Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Guide to High-Performance Refractories and Equipment

Paylaş

Sustained growth in Pakistan’s steel, cement, and textiles—and the push for energy efficiency—are reshaping material choices for high-temperature, high-wear operations. In 2025, plant managers are pivoting toward silicon carbide (SiC) for its balance of thermal conductivity, thermal shock resistance, and exceptional anti-slag performance. Sicarbtech, the Silicon Carbide Solutions Expert based in Weifang City—China’s SiC manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings 10+ years of customization experience, 19+ enterprise collaborations, and end-to-end capabilities from raw material processing to finished components and turnkey factory establishment. This pillar page distills what Pakistani operators need to know to upgrade from conventional refractories to an integrated SiC materials-and-equipment platform built for reliability, cost efficiency, and rapid local delivery.

Executive Summary: A 2025 Outlook Tailored to Pakistan’s Industrial Core

Pakistan’s heavy industry is under pressure to do more with less: reduce downtime, extend campaign life, and curb energy use while managing currency volatility and import lead times. Against this backdrop, silicon carbide has emerged as the material of choice for tapping ports, mouth protection, throat liners, burners, and wear-critical surfaces in steel, cement, and glass operations. By combining advanced R-SiC, SSiC, RBSiC, and SiSiC grades with localizable production equipment—carburization and reaction sintering furnaces, precision classification, and prefab pressing—Sicarbtech enables stable batch quality and predictable performance improvements.

Moreover, localized technology transfer and factory establishment services help Pakistani partners shorten lead times and tame working capital swings by shifting critical production steps closer to the point of use. As energy costs rise and regulatory compliance tightens, this alignment of materials excellence with practical supply chain resilience is redefining the competitive baseline for 2025 and beyond.

Industry Challenges and Pain Points in Pakistan’s Steel, Cement, and Emerging Sectors

