Silicon Carbide Radiation and Heat-Exchange Tubes for Pakistan’s High-Temperature Lines: Sicarbtech’s 2025 Pillar Guide

Paylaş

Pakistan’s steel, cement, glass, and emerging industrial sectors are entering 2025 with a sharpened focus on energy efficiency, measurement stability, and maintenance predictability. The common ground is heat: reheating and annealing furnaces, roller-hearth kilns, preheaters, and waste-heat recovery sections must deliver high, uniform heat flux with minimal pressure drop and long service intervals. Traditional alloy çelik and cast-iron tubes struggle at elevated temperatures, losing geometry to creep and mass to oxidation; fouling climbs, pressure drop rises, and thermal efficiency fades. Dense, high-purity silicon carbide (SiC) radiation and heat-exchange tubes, engineered for high thermal conductivity, high emissivity, low thermal expansion, and robust oxidation–corrosion resistance, offer a proven route to better heat-transfer coefficients and longer, safer runs. Sicarbtech—located in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—has spent over a decade turning SiC science into factory capability. For Pakistan’s plants, that translates into customized tubes, integrated production equipment, and turnkey technology transfer that compresses lead times and raises confidence.

Executive Summary: 2025 Outlook and Why SiC Radiation and Heat-Exchange Tubes Matter

