Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Guide to Tundish Flow-Control Ceramics

Paylaş

Pakistan’s steel sector is accelerating its push into clean steel, longer casting sequences, and tighter dimensional tolerances, even as energy costs and currency volatility challenge procurement predictability. In this environment, industrial silicon carbide (SiC) has emerged as the material platform that stabilizes continuous casting performance where it matters most: the tundish nozzle, slide plate, and submerged entry nozzle. Sicarbtech—headquartered in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—delivers more than a decade of SiC customization, full-cycle manufacturing capability, and turnkey technology transfer for partners who want to localize production in Pakistan. This pillar page translates global best practices into practical, localized guidance for 2025 and beyond.

Executive Summary: 2025 Outlook and Why Dense Silicon Carbide Matters for Pakistan

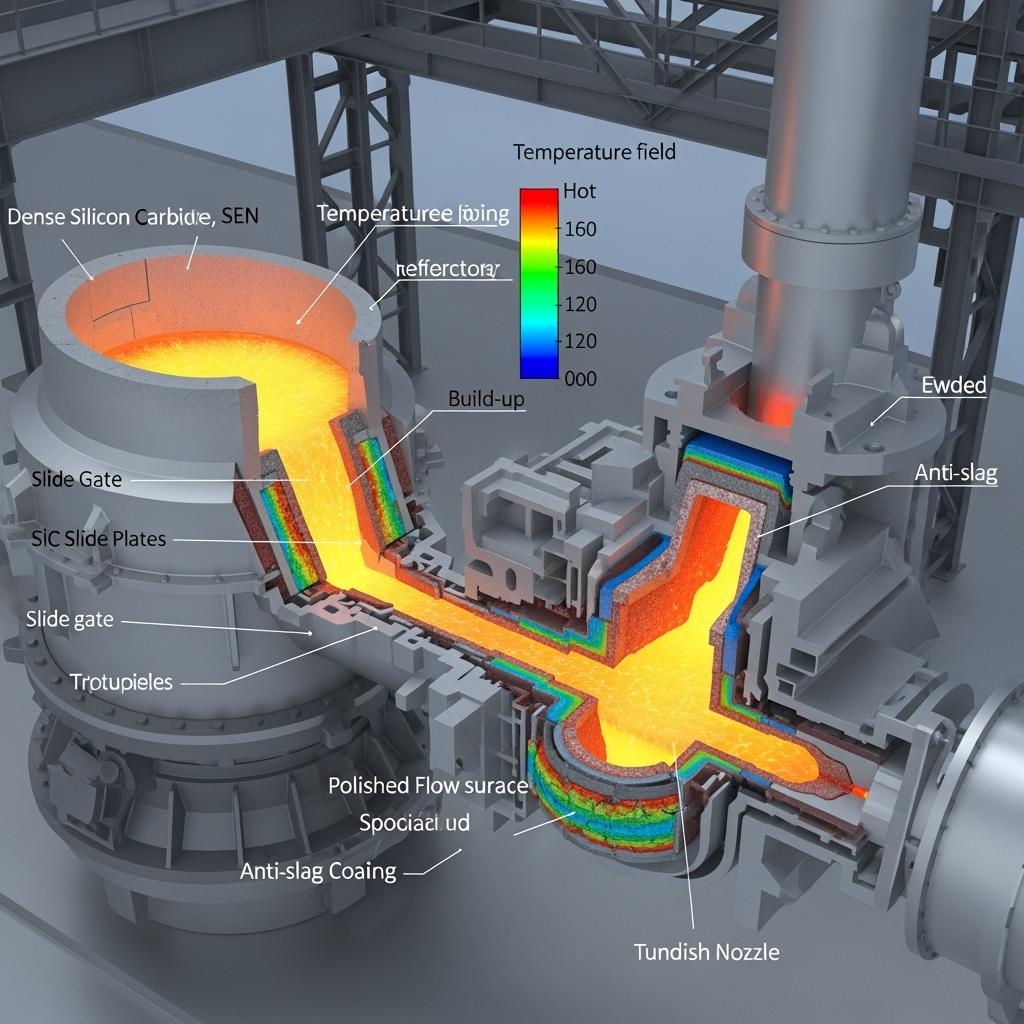

As electric furnace–refining–continuous casting (EAF–LF–CC) becomes the dominant route in Pakistan, tundish flow-control components are under new levels of scrutiny. Casting speed stability, sequence length, and breakout risk directly relate to the microstructure, surface finish, and dimensional stability of nozzles and plates. Dense silicon carbide—manufactured by reaction sintering or liquid-phase sintering and finished with high-precision machining—provides high hardness, low permeability, and outstanding thermal shock resistance. The result is reduced nozzle build-up and clogging, fewer groove-wear events, and more consistent discharge coefficients at high speeds.