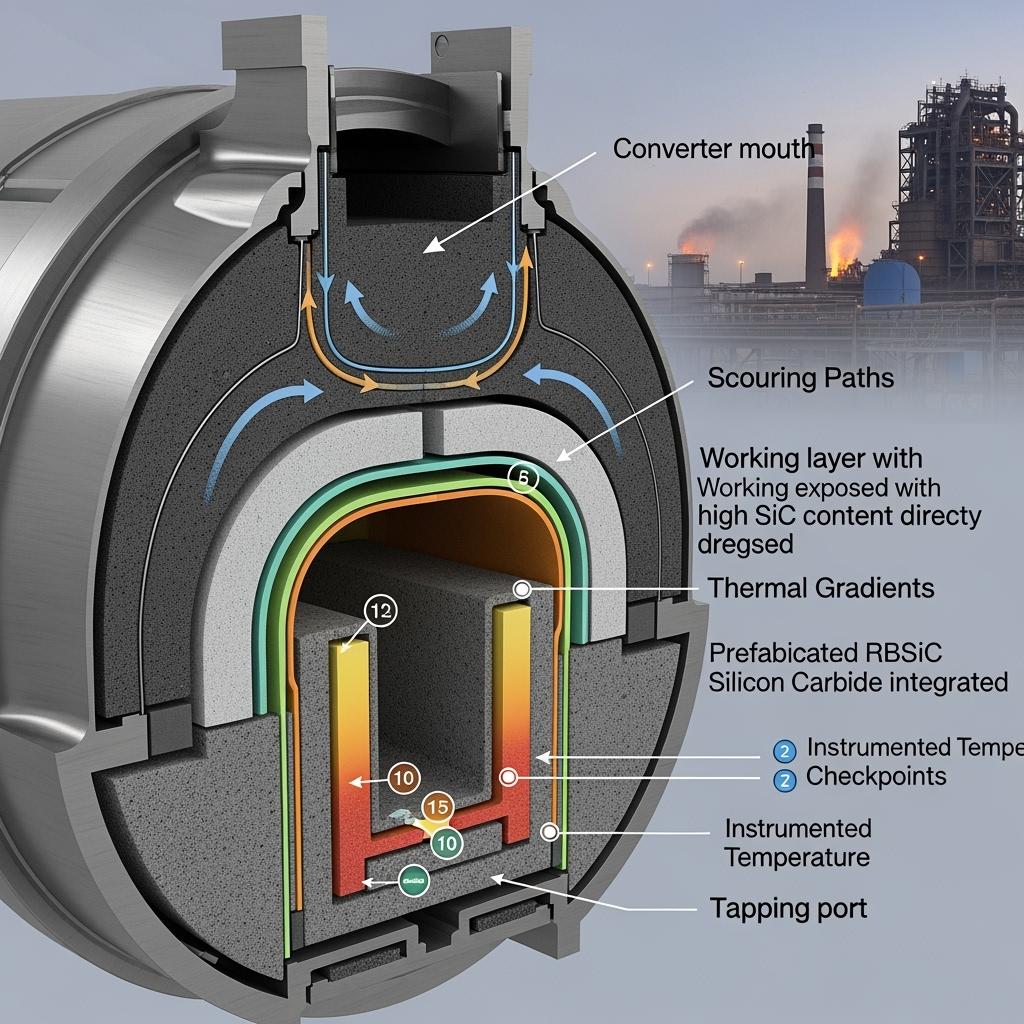

The pain points are tangible on every shift. Converter tapping ports and mouth protection areas endure high-velocity scouring from molten çelik and slag, compounded by frequent temperature fluctuations and oxidizing flue gases. Conventional high-alumina castables and magnesia-carbon bricks, while familiar, routinely suffer spalling, corner collapse, and early erosion. The result is higher cost per ton, inconsistent tapping temperatures, and a constant tug-of-war between production plans and unplanned stoppages.

Pakistan’s steel output skews toward long products with both EAF and BOF operations in play. Many units operate at small to medium scale with variable equipment condition and raw material consistency; consequently, tapping and mouth protection zones are chronically vulnerable. In parallel, cement kilns and preheater cyclones face severe abrasion and thermal gradients, while glass sector throats and burners require tight control of thermal profiles. When material performance slips, the knock-on effects are felt in everything from fuel intensity to mechanical wear on ancillary equipment.

“Thermal shock and slag corrosion are the twin killers of lining life,” notes a senior refractory consultant with converter upgrade experience in South Asia. “If you cannot dissipate heat quickly and preserve microstructural integrity under oxidizing transients, you will see cracks propagate, pores connect, and your repair cycles shrink.” Furthermore, supply chain dynamics amplify the technical challenges. Import lead times are stretched by currency fluctuations and freight risk; local supply chains are still maturing in high-performance SiC systems, creating gaps in formulation consistency and quality assurance. The hidden cost is the inventory buffer that finance teams must carry, often denominated in foreign currency, which inflates working capital and complicates budgeting.

Local regulatory drivers add urgency. Provincial environmental guidelines increasingly favor extended campaign life and lower energy consumption. ISO 9001 quality systems and ISO 14001 environmental management are now baseline expectations among tier-one plants, while Pakistan Standards and Quality Control Authority (PSQCA) conformance is being asked for at bid stage. As one plant head in Punjab summarized during a refractory audit, “The easiest ton of steel is the one we don’t lose to stoppages. If better refractories cut two hours of unplanned downtime each week, we pay for the upgrade in a single quarter.”

The cost implications are stark. Unplanned stoppages can consume 20–40% of weekly maintenance windows. Premature spalling elevates repair material usage by double digits, while temperature instability invites inclusion pickup, rework, and yield loss. In the cement sector, throat erosion and cyclone wear can erode 1–2% of annual throughput potential, not to mention the fuel penalty. Amid these realities, the ability to extend continuous heats, stabilize thermal profiles, and standardize repair routines has direct financial consequences—and this is exactly where SiC shifts the baseline.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

