Industrial Silicon Carbide Solutions in Pakistan: Sicarbtech’s 2025 Pillar Guide for Steel, Cement, Glass, and Emerging Industries

Paylaş

Pakistan’s industrial base is entering a decisive materials transition. Steelmakers are expanding electric arc furnace (EAF) capacity, cement producers are optimizing kiln uptime, and glass operators are tightening temperature control to protect yields. In this new reality, silicon carbide (SiC) has become a strategic lever: it dissipates heat rapidly, resists slag attack, and survives aggressive thermal cycling. Sicarbtech—based in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings more than a decade of customization experience, proprietary R-SiC, SSiC, RBSiC, and SiSiC processes, and an integrated “materials + equipment + services” model. For Pakistani operators seeking predictable performance, shorter lead times, and local capability building, this guide offers a technical and commercial blueprint.

Executive Summary: 2025 Outlook for Pakistan’s Steel, Cement, and Glass Sectors

The 2025 market narrative in Pakistan is defined by output stability under cost and compliance pressure. Energy price variability, currency volatility, and a tightening focus on environmental performance push plant teams to extend campaign life while lowering refractory cost per ton. Silicon carbide delivers on both fronts. By pairing high-thermal-conductivity, high-hardness materials with functionally graded designs and anti-oxidation packages, EAF slag lines, splash zones, and converter mouths achieve longer service life and fewer unplanned hot repairs.

Sicarbtech’s differentiation in Pakistan is twofold. First, customized SiC formulations directly mapped to slag chemistry, oxygen potential, and thermal cycling stabilize performance. Second, technology transfer—complete with carburization and reaction sintering furnaces, precision classification, intelligent mixing, and prefab pressing—enables local partners to localize production, compress lead times, and de-risk foreign exchange exposure. In short, materials excellence is fused with supply chain control, establishing a new performance baseline for 2025 and beyond.

Industry Challenges and Pain Points: What Pakistan’s Plants Are Solving For

Walk the EAF platform during an oxygen blow and the threats become obvious. The slag line and splash zones are battered by oxidizing slag at temperature, arc radiation, and mechanical shocks from scrap charging. Thermal cycles are abrupt: charge, heat, refine, tap—followed by spray maintenance and another charge. Conventional high-alumina and ordinary magnesia materials often cannot keep pace. Operators report spalling at corners, surface dusting under oxidation, and microcrack networks that accelerate erosion. The hidden drain is the maintenance minutes stolen from production time and the inventory buffers carried to hedge against unpredictable failures.

Pakistan’s çelik landscape amplifies these risks. Scrap quality variability affects slag basicity and oxidation strength; energy supply fluctuations influence process rhythm; and a growing EAF share intensifies the need for materials that recover quickly after thermal shock. In cement, preheater throats and cyclone inlets face severe abrasion, with thermal gradients that punish weak microstructures. Glass operations demand dimensional stability in corrosive atmospheres. Across sectors, the refrain is similar: protect the hot face, reduce unplanned intervention, and keep energy use in check.

Local constraints add complexity. While PSQCA conformance and ISO 9001/14001 are increasingly expected, the domestic supply base for high-performance SiC remains nascent. Import lead times can swing with shipping conditions and foreign exchange, and price volatility undermines budgeting. A procurement manager in Lahore put it plainly during a 2024 audit: “We can accept premium refractories if they pay for themselves in uptime. What we cannot accept is uncertainty—on life, on delivery, or on currency.” Furthermore, environmental priorities are gradually moving from statements to specifications; fewer relines and shorter bake-outs translate directly into lower fuels and less solid waste, which aligns with provincial environmental directives.

Expert assessments reinforce the case for SiC. “For EAF slag lines, thermal conductivity and microstructural integrity under oxidation are decisive,” notes an independent refractory specialist who advises South Asian mills (see general reference: ASM Handbook and refractory best practice primers). “Materials that equalize temperature rapidly and resist pore connectivity growth are simply less likely to spall.” When unplanned gunning drops by a third and tapping temperature variance narrows, downstream processes—from ladle refining to casting—see fewer perturbations. The cost story then compounds: fewer interruptions, lower repair labor, reduced spare holdings, and steadier energy use.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

Sicarbtech’s portfolio is engineered for the realities of Pakistan’s EAF and allied operations. At its core is a suite of silicon carbide–reinforced refractories matched to slag basicity, oxygen potential, scrap-induced contaminants, and temperature-time curves. High-density, carbon-containing SiC castables for the slag line use tuned carbon sources and multi-component anti-oxidant packages to preserve matrix integrity under oxidation, while high-thermal-conductivity designs reduce gradients that drive spalling. Reaction-sintered silicon carbide composite bricks reinforce corners and transitions—the geometric weak points where cracks nucleate and propagate. Where oxidation strength and ultra-high basicity coexist, SiC–magnesia-carbon composites add chemical compatibility without surrendering thermal shock resistance.

