Orta Gerilim Dönüştürücüler, Çekiş ve Şebekeye Bağlı Sistemler için Silisyum Karbür Yüksek Gerilim Güç Modülleri

Paylaş

Ürüne Genel Bakış ve 2025 Pazar İlgisi

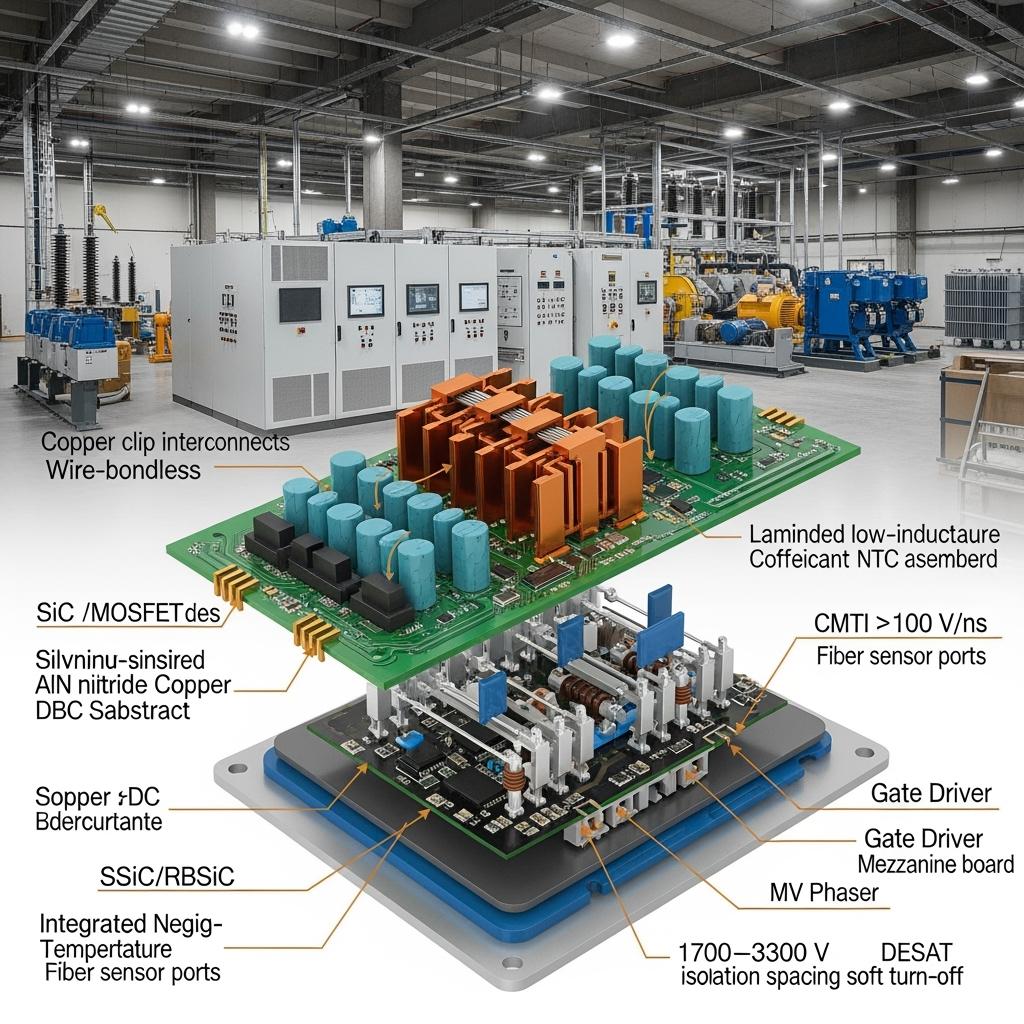

Silisyum karbür (SiC) yüksek gerilim güç modülleri, orta gerilim (OG) sürücüler, çekiş invertörleri ve şebekeye bağlı konvertörler için kilovolt sınıfı DC bağlantı gerilimlerinde kompakt, verimli ve sağlam dönüşüm sağlar. AlN/Si3N4 DBC, gümüş sinterleme kalıp bağlantısı ve düşük endüktanslı bara çubukları ile gelişmiş paketlerde 1200–3300 V SiC MOSFET'ler ve diyotlardan yararlanan bu modüller, geleneksel IGBT'lere kıyasla yüksek anahtarlama frekansı, daha düşük kayıplar ve yüksek sıcaklıkta çalışma sağlar.

