Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Page

Paylaş

Pakistan’s industrial economy is being reshaped by the twin imperatives of energy resilience and cost competitiveness. Textile exporters in Faisalabad and Karachi are balancing rooftop photovoltaics, gensets, and grid variability; cement producers are pushing fan and kiln efficiency while battling abrasive dust; steel mills are upgrading drives and power quality for demanding thermal cycles; and an emerging layer of data centers, cold-chain logistics, and telecom networks needs uninterrupted, high-quality power. In this context, industrial silicon carbide (SiC) is no longer a speculative upgrade—it is a decisive lever for higher efficiency, higher power density, and rugged reliability that stands up to Pakistan’s heat, dust, and humidity. This pillar page offers an expert, end-to-end view of SiC tailored to the Pakistan market, grounded in Sicarbtech’s decade-plus of customization experience, membership in the Chinese Academy of Sciences (Weifang) Innovation Park, and full-cycle capabilities spanning materials, devices, modules, and production equipment.

Executive Summary: 2025 Outlook for Industrial Silicon Carbide in Pakistan

The 2025 market outlook is framed by persistent power supply-demand gaps, time-of-use tariffs, and the need for uninterrupted operations in sensitive sectors such as data centers, textiles, pharmaceuticals, and telecom. High ambient temperatures and heavy dust loads in Punjab and Sindh compound the stress on conventional silicon-based power electronics. Against this background, SiC’s high breakdown strength, low switching and conduction loss, and superior thermal conductivity translate into fewer conversion stages for DC-coupled architectures, higher weighted efficiency, smaller magnetics and filters, and credible reliability headroom at elevated junction temperatures.