Sicarbtech’s integrated model blends material formulation, densification processes, forming and machining equipment, and onsite services. Moreover, our technology transfer packages enable Pakistani partners to build localized lines for reaction sintering, cold isostatic pressing, and CNC finishing, dramatically shortening lead times and limiting exposure to exchange-rate swings. In 2025, this fusion of materials excellence and supply chain control is becoming a prerequisite rather than a luxury.

Industry Challenges and Pain Points: Continuous Casting Realities in Pakistan

Visit a Pakistani caster during a demanding sequence and the stressors are evident. The submerged entry nozzle must maintain flow stability while resisting scouring from high-velocity steel and inclusions. Slide plates are expected to maintain sealing and flatness under repeated thermal cycling. Tundish nozzles face alternating exposure to oxidizing slag and molten çelik, with dimensional precision crucial to avoid turbulence and inclusion entrainment. When conventional alumina–carbon or clay/oxide ceramics meet long sequences and higher casting speeds, oxidation-induced porosity growth and penetration-driven build-up can creep in. Groove formation at critical edges forces premature change-outs, while nozzle adhesion and clogging increase the risk of speed fluctuations and, in worst cases, breakout scenarios.

Pakistan’s market dynamics amplify these technical risks. The equipment landscape is heterogeneous, with both legacy and upgraded casters operating side by side. Scrap variability and refining practices introduce shifts in oxygen potential and inclusion chemistry, which can drive unpredictable adhesion and wear patterns on flow surfaces. Additionally, the cost of uncertainty is significant. Import lead times can be volatile, spares must be stocked in larger volumes to insure against delays, and maintenance teams lose valuable minutes to reactive cleaning and emergency replacements.

Furthermore, compliance expectations are rising. Plants increasingly require ISO 9001-aligned documentation and PSQCA conformity for critical components, while environmental targets encourage longer service life and lower waste. “The recurring failure modes we see on conventional flow-control materials—oxidation porosity, penetration at edges, and surface roughness growth—translate directly into casting speed noise,” observes a South Asia-focused casting technologist, citing established refractory and casting references. “To keep the caster in a stable window, you need surface quality, density, and oxidation resistance to hold together across sequences.” A plant metallurgist in Punjab put it more bluntly during a 2024 review: “If we can keep the nozzle surface clean and dimensions tight, the caster behaves. If not, our plan turns into a hope.”

Cost implications are non-trivial. Each unplanned nozzle change-out can cost hours of lost capacity in a busy week. Build-up that forces speed reductions can translate into throughput shortfalls, while surface defect excursions ripple into downstream rolling and finishing. In short, the line needs dense, low-permeability ceramics with high hardness and a polished, low-wettability flow surface that refuse to degrade under the very start–stop cycles that define the plant’s cadence.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