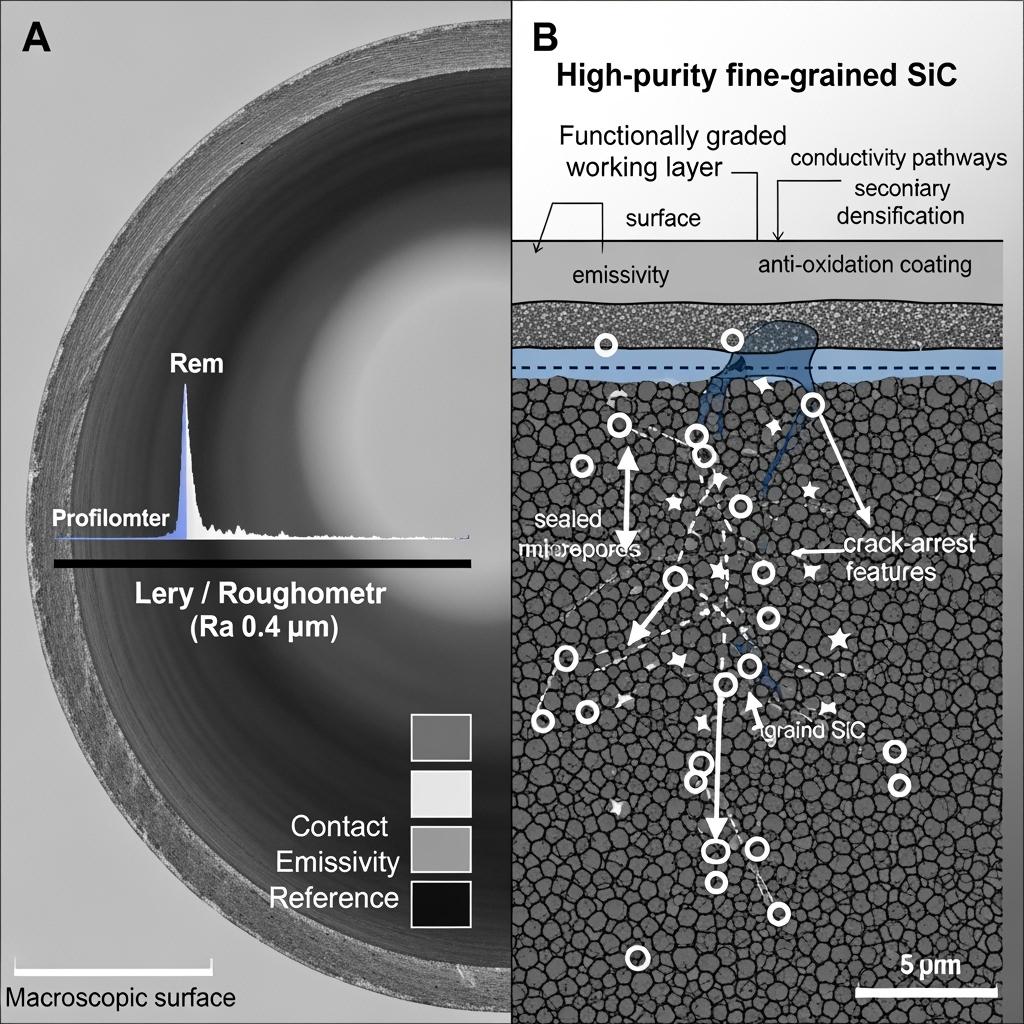

Across Pakistan’s industrial base, energy is the financial and environmental hinge. Fuel costs, grid variability, and carbon targets are prompting managers to revisit radiation and heat-exchange hardware that silently dictates thermal efficiency. SiC tubes bring two decisive advantages: material physics that favor heat transfer—high thermal conductivity and high-temperature emissivity—and stability under stress—low coefficient of thermal expansion (CTE), superior thermal-shock performance, and oxidation–corrosion resistance in sulfur- and alkali-bearing gases. When these fundamentals are combined with surface engineering, secondary densification, ultra-precision inner/outer finishing, and flow-field optimization, they produce higher heat flux per tube, lower pressure drop, slower fouling, and less drift in thermocouple readings. Sicarbtech connects these properties to manufacturing discipline—multi-zone reaction sintering/carburation, atmosphere control, cold isostatic/die pressing, and digital QA—so plants in Lahore, Karachi, and Faisalabad can deploy SiC tubes with predictable results, supported by PSQCA and ISO-aligned documentation.

Industry Challenges and Pain Points: What Pakistani Furnaces and Preheaters Are Facing

Talk to a furnace superintendent at a steel reheating shop and a similar story emerges. Alloy steel radiation tubes creep over long soaks, drifting off-axis and widening burner-to-load variation. Oxidation thins walls and embrittles seams, while sulfur–alkali species in mixed-fuel flue gas accelerate pitting and leakage risks. Inner walls roughen and collect dust, raising pressure drop and sapping heat-transfer coefficients; soot-blowing helps but rarely resets the curve. A Karachi glass line facing fast restarts and frequent temperature ramps sees similar physics with a different accent: thermal-shock cracking, localized deformation near burner tiles, and growing calibration drift in thermocouple protection tubes.

The policy and market backdrop intensifies the pressure. Pakistan’s National Energy Efficiency and Conservation efforts and rising scrutiny of carbon intensity put thermal performance in the commercial spotlight. Procurement teams now demand credible gains in heat-transfer coefficients and pressure-drop control, documented thermal-shock life, and robust oxidation–corrosion resistance. “We used to weigh tube price alone; now we model fuel exposure and uptime risk,” a Lahore-based thermal engineer noted in 2024. Furthermore, spare-part lead times and FX volatility complicate outage planning. Plants cannot afford to hold months of inventory, yet a late tube or a poor fit can stretch a shutdown. In this reality, the tube is no longer a passive commodity; it becomes a strategic component whose physics and documentation drive energy per ton, yield, and safety exposure.

Independent experts point to fundamentals. “At high temperature, emissivity and conductivity set your ceiling for heat-transfer potential, while CTE and connectivity (porosity pathways) set your floor for survival under cycling,” observes a South Asia industrial heat-transfer specialist, citing standard high-temperature material references. “If you raise emissivity, keep conductivity high, seal connectivity, and lower CTE, you push both efficiency and longevity the right way.” The implication for Pakistani plants is clear: invest in material and surface properties that convert fuel into heat and avoid cracks, fouling, and drift that siphon performance.