Pakistan'ın tekstil, çimento ve çelik endüstrileri ve ülkenin gelişen demiryolu/transit ve yenilenebilir şebeke entegrasyonu için SiC HV modülleri kritik ihtiyaçları karşılar:

- Daha yüksek verimlilik, 7/24 endüstriyel hatlarda ve veri açısından kritik tesislerde güç ve soğutma maliyetlerini düşürür.

- Kompakt OG konvertörleri, alana bağlı MCC odalarını ve konteynerize trafo merkezlerini güçlendirmeye yardımcı olur.

- Hızlı, yüksek doğruluklu kontrol, güç kalitesini iyileştirerek NTDC Şebeke Kodu hedeflerini destekler.

- Yüksek ortam sıcaklıkları (40–45°C) ve tozlu koşullar, güvenilirlik için üretilmiş paketleme ve termal sistemler gerektirir.

Sicarb Tech, çok seviyeli topolojiler (NPC/TNPC/ANPC) ve 2 seviyeli çekiş invertörleri için entegre kapı sürücü seçenekleri ve teşhis amaçlı algılama yolları ile yapılandırılabilir 1200 V, 1700 V, 2400 V ve 3300 V modül aileleri sunmaktadır.

Teknik Özellikler ve Gelişmiş Özellikler

Temsili modül yetenekleri (uygulamaya göre özelleştirilebilir):

- Gerilim ve akım sınıfları

- 1200 V, 1700 V, 2400 V, 3300 V SiC MOSFET/diyot modülleri

- Modül başına sürekli akım: 200–1200 A (termal ve soğutmaya bağlı)

- Koruma ile koordine edilen dalgalanma ve kısa devre sağlamlığı

- Topolojiler ve anahtarlama

- Çekiş/yardımcı program için 2 seviye; OG sürücüler ve STATCOM/PV için 3 seviye NPC/TNPC/ANPC

- Anahtarlama frekansı: Tipik olarak 5–50 kHz (daha düşük gerilim yığınlarında daha yüksek olabilir)

- Ayarlanabilir kapı direnci ve entegre Miller kelepçesi aracılığıyla dv/dt kontrolü

- Kayıplar ve termal performans

- İletim kaybı: Yüksek RDS(on) akım yoğunluğu için optimize edilmiş düşük SiC kalıpları

- Anahtarlama kaybı: IGBT'lerden önemli ölçüde daha düşük; yumuşak toparlanma diyotları

- Termal: AlN/Si3N4 DBC, gümüş sinterleme kalıp bağlantısı, SSiC taban plakaları; sıvı veya yüksek performanslı hava soğutma

- Hedef RθJC anahtar konumu başına: 0,05–0,15 K/W (tasarıma bağlı)

- İzolasyon ve güvenlik

- 3,3 kV sınıfı çalışma için IEC 60664'e göre yüzey kaçağı/boşluk

- Uzun kablolu OG uygulamaları için modül seviyesinde kısmi deşarj taraması

- Algılama ve koruma

- Gömülü NTC/RTD; gelişmiş termal haritalama için isteğe bağlı fiber Bragg sensörleri

- DESAT kısa devre tespiti (<2 µs), yumuşak kapanma, UVLO, OCP/OVP/OTP

- Sicarb kapı sürücü paketi ile kullanıldığında izolasyon izleme ve sızıntı eğilimi

- Arayüzler ve uygunluk

- İzole kapı sürücüleri (CMTI ≥100 V/ns) ve dijital kontrol platformları ile uyumlu

- Standart uyumu: IEC 61800 (OG sürücüler), IEC 62477-1 (güç konvertörleri), IEC 62109 (PV), IEC 61000 EMC; PEC uygulamaları ve NTDC Şebeke Kodu'na hazır