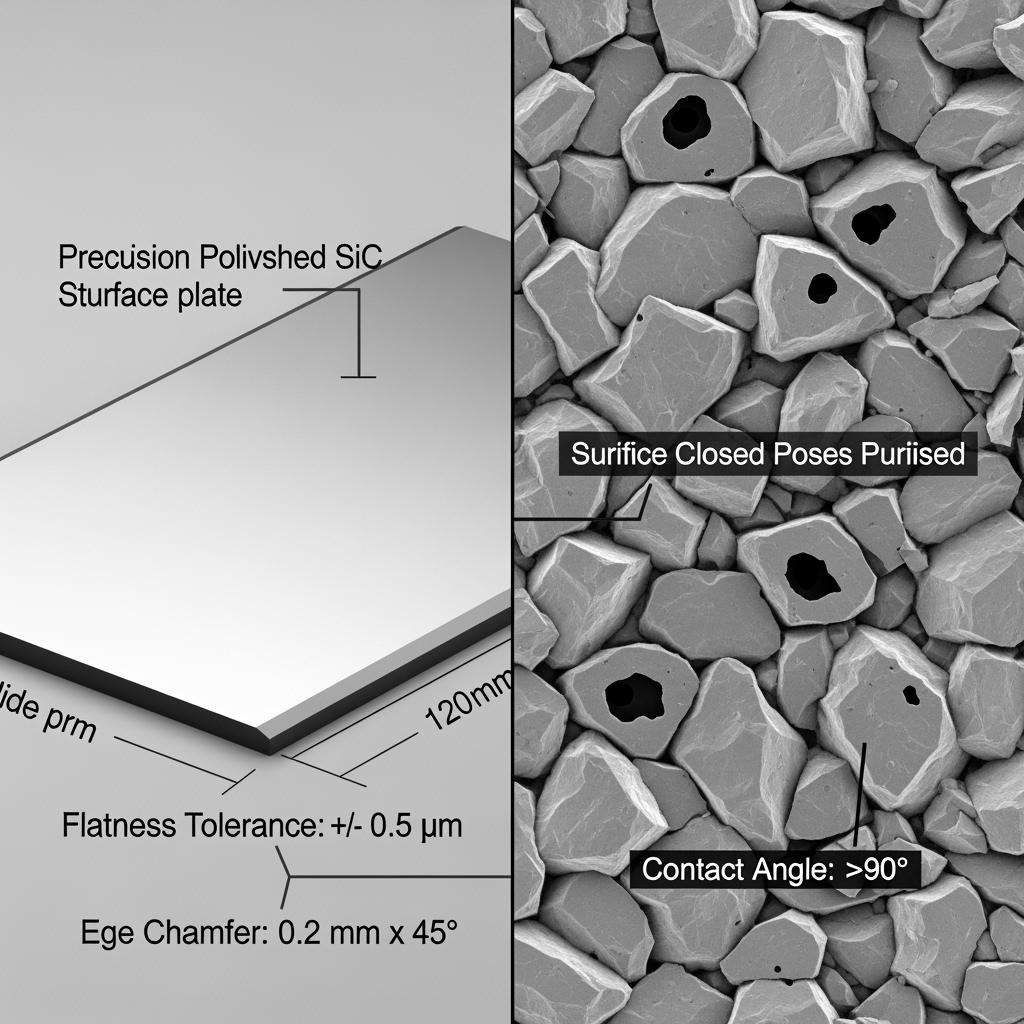

Sicarbtech’s portfolio is engineered as a complete system for tundish flow control. At its core are dense silicon carbide ceramics—submerged entry nozzles (SEN), slide plates, and tundish nozzles—produced via reaction sintering or liquid-phase sintering to achieve low open porosity and a closed-pore architecture. Precision CNC machining and multi-stage polishing deliver a controlled surface roughness, supporting stable discharge coefficients and reduced turbulence. For slide plates, high flatness and wear control preserve sealing integrity and minimize torque deviations over the campaign.

To handle Pakistan’s variable practices and clean steel needs, we complement base components with a suite of performance enhancers. Anti-oxidation composite additives stabilize carbon-influenced interfaces; low-wettability anti-slag coatings reduce adhesion and build-up; and ultra-low-permeability nozzle sleeves provide a secondary barrier against penetration. Reaction-sintered nozzle liners and SiC wear rings further harden high-stress contact points, while SiC flow-guiding throat prefabs help shape the flow field when casting conditions require geometry tuning.

Crucially, Sicarbtech’s offering spans the equipment and process controls needed for local production. Reaction sintering furnaces or high-temperature densification kilns establish density and strength; cold isostatic pressing improves green-body uniformity; precision classification and demagnetization stabilize purity and particle-size distribution; intelligent mixing and granulation optimize rheology; and CNC finishing with dimensional inspection ensures repeatability. “Dense silicon carbide is unforgiving of process drift,” notes a Sicarbtech process lead. “That’s why our packages include not just machines, but furnace curves, tool paths, inspection protocols, and SPC dashboards that lock in quality under Pakistan’s ambient and utility realities.”

Side-by-Side Technical Performance for Continuous Casting Flow Control

| Performance comparison for tundish flow-control components in Pakistan | Dense Silicon Carbide Ceramics (Reaction/Liquid-Phase Sintered) | Alumina–Carbon Systems | Conventional Oxide/Clay Ceramics |

|---|---|---|---|

| Bulk density (g/cm³) | 2.7–3.15 | 2.6–2.9 | 2.2–2.7 |

| Apparent porosity (%) | ≤ 6 (typ. 3–5) | 8–14 | 12–20 |

| Thermal conductivity at RT (W/m·K) | 25–120 | 8–20 | 2–6 |

| Cold crushing strength (MPa) | 150–350 | 80–180 | 60–120 |

| Flexural strength at RT (MPa) | 25–60 | 10–30 | 8–20 |

| Thermal shock (1000°C water quench) | ≥ 30–60 cycles | 15–30 | 10–20 |

| Wettability/build-up tendency | Low with coatings | Orta düzeyde | Daha yüksek |

| Permeability (relative) | 30–60% lower | Başlangıç Noktası | Yüksek |

| Dimensional stability at 1600–1700°C | Mükemmel | Orta düzeyde | Moderate to low |

| Typical life uplift in Pakistan use | +30–80% | Başlangıç Noktası | Lower at long sequences |

