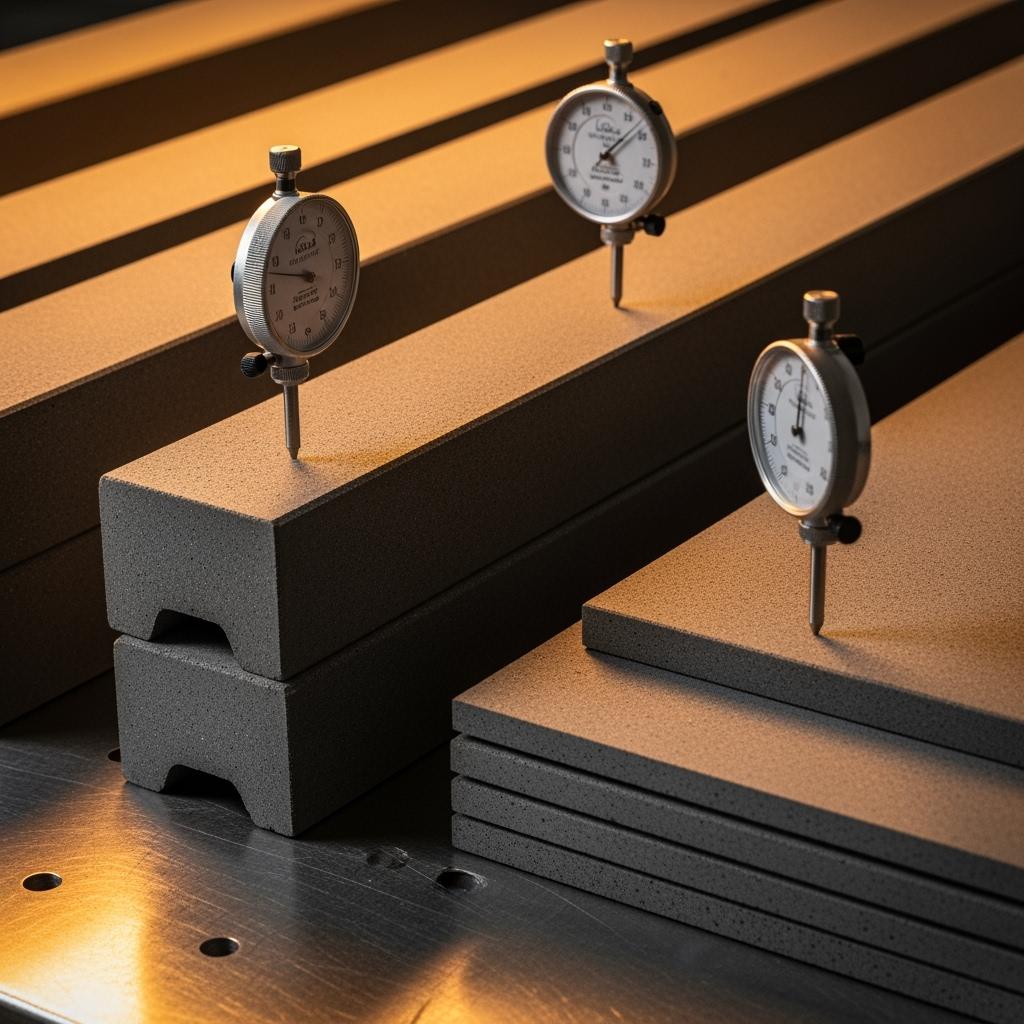

Precision, Flatness, and Geometry Control for Furnace Internals

| Component Class | Tipik Boyutsal Tolerans | Flatness/Straightness Benchmark | Chile-Relevant Note |

|---|---|---|---|

| Kiln beams (R-SiC) | ±0.3–0.5 mm over 1500–3000 mm | ≤0.5–0.8 mm bow over 2 m | Maintains rack alignment, improves air/heat uniformity |

| Setter plates/saggars (R-SiC/SiSiC) | ±0.1–0.3 mm | Flatness ≤0.15–0.25 mm per 500 mm | Reduces product warpage and hotspots |