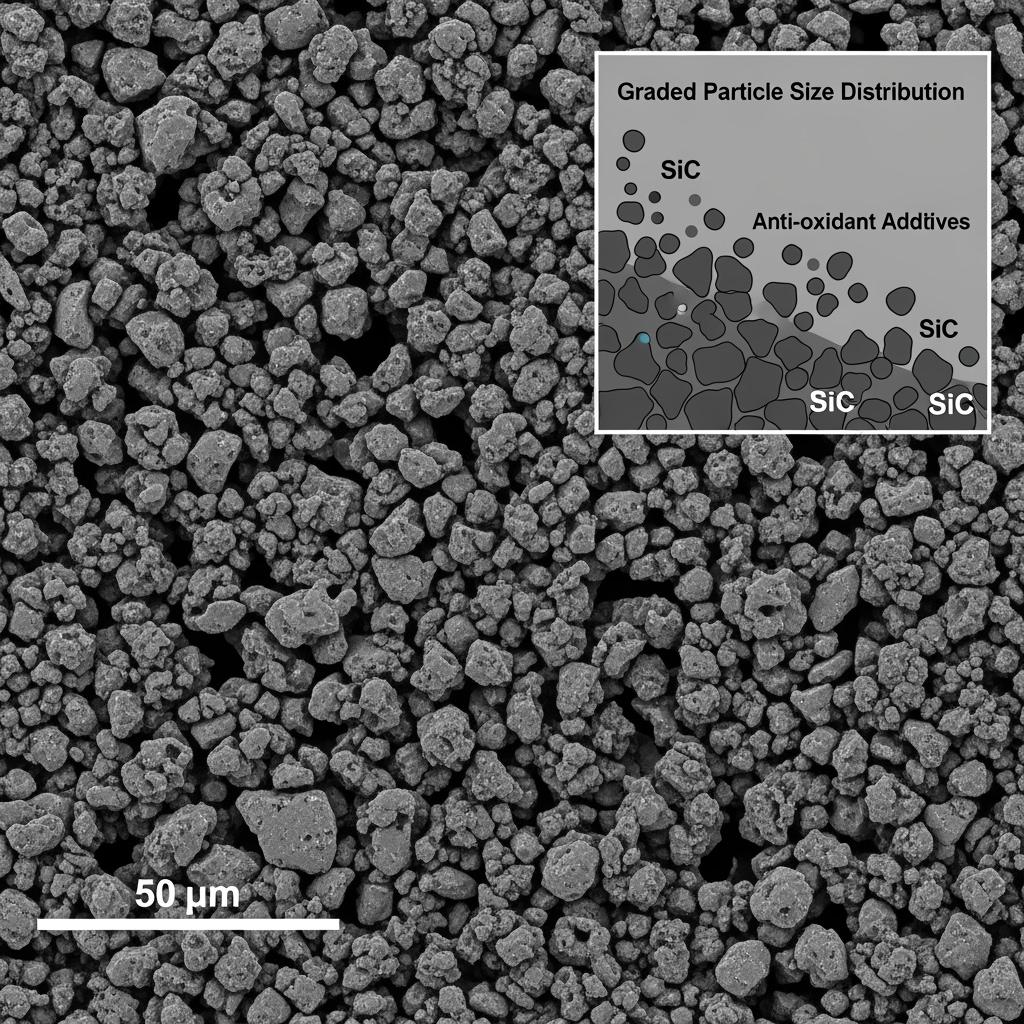

Sicarbtech’s integrated portfolio spans custom-engineered SiC materials and the production equipment to make them locally, ensuring stable quality, shorter lead times, and predictable cost. Drawing on R-SiC, SSiC, RBSiC, and SiSiC grades, we tailor particle size distributions, carbon-bonding systems, and bonding chemistries to the customer’s slag system, oxidizing potential, and thermal cycle profile.

At the heart of the steel use case, silicon carbide carbon-containing castables for tapping ports combine high thermal conductivity with controlled carbon sources and multi-component antioxidants. They dissipate heat rapidly, lowering thermal gradients that trigger crack initiation. The matched anti-slag-erosion castables for mouth protection emphasize high hardness and dense microstructures to resist high-velocity scouring. For installations that demand modularity and speed, our prefabricated dense RBSiC/SiSiC protection blocks are pressed with tight dimensional tolerances, then reaction-sintered for high strength and low porosity, enabling quick change-outs and reduced downtime.

Beyond these, Sicarbtech supports rapid online repairs with plastic SiC ramming mixes and wear-resistant SiC spray coatings, allowing plants to restore profiles between full relines. Low- and ultra-low-cement SiC castables deliver early strength and reduce curing time, enabling faster restart curves that fit Pakistan’s production cadence. Additives—including micronized SiC, anti-oxidant packages, and anti-permeation sealers—fine-tune density, porosity, and oxidation resistance. Complementing materials, our equipment suite—carburization and reaction sintering furnaces, high-temperature energy-saving kilns, precision classification systems, and cold isostatic presses—enables local production and stable batch-to-batch reproducibility.