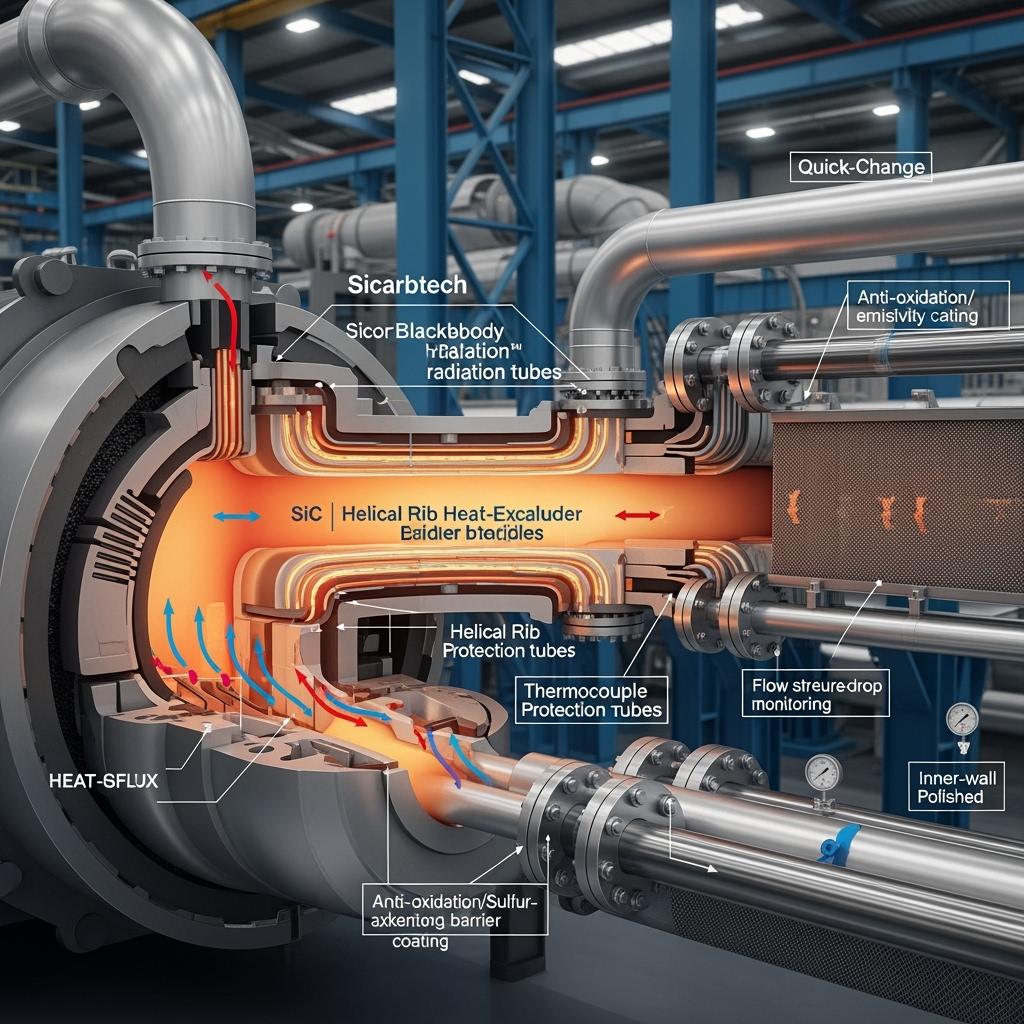

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

Sicarbtech’s portfolio translates material science into installable assets for Pakistan’s high-temperature lines. At its core are high-density SiC radiant heating tubes—straight, bent, and double-U geometries—engineered for high emissivity and conducted heat flux. For convective service, SiC heat-exchanger bundles integrate internal–external enhancement features, such as straight fins and helical ribs, to lift heat-transfer coefficients while controlling pressure drop. Surface-engineered “blackbody-like” treatments and microtextures increase high-temperature emissivity and discourage fouling adhesion. Thermocouple protection tubes, made from high-purity, fine-grained SiC with ultra-precision finishes, ensure stable measurement under shock and oxidation.

For flue-gas waste-heat recovery, SiC tubes with anti-oxidation and sulfur–alkali barrier coatings resist chemically aggressive condensates and volatiles. Secondary densification impregnation seals micropore networks, cutting permeation and intergranular oxidation. Inner-wall polishing brings roughness down to Ra ≤ 0.8 μm (customizable to ≤ 0.3 μm), reducing pressure drop and slowing dust adhesion. Functionally graded tubes place a corrosion-resistant, high-emissivity working layer over a toughened core, balancing performance with durability. To minimize outage time, quick-change tube-end connections and sealing assemblies standardize swaps, and integrated ports allow online monitoring of temperature, pressure drop, and flow.