In Pakistani casters where long sequences and clean-steel practices intensify thermal and chemical demands, dense SiC’s blend of high conductivity, low permeability, and controlled surface finish translates into fewer build-ups, more stable speeds, and longer, cleaner runs.

Real-World Applications and Success Stories in Pakistan

A continuous caster in Punjab targeting longer sequences on low-alloy grades adopted a package comprising a dense silicon carbide SEN, a high-flatness SiC slide plate, and a low-wettability anti-slag coating, along with a quick-change nozzle module. Over a six-month period, average SEN and slide-plate life rose from around 220 heats per sequence to 340 heats. Build-up cleaning frequency fell by approximately 45%, casting speed fluctuation amplitude dropped by about 20%, and strand surface defect rates improved by roughly 18%. The line recorded a 28% reduction in unplanned downtime, and the combined cost per ton for refractories and downtime decreased by about 15%.

Another operator in Sindh, dealing with adhesion-linked nozzle clogging, introduced reaction-sintered SiC nozzle liners and ultra-low-permeability sleeves, coupled with precision-polished flow surfaces. Sequence length increased by 12–18% across mixed-grade campaigns, and nozzle-change torque stabilized enough to cut replacement time by nearly a third. These improvements were most pronounced during hot summer months when ambient temperature shifts had historically worsened dimensional drift on conventional components.

Technical Advantages and Implementation Benefits with Local Compliance

Dense silicon carbide’s physics align with Pakistan’s KPIs. High thermal conductivity equalizes temperatures around the flow channel, reducing gradients that spawn microcracks during start–stop cycles and ladle changes. High hardness and a dense matrix minimize groove wear and edge erosion, especially where velocity peaks at contraction points. When combined with surface engineering—polishing and low-wettability coatings—SiC limits slag-ring formation and nozzle adhesion, keeping discharge coefficients predictable.

On the compliance front, longer component life and fewer change-outs reduce waste generation and energy tied to heating cycles, which supports ISO 14001-aligned objectives. Sicarbtech’s documentation templates and SPC-driven QC workflows facilitate ISO 9001 alignment and PSQCA conformity. Plants can fold our inspection routines—ultrasonic/eddy-current checks, coordinate measuring for geometry, and surface roughness records—into existing QA plans, simplifying audits and tenders.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s differentiator is the ability to move Pakistan from buyer to maker. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, we provide proprietary recipes and process windows for R-SiC, SSiC, RBSiC, and SiSiC grades tailored to flow-control needs. Technology transfer packages include:

- Feasibility studies and plant layouts optimized for Pakistani utilities, labor profiles, and throughput targets, with staged CAPEX steps from pilot to full scale.

- Equipment specifications for reaction sintering furnaces or high-temperature densification kilns, cold isostatic presses for uniform compaction, and hot-press options for select geometries.

- Precision classification and demagnetization systems to stabilize purity and PSD; intelligent mixing and granulation to tune rheology; and CNC machining and polishing lines with tool-path libraries to achieve target flatness and surface roughness.

- Non-destructive testing protocols—ultrasonic, eddy current, and coordinate measurement—embedded with traceable batch IDs, alongside dimensional inspection gates to quarantine deviations.

- QA frameworks aligned with ISO 9001 and environmental management aligned with ISO 14001, plus safety SOPs consistent with ISO 45001 principles where applicable. We also assist with PSQCA documentation packs for local conformity.

- Training modules for operators and maintenance teams, commissioning support with furnace curve tuning, and remote monitoring dashboards for SPC on density, porosity, CCS/MOR, and thermal shock metrics.

- Ongoing technical support: quarterly audits, on-demand troubleshooting, and formulation/geometry iteration using your process data (casting speeds, flux chemistry, temperature profiles, and defect maps).