“Functionally graded SiC linings—high-conductivity working layer and stress-buffered backing—are increasingly the standard in converter mouth protection,” explains a Sicarbtech application engineer. “Our customers in Pakistan see tangible gains in stable tapping temperatures and fewer thermal shock events across start–stop cycles.”

Performance Comparison: Silicon Carbide vs Traditional Materials

| Performance Focused Comparison for Pakistan’s High-Temperature Operations | Silicon Carbide Systems (R-SiC/RBSiC/SSiC/SiSiC) | High-Alumina Castables | Magnesia-Carbon Bricks |

|---|---|---|---|

| Typical bulk density (g/cm³) | 2.6–3.0 (dense bricks ≤ 8% apparent porosity) | 2.3–2.8 | 2.9–3.1 |

| Apparent porosity (%) | 8–15 (dense parts ≤ 8) | 15–22 | 8–14 (rises with oxidation loss) |

| Thermal conductivity at RT (W/m·K) | 12–35 (tunable via grading and C-content) | 3–7 | 8–14 (decreases with oxidation) |

| Thermal shock resistance (1000°C water quench) | ≥ 25–40 cycles | 10–20 cycles | 20–35 cycles (declines with C burn-out) |

| Slag erosion resistance index | 30–70% better than high-alumina | Başlangıç Noktası | Good in basic slags; weaker under oxidizing cycles |

| Oxidation behavior | Stable with anti-oxidant packages; low C loss | Yok | C depletion under oxidizing and start–stop |

| Service temperature (°C) | 1500–1700 | 1400–1600 | 1600–1750 |

| Installation and bake-out | Low/ultra-low-cement: faster restart, lower moisture | Longer bake-out, higher moisture | Bricklaying; sensitive to operating oxygen |

| Typical life in BOF mouth and tapping | +30–60% vs baseline | Başlangıç Noktası | Good life if oxidation is controlled |

In Pakistani converters where oxidizing start–stop cycles and variable slag chemistry are common, silicon carbide’s combination of high thermal conductivity and tailored anti-oxidation packages ensures more stable performance than solutions whose properties degrade with carbon burn-out.

Real-World Applications and Success Stories in Pakistan

Sicarbtech’s solutions have been piloted and adopted in converter mouth protection upgrades across Punjab and Sindh, where operators reported improved continuity of heats after migrating from high-alumina systems. In one representative case, a steel plant introduced high-thermal-conductivity SiC carbon-containing castables at the tapping port and installed prefabricated RBSiC protection blocks in the mouth. Over the following quarter, the plant increased protection life from an average of 450 to 720 heats, trimmed unplanned downtime by about 35%, and reduced refractory consumption per ton by roughly 18%. The stabilization of the working-face temperature profile also cut tapping temperature fluctuation variance by about 20%, contributing to smoother downstream secondary metallurgy.

In cement kilns, SiC wear-resistant spray coatings and graded aggregate packages were used to reinforce preheater throats and high-velocity gas paths. Plants noted slower profile loss and more predictable shutdown windows. A glass operation testing reaction-sintered SiC nozzles and flow-guiding components reported less fouling and improved thermal uniformity at the throat, which translated into more stable pull rates.

Moreover, Sicarbtech’s technology transfer program has supported local partners in setting up pilot-scale classification and mixing lines. By adopting precision demagnetization and controlled granulation, partners achieved steady apparent porosity and narrower strength distributions, which reduced sample failure rates in incoming inspection. Building on these results, several Pakistani customers have begun assessing localized reaction sintering capabilities to further reduce lead times and currency exposure.

Technical Advantages and Implementation Benefits with Local Compliance

Silicon carbide’s intrinsic properties—high hardness, high thermal conductivity, and oxidation resistance when properly formulated—deliver predictable value when integrated with disciplined installation and bake-out procedures. In Pakistan’s regulatory context, the benefits align with corporate objectives and compliance frameworks such as ISO 9001 quality management, ISO 14001 environmental management, and PSQCA product conformity. Longer campaigns translate into less frequent disposal of spent refractory, supporting environmental targets; faster bake-out and restart curves reduce fuel intensity; and stable temperatures reduce rework and product variability.