Sicarb Tech gelişmiş özellikleri:

- Güç döngüsü dayanıklılığı için kablo bağımsız bakır klips bağlantıları

- Ultra düşük endüktans için lamine bara çubukları ve Kelvin kaynak bağlantıları

- Entegre sürücüler ve arıza telemetrisi ile isteğe bağlı akıllı modül varyantı

OG ve Şebekeye Bağlı Sistemler için Verimlilik, Yoğunluk ve Güvenilirlik Kazanımları

| Pakistan'ın endüstriyel ve şebeke ihtiyaçları için yüksek verimli OG dönüşümü | SiC yüksek gerilim güç modülleri (Sicarb Tech) | Silisyum IGBT OG modülleri |

|---|---|---|

| Nominal güçte ağırlıklı verimlilik | Çok seviyelide 'den fazla elde edilebilir | Tipik olarak –96 |

| Anahtarlama frekansı yeteneği | Daha yüksek (5–50 kHz) daha küçük manyetikler sağlar | Daha düşük (1–5 kHz) |

| Termal boşluk ve ortam dayanıklılığı | Sağlam paketleme ile 175°C Tj'ye kadar çalıştırılabilir | Daha düşük Tj kapasitesi, ısıda düşürme |

| Güç yoğunluğu (konvertör seviyesi) | Birçok tasarımda 10 kW/L'den fazla mümkündür | Aynı güç için daha büyük |

| Dinamik tepki ve kontrol | Yüksek bant genişliği, daha düşük THD | Daha yavaş tepki, daha yüksek dalgalanma |

Temel Avantajlar ve Kanıtlanmış Faydalar

- Verimlilik ve ayak izinde kademeli değişiklik: %5–8 sistem verimliliği iyileşmesi; silisyum temel hatlarına kıyasla –35'e varan hacim azalması, sermaye harcamalarını ve işletme giderlerini azaltır.

- OG'ye hazır güvenilirlik: Gümüş sinterleme bağlantısı, AlN/Si3N4 DBC ve SSiC taban plakaları, çimento ve çelik fabrikalarındaki sert termal döngülerden ve titreşimden kurtulur.

- Şebeke uyumlu dalga biçimleri: Daha yüksek anahtarlama frekansı ve çok seviyeli kontrol, THD'yi azaltır, filtre gereksinimlerini ve transformatör gerilimini azaltır.

- Daha hızlı dinamik performans: Çekiş ve endüstriyel sürücüler için hızlı tork ve güç kontrolü, proses kararlılığını artırır.

Uzman sözü:

"1,7–3,3 kV'deki SiC modülleri, OG sürücü ve şebeke uygulamalarını dönüştüren, benzeri görülmemiş verimlilik ve kontrol bant genişliğine sahip çok seviyeli konvertörler sağlar." — IEEE Power Electronics Magazine, Geniş Bant Aralıklı Cihazlara Sahip Orta Gerilim Konvertörleri, 2024

Gerçek Dünya Uygulamaları ve Ölçülebilir Başarı Hikayeleri

- Çimento fabrikası OG fan sürücüsü (Pencap):

- Sıvı soğutmalı 1700 V SiC modülleri kullanan 3 seviyeli ANPC sürücü fazı.

- Sonuçlar: IGBT güçlendirmesine kıyasla ~%6,8 enerji azaltımı; motor terminallerinde iyileştirilmiş THD; pozitif basınçlı kabin, toz girişini azaltır; daha az EMI alarmı.

- Çelik yardımcı OG pompa sürücüsü (Karaçi):

- Endüstriyel kullanım için uyarlanmış 2 seviyeli SiC çekiş sınıfı modülleri.

- Performans: %4–6 verimlilik artışı; kabin ayak izi azaltıldı; daha düşük termal gerilim nedeniyle bakım aralıkları uzatıldı.

- Şebekeye bağlı PV invertör (Sindh sanayi bölgesi):

- 1700 V SiC modülleri ile 1500 Vdc PV aşaması; LCL filtresi küçültüldü.