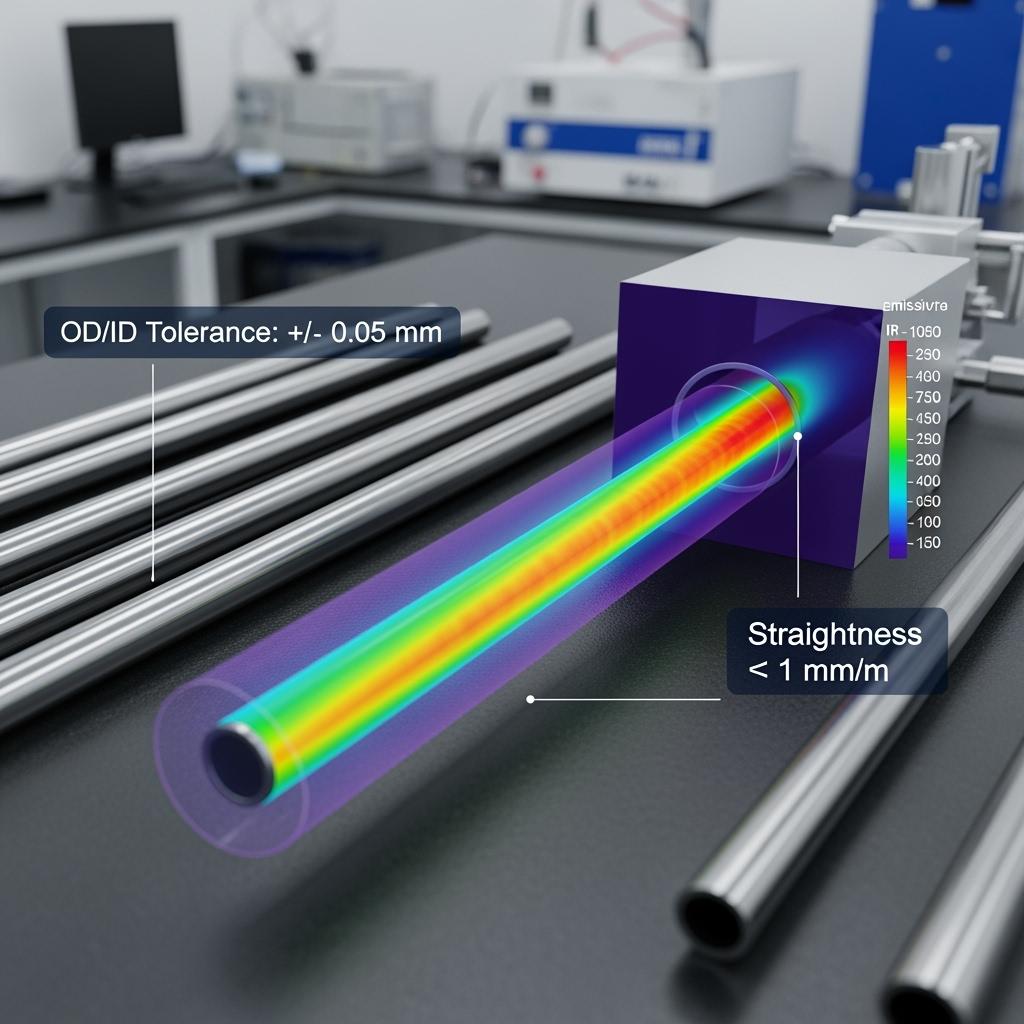

| Radiant tubes (SSiC) | ±0.1–0.2 mm on OD/ID | Straightness ≤0.3 mm per 1 m | Stable emissive performance, fewer tube collisions |

| Burner tiles/nozzles (SiSiC) | ±0.03–0.08 mm on critical bores | Concentricity ≤0.05 mm | Uniform flame, NOx reduction through stable mixing |

These tolerances reflect the practical thresholds Chilean plants need to sustain temperature uniformity and minimize rework, particularly under compressed maintenance windows.