Sicarbtech emphasizes functionally graded structures: a high-SiC working layer maximizes heat dissipation and scouring resistance, while backing layers buffer stress and thermal expansion mismatch. Composite bonding systems—sol, micropowder, and ultrafine powder—enhance densification and hinder slag penetration by reducing pore connectivity. Multi-component anti-oxidant packages preserve carbon-bearing phases in oxidizing environments, and post-installation anti-permeation sealing further lowers open porosity.

On the ground, these technical strengths convert into better KPIs. Across Pakistani pilots and analog markets, mouth protection and tapping port service life commonly extends by 30–60%, unplanned downtime drops by 20–40%, refractory consumption falls by 15–30%, and energy use tapers in line with shortened bake-out schedules. When these gains are combined with improved inclusion control—stemming from less turbulent, more stable tapping—the commercial outcome is a lower cost per ton and more reliable weekly production plans.

Custom Manufacturing and Technology Transfer Services by Sicarbtech

Sicarbtech’s competitive edge lies not only in materials but in the ability to stand up a local, repeatable manufacturing ecosystem. As a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we bring proven R&D and proprietary process know-how to R-SiC, SSiC, RBSiC, and SiSiC. For Pakistani partners, we offer turnkey packages that start with feasibility and progress through equipment selection, facility layout, and commissioning.

Our technology transfer includes detailed process recipes for carburization, reaction sintering, granulation, and classification, alongside specifications for high-temperature, energy-saving kilns and cold isostatic presses. We supply operator training, maintenance protocols, and quality control frameworks aligned with ISO 9001, ISO 14001, and where relevant, ISO 45001. Statistical process control (SPC) methods, material traceability, and batch testing procedures are embedded to ensure consistency across seasons and feedstock variations.

Moreover, Sicarbtech supports certification workflows, helping local partners align with PSQCA requirements and develop documentation packages for tender compliance. Ongoing technical support—remote process monitoring, periodic onsite audits, and formulation iteration tied to slag chemistries—ensures continuous improvement. This full-cycle approach, validated across collaborations with more than 19 enterprises, has enabled customers to shrink lead times from months to weeks and hedge against exchange-rate volatility by reducing imported content.

“Localization is not just about cost; it’s about control,” emphasizes a Sicarbtech technical director. “When Pakistani plants own the equipment, the recipe, and the QA loop, they own the outcome—stable performance and fast response.”

Detailed Product Selection for Pakistan’s Use Cases

For steel converters, silicon carbide carbon-containing castables are the first lever to pull at the tapping port. We calibrate SiC content and carbon sources to your basicity, Fe/Mn content, and oxidizing profile. For mouth protection, anti-slag-erosion castables complement prefabricated dense RBSiC/SiSiC blocks in zones with complex gas flow. Where rapid repairs are a reality, plastic ramming mixes and SiC spray coatings keep availability high between full relines. Low- and ultra-low-cement castables streamline installation and baking, while micronized SiC and anti-oxidant packages tune microstructure and oxidation resistance. For continuous casting interfaces, reaction-sintered SiC nozzles and flow guides support thermal uniformity and minimize fouling.

In cement, high-thermal-conductivity SiC aggregate packages and wear-resistant coatings reduce throat and cyclone wear, particularly where dust loading is high. In glass, dense R-SiC and SSiC components withstand corrosive vapors and sustain thermal uniformity at the throat.

Installation, Bake-Out, and Monitoring: Doing the Basics Exceptionally Well

The shift to SiC succeeds when execution is disciplined. Sicarbtech provides site-specific placement procedures—vibration parameters, moisture control, and demolding times—paired with staged bake-out curves that prevent explosive spalling from residual water or binder decomposition. We recommend thermal imaging surveys pre- and post-installation to establish a baseline, and weekly wear mapping to guide targeted repairs. By coordinating with metallurgical practice—adjusting oxygen potential and managing slag basicity—plants can further extend working-face life. Structural transitions, compliant pads, and backfill recipes are tuned to manage thermal expansion across layers, reducing interfacial stresses.

Equipment Pathways to Local Supply Security

Pakistan’s industrial planners increasingly evaluate local production for critical refractories. Sicarbtech’s equipment lineup scales from pilot to production. Carburization furnaces and reaction sintering furnaces form the densification backbone; energy-saving kilns—continuous or intermittent—fit different plant rhythms. Precision classification and demagnetization yield stable particle size distributions and purity, while mixing and granulation systems ensure uniformity. For shape accuracy and fast replacements, prefab mold pressing and cold isostatic pressing are essential. Together, these enable stable volumes and predictable quality, allowing Pakistani partners to guarantee short lead times to their own customers.