- Sonuç: CEC ağırlıklı verimlilik ,0; reaktif güç desteği iyileştirildi; transformatör ısınma olayları azaldı.

【Görüntü istemi: ayrıntılı teknik açıklama】 Bölünmüş sahne: 1) dv/dt açıklamaları ile 1700 V SiC modülleri kullanan 3 seviyeli ANPC faz bacağı; 2) SSiC taban plakası altında akış kanalları olan sıvı soğutmalı soğuk plaka; 3) Daha küçük LCL filtresi ve verimlilik eğrisini gösteren şebekeye bağlı kabin. RDS(on), anahtarlama frekansı ve PD taraması için etiketler ekleyin. Foto-gerçekçi, 4K.

Seçim ve Bakımla İlgili Hususlar

- Gerilim ve topoloji seçimi

- 1000–1500 Vdc bağlantılar için 1700 V; daha yüksek DC otobüsleri veya basamaklı H köprü OG sürücüleri için 2400/3300 V.

- Cihaz gerilimini ve filtre boyutlarını azaltmak için OG sürücüler için NPC/ANPC'yi seçin; uygun olduğunda çekiş basitliği için 2 seviye.

- Termal ve soğutma

- En kötü durum 45°C ortamı modelleyin; kabin başına ~250 kW'ın üzerinde veya yüksek irtifa bölgelerinde sıvı soğutma seçin.

- Taban plakası düzlüğünü ve TIM uygulamasını doğrulayın; korozyonu ve kirlenmeyi önlemek için soğutucu kalitesini izleyin.

- EMI ve izolasyon

- IEC 60664'e göre yüzey kaçağı/boşluğu koruyun; uzun motor kabloları için dv/dt filtreleri uygulayın.

- İzolasyon sağlamlığını sağlamak için modül ve montaj seviyesinde PD testi.

- Kapı sürücüsü ve koruma

- Yüksek CMTI izolatörleri, modül SOA ile koordine edilmiş DESAT eşikleri, güvenilir kapanma için negatif kapı önyargısı.

- Kısa devreler sırasında aşırı gerilimi sınırlamak için arıza kaydı ve yumuşak kapanma.

- Servis uygulamaları

- Termal ve anahtarlama gerilim günlüklerini kullanarak koşula dayalı bakım.

- Bara çubuk bağlantıları için tork doğrulaması; planlı soğutucu/filtre kontrolleri.

Sektör Başarı Faktörleri ve Müşteri Görüşleri

- Başarı faktörleri:

- Ön uç şebeke çalışması (harmonikler, titreme) ve transformatör değerlendirmesi

- Termal ve hava akışı tasarımı, en yoğun yaz pilotlarında doğrulandı

- OG güvenliği, PD farkındalığı ve dv/dt yönetimi konusunda eğitim

- Hızlı değiştirme için yedek modül ve sürücü stratejisi

- Referans (Elektrik Süpervizörü, büyük bir çimento üreticisi):

- "SiC OG modülleri, ihtiyacımız olan verimlilik artışını sağladı. Daha küçük filtre ve soğutucu kabinler, bakımı önemli ölçüde basitleştirdi."

Gelecekteki Yenilikler ve Pazar Eğilimleri

- 2025–2027 görünümü:

- Daha yüksek akım yoğunluğu için çift taraflı soğutmalı ve kablo bağımsız yığınlara sahip 3300 V+ SiC

- Ömür tahmini ve uyarlanabilir güç düşürme için dijital ikizler ve gömülü sensörler

- 200 mm SiC yonga levha kullanımı maliyetleri düşürüyor; Güney Asya'da bölgesel montaj ortaklıkları

- Kararlılık ve atalet emülasyonu için SiC ile STATCOM ve şebeke oluşturan invertör uygulamalarının genişletilmesi

Sektör perspektifi:

"Orta gerilim dönüşümü, daha yüksek verimlilik ve daha küçük pasif bileşenlerle kontrol edilebilirlik elde etmek için hızla geniş bant aralıklı yarı iletkenlere yöneliyor." — IEA Teknoloji Perspektifleri 2024, Güç Elektroniği bölümü

Sık Sorulan Sorular ve Uzman Yanıtları

- SiC MV modülleri, IGBT'lerin doğrudan yerine geçebilir mi?

