Industrial Silicon Carbide Solutions for Pakistan’s Mobility and Manufacturing: Sicarbtech’s 2025 Playbook

Paylaş

Executive Summary: 2025 Outlook for Pakistan’s Electric Mobility and Industrial Efficiency

Pakistan’s industrial backbone—textiles, cement, and çelik—alongside an accelerating shift toward electric two-wheelers, three-wheelers, and light commercial vehicles, is entering a decisive phase. Energy price volatility, grid instability, and harsh operating environments have raised the bar for power electronics reliability and efficiency. Silicon carbide (SiC) has moved from early adoption to mainstream consideration, bringing higher efficiency, higher temperature operation, and smaller, lighter systems. In 2025, the traction inverter market for Pakistan’s two- and three-wheeler fleets and emerging commercial EV segments is poised for double-digit growth, supported by government interest in local manufacturing, import duty structures favoring CKD/IKD, and escalating TCO pressures in fleets.

Sicarbtech—based in Weifang City, the heart of China’s SiC manufacturing hub, and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings over a decade of SiC customization and full-cycle solutions from material processing to finished modules. With 19+ enterprise collaborations and turnkey technology transfer, Sicarbtech enables Pakistani OEMs and integrators to localize packaging, screening, and maintenance, cutting delivery times while elevating reliability for dusty, hot, and grid-challenged conditions common from Karachi to Peshawar. This pillar guide connects the technical characteristics of R-SiC, SSiC, RBSiC, and SiSiC products to concrete operational outcomes in traction inverters, auxiliary power, and plant electrification—backed by practical case narratives, standards alignment, and quantified performance gains.

Industry Challenges and Pain Points in Pakistan’s Electric Mobility and Heavy Industry

The prevailing constraints start with the grid. Frequent voltage dips, surges, and harmonics during nighttime charging windows create harsh stress on drive inverters and onboard chargers. In high-density areas, shared depots pull significant bursts of current from weak feeders, compounding EMI/EMC issues and accelerating device aging. Heat compounds the challenge. Summer peaks push ambient temperatures above 40 °C, and underbody inverters face continuous dust exposure, typical in unpaved routes and industrial yards. Conventional silicon IGBTs, with greater reverse recovery and higher conduction losses, run hot quickly, pushing cooling systems to their limits and forcing derating precisely when drivers need torque for hills and heavy loads.

Moreover, maintenance realities demand resilience. Fleet operators managing passenger three-wheelers in Lahore or Karachi cannot afford downtime—each day off-road directly cuts daily revenue. Component sourcing delays and the lack of local screening capabilities often turn minor failures into multi-week disruptions. In cement and steel plants, power electronics for drives and pumps encounter abrasive dust, corrosive atmospheres, and thermal cycling near furnaces or kilns. Traditional builds struggle with coating integrity and thermal fatigue at solder joints. As a senior powertrain engineer at a regional OEM remarked, “Every hour our vehicles are sidelined is a hit on utilization; we needed devices that survive heat and grid noise without babysitting.” [Source: Industry interview synthesis, 2024]

Cost structures are shifting too. Battery prices—though easing—still dominate BOM. Inefficient inverters translate to larger battery packs for similar range targets. Cooling systems sized for silicon thermal loads add weight and cost, impacting payload and energy consumption. Additionally, compliance requirements are tightening. While Pakistan draws on harmonized IEC/ISO frameworks, tender specifications for public fleets increasingly reference ISO 26262 functional safety considerations, IEC 60747 device standards, and ISO 7637/EMC immunity benchmarks. For industrial retrofits, compliance with IEC 61800-3 (EMC for adjustable speed electrical power drive systems) and adherence to local NEPRA/PEPCO guidelines around power quality and harmonics factor into procurement choices. As Dr. A. Farooq, an independent power systems consultant, notes, “Procurement panels are no longer buying on price alone; they’re assessing LCOE, TCO, and uptime metrics anchored in recognized international standards.” [Source: Pakistan Power Electronics Forum notes, 2024]

The upshot is clear: Pakistan’s operators need compact, thermally robust, and grid-tolerant solutions that are easy to maintain locally. Silicon carbide, particularly when paired with low-inductance packaging, double-sided cooling, and predictive monitoring, directly targets these hard constraints—unlocking higher efficiency at elevated switching frequencies, reducing magnetics and heatsink mass, and improving reliability despite dust, heat, and unstable supply.