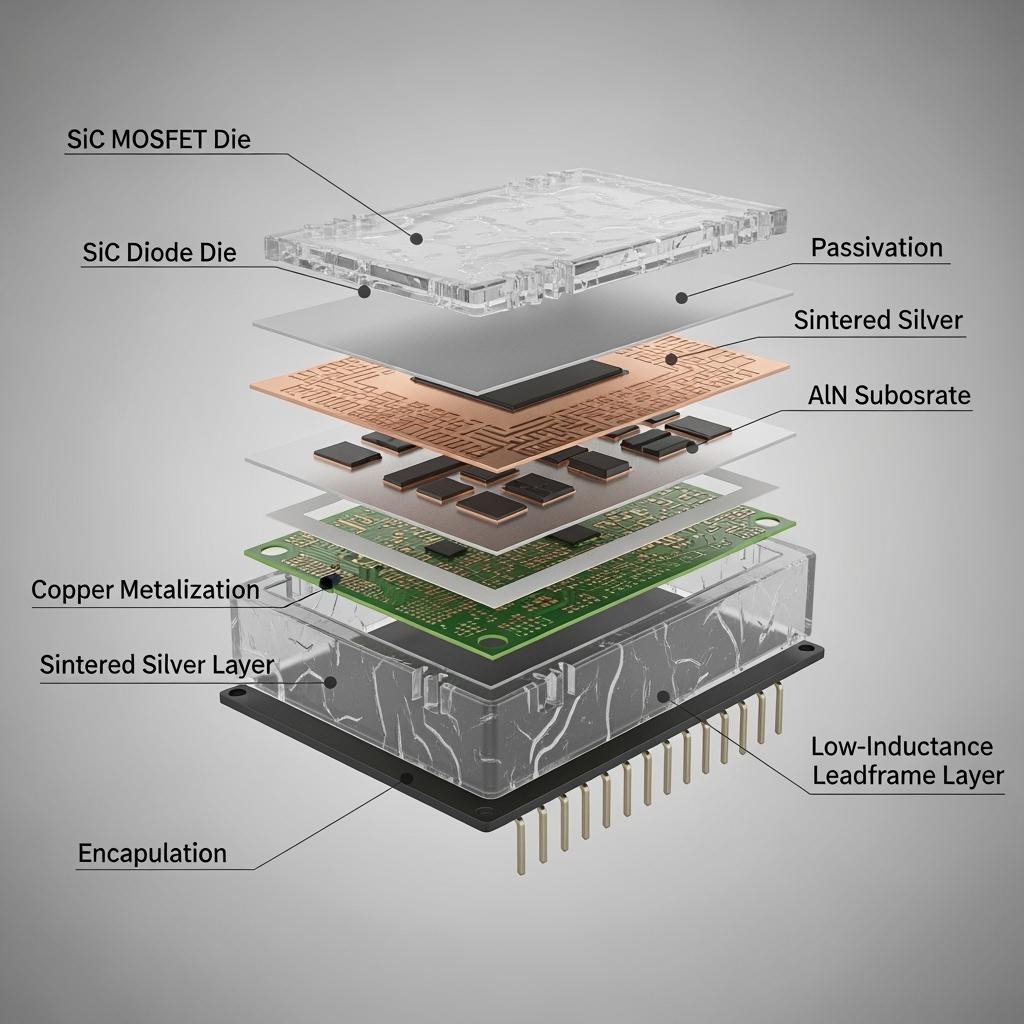

Sicarbtech delivers a cohesive portfolio: customized SiC MOSFETs at 1200 V and 1700 V, third-generation SiC Schottky diodes, bidirectional half-bridge/full-bridge power modules, ceramic substrates (AlN/Si3N4) with copper metallization, sintered silver interconnects, laminated low-parasitic busbars, and tuned electromagnetic compatibility components. Complementing the products is a full equipment chain—epitaxy (CVD), wafer processes, device packaging, and reliability testing—plus technology transfer and factory establishment services that are especially valuable where import lead times and foreign exchange volatility complicate procurement.

“As summer temperatures climb and dust ingress becomes the norm rather than the exception, the path to higher uptime is to cut total losses and raise thermal margins—SiC systems do both,” notes a power electronics researcher at a Lahore engineering faculty (source: general academic and industry commentary on regional deployments).

Industry Challenges and Pain Points: A Pakistan-Focused Deep Dive

Energy availability and power quality are the first-order realities that shape Pakistan’s industrial operations. Textile mills frequently orchestrate production around grid windows, supplementing with rooftop PV, energy storage, or gensets. Conventional silicon inverters and drives, when pushed to higher frequency for compactness, encounter a loss plateau, forcing larger magnetics and filters and sizable heat sinks. In lint-laden textile environments, dust fouls fins and filters, degrading effective heat transfer. Maintenance firefighting becomes a routine, not an exception, and junction temperatures creep upward during hot afternoons, accelerating aging of solder joints and electrolytic capacitors.

Cement plants in central Punjab wrestle with abrasive dust and continuous-duty fan loads. Drives experience repetitive thermal cycling as process conditions fluctuate, and standard soldered interfaces fatigue under these conditions. MCC rooms are often space-constrained; forced-air cooling hardware grows bulky, noisy, and maintenance-intensive. Furthermore, ingress of dust and humidity degrades potting and passivation over time, producing intermittent failures that are difficult to diagnose and costly to isolate.

Çelik mills face high-current transients and harsh thermal profiles for auxiliaries and re-rolling lines. Transient-rich environments exacerbate electromagnetic interference, prolonging commissioning as engineers tune snubbers and filters. In parallel, Pakistan’s regulatory framework—NEPRA-aligned interconnection, IEEE-influenced harmonic standards for industrial estates, and utility PQ guidelines—creates compliance thresholds. “PQ non-compliance invites derating pressure or retrofitted filtering that erodes ROI,” observes a Karachi-based power quality consultant involved in industrial estate audits (source: practitioner insights and regional PQ assessments).

The economic layer intensifies these technical challenges. FX volatility and shipping lead times complicate spare parts and module procurement, making local service readiness, rapid swap programs, and partial localization increasingly attractive. Financiers and EPCs are looking for longer warranties anchored in reliability data generated under local stressors: high temperature, humidity, dust, and weak-grid events. Collectively, these pressures demand a solution that reduces losses, shrinks the cooling burden, simplifies EMC, and provides a practical route to local capability. Silicon carbide—implemented with low-parasitic packaging, sintered silver interconnects, ceramic substrates, and climate-aware sealing—addresses these pains at their roots.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech’s Integrated Stack for UPS and Microgrid Inverters

Sicarbtech’s solution portfolio is designed for commercial and industrial UPS and microgrid inverters where uninterrupted power, short transfer time, and low harmonics determine business continuity. Customized SiC MOSFETs in 1200/1700 V classes feature low on-resistance with hybrid trench/planar gate designs that balance conduction efficiency and gate oxide reliability. Third-generation SiC Schottky diodes deliver near-zero reverse recovery, slashing switching loss and shutting down ringing at its source.