“Transferring a furnace is easy; transferring a process culture is what ensures Pakistan’s lines get repeatable quality,” a Sicarbtech technical director emphasizes. Evidence from collaborations with 19+ enterprises shows consistent improvements in component life, change-out time, and variability reduction when partners adopt the full stack—recipe, equipment, QC, and feedback loops.

Pakistan-Focused Technical Specification Ranges and QA Guidance

| Specification ranges relevant to Pakistan’s casters | Dense SiC Target Values | Local QA and testing guidance |

|---|---|---|

| Bulk density (g/cm³) | 2.7–3.15 | Verify per ISO/ASTM equivalents; track SPC by batch/season |

| Apparent porosity (%) | ≤ 6 (3–5 preferred) | Record sintering curve; correlate to permeability tests |

| Cold crushing strength (MPa) | 150–350 | ISO 10059/ASTM C133 equivalents; document coupon location |

| Flexural strength RT (MPa) | 25–60 | Bend tests with traceable heat/soak logs |

| Thermal shock (1000°C water quench) | ≥ 30–60 cycles | Cross-check with plant start–stop profiles |

| Max service temperature (°C) | 1600–1750 | Confirm vs alloy and oxygen potential |

| Conductividad térmica (W/m·K) | 25–120 | Validate with IR thermography near flow surface |

| High-temp dimensional change (3 h) | ≤ 0.3% | CMM before/after; retain records for audits |

| Surface roughness Ra (µm) | As specified for flow stability | Audit against discharge coefficient targets |

Operational Outcomes Comparison That Drive Cost and Stability

| Operational outcomes important to Pakistan’s continuous casting | Dense SiC SEN + SiC Slide Plate + Low-Wettability Coating | Alumina–Carbon or Conventional Oxide Baselines |

|---|---|---|

| Sequence length and speed stability | +10–30% sequence length; 15–25% better speed stability | Baseline; speed drift under adhesion |

| Build-up/clogging events | −30–60% with polished, coated surfaces | Higher; frequent cleaning |

| Change-out time and torque variance | −20–40% replacement time; steadier torque | Variable; alignment issues |

| Strand surface defects | −15–30% defects linked to inclusions/turbulence | Higher variability |

| Energy and waste footprint | Fewer relines and reheats | More frequent cycles |

| Supply chain risk | Localizable via tech transfer and modular spares | Import dependence; FX exposure |

Innovation That Matters: From Pores to Polishing

Sicarbtech’s innovation roadmap is grounded in field reality. Densification routes combine reaction sintering and liquid-phase sintering to minimize open pores and control second-phase distribution. Grain-boundary purification and orientation reduce embrittlement and oxidation pathways at high temperature. Surface engineering brings micro–nano texturing and specialized anti-slag coatings to suppress wetting and adhesion. Functionally graded designs pair an ultra-dense, hard flow surface with a toughened, stress-buffering backing to resist thermal and mechanical shocks. Precision manufacturing—cold isostatic pressing, CNC finishing, and staged polishing—locks in geometry and surface quality, while non-destructive testing and coordinate measurement ensure that every component shipped meets the caster’s need for dimensional and functional repeatability.

Future Market Opportunities and 2025+ Trends in Pakistan

Three trends define the path forward. First, clean steel adoption and higher casting speeds will continue to raise the bar for flow-control ceramics. Dense SiC’s low permeability and polished surfaces are well suited to suppress build-up and turbulence at these speeds, translating directly into yield protection for downstream rolling lines. Second, localized manufacturing will move from aspiration to action. As more Pakistani plants commit to in-country reaction sintering, cold isostatic pressing, and CNC finishing, lead times will shrink from months to weeks, and spare strategies will become modular and data-driven. Third, digital feedback loops will mature; plants will correlate casting speed curves, surface defect maps, and nozzle-change logs with component microstructure and geometry, enabling closed-loop optimization that steadily raises campaign predictability.

On scale, a medium-to-large caster in Pakistan typically consumes 80–250 sets of tundish flow-control components annually—equating to tens to hundreds of tons of dense SiC ceramics per year. With line upgrades and a rising share of higher value grades, national demand could reach several hundred to over a thousand tons annually. Layer in local machining and inspection lines, and the total market value rises to tens to hundreds of millions in Pakistani Rupees, depending on adoption pace and financing conditions. Providers who combine high-purity raw materials, stable process control, precision finishing, onsite support, and rapid spares will win share; Sicarbtech’s integrated model is deliberately structured to meet these criteria.

As one regional expert summarized in a 2025 briefing referencing global steel statistics and refractory practice primers, “Flow control is the heartbeat of the caster. When materials, geometry, and process data are aligned, breakthroughs in stability look like common sense.”