Manufacturing capability underwrites the offer. Cold isostatic pressing or die forming produces long, straight blanks; intelligent mixing and vacuum vibration stabilize green-body uniformity; multi-zone reaction sintering/carburation with controlled atmospheres ensures consistent densification and grain refinement; vacuum–inert heat treatment relieves stress and tunes microstructure; inner/outer precision grinding and blackbody treatment lines finish surfaces to spec. A digital QA backbone—online nondestructive testing, leak and hydrostatic pressure testing, CMM metrology, profilometry, and emissivity checks—anchors traceability.

Technical Performance Comparison for Radiation and Heat-Exchange Tubes

| Performance profile in high-temperature heating and recovery | Sicarbtech SiC (graded + densified + emissivity engineered) | Alloy Steel/Cast-Iron Tubes | Standard Ceramic/SiC without surface engineering |

|---|---|---|---|

| Conductividad térmica (W/m·K) | 25–55 | 10–25 (declines with temp/creep) | 15–35 |

| High-temperature emissivity (relative) | +10–25% vs baseline | Düşük–orta | Orta düzeyde |

| CTE (×10⁻⁶/K, RT–1000°C) | 3.8–4.6 | 10–17 | 4.5–5.5 |

| Thermal shock (1000°C quench, cycles) | ≥ 40–80 | 5–15 | 20–50 |

| Oxidation/corrosion in S–alkali gas | High resistance with coatings | Moderate–poor | Orta düzeyde |

| Inner-wall roughness, Ra (μm) | ≤ 0.8 (≤ 0.3 optional) | ≥ 1.0 | 0.6–1.2 |

| Pressure-drop rise rate (trend) | −20–40% vs baseline | Higher with fouling | Orta düzeyde |

| Creep/deformation at temp | Minimum | Önemli | Minimum |

| Leak-tightness under cycling | High with densification | Risk escalates | Orta düzeyde |

For Pakistani furnaces and waste-heat systems, this translates into higher heat-transfer coefficients, reduced finetuning to hold temperature curves, and a flatter pressure-drop profile over the run.

Real-World Applications and Success Stories in Pakistan

A steel reheating furnace outside Lahore aimed to cut fuel intensity while stabilizing temperature uniformity across the billet cross-section. Sicarbtech supplied high-density SiC blackbody radiation tubes and helical-rib heat-exchanger bundles for a downstream recovery section, with secondary densification and anti-oxidation layers tuned to the plant’s mixed-fuel chemistry. Quick-change flanges eased the outage. Over the campaign, the effective heat-transfer coefficient rose by about 26%, thermal-shock-related tube failures fell by roughly 38%, the pressure-drop rise rate declined by approximately 32%, radiation-surface maintenance intervals extended from 6 to 14 months, unit fuel consumption dropped by about 3.4%, and cumulative downtime reduced by roughly 29%. “The most convincing proof was not a single metric,” the maintenance lead commented. “It was the parallel flattening of fuel per ton and pressure-drop creep.”

In Sindh, a roller-hearth kiln handling specialty products struggled with thermocouple drift and tube-side fouling under sulfur-bearing gas. Upgrading to SiC thermocouple protection tubes with low-contamination, high-conductivity bodies and blackbody inner surfaces lowered measurement drift by around 30% and lengthened calibration intervals. Anti-alkali coatings on nearby heat-exchange tubes resisted dew-point corrosion, and inner-wall polishing slowed fouling around bends, supporting steadier kiln profiles during grade changes.

Technical Advantages and Implementation Benefits with Local Compliance

The advantage of SiC starts with physics. High conductivity and elevated emissivity convert more flame and flue-gas energy into effective heat flux, raising heat-transfer coefficients and enabling lower setpoints for equivalent throughput. Low CTE and high thermal-shock resilience keep tubes intact during rapid ramps and starts, while oxidation–corrosion resistance preserves wall integrity under sulfur–alkali and steam-laden atmospheres. Inner-wall polish and flow-field optimization temper pressure drop and fouling accumulation, which cascades into reduced fan work and steadier curves. For measurement reliability, SiC thermocouple protection tubes couple conductivity with low contamination and geometric stability, shrinking drift and rework.