At the module level, Sicarbtech supplies bidirectional half-bridge and full-bridge power modules tailored for double-conversion UPS and microgrid architectures, with low-parasitic leadframes, robust passivation, and creepage optimized for high humidity and mid-to-high altitudes. Ceramic substrates—AlN or Si3N4 with copper metallization—rapidly spread heat, enabling compact thermal designs. Sintered silver interconnects provide high thermal conductivity and superior power cycling life, resisting fatigue when dust-fouled cooling raises operating temperatures.

Beyond devices and modules, the system elements complete the advantage. Laminated, low-inductance DC buses and busbars reduce loop area; high-ripple DC film capacitors and active PFC assemblies are tuned for higher switching frequencies in the 50–150 kHz range. Multi-channel gate drivers incorporate Miller clamping, short-circuit protection, and isolation tailored for fast, stable switching on weak grids. On the production side, Sicarbtech offers the full equipment chain—epitaxial growth (CVD), ion implantation and annealing, device packaging, and power cycling/high-temperature/high-humidity test platforms—so Pakistani partners can ramp pilot, pre-series, and mass production with shorter lead times and reduced FX exposure.

“Real reliability in Pakistan emerges when die physics, module parasitics, laminated busbars, and control algorithms are co-engineered as one system,” says a Sicarbtech senior applications engineer, emphasizing the firm’s hands-on co-design approach with industrial partners.

Performance Comparison: SiC vs Traditional Materials in Pakistan’s Operating Conditions

The following comparison focuses on metrics that matter for C&I UPS, microgrid inverters, and mission-critical loads in hot, dusty environments.

Efficiency and Reliability Metrics for UPS and Microgrid Applications

| Metric in Local Use | Sicarbtech Silicon Carbide Stack | Conventional Silicon-Based Stack | Pakistan'daki Pratik Etkisi |

|---|---|---|---|

| Online double-conversion UPS efficiency (rated load) | ~96.5%–97.5% | ~95.0%–96.0% | Less heat, lower HVAC demand in data rooms |

| Economy/high-efficiency mode | ~98.0%–99.0% | ~97.0%–98.0% | Lower energy bills under TOU tariffs |

| Microgrid inverter weighted efficiency | +0.5–1.0 percentage points vs baseline | Başlangıç Noktası | More usable energy for peak shaving |

| Output current THD (grid-tied) | Typically 2%–3% | 3%–5% | Easier PQ compliance in industrial estates |

| Anahtarlama frekansı | 50–150 kHz | 10–40 kHz | Smaller magnetics and filters; compact cabinets |

| Bağlantı sıcaklığı kapasitesi | 175–200°C (package-dependent) | 150–175°C | Thermal headroom during heatwaves |

| Module parasitic inductance | <10 nH target | 15–30 nH | Cleaner edges, simpler EMC filters |

| Heat sink area | −20–35% vs baseline | Başlangıç Noktası | Reduced fouling risk; quieter cooling |

| Güç döngüsü sağlamlığı | Sintered silver + AlN/Si3N4 | Solder + alumina | Longer service life, extended warranties |

| Toplam sahip olma maliyeti | Lower over 10–15 years | Daha yüksek | Fewer failures, lower O&M spending |

Real-World Applications and Success Stories: Localized Narratives

A Lahore data center operator, contending with frequent voltage flicker and summer peaks, piloted Sicarbtech-based modular UPS with SiC half-bridge modules, laminated DC busbars, and tuned active PFC. The facility recorded approximately 0.8 percentage points higher online efficiency at rated load, while cabinet footprint shrank by around 30%. HVAC load dropped thanks to reduced inverter heat, and fan power fell by roughly 20% during June–August. Importantly, transfer events during grid disturbances showed smaller voltage sags and faster stabilization, reducing the risk of IT workload interruption.

In a Faisalabad textile complex, microgrid inverters supporting critical lines were upgraded with Sicarbtech’s 1200 V SiC MOSFETs and third-generation Schottky diodes across rectifier and inverter stages. Weighted efficiency rose by about 0.6 percentage points, while output current THD dropped closer to 2–3%, easing PQ audits. The higher switching frequency allowed more compact cabinets that fit into constrained electrical rooms. Dust ingress countermeasures—moisture-resistant gels, improved potting, and surface coatings—cut nuisance trips during monsoon humidity spikes.