Sıkça Sorulan Sorular

Which dense silicon carbide products are best for Pakistani continuous casting lines?

For long sequences and clean steel, pair a dense SiC submerged entry nozzle with a high-flatness SiC slide plate and a dense SiC tundish nozzle. Add a low-wettability coating on flow surfaces and consider ultra-low-permeability sleeves or reaction-sintered liners where adhesion has historically driven clogging.

How much improvement can we expect in life and casting speed stability?

Typical field gains are 30–80% longer life for nozzles and slide plates, 15–25% tighter casting speed stability, and 30–60% fewer build-up/clogging events. Plants often report 20–40% reductions in change-out time once quick-change modules and flatness controls are standardized.

Can Sicarbtech help localize production to reduce lead times and FX exposure?

Yes. We provide complete technology transfer: process know-how, equipment specifications, plant layout, operator training, QA documentation, and commissioning. Partners can localize reaction sintering, cold isostatic pressing, classification, mixing, CNC finishing, and inspection to reach 2–4 week lead times once stabilized.

What certifications and QA documentation do you support for Pakistani tenders?

Our QC frameworks align with ISO 9001; environmental practices align with ISO 1401; safety SOPs reflect ISO 45001 principles. We support PSQCA conformity and provide SPC dashboards for density, porosity, CCS/MOR, thermal shock, and dimensional checks.

How do dense SiC components resist oxidation, penetration, and build-up?

Through closed-pore, low-permeability microstructures; purified grain boundaries; stabilized interfaces; and surface engineering (polishing plus anti-slag coatings) that lower wettability. Reaction-sintered liners and sleeves add a secondary barrier at hot spots.

What installation and O&M practices are critical for success?

Preheat and bake-out profiles must be disciplined to avoid thermal shock; torque specifications and locating datums ensure alignment; coatings are applied under clean conditions; and online cleaning routines are calibrated to avoid surface damage. We supply SOPs and checklists compatible with your CMMS.

What data should we share for customized geometry and formulation?

Casting speed ranges, sequence lengths, steel grade mix, flux properties, tundish temperature curves, and a failure-mode library (scouring patterns, adhesion sites, oxidation signatures). With these, we tune densification route, particle grading, flow-channel geometry, and surface finish.

How does Sicarbtech ensure batch-to-batch consistency in Pakistan’s climate?

By combining controlled raw materials, precision classification/demagnetization, SPC on sintering curves and densities, and post-process dimensional/surface audits. We also run seasonal reviews to adjust curves and milling parameters in response to ambient shifts.

Can dense SiC integrate with quick-change modules on existing casters?

Yes. We machine to your interface standards and tolerance stack-ups, validate with CMMs and fit trials, and provide wear rings/locating parts to minimize assembly drift. Many sites see immediate maintenance time savings.

What is a realistic roadmap to localize a full SiC flow-control line?

Most partners start with classification/mixing and CNC finishing on imported green bodies, then add cold isostatic pressing and reaction sintering as volumes justify. Sicarbtech phases CAPEX, staffing, and training to de-risk each step while guarding quality.

Operasyonlarınız için Doğru Seçimi Yapmak

Dense silicon carbide is not simply a tougher ceramic—it is an engineered pathway to steadier casting, fewer interventions, and lower total cost. In Pakistan’s 2025 market, where delivery certainty and clean-steel ambitions meet, Sicarbtech’s integrated approach—materials, densification, forming, precision finishing, QA systems, and onsite services—gives plant teams control over both performance and supply. If your constraints are speed drift, recurring build-up, and change-out variability, the step-change to dense SiC with disciplined process control will be visible in your KPIs within a single quarter.

Uzman Danışmanlığı ve Özel Çözümler Alın

Share your casting window—steel grades, speeds, sequence targets, and pain points—and Sicarbtech will propose a tailored dense SiC package with modeled life gains, geometry options, coating strategies, and an implementation plan. If localization is a priority, we will map a phased technology transfer that fits your CAPEX and timeline.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

E-posta: [email protected]

Telefon/WhatsApp: +86 133 6536 0038

Makale Meta Verileri

Last updated: 2025-09-19

Bir sonraki planlı güncelleme: 2026-01-15

Content freshness indicators: 2025 Pakistan market outlook validated; technical ranges reviewed against current field data; PSQCA/ISO alignment checked; contact information verified for Pakistan engagements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.