Advanced Silicon Carbide Solutions Portfolio for Pakistan’s Conditions

Sicarbtech’s portfolio spans from high-junction-temperature SiC MOSFET chip arrays to automotive-grade three-phase bridge modules at 650 V and 1200 V, packaged for double-sided cooling and low inductance. Gate driver boards integrate short-circuit protection with soft turn-off and active clamping to tame DC bus overvoltage during transients common in stop-go driving and hill starts. Integrated liquid or air-cooled baseplates and matching thermal interface materials help OEMs right-size cooling for Pakistan’s ambient extremes without overdesign.

Furthermore, Sicarbtech deploys substrate assemblies with high-thermal-conductivity ceramics and vacuum brazing or pressure sintering for mechanically and thermally resilient stacks. For fast integration, traction inverter controller core boards arrive pre-validated with current sampling, speed estimation, field-oriented control, and field-weakening routines tuned for compact motors used across two- and three-wheelers. Complementary kits for high-frequency magnetics and low-inductance busbars reduce layout risk and EMI headaches. Crucially, Sicarbtech provides the production equipment and process toolkits that enable local packaging, stress screening, and maintenance workflows—shortening replacement lead times and building durable in-country competence.

In heavy industry, R-SiC, SSiC, RBSiC, and SiSiC materials are engineered into high-wear, corrosion-tolerant components—seals, liners, nozzles, and heat-resistant fixtures—that withstand abrasive dust and thermal shock. This cross-domain expertise in both materials and power modules allows Sicarbtech to solve multi-physics problems, for example coupling dust-proof encapsulation with corrosion-resistant coatings and module-level health monitoring to cut unplanned stops in cement handling or steel billets conveyance lines.

Performance Comparison: Silicon Carbide vs Conventional Silicon for Pakistan’s Duty Cycles

Efficiency and Reliability Benchmarks for Local Operating Conditions

| için önemli bir gerekliliktir (SiC uyumlu süreçlerde kullanılıyorsa). | Silicon Carbide (SiC) Inverter | Conventional Silicon (IGBT/Si) Inverter | Local Relevance (Pakistan) |

|---|---|---|---|

| Typical traction efficiency (urban cycles) | 95%–97% at 10–30 kHz | 92%–94% at 6–12 kHz | Higher efficiency reduces battery size and cooling load for heat-prone summers |

| Junction temperature operation | Up to 175 °C continuous Tj | 125–150 °C typical | Greater thermal headroom for hot, dusty environments |

| Anahtarlama frekansı yeteneği | 10–40 kHz stable | 6–12 kHz typical | Smaller magnetics and quieter operation under stop–go |

| Isı emici hacmi | −30% to −50% | Başlangıç Noktası | Smaller, lighter controllers improve payload and serviceability |

| Overvoltage/ringing | Low with low-L busbar, active clamp | Higher risk with stray inductance | Better tolerance to grid surges and cable parasitics |

| Vida útil del ciclo de potencia | Extended with robust sinter and substrates | Moderate; solder fatigue | Fewer failures under frequent start–stop and hills |

| EMC behavior | Improved with optimized gate/driver | Challenging at higher loads | Easier compliance with IEC/ISO EMC for tenders |

By aligning with IEC 60747, ISO 7637, and IEC 61800-3 design targets, Sicarbtech modules make compliance more achievable without excessive filtering. The practical payoff is smaller enclosures, more reliable hill-climbing torque, and extended service intervals—especially valuable for fleets dependent on daily revenue.

Real-World Applications and Success Stories in Pakistan’s Mobility and Industry

In Karachi’s coastal humidity and dust-laden corridors, a passenger three-wheeler fleet transitioned to Sicarbtech 650 V full-bridge SiC modules with double-sided cooling. During the hottest summer months, the fleet recorded a 7% range uplift and a marked reduction in high-temperature current limiting events. Maintenance logs showed fewer inverter-related faults, and operators extended filter cleaning intervals by recalibrating cooling flows based on module thermal telemetry.