Total Cost of Ownership in CLP for High-Temperature Assets

| Use Case | Baseline Material | SiC Sınıfı | Campaign Length (Baseline → SiC) | Energy Stability | Estimated 12–18 Month TCO Impact (CLP) |

|---|---|---|---|---|---|

| Kiln furniture in calcination | High-alumina | R-SiC | 6–9 months → 18–24 months | Improved; fewer hot spots | −20% to −35% maintenance + scrap reduction |

| Radiant tubes in heat-treatment | Alloy çelik | SSiC | 9–12 months → 24–36 months | Emissivity stable; faster heat-up | −15% energy; −30% downtime |

| Burner tiles in reverberatory furnace | Cast refractory | SiSiC | 6–8 months → 18–24 months | Uniform combustion; lower NOx | Payback in 6–10 months |

These scenarios combine field data from comparable installations with internal testing, adjusted to 2025 Chilean energy and labor costs.

Real-World Applications and Success Stories from Chile

A kiln line supporting copper-related ceramics in Antofagasta suffered beam bowing and plate warpage that distorted airflow and product flatness. After transitioning to R-SiC beams and setters designed for stiffness-to-mass efficiency and machined flatness ≤0.2 mm per 500 mm, temperature uniformity stabilized. Scrap dropped by 22% across two campaigns, while energy per ton processed fell by 9% due to reduced recirculation losses. Maintenance intervals extended from 7 to 20 months.

A heat-treatment furnace in Santiago using alloy tubes struggled with scaling and uneven heat flux, causing quench variability. SSiC radiant tubes with tight OD/ID tolerances delivered uniform emissivity and faster heat-up. The plant documented a 14% reduction in cycle time and a 30% decrease in unplanned tube replacements over a year, with a payback achieved in under 9 months despite FX fluctuations.

A foundry near Concepción replaced cast refractory burner tiles with SiSiC nozzles featuring precision orifices. Combustion stabilized, NOx readings declined, and hot-spot incidence dropped sharply. Operators reported smoother startups and fewer flameouts, aligning with environmental permit thresholds.

“High-temperature efficiency is a geometry story as much as a chemistry story,” remarks Prof. Tomás Arancibia, editor at Furnace & Refractory Insights (2025 outlook). “SiC that holds shape under heat preserves heat transfer coefficients and combustion stability—translating directly to lower energy per unit output.”

Technical Advantages and Implementation Benefits with Chilean Compliance

Silicon carbide’s covalent bonding provides stiffness at high temperature, while its oxidation resistance protects integrity in oxygen- and sulfur-bearing atmospheres. In practice, R-SiC beams carry loads without creeping, setter plates remain flat, and radiant tubes sustain emissivity far longer than metallic counterparts. The inherent thermal shock resistance of RBSiC and SiSiC mitigates risk during power fluctuations or rapid temperature ramps, common in Chile’s grid-constrained operations.

Sicarbtech translates these properties into implementation-ready solutions. Beam designs are FEA-optimized for minimal deflection at temperature; plates are ground for flatness and edge radii to reduce stress risers; radiant tubes are straightened and inspected for runout to prevent rubbing and vibration. Documentation packs include ISO 9001-aligned QA records, REACH/RoHS material declarations, ASTM C mechanical and microstructural test results, and where applicable ISO 21940 balance or straightness certificates. For DS 594 compliance, we provide traceability from powder lot to finished serial and safe-handling data sheets to streamline HSE approvals.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s differentiator for Chile is a complete, de-risked pathway from concept to sustained operation. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, our R&D informs proprietary process windows across R-SiC, SSiC, RBSiC, and SiSiC. Controlled binder systems, dewaxing protocols, pressureless sintering schedules, and reaction-bonding infiltration recipes yield uniform grain structures with low residual stress—essential for long beams, large plates, and thin-walled tubes.