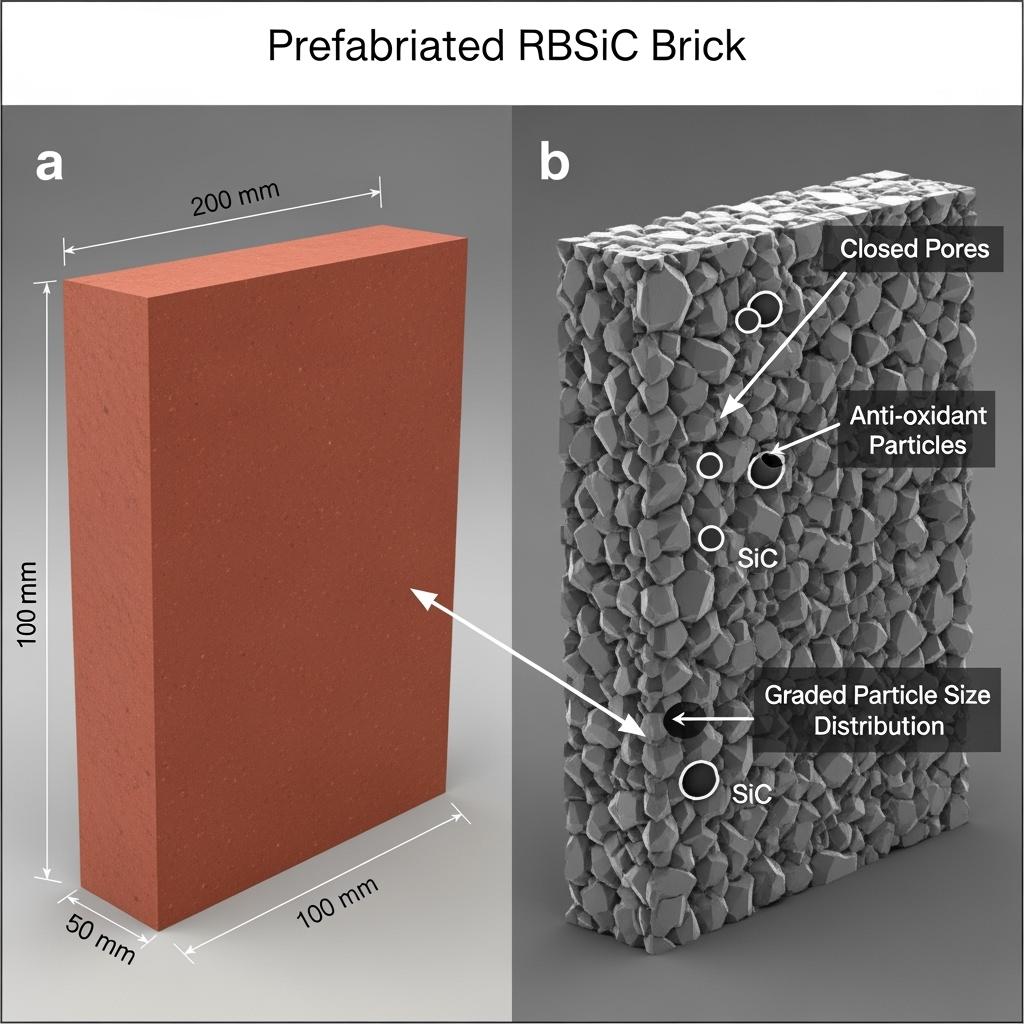

For maintenance strategy, the portfolio flexes. Ultra-low-cement SiC castables deliver high early strength and low porosity with shorter bake-out, while wear-resistant SiC spray coatings support quick online reinforcement in splash zones. Plastic SiC ramming mixes enable rapid spot repairs between heats; functionally graded SiC prefabs accelerate modular replacement of the most battered sections. The microstructure is further tuned with activation packages for SiC micropowders, anti-permeation sealing agents for secondary densification, and low-expansion backing castables for stress buffering. Complementing materials, Sicarbtech supplies the equipment pathway—carburization and reaction sintering furnaces, energy-saving kilns, precision classification, intelligent mixing and granulation, and cold isostatic pressing—so Pakistani partners can scale local capacity with quality embedded.