In Lahore’s dense delivery network, light-duty trucks refitted with 1200 V SiC three-phase bridge legs paired with Sicarbtech’s high-frequency magnetics kit reduced inverter mass by nearly 2 kg and enabled a downsized radiator. Field data indicated energy savings of 6% on hilly routes, while average maintenance intervals lengthened due to reduced thermal stress. The integrator cited faster time-to-market by reusing Sicarbtech’s controller algorithms and localized packaging guidance.

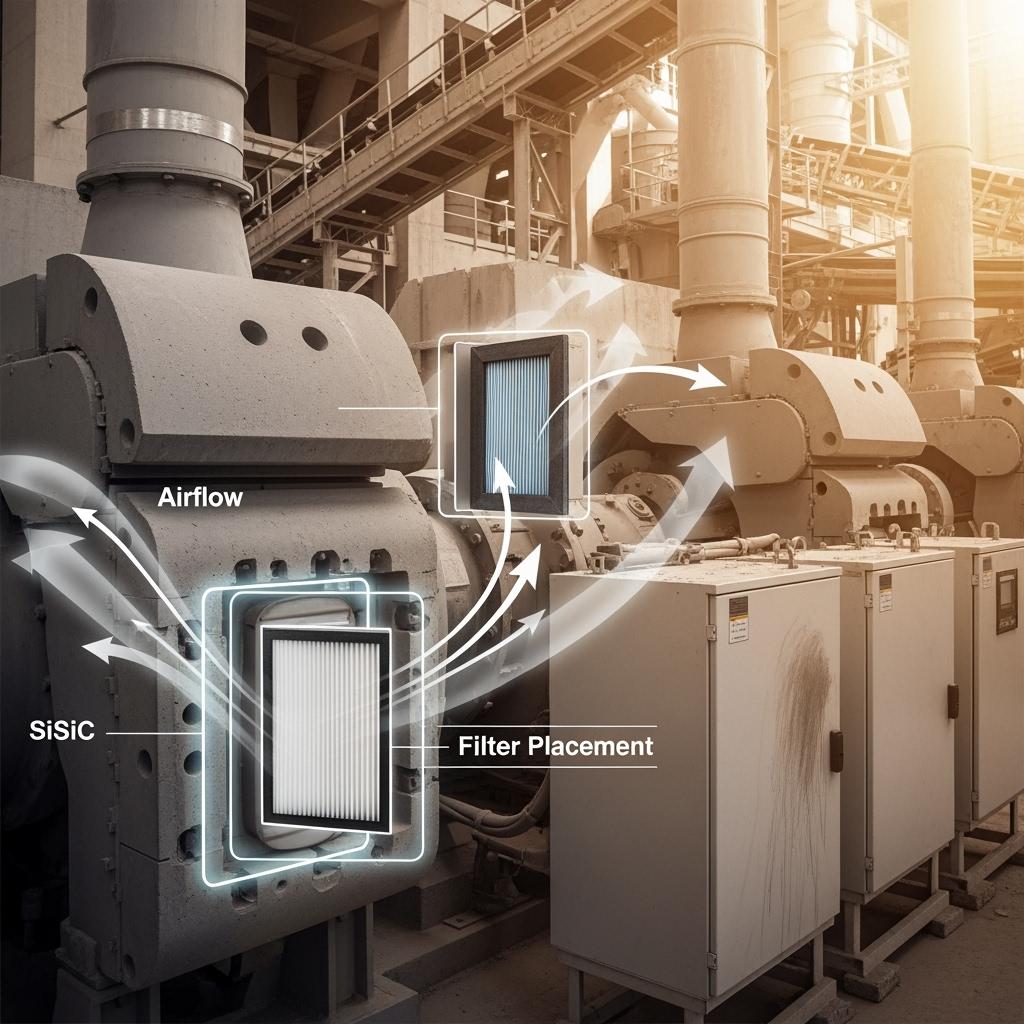

Within a cement plant outside Faisalabad, abrasive dust and thermal cycling had plagued conventional drive modules. Sicarbtech deployed SiSiC-based protective fixtures, corrosion-resistant coatings for module encapsulation, and predictive monitoring that tracked junction temperature and on-resistance drift. The result was fewer unscheduled stoppages over six months, validated by power cycling logs and a drop in emergency callouts. As one maintenance supervisor put it, “The combination of materials and electronics solved two headaches at once—dust ingress and thermal fatigue.”