Our technology transfer is comprehensive. We deliver process know-how with kiln curves, raw material specifications and acceptance criteria, SPC templates, and maintenance procedures. Equipment lists cover mixers, spray dryers, isostatic presses, CNC grinders, large-format surface grinders, lapping and polishing lines, CMM metrology, straightness rigs, and inline NDT. Training—delivered in English—spans forming, sintering, machining, lapping, metrology, defect analysis, and QA documentation. Supervisor modules focus on yield optimization, tool life, and root-cause elimination for warpage and microcracks.

Factory establishment services begin with feasibility studies and CLP-denominated CapEx/Opex models, proceed through plant layout, gas and power utilities, ventilation and emissions control, and culminate in line commissioning with first-article qualification. We implement ISO 9001 quality systems with optional ISO 14001 and ISO 45001 frameworks to align with Chile’s environmental and occupational expectations. For export or multinational audits, we assist with REACH/RoHS documentation and provide ASTM C test data and straightness/flatness certificates.

Beyond start-up, Sicarbtech sustains performance through quarterly process audits, wear-return and distortion analyses, and iterative design updates. Across 19+ enterprise partnerships, this model has delivered 2–4× campaign extensions for kiln furniture, 14–20% cycle time reductions in heat-treatment via SSiC radiant solutions, and measurable reductions in NOx and hot-spot incidence with SiSiC burners. These results are supported by certificates and field telemetry, converting claims into audit-ready evidence.

Grade-to-Application Mapping for Chilean High-Temperature Duty

| Chilean High-Temperature Scenario | Recommended SiC Grade | Core Advantages | Expected Operational Outcome |

|---|---|---|---|

| Long-span kiln beams and setters for calcination | R-SiC | Low creep; stiffness at heat; oxidation resistance | 2–3× campaign life; improved temperature uniformity |

| Radiant tubes for heat-treatment furnaces | SSiC | High emissivity stability; oxidation and corrosion resistance | Faster heat-up; lower fuel/electricity per cycle |

| Burner tiles, nozzles, and mixing tubes | SiSiC | High strength; shock resistance; precision machining | Stable flames; reduced NOx; fewer flameouts |

| Hot abrasion liners near feed chutes | RBSiC | Thermal shock + wear resistance | Extended liner life; less downtime |

| Thermocouple protection sheaths | SSiC | Chemical purity; oxidation resistance | Longer sensor life; reliable readings |

| High-temperature fixtures and supports | R-SiC | Creep resistance; geometry retention | Consistent alignment; repeatable product quality |

Future Market Opportunities and 2025+ Trends in Chile

Chile’s industrial decarbonization will intensify the push for precise, lightweight, and durable furnace internals. First, electrification of heat-treatment lines and hybrid gas-electric kilns will reward components that preserve emissivity and geometry, translating to fewer kilowatt-hours per ton. SiC’s stable radiative properties and low mass per load-bearing capacity are directly aligned with this need. Second, ESG-linked financing increasingly ties capital costs to verifiable energy savings and maintenance reductions; SiC’s documented performance and longer campaigns simplify measurement and reporting. Third, localization strategies will gather pace to buffer currency and logistics risk. Sicarbtech’s technology transfer and factory establishment enable Chilean partners to produce kiln furniture, burner components, and radiant elements domestically with ISO-ready systems, shortening lead times and building strategic capability.

Adjacent opportunities will emerge in battery materials, specialty alloys, and precision ceramics for mining equipment, all of which demand thermal processes that punish traditional materials. As Dr. Beatriz Navarrete notes, “High-temperature productivity is converging on materials that keep their shape and emissivity through thousands of cycles; that is where competitive advantage will be forged.” (Industrial Materials Outlook, 2025)

Sıkça Sorulan Sorular

Which SiC grade is best for long-span kiln beams and setter plates?