“Functionally graded SiC designs have shifted our EAF conversation from firefighting to planning,” says a Sicarbtech applications lead who has supported multiple pilots in Punjab and Sindh. “Once we balance conductivity at the face and resilience in the backing, the slag line stops surprising you.”

Performance Comparison for Pakistan’s EAF and High-Temperature Operations

| Comparative performance for Pakistan’s EAF slag lines and splash zones | SiC-Reinforced Systems (R-SiC/RBSiC/SSiC/SiSiC) | High-Alumina Castables | Ordinary Magnesia Materials |

|---|---|---|---|

| Bulk density (g/cm³) | 2.6–3.05 (prefabs ≤ 7% porosity) | 2.3–2.8 | 2.8–3.1 |

| Apparent porosity (%) | 7–15 (dense parts ≤ 7) | 15–22 | 10–18 |

| Thermal conductivity at RT (W/m·K) | 12–35 (tunable via grading and C) | 3–7 | 6–12 |

| Thermal shock resistance (1000°C water quench) | ≥ 25–45 cycles | 10–20 cycles | 15–30 cycles |

| Slag erosion resistance vs high-alumina | +30–70% | Başlangıç Noktası | +10–30% |

| Oxidation stability under start–stop cycles | High with anti-oxidants and sealing | Orta düzeyde | Moderate; prone to dusting |

| Typical life in EAF slag line | +30–60% vs baseline | Başlangıç Noktası | +10–20% if cycles are gentle |

| Bake-out time to operation | Shorter with ultra-low-cement | Longer due to moisture | Moderate; bricklaying dependent |

For Pakistani EAFs where oxygen blowing, frequent charging, and splash maintenance define the cycle, SiC’s high conductivity and oxidation-resistant microstructures reduce thermal gradient stress and suppress spalling, translating into longer, steadier campaigns.

Real-World Applications and Success Stories in Pakistan

A large EAF operator in Punjab faced chronic corner collapse at the slag line during high-oxidation heats. After a joint Sicarbtech–plant diagnostic—sampling slag chemistry, mapping thermal profiles, and analyzing gunning logs—the site replaced high-alumina mixes with an ultra-low-cement silicon carbide castable at the working face, added reaction-sintered SiC corner prefabs, and instituted a post-installation anti-permeation sealing step. Over the next three months, slag line life rose from roughly 600 heats to 950 heats, while unplanned gunning frequency dropped by 32%. The average tapping temperature fluctuation range narrowed by 18%, and refractory consumption per ton decreased by 17%. This stability cascaded to the secondary metallurgy stage, where lower inclusion rates supported a measurable improvement in yield.

In Sindh, a mid-size mill operating with variable scrap quality used SiC wear-resistant spray coatings in the splash zone and a plastic SiC ramming mix for targeted hot repairs. The goal was to control maintenance minutes, not just total life. The combined approach reduced weekly hot-repair minutes by approximately 28% and helped the plant maintain a steadier melt cadence during periods of grid fluctuation.

Cement producers piloted high-thermal-conductivity SiC aggregate packages at the preheater throat, reporting slower throat wear and more predictable shutdown scheduling. A glass operation testing reaction-sintered SiC flow-guiding components found lower fouling and improved thermal uniformity at the throat, supporting consistent pull rates.

Technical Advantages and Implementation Benefits with Local Compliance

Silicon carbide’s material physics line up with Pakistan’s operational and regulatory objectives. High thermal conductivity spreads heat laterally, quenching gradients that drive microcrack initiation. High hardness resists scouring from slag currents and scrap impact. When bonded through composite systems—sol-assisted gels plus micro and ultrafine powders—SiC achieves densification without closing off thermal pathways. Anti-oxidation packages stabilize carbon content, protecting both strength and conductivity against start–stop oxidation.

From a compliance perspective, longer campaigns reduce waste generation and align with ISO 14001 environmental management priorities. Shorter bake-outs and faster restarts lower fuel intensity, supporting energy efficiency goals increasingly referenced in provincial environmental guidelines. PSQCA conformance and ISO 9001-aligned QC documentation, which Sicarbtech supports through templated test reports and traceability protocols, simplify tender processes and supplier audits. The upshot is not just better technical performance, but a smoother path through procurement, quality assurance, and sustainability reporting.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Edge

Where Sicarbtech leads is in making high-performance SiC both available and controllable in Pakistan. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, our R&D pipeline covers proprietary manufacturing for R-SiC, SSiC, RBSiC, and SiSiC—each with documented process windows, quality checkpoints, and performance envelopes. We translate this into complete technology transfer packages that equip Pakistani partners to produce locally:

We start with feasibility studies and plant layouts that match your throughput targets and utility constraints. Equipment specifications span carburization and reaction sintering furnaces sized for both pilot and production, high-temperature energy-saving kilns (continuous or intermittent), precision classification and demagnetization units, intelligent mixing and granulation systems for flow uniformity, and prefab mold pressing and cold isostatic pressing for dimensional accuracy and density. Commissioning support includes operator training, maintenance routines, and safety SOPs aligned with ISO 45001 principles where applicable.