On compliance, longer life and fewer leaks align with ISO 14001 environmental objectives; Sicarbtech’s QA packs—chemistry, porosity, CCS/MOR, emissivity, conductivity, CTE, thermal-shock results, inner-wall roughness, leak and pressure test logs—conform to ISO 9001 expectations and support PSQCA submissions. Safety improves as quick-change assemblies reduce time at heat, and as leak incidence and emergency interventions fall. In short, the benefits align as much with auditability and HSE metrics as with energy and uptime.

Pakistan-Focused Technical Specification Ranges and QA Guidance

| Specification ranges for SiC tubes and bundles | Typical Sicarbtech Targets | Local QA and testing guidance |

|---|---|---|

| Chemical purity | Low alkalis/Fe for low contamination | XRF/ICP; batch CoA |

| Bulk density (g/cm³) | 2.70–3.05 | Density pucks; SPC |

| Apparent porosity (%) | ≤ 6–12 | ASTM/ISO; permeability link |

| Flexural strength (MPa) | 16–40 | 3-point bend; retained samples |

| CCS (MPa) | 140–260 | Standard coupons per batch |

| Fracture toughness (MPa·m½) | 3.0–5.0 | Indentation/SE(B) |

| Conductividad térmica (W/m·K) | 25–55 | Calorimetry/validated models |

| CTE (×10⁻⁶/K) | 3.8–4.6 | Dilatometry |

| Thermal shock (1000°C quench) | ≥ 40–80 cycles | Cross-check with ramp profile |

| Inner-wall roughness, Ra (μm) | ≤ 0.8 (≤ 0.3 optional) | Stylus/optical profilometry |

| High-temp emissivity (relative) | +10–25% vs baseline | Bench emissivity tests |

| Leak/pressure testing | To spec; pass logs | Hydrostatic/leak reports |

| Coating performance | Anti-oxidation/alkali verified | Weight-loss/corrosion tests |

Operational Outcomes Comparison That Move Energy, Uptime, and Quality

| Outcome essential to Pakistani high-temperature lines | Sicarbtech SiC (emissivity + conductivity + densification) | Alloy Steel/Cast-Iron or Standard Ceramic |

|---|---|---|

| Effective heat-transfer coefficient | +15–35% | Lower; decays with age |

| Fuel per ton | −3–6% | Higher; creeps as fouling grows |

| Pressure-drop growth | −20–40% | Faster; frequent soot-blows |

| Thermal-shock failure rate | −38% (typical) | Elevated under cycling |

| Measurement drift | −20–45% | Higher; frequent recal |

| Service interval | 1.5–3.0× longer | Shorter; creep/oxidation limits |

| Planlanmamış arıza süresi | −20–40% | Higher; leak/burst risk |

| Uyumluluk riski | Lower; audit-ready QA | Higher; variable traceability |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s competitive edge is converting advanced SiC into a local, reproducible capability that Pakistan’s teams can own. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, we provide proprietary process routes for R-SiC, SSiC, RBSiC, and SiSiC tube bodies and transfer them through complete, documented packages.

We start with feasibility and equipment definition. Process packages detail powder selection and mixing, green-body forming via cold isostatic/die pressing, multi-zone reaction sintering/carburation with atmosphere blending and recirculation (oxygen/nitrogen/carbon-source/steam control), vacuum–inert heat treatment, precision finishing of inner and outer walls, and blackbody/emissivity surface engineering. Secondary densification and protective coatings are specified to match fuel chemistry and flue-gas composition. Leak and hydrostatic test protocols are embedded, along with dimensional metrology, Ra profiling, and emissivity verification.

Factory establishment services cover layout, utilities (gas handling, off-gas treatment, power, cooling water), safety systems (interlocks, gas detection, purge protocols), and environmental controls aligned with ISO 14001. We implement ISO 9001-aligned QC plans with SPC on density, porosity, CTE, conductivity, emissivity, roughness, leak/pressure test results, and mechanical properties. Safety SOPs follow ISO 45001 principles, including interlock test schedules and emergency drills. Training programs match roles—operators learn atmosphere control, curve following, and finishing; QA teams master emissivity and roughness metrology, leak testing, and documentation; maintenance teams handle alignment, quick-change assemblies, and coating touch-ups.