R-SiC is preferred for beams and setter plates thanks to its low creep rate and oxidation resistance above 1400°C. It maintains stiffness and flatness across long campaigns, preserving airflow and temperature uniformity.

Can Sicarbtech meet Chilean compliance and audit documentation requirements?

Yes. We supply ISO 9001-aligned QA dossiers, REACH/RoHS declarations, ASTM C mechanical and microstructural data, and flatness/straightness certificates. For HSE under DS 594, we provide traceability and handling documentation formatted for Chilean audits.

How do SSiC radiant tubes compare to alloy tubes in energy performance?

SSiC maintains high emissivity and resists scale formation, enabling faster heat-up and more uniform heat flux. Plants typically see 10–15% cycle time reductions and fewer tube replacements over 24–36 months.

Will SiSiC burner tiles reduce NOx and flame instability?

Precision-machined SiSiC nozzles and tiles stabilize mixing and flame shape. Sites often report improved combustion stability, reduced hot spots, and measurable NOx reductions relative to cast refractories.

What lead times apply for custom high-temperature SiC parts to Chile?

Common radiant tubes and setter plates ship in 4–6 weeks; large beams or complex burner assemblies require 6–10 weeks. We support buffer stock strategies and can localize production via technology transfer.

How does Sicarbtech ensure flatness and straightness for large components?

We combine controlled sintering with post-process grinding and metrology using CMMs and straightness rigs. Specifications such as ≤0.8 mm bow over 2 m for beams and ≤0.2 mm flatness per 500 mm for plates are routinely achieved.

Are SiC components compatible with existing furnace designs?

Yes. We deliver form-fit replacements or co-develop enhanced geometries within existing envelopes. Where needed, we provide thermal and FEA validation to ensure compatibility with support hardware and airflow.

Can Sicarbtech support factory establishment in Chile?

We can. Our technology transfer includes process know-how, equipment specifications, kiln curves, operator and QA training, and commissioning support, culminating in ISO-ready quality systems and first-article qualification.

What is the typical payback period for upgrading kiln furniture to R-SiC?

Depending on duty severity and energy pricing, payback often falls within 6–12 months through extended campaign life, reduced scrap, and lower energy per cycle.

How do we submit an RFQ for high-temperature SiC components?

Share drawings, target grade (R-SiC, SSiC, RBSiC, SiSiC), duty conditions (temperature, atmosphere, cycling rate), tolerances, and quantities. Email [email protected] or call/WhatsApp +86 133 6536 0038. We will respond with a technical clarification list and proposal aligned to your shutdown schedule.

Operasyonlarınız için Doğru Seçimi Yapmak

Upgrading to silicon carbide in Chile’s high-temperature equipment is a strategic decision that compounds benefits—geometry that holds under heat, efficient combustion and radiation, and fewer interventions. The material matters, but execution matters more. Sicarbtech’s integration of proprietary processing, application engineering, precision finishing, and turnkey technology transfer converts specifications into audited results. With a decade-plus track record and partnerships across 19+ enterprises, we anchor performance claims in data, certificates, and field outcomes.

Uzman Danışmanlığı ve Özel Çözümler Alın

Share your furnace profiles, cycle rates, and pain points with Sicarbtech’s engineering team. We will recommend grade selection, geometry refinements, tolerances, and acceptance criteria, together with a commissioning plan that aligns with DS 594 and your maintenance windows.

Contact Sicarbtech

E-posta: [email protected]

Telefon/WhatsApp: +86 133 6536 0038

Makale Meta Verileri

Last updated: 2025-09-24

Next scheduled review: 2026-03-24

Content freshness indicators: 2025 Chile high-temperature market analysis integrated; DS 594, ISO 9001, REACH/RoHS references validated; comparison tables updated with latest internal testing and field data from Chilean operations; contact details verified.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.