Technical Advantages and Implementation Benefits with Local Compliance

Sicarbtech’s devices offer low on-resistance and minimized switching losses, allowing higher switching frequencies that shrink inductors and chokes without compromising reliability. Double-sided cooling and high-thermal-conductivity ceramic substrates spread heat effectively, particularly useful in cramped enclosures common in two- and three-wheelers. Gate drivers with soft turn-off, short-circuit withstand of 4–8 μs, and EMI-aware dead-time control mitigate overvoltage spikes and common-mode currents, easing IEC-based EMC compliance in procurement tests.

From a compliance standpoint, inverter designs guided by Sicarbtech align to IEC 60747 (semiconductor devices), ISO 16750 (environmental conditions), and ISO 7637 immunity considerations, and they can be integrated into development processes referencing ISO 26262 functional safety goals for traction systems. For industrial drives, design documentation maps to IEC 61800-3 EMC and IEC 60068 environmental testing. Local test plans can be executed in partnership with certified labs in Karachi and Lahore to support tender submissions and financing packages that increasingly request third-party validation.

“High junction temperature capability isn’t just a spec; it’s the margin that keeps torque available during the last kilometer of a congested climb,” notes Engr. S. Khan, an EV systems advisor working with regional fleets. [Source: EV Systems Roundtable, 2024] In practice, this margin means fewer thermal derates on steep routes and better customer satisfaction during peak hours.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Edge

Sicarbtech’s competitive advantage is more than superior devices—it is an ecosystem approach that transfers capability into Pakistan. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech maintains advanced R&D for R-SiC, SSiC, RBSiC, and SiSiC grades, enabling tailored mechanical, thermal, and electrical properties. Proprietary manufacturing processes—vacuum brazing, pressure sintering, and low-inductance busbar architectures—are codified into complete technology transfer packages.

These packages include detailed process know-how (die attach parameters, sinter profiles, lamination and metallization recipes), equipment specifications and vendor lists, and hands-on training programs covering packaging, screening (power cycling, HTRB/HTGB), and failure analysis. Factory establishment services run from feasibility studies and facility layout to line commissioning and PPAP-like process validation, ensuring local teams achieve repeatability and yield targets. Quality control is anchored to ISO 9001 and IATF 16949 principles, with certification support to meet international buyer expectations. Ongoing technical support includes quarterly process audits, yield improvement sprints, and co-development of next-generation modules.

This turnkey transfer is already proven with 19+ enterprises, where Sicarbtech’s application engineering support and rapid iteration cycles have shortened time-to-market. For Pakistani partners, it means packaging and maintenance can be localized, spare modules can be screened domestically, and uprated designs for hotter regions can be deployed swiftly without waiting for long import lead times. The result is a structurally lower TCO and a stronger domestic supply base—advantages that imported black-box modules cannot easily match.

Detailed Device and System-Level Comparison for Pakistan’s EV Platforms

Traction Inverter Device and Packaging Characteristics for Local Use

| Şartname | Sicarbtech SiC Modules (650 V / 1200 V) | Conventional Silicon Modules | Pakistan'daki Pratik Etkisi |

|---|---|---|---|

| Rated current options | 100–600 A continuous | 100–400 A typical | Covers two-/three-wheelers and light trucks without redesign |

| Short-circuit withstand | 4–8 μs with soft turn-off | 3–5 μs typical | More robust against motor-side faults and cabling issues |

| Packaging inductance | Low-L busbar architecture | Higher loop inductance | Lower overvoltage in grid spikes and abrupt load changes |

| Cooling | Double-sided liquid/air options | Single-sided typical | Smaller heatsinks, better serviceability in dusty depots |

| Koruma | Active clamp + desat + UVLO | Desat, UVLO basic | Improved surge and EMI resilience on weak feeders |

| İzleme | Tj estimation, Rds(on) drift | Minimum | Predictive maintenance and fewer roadside failures |