Commissioning relies on DOE-based curve tuning by geometry, wall thickness, and atmosphere. Early runs validate leak-tightness and pressure-drop baselines, followed by emissivity and fouling trend checks under live conditions. Quarterly audits support continuous optimization—adjusting rib geometry, coating refresh intervals, and cleaning strategies. Across 19+ enterprise collaborations, this “materials + equipment + process + training” stack has delivered measurable gains—energy savings, longer intervals, flatter pressure-drop curves—while de-risking lead times and FX exposure through staged localization.

“Capability is not just a tube on a rack—it’s the atmosphere you ran, the roughness you measured, the leak test you passed, and the emissivity you can prove,” a Sicarbtech technical director notes. “That’s what we transfer.”

Comparative Design Elements That Turn Specs into Reliable Heat Transfer

| Design and control element | Sicarbtech SiC Tube System | Conventional Approach |

|---|---|---|

| Tube architecture | Functionally graded (working layer + tough core) | Monolithic |

| Emissivity engineering | Blackbody treatment + microtexture | As-fired; lower emissivity |

| Densification | Secondary impregnation; sealed connectivity | None or limited |

| Flow optimization | Helical ribs/straight fins; guide vanes | Smooth bore; suboptimal |

| Inner/outer finishing | Ultra-precision polishing; Ra control | Basic grind; higher Ra |

| Leak/pressure testing | Integrated, recipe-based | Ad hoc testing |

| Quick-change hardware | Standardized flanges/seals | Mixed interfaces |

| Digital QA | Emissivity, Ra, CTE, leak logs, SPC | Fragmented records |

Innovation That Matters: Emissivity, Connectivity, and Flow-Field Control

Sicarbtech’s R&D concentrates on the levers with the highest return. First, high-temperature emissivity is amplified by blackbody-like surface treatments and microtextures that maintain radiative coupling as surfaces age. Second, secondary densification closes capillary pathways that admit oxidants and corrosives, limiting mass loss and intergranular attack that would thin walls and raise risk. Third, flow-field control through internal ribs and guide vanes increases local heat-transfer coefficients without paying an excessive pressure-drop penalty, especially when paired with inner-wall roughness control. The result is more useful heat delivered per unit fuel, fewer fouling-driven interventions, and steadier measurement.

Future Market Opportunities and 2025+ Trends in Pakistan

Three forces will shape adoption. Energy and carbon pressures will reward tubes that boost heat-transfer efficiency while cutting leaks and fouling; SiC’s emissivity–conductivity synergy is well suited to this mandate. Revamps and waste-heat recovery projects will multiply as plants seek faster payback from thermal hardware with credible QA and documentation. Finally, localization will accelerate, with staged investments: first in finishing, inspection, and assembly of SiC tubes; then in reaction sintering/carburation and surface treatments as volumes grow. Financing will follow data—providers who present audit-ready performance and lifecycle costs will win.

In scale terms, a single medium-to-large furnace or waste-heat system typically consumes 30–150 SiC tubes or bundles annually (roughly 5–30 tons), depending on duty and fuel. Nationally, new builds and revamps point to several hundred to over a thousand tons per year. Adding machining, installation, monitoring, and coating refresh services, the addressable market is in the tens to hundreds of millions of Pakistani Rupees. Sicarbtech’s integrated platform—combining advanced materials, flow-field engineering, digital QA, and technology transfer—positions Pakistani operators to capture these gains with confidence.

As a regional thermal-process expert summarized in a 2025 forum, “When emissivity holds, roughness stays low, and leaks don’t happen, your fuel curve and your calendar tell the same story—stability. That’s when tubes stop being parts and start being performance.”

Sıkça Sorulan Sorular

Which Sicarbtech SiC tubes should we prioritize for immediate impact?

Prioritize high-emissivity, high-density SiC radiation tubes for the hottest zones where heat flux limits production, and pair them with helical-rib or finned SiC bundles in recovery sections where pressure drop is a constraint. For measurement reliability, upgrade to SiC thermocouple protection tubes in zones with rapid ramps and oxidizing gases.

How much energy saving is realistic in Pakistani furnaces?