- Doğrudan değil. Kontrol stratejisi, dv/dt ve kapı sürüşü uyarlanmalıdır. Ancak, mekanik ayak izleri uyumlu hale getirilebilir, bu da sonradan takmayı kolaylaştırır.

- 1 MW'ın üzerinde hangi soğutma yöntemi önerilir?

- Korozyon kontrollü döngülerle sıvı soğutma önerilir; akış hızlarını ve plaka ΔP'sini pompanın kapasitesine karşı doğrulayın.

- Eski motorlarla dv/dt'yi nasıl yönetirsiniz?

- RG ve Miller kelepçesini ayarlayın; uzun kablo mesafeleri için dv/dt veya sinüs filtreleri ekleyin; IEC 60034-17/-25'e göre yalıtım koordinasyonunu sağlayın.

- MV sürücülerde hangi verimlilikleri bekleyebiliriz?

- Uygulamaya bağlıdır, ancak SiC ile çok seviyeli topolojilerde >'lik dönüştürücü aşaması verimliliği elde edilebilir.

- Yalıtım güvenilirliği nasıl sağlanır?

- İlgili gerilimlerde PD taraması, takviyeli yüzey atlaması/boşluk ile düzen ve kirlenme yollarını önlemek için kaliteli TIM'ler/contalar.

Bu Çözüm Operasyonlarınız İçin Neden İşe Yarıyor?

SiC yüksek gerilim güç modülleri, kompakt, verimli MV dönüştürücüler, çekiş sürücüleri ve Pakistan'ın ısı, toz ve şebeke değişkenliğine göre uyarlanmış şebekeye bağlı sistemler sunmak için düşük anahtarlama/iletkenlik kayıplarını sağlam ambalajlarla birleştirir. Sonuç, ölçülebilir enerji tasarrufu, daha küçük filtreler ve kabinler, iyileştirilmiş güç kalitesi ve daha uzun bakım aralıklarıdır; çimento fırınları, çelik yardımcıları, tekstil hatları ve yenilenebilir bağlantılar için kritik avantajlar.

Özel Çözümler için Uzmanlarla Bağlantı Kurun

Sicarb Tech ile MV ve şebeke projelerinizi geliştirin:

- Çin Bilimler Akademisi'nin desteğiyle 10+ yıllık SiC üretim uzmanlığı

- Gelişmiş modül ambalajlaması ile R-SiC, SSiC, RBSiC ve SiSiC malzemelerinde özel ürün geliştirme

- Yerel değer yaratımı için teknoloji transferi ve fabrika kurulum hizmetleri

- Kapı sürücüleri, bara ve uyumluluk desteği dahil olmak üzere malzemelerden bitmiş MV modüllerine kadar anahtar teslimi teslimat

- 19+ işletmeyle kanıtlanmış sonuçlar; hızlı prototip oluşturma, PD testi ve pilot uygulamalar

Tesisiniz veya şebekeye bağlı projeniz için ücretsiz bir MV dönüştürücü fizibilite çalışması ve YG analizi alın.

- E-posta: [email protected]

- Telefon/WhatsApp: +86 133 6536 0038

Kapanma pencereleri ve devreye alma programları için teslim sürelerini güvence altına almak üzere 2025 4. çeyrek mühendislik ve üretim slotlarını ayırtın.

Makale Meta Verileri

- Son güncelleme: 2025-09-11

- Bir sonraki planlanan inceleme: 2025-12-15

- Yazar: Sicarb Tech Uygulama Mühendisliği Ekibi

- Contact: [email protected] | +86 133 6536 0038

- Standartlara odaklanma: IEC 61800 (MV), IEC 62477-1, IEC 62109, IEC 61000, IEC 60664; PEC uygulamaları ve NTDC Şebeke Kodu kalite kriterleri ile uyumlu

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.