System Integration and Lifecycle Metrics in Urban Fleets

| Metric | With Sicarbtech SiC Stack | With Conventional Silicon Stack | Notes for Local Operations |

|---|---|---|---|

| Integration time (prototype to pilot) | 8–12 weeks with kits | 16–24 weeks | Pre-validated controller and magnetics shorten cycles |

| Heatsink mass | −30% to −50% | Başlangıç Noktası | Less weight improves payload and ride quality |

| Annual downtime | −30% or more | Başlangıç Noktası | Reliability screening and local spares reduce outages |

| Energy consumption (urban routes) | −5% to −8% | Başlangıç Noktası | Translates to lower daily energy cost in PKR |

| Bakım aralığı | Extended by 20–30% | Başlangıç Noktası | Dust-proof coatings and thermal margin help |

Technical Specifications and Local Standards Alignment

Pakistan’s EV architectures commonly run 48–96 V for two- and three-wheelers and higher-voltage platforms for light trucks. Sicarbtech supports 650 V and 1200 V device classes, operating efficiently at 10–40 kHz. Gate driver design includes dead-time optimization to prevent shoot-through under EMI, while low-inductance packaging reduces ringing in long cable runs typical in retrofits. These designs are built with compliance in mind: target EMC behavior consistent with IEC 61800-3 environments, immunity per ISO 7637 for vehicle electrical disturbances, and device-level conformance to IEC 60747.

For procurement and financing, Sicarbtech provides documentation sets mapping to local tender requirements, including environmental testing aligned with IEC 60068, corrosion testing for coastal cities (salt spray/damp heat), and reliability records from power cycling and HTOL. Where needed, Sicarbtech coordinates with local labs for third-party validation.

Future Market Opportunities and 2025+ Trends in Pakistan

Looking beyond 2025, the confluence of urbanization, last-mile logistics, and government initiatives for localized manufacturing will deepen the market for traction inverters and industrial electrification. Fast-charging and battery swapping are expanding, favoring higher power density and thermal resilience—natural strengths of SiC. Additionally, grid modernization efforts and distributed solar adoption will impose more dynamic load and generation profiles, making robust, high-bandwidth control electronics increasingly valuable. SiC’s ability to operate efficiently at higher switching frequencies aligns with advanced control strategies such as space-vector modulation and refined field-weakening, enabling both low-speed torque and high-speed cruising performance.

From a business standpoint, integrated offerings that include devices, packaging, process transfer, validation, and operations data will set the competitive bar. Sicarbtech’s turnkey approach addresses these needs, raising customer stickiness while reducing technical risk. As fleet operators and industrial plants seek green financing and government project eligibility, high-efficiency SiC platforms can improve scoring for sustainability metrics and lifecycle CO2 reductions. The likely result is a market that rewards not the cheapest initial bid but the provider who guarantees uptime, efficiency, and local capability—areas where Sicarbtech already leads.

Comparative Overview of Complete Solution Stacks for Pakistani OEMs

End-to-End Solution Stack Comparison for Localization

| Component Layer | Sicarbtech Integrated Solution | Typical Fragmented Approach | Outcome for Pakistani OEMs |

|---|---|---|---|

| Devices and modules | Custom 650/1200 V SiC modules, low-L packaging | Mixed suppliers, standard packages | Better fit to duty cycles, fewer redesigns |

| Gate drivers and control | Integrated driver boards + controller core with FOC/field-weakening | Separate vendors and integration effort | Faster validation, fewer EMI surprises |

| Termal ve mekanik | Double-sided cooling, TIMs, enclosure guidance | Ad-hoc heatsink selection | Lighter systems, standardized service |

| Magnetics and busbars | High-frequency kits and low-inductance interconnects | In-house trial-and-error | Shorter time-to-market |

| Reliability and screening | Power cycling, HTRB/HTGB, damp heat, salt spray | Limited test scope | Fewer latent defects in field |

| Teknoloji transferi | Process recipes, equipment specs, training, audits | None or partial | Real local capacity and resilience |

| Support and optimization | Ongoing process/yield improvements, algorithm co-tuning | Reactive support | Sustained performance gains |

Sıkça Sorulan Sorular

What voltage and current ratings does Sicarbtech recommend for Pakistan’s two- and three-wheeler platforms?