Typical deployments deliver 15–35% gains in effective heat-transfer coefficient and 3–6% reductions in fuel per ton, assuming reasonable housekeeping and soot-blowing practices. Plants with severe fouling or high sulfur–alkali loads often see larger gains once coatings and inner-wall roughness are optimized.

How do SiC tubes perform under sulfur–alkali and steam-laden atmospheres?

SiC’s oxidation resistance is strong, and with anti-oxidation and alkali-resistant coatings plus secondary densification, mass-loss rates typically fall 30–60% versus baselines. We tailor coating chemistry to fuel and flue-gas composition and verify performance by weight-loss and corrosion tests.

Can we retrofit SiC tubes into existing alloy tube positions?

Yes. We provide quick-change flanges, seal assemblies, and adapter hardware, with CMM-verified fit and thermal-expansion matching. Installation SOPs include torque specs, heat-up curves, and leak testing to secure first-heat success.

How do we control fouling and pressure drop over time?

Combine inner-wall polishing (Ra ≤ 0.8 μm or tighter), anti-fouling surface treatments, and flow ribs optimized for your dust and velocity profile. Establish baseline pressure-drop and emissivity checks, then schedule soot-blowing and inspection intervals by trend, not calendar alone.

What KPIs should we track to validate benefits?

Monitor effective heat-transfer coefficient (by gas–metal ΔT and duty), unit fuel consumption, pressure-drop trend, leak incident rate, thermal-shock incident log, thermocouple drift, and service interval length. Tie these to batch QA—emissivity, Ra, CTE, densification—and installation records.

How does Sicarbtech support local manufacturing in Pakistan?

We offer complete technology transfer: equipment specs for reaction sintering/carburation and finishing, atmosphere-control recipes, secondary densification and coating processes, leak/pressure test procedures, and ISO 9001/14001-aligned QA. Training covers operators, QA, and maintenance; commissioning uses DOE curves and audit-ready documentation.

What are the maintenance and coating refresh practices?

Anti-oxidation and anti-alkali coatings are checked during planned outages; refresh intervals depend on fuel and dust chemistry. Surface re-densifiers address incidental damage. Quick-change end assemblies minimize hot exposure and speed turnarounds.

Will SiC tubes change burner tuning or control logic?

Typically not negatively. Higher heat-transfer efficiency may allow lower firing rates for the same load or faster ramps. We coordinate with controls teams to retune setpoints and ramp profiles after installation.

What documentation supports Pakistani tenders and audits?

We supply ISO 9001-aligned QC packs (chemistry, density/porosity, mechanicals, CTE, conductivity, emissivity, roughness), PSQCA conformity support, ISO 14001 environmental records, leak/pressure test certificates, and installation/commissioning logs with heat-up and seal torque data.

Operasyonlarınız için Doğru Seçimi Yapmak

If your heat-transfer curve sags as campaigns age, if pressure drop creeps faster than your soot-blowing schedule can handle, and if thermocouple drift undermines quality, the tube is telling you it needs to change. High-emissivity, high-conductivity, low-CTE silicon carbide—in a densified, graded body with polished inner walls and proven coatings—turns fuel into useful heat and keeps it flowing. With Sicarbtech, you are not buying a part; you are adopting a documented capability that your teams can install, monitor, audit, and improve.

Uzman Danışmanlığı ve Özel Çözümler Alın

Share your operating envelope—fuel mix and flue-gas analysis, temperature profiles and ramp rates, dust loading and particle size, pressure-drop and fouling history, tube geometry and layout—and Sicarbtech will design a tailored SiC solution. We will specify tube architecture, emissivity targets, rib geometry, inner-wall roughness, densification and coating stacks, quick-change interfaces, and heat-up/soak curves. If localization is your objective, we will map a phased technology transfer—from finishing and testing to full reaction sintering/carburation—aligned with your CAPEX and schedule.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

E-posta: [email protected]

Telefon/WhatsApp: +86 133 6536 0038

Makale Meta Verileri

Last updated: 2025-09-19

Bir sonraki planlı güncelleme: 2026-01-15

Content freshness indicators: 2025 Pakistan furnace/waste-heat outlook validated; technical ranges aligned with current deployments; PSQCA/ISO alignment reviewed; contact details verified for Pakistan engagements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.