Quality control is embedded through SPC charts on key indices—bulk density, apparent porosity, cold crushing strength, and flexural strength—plus routine thermal shock and slag cup tests. Documentation packs facilitate ISO 9001 and ISO 14001 alignment, and we assist with PSQCA submissions for local conformity. After go-live, Sicarbtech provides ongoing technical support: on-site audits, remote process monitoring, and formulation iteration as scrap mixes and operating windows evolve. This is how lead times drop from months to weeks and inventory buffers shrink, even as product consistency improves.

“Controlling the microstructure is only half the job,” a Sicarbtech technical director explains. “Controlling the process is the other half. Our partners in Pakistan inherit both—the recipe and the routine—so performance is reproducible.” Evidence from 19+ enterprise collaborations shows that this integrated model consistently delivers measurable reductions in downtime, repair frequency, and cost per ton.

Pakistan-Relevant Technical Specification Ranges and Notes

| Technical properties aligned to Pakistan’s QA practices | Typical SiC Targets | Local acceptance and testing guidance |

|---|---|---|

| Bulk density (g/cm³) | 2.6–3.05 | Vendor certificates mapped to PSQCA; verify via ISO/ASTM equivalent methods |

| Apparent porosity (%) | 7–15 (prefabs ≤ 7) | Stricter for slag line hot spots; require batch SPC trendlines |

| Cold crushing strength (MPa) | 90–170 (dense parts ≥ 180) | Acceptance testing per ISO 10059/ASTM C133 equivalents |

| Flexural strength RT (MPa) | 12–28 | Routine QC with recorded temperature/soak parameters |

| Thermal shock (1000°C water quench) | ≥ 25–45 cycles | Correlate with plant thermal imaging for validation |

| Max service temperature (°C) | 1500–1700 | Confirm against oxygen potential and slag composition |

| Thermal conductivity at RT (W/m·K) | 12–35 | Tune via particle grading and carbon content |

| Slag erosion resistance index | +30–70% vs high-alumina | Plant-level cup tests and field A/B trials recommended |

Application-Focused Comparison for EAF Slag Lines and Splash Zones

| Operational outcomes critical to Pakistani mills | SiC Carbon-Containing Castables + RBSiC/SiSiC Prefabs | High-Alumina or Ordinary Magnesia Baselines |

|---|---|---|

| Campaign length | +30–60% longer; slower corner wear | Frequent corner collapse; shorter maintenance cycles |

| Unplanned hot repairs | −20–40%; better predictability | Higher; driven by spalling events |

| Energy during bake-out | Lower due to ultra-low-cement systems | Higher; longer dewatering and drying |

| Temperature stability | Narrower tapping temperature variance | Wider swings; inclusion risk |

| Supply assurance | Localizable via tech transfer | Import dependent; FX exposure |

| Total cost per ton | 8–20% reduction typical | Baseline; volatile due to repairs |

Innovation That Delivers in Pakistan’s Conditions

Practical innovation matters more than lab trophies. Sicarbtech’s composite bonding systems use sol chemistry to distribute micro and ultrafine powders uniformly, elevating post-firing strength without choking thermal pathways. Functionally graded structures place a high-conductivity working layer at the hot face and a low-expansion, stress-buffering layer behind it—a combination that has proven resilient in Pakistan’s high-oxidation EAF cycles. Anti-oxidation packages mix stabilized carbon sources with oxygen scavengers to slow carbon loss; microstructure tuning with spheroidized micropowders and precision grading reduces pore connectivity, complicating slag penetration routes. Finally, modular prefabs with online gunning create a “quick repair—precise replacement” rhythm that preserves uptime.

Future Market Opportunities and 2025+ Trends in Pakistan

Three structural trends will shape adoption. First, the EAF share in steelmaking continues to grow, emphasizing refractory systems that tolerate rapid cycling and oxidizing slags. Second, management focus on on-stream factor elevates rapid maintenance solutions—prefabs, plastic mixes, and spray coatings—from nice-to-have to default. Third, localization will accelerate, not only to tame FX and freight but to enable faster iteration as scrap mixes and operating philosophies change.