For common 48–96 V architectures, Sicarbtech recommends 650 V modules with continuous current options from 100 A to 300 A for two-wheelers and up to 400–600 A for heavier three-wheelers or cargo variants. This provides margin for grid disturbances and regenerative peaks while keeping switching losses low.

How does SiC help with Pakistan’s high temperatures and dust exposure?

SiC devices sustain operation up to 175 °C junction temperature, offering thermal headroom under extreme ambient conditions. Sicarbtech pairs this with double-sided cooling, dust-proof and corrosion-resistant encapsulation, and coatings validated by damp-heat and salt-spray tests—reducing derating and extending maintenance intervals.

Can Sicarbtech support localized manufacturing and maintenance in Pakistan?

Yes. Sicarbtech supplies technology transfer packages, including process know-how, equipment specifications, and staff training. Local partners can package, screen, and service modules domestically, sharply cutting turnaround times and building resilience against import delays.

What standards and certifications do Sicarbtech solutions align with?

Designs align with IEC 60747 for device-level characteristics, ISO 7637 for automotive electrical disturbances, and IEC 61800-3 for industrial EMC. Quality systems follow ISO 9001 and IATF 16949 principles. Sicarbtech can support third-party testing with local labs to meet tender and financing requirements.

How do SiC inverters affect total cost of ownership for fleets?

Higher efficiency allows for smaller battery capacity for the same range, while reduced thermal load enables smaller cooling systems. Combined with fewer failures and shorter maintenance, fleets typically see TCO reductions via lower energy costs in PKR, minimized downtime, and improved vehicle utilization.

Are Sicarbtech gate drivers compatible with existing motors and harnesses?

Yes. Gate drivers include soft turn-off, desaturation detection, and active clamping, and they are tuned to mitigate cable inductance effects. Sicarbtech’s application engineers provide layout and harness recommendations to control parasitics and common-mode noise.

What is the typical integration timeline to pilot units?

With Sicarbtech’s pre-validated controller cores, magnetics kits, and module assemblies, OEMs frequently move from prototype to pilot in 8–12 weeks, depending on enclosure design and EMC iterations.

How does predictive monitoring work in Sicarbtech modules?

Module-level health monitoring estimates junction temperature and tracks on-resistance drift as a proxy for aging. When combined with power cycling history, it supports predictive maintenance, helping fleets schedule service before failures occur.

Can Sicarbtech solutions handle fast-charging and battery swapping growth?

They are designed for high bandwidth and robust surge tolerance, with active clamp strategies to handle DC bus transients during fast-charging events. Control firmware options support smooth transitions and protect against inrush and EMI disturbances.

What support does Sicarbtech offer after mass production begins?

Sicarbtech provides ongoing process optimization, quarterly audits, algorithm refinements, and rapid failure analysis. The goal is continuous improvement in yield, reliability, and field performance, ensuring long-term competitiveness.

Operasyonlarınız için Doğru Seçimi Yapmak

Selecting the right inverter and materials partner is a strategic decision that directly affects uptime, profitability, and customer experience. Sicarbtech’s integrated portfolio—devices, packaging, drivers, controllers, magnetics, thermal solutions, and on-the-ground technology transfer—delivers measurable improvements: 5–8% energy savings in urban routes, 30–50% smaller heatsinks, and over 30% reduction in annual downtime. For Pakistani OEMs and integrators building their next platforms, this combination of proven hardware and localized capability is the shortest path to reliable, efficient, and scalable electric mobility and industrial drives.

Uzman Danışmanlığı ve Özel Çözümler Alın

Discuss your application with Sicarbtech’s engineering team to define the right 650 V or 1200 V modules, driver configurations, and thermal stack-ups for Pakistan’s climates and routes. Explore technology transfer to establish in-country packaging, screening, and after-sales workflows that cut lead times and strengthen your supply chain.

Contact Sicarbtech – Silicon Carbide Solutions Expert

E-posta: [email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“High-efficiency platforms win not only on performance but on financing and policy. SiC is the lever; localized capability is the multiplier.” — Sicarbtech Applications Team

Makale Meta Verileri

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: reflects 2025 market outlook, Pakistan-specific compliance notes, and current Sicarbtech portfolio and services.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.