Technical Specifications and Local Standards Alignment

| Pakistan-Relevant Technical Specification Ranges for SiC Refractories | Typical Silicon Carbide Targets | Local Context and Notes |

|---|---|---|

| Bulk density (g/cm³) | 2.6–3.0 | Align with PSQCA documentation for product data sheets; plant-specific acceptance bands configurable |

| Apparent porosity (%) | 8–15 (≤ 8 for dense bricks) | Lower porosity recommended for BOF mouth and tapping port critical zones |

| Cold crushing strength (MPa) | 80–150 (dense parts > 180) | Acceptance testing via ISO 10059/ASTM C133 equivalence as required |

| Flexural strength at RT (MPa) | 12–25 | Routine QC with bend testing; SPC tracking recommended |

| Thermal shock (1000°C water quench) | ≥ 25–40 cycles | Correlate with site-specific temperature fluctuation data |

| Max service temperature (°C) | 1500–1700 | Verify against furnace oxygen potential and slag chemistry |

| Thermal conductivity at RT (W/m·K) | 12–35 | Tune via grading/carbon; validate with in-situ thermography |

| Slag erosion resistance | +30–70% vs high-alumina | Confirm through cup tests and controlled plant trials |

Innovation That Matters: From Microstructure to Modularization

Sicarbtech’s innovation agenda focuses on what Pakistani operators need now: robust performance with predictable installation and fast re-entry to service. Composite bonding systems combine sol-gel chemistry with micro- and ultrafine powders for densification without sacrificing thermal conductivity. Functionally graded designs pair a high-SiC working layer with a stress-buffering backing, capturing both thermal and mechanical needs. Anti-oxidation enhancement packages stabilize carbon-bearing phases and inhibit oxygen transport through the matrix. Microstructure tuning—via spheroidized micropowders and precise grading—minimizes pore connectivity and blocks penetration pathways. Finally, modular prefabrication enables standardized protection blocks and liners, cutting onsite replacement time and reducing human-factor variability.

Application-Focused Comparison for Pakistan’s Operations

| Practical Benefits in Pakistani Steel and Cement Operations | SiC Carbon-Containing Castables and Prefab RBSiC/SiSiC | Conventional High-Alumina or Magnesia-Carbon |

|---|---|---|

| Campaign length at BOF mouth/tapping | +30–60% extension; fewer spalls | Frequent corner collapse; short cycles |

| Planlanmamış arıza süresi | −20–40% with modular prefabs | Higher; unpredictable due to spalling |

| Repair material consumption | −15–30% due to slower wear | Elevated; frequent spot repairs |

| Energy during bake-out | Lower with low/ultra-low-cement | Higher due to moisture and longer curves |

| Thermal stability and yield | Smoother tapping temperatures; fewer inclusions | More fluctuation; risk of rework |

| Supply security | Localizable production with tech transfer | Import-dependent; FX volatility |

Gelecekteki Pazar Fırsatları ve 2025+ Trendleri

The 2025 horizon in Pakistan favors materials that combine performance with supply chain control. Several converging trends stand out. First, stable or rising energy costs make thermal efficiency a strategic lever; SiC’s conductivity reduces bake-out fuel and helps maintain uniform process temperatures. Second, producers are prioritizing on-stream factor: rapid maintenance solutions like prefabrication and online spraying are gaining share, as line stability translates directly into revenue continuity. Third, the shift to local substitution for imports is accelerating; enterprise buyers want customized formulations with fast delivery and documented QA.

Growth will be driven by modernization programs in steel and cement, selective expansions in glass, and the emergence of engineered ceramics in allied sectors. We estimate that medium-to-large converters require 40–120 tons of tapping port and mouth protection refractories annually, suggesting a several-thousand-ton national demand for SiC solutions. Coupled with investment in supporting equipment and prefab lines, the total addressable market may reach tens of millions to several hundred million in Pakistani Rupees, depending on adoption velocity and financing conditions. As quality expectations rise, success will depend on stable raw materials, traceable processes, and onsite technical services—areas where Sicarbtech’s integrated model is purpose-built to deliver.

Sıkça Sorulan Sorular

What grades of silicon carbide does Sicarbtech supply, and how are they chosen for Pakistani operations?