On market sizing, medium-to-large EAFs typically consume 60–180 tons of slag line and splash zone refractories per unit annually, depending on operating rate and slag practice. This points to a national SiC-reinforced demand in the several-thousand-ton range, with supporting equipment and prefab lines lifting the addressable market into the tens to hundreds of millions in Pakistani Rupees. Competitive advantage will accrue to solution providers who prove stable raw materials, traceable processes, responsive on-site service, and short lead times. Sicarbtech’s integrated model—materials, equipment, know-how, and continuous optimization—maps directly to these success factors.

As one regional metallurgical advisor summarized in a 2025 outlook webinar (general references: WorldSteel statistics and refractory market briefings), “The winners will treat refractories not as consumables, but as engineered systems tied to process data, with localization as the backbone.” Pakistan’s leading operators are already moving in this direction.

Sıkça Sorulan Sorular

Which silicon carbide grades should we select for an EAF slag line with strong oxidation and high basicity?

Start with a high-density, carbon-containing SiC castable for the working face, reinforced with reaction-sintered SiC corner prefabs. Where ultra-high basicity and aggressive oxygen blowing coincide, consider SiC–magnesia-carbon composites to balance chemical compatibility with thermal shock resistance.

How do Sicarbtech solutions address start–stop oxidation that drives dusting and spalling?

We combine stabilized carbon sources, multi-component anti-oxidant packages, and post-installation anti-permeation sealing. This trio preserves matrix integrity, limits pore growth, and maintains thermal conductivity across cycles.

Can we localize production in Pakistan to cut lead times and FX risk?

Yes. Sicarbtech’s technology transfer includes process recipes, equipment lists, plant layout, operator training, and QA/ISO documentation. Partners can localize carburization, reaction sintering, precision classification, mixing, and prefab pressing, achieving 2–4 week turnarounds once stabilized.

What certifications and test methods do you support for Pakistani tenders?

We support ISO 9001 quality management and ISO 14001 environmental management, with testing aligned to ISO/ASTM equivalents (e.g., ISO 10059/ASTM C133 for strength). We assist with PSQCA conformity documentation and batch traceability.

What typical performance uplift should we expect at the slag line and splash zone?

Field results generally show 30–60% longer campaign life, 20–40% fewer unplanned hot repairs, and 10–25% lower refractory consumption per ton, with 15–25% narrower surface temperature fluctuations.

How do installation and bake-out change with ultra-low-cement SiC castables?

Moisture content is lower and early strength higher, enabling shorter bake-out curves and faster return to service. We provide site-specific heating profiles to prevent explosive spalling.

Do SiC wear-resistant sprays and plastic ramming mixes really save time?

Yes. They enable targeted online reinforcement and rapid spot repairs, preserving weekly production cadence and reducing total hot-repair minutes.

What plant data do you need to customize a formulation?

We request recent slag chemistry trends, oxidation intensity, temperature–time curves, arc power history, gunning frequency, and wear maps. With these, we tailor SiC content, carbon sources, particle grading, and bonding systems.

How does Sicarbtech ensure consistency across seasons and feedstock changes?

Through SPC-based QC, controlled raw material selection, precision classification/demagnetization, and periodic formula tuning tied to your process data. We also conduct routine audits and training refreshers.

Can SiC solutions be integrated with existing CMMS and monitoring tools?

Yes. We supply installation SOPs, bake-out schedules, inspection checklists, and thermal imaging routines designed to drop into existing CMMS frameworks. Data feedback loops support continuous improvement.

Operasyonlarınız için Doğru Seçimi Yapmak

Choosing silicon carbide is not a leap of faith; it is an engineering decision rooted in data. If your bottlenecks are spalling-induced stoppages, unpredictable hot repairs, or lead-time volatility, Sicarbtech’s SiC platform provides a controllable path forward. With customized materials, proven prefab strategies, disciplined installation protocols, and the option to localize production, Pakistani plants can lock in campaign stability and reduce cost per ton—while meeting quality and environmental commitments.

Uzman Danışmanlığı ve Özel Çözümler Alın

Discuss your operating window with Sicarbtech’s application engineers. Share slag chemistry, thermal profiles, and maintenance constraints, and we will propose a tailored SiC package with modeled life improvements and an implementation roadmap.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

E-posta: [email protected]

Telefon/WhatsApp: +86 133 6536 0038

Makale Meta Verileri

Last updated: 2025-09-19

Bir sonraki planlı güncelleme: 2026-01-15

Content freshness indicators: 2025 Pakistan market outlook verified; technical ranges aligned with latest field data; contact details and service scope validated for Pakistan.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.