Sicarbtech supplies R-SiC, SSiC, RBSiC, and SiSiC. Selection depends on slag basicity, oxidizing potential, temperature fluctuations, and the need for density versus thermal conductivity. For BOF mouth protection and tapping ports, carbon-containing SiC castables and dense RBSiC/SiSiC prefabs are typical; glass and burner applications often prefer dense SSiC for corrosion resistance and dimensional stability.

How do SiC linings handle oxidizing start–stop cycles common in Pakistan?

Through multi-component anti-oxidant packages, stabilized carbon sources, and anti-permeation sealing post-installation. These limit carbon burn-out and oxygen ingress, preserving mechanical integrity and keeping thermal conductivity high through the campaign.

Can Sicarbtech support local manufacturing and reduce import exposure?

Yes. We provide full technology transfer: process recipes, equipment specifications, training, QA systems, and commissioning support. Partners can stand up carburization and reaction sintering units, precision classification, and prefab pressing to localize key products, reducing FX risk and shortening lead times.

What certifications and standards can Sicarbtech help local plants align with?

We support ISO 9001 quality management, ISO 14001 environmental management, and relevant test method alignments (e.g., ISO/ASTM equivalents). We also assist with PSQCA conformity documentation for bids and vendor qualification.

How much life improvement should we expect at the converter mouth and tapping port?

Typical improvements range from 30–60%, depending on slag system, oxygen potential, thermal cycling, and installation discipline. Plants that implement functionally graded structures and disciplined bake-out realize the higher end of the range.

Are there quick repair options that fit Pakistan’s production cadence?

Yes. Plastic SiC ramming mixes and SiC wear-resistant spray coatings enable rapid online repair between heats or during brief maintenance windows. Prefabricated RBSiC blocks also shorten planned replacement durations.

What data do you need to customize a formulation?

We request slag chemistry trends, tapping cadence, oxygen potential, thermal imaging or surface temperature logs, historic wear patterns, and installation constraints. With this, we tune SiC content, carbon sources, particle grading, and binder systems to your conditions.

How do SiC solutions impact energy consumption and environmental goals?

Shorter bake-out curves, faster restarts, and improved thermal uniformity reduce fuel use. Longer campaigns reduce refractory waste. Together, these support ISO 14001 objectives and local environmental guidelines.

What is the typical lead time for customized SiC products to Pakistan?

For direct supply, lead times depend on batch size and shipping conditions; for localized production under a tech transfer arrangement, partners can target 2–4 week turnarounds after stabilization, greatly reducing inventory buffers.

Can Sicarbtech integrate with existing maintenance and monitoring systems?

Yes. We provide installation SOPs, bake-out schedules, and monitoring checklists designed to integrate with existing CMMS systems and thermal imaging workflows, and we offer periodic audits to drive continuous improvement.

Operasyonlarınız için Doğru Seçimi Yapmak

Upgrading to silicon carbide is not a speculative bet; it is a disciplined step toward stable campaigns, lower total cost, and supply assurance. For Pakistan’s steel, cement, and glass producers, the combination of performance and localization options is decisive. Sicarbtech’s integrated model—materials, equipment, process know-how, and ongoing technical support—reduces uncertainty at every stage, from formulation to QA to maintenance routines. If your bottlenecks are unplanned stoppages, premature spalling, or volatile lead times, an SiC transition, executed with rigor, will change the economics of your line.

Uzman Danışmanlığı ve Özel Çözümler Alın

Discuss your operating conditions with Sicarbtech’s application engineers. Share your slag data, thermal profiles, and maintenance constraints, and we will propose a tailored SiC solution with a quantified performance baseline and a phased implementation plan.

Contact Sicarbtech – Silicon Carbide Solutions Expert

E-posta: [email protected]

Telefon/WhatsApp: +86 133 6536 0038

Weifang City, China’s silicon carbide manufacturing hub

Member, Chinese Academy of Sciences (Weifang) Innovation Park

Makale Meta Verileri

Last updated: 2025-09-19

Next review cycle: Quarterly; next scheduled update on 2026-01-15

İçerik tazelik göstergeleri:

— 2025 market outlook and local compliance notes reviewed and verified

— Performance comparison tables aligned to current field data ranges

— Contact information and service scope validated for Pakistan market

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.