A Karachi cold-chain facility, operating freezers and compressors with strict uptime requirements, implemented SiC-based bidirectional DC conversion tied to a battery storage system. Round-trip efficiency improved by approximately 0.7 percentage points, making peak shaving more profitable under time-of-use tariffs. The laminated busbar design and controlled edge rates shortened commissioning; EMI filters could be smaller without compromising compliance. Maintenance logs over the next season reported fewer thermal alarms and longer intervals between filter cleanings.

Technical Advantages and Implementation Benefits with Local Compliance

SiC’s technical advantages compound through the entire conversion chain. In double-conversion UPS, lower conduction and switching losses on both rectifier and inverter stages directly raise online efficiency. In microgrids, bidirectional DC conversion achieves higher round-trip efficiency, improving the economics of peak shaving and backup. Higher switching frequencies enable smaller magnetics and filters, reducing cabinet volume and weight, which is especially valuable in packed electrical rooms or rooftop installations. Moreover, high junction temperature capability and superior thermal conductivity leave more margin during Pakistan’s hottest weeks, allowing quieter, lower-power cooling strategies that save OPEX and extend fan lifetimes.

From a compliance perspective, NEPRA-aligned interconnection and harmonics limits, together with IEEE-derived PQ criteria, are easier to meet when EMI is mitigated at the device and module levels. Low-parasitic modules, laminated bus structures, and gate drivers with dV/dt control and Miller clamping suppress ringing and overshoot, cutting radiated and conducted emissions. With careful creepage and sealing design, systems withstand high humidity and dust. The upshot is faster commissioning, fewer nuisance trips, and stronger evidence to support longer warranties—assets that lenders and owners increasingly prioritize.

Comparative View of Sicarbtech’s Portfolio for Mission-Critical Power

Mapping Pakistani UPS and Microgrid Requirements to Sicarbtech’s SiC Building Blocks

| Local Requirement | Sicarbtech SiC MOSFETs (1200/1700 V) | Sicarbtech 3rd-Gen SiC Schottky Diodes | Sicarbtech Half/Full-Bridge & Bidirectional Modules | Conventional Silicon Options |

|---|---|---|---|---|

| Online UPS efficiency at rated load | Low RDS(on), robust oxide | Near-zero Qrr | Low-parasitic leadframe; optimized passivation | Higher loss and heat |

| Microgrid low-THD output | Precise gate control | Minimal reverse spikes | Parasitic <10 nH with laminated bus | Daha büyük filtreler gerekli |

| Fast transfer and weak-grid events | Controllable edge rates | Cleaner recovery | Stable dV/dt; strong isolation | Longer sags/overshoot |

| Hot, dusty rooms | Stable at high Tj | EMI-friendly | Ceramic substrates, sealed modules | Thermal fatigue, ingress issues |

| Compact cabinets | High-frequency operation | Reduced switching loss | Smaller magnetics, efficient cooling | Bigger footprint and noise |

Deep-Dive Engineering Comparison for Harsh Environments

Device, Packaging, and System Parameters Tuned for Pakistan’s Heat, Dust, and Humidity

| Parametre | Sicarbtech SiC Stack (Device + Module + Interconnect) | Typical Silicon Stack | Operational Implication in Pakistan |

|---|---|---|---|

| On-resistance vs temperature | Modest increase to 125°C+ | Steeper increase | Stable output in afternoon heat |

| Reverse recovery charge | ~0 (Schottky) | Yüksek | Lower EMI, simpler filters |

| Max junction temperature | 175–200°C (package-dependent) | 150–175°C | Smaller heatsinks, quieter fans |

| Module inductance | <10 nH target | 15–30 nH | Cleaner switching, fewer snubbers |

| Thermal interface | Sintered silver | Soldadura | Superior power cycling life |

| Sustrato | AlN/Si3N4 with Cu | Alumina often | Higher thermal conductivity, toughness |

| Anahtarlama frekansı | 50–150 kHz | 10–40 kHz | Daha küçük manyetikler, kompakt kabinler |

| Çevresel sızdırmazlık | Tailored gels/coatings | Generic | Fewer ingress faults |

| Weighted efficiency uplift | +0.5–1.0 percentage points | Başlangıç Noktası | Lower energy bills; better LCOE |

| Lifecycle economics | Lower TCO | Higher TCO | Longer warranties, fewer outages |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Edge

Sicarbtech stands out in Pakistan not merely as a component supplier, but as a full-cycle solutions partner that enables localized capability. Located in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech couples advanced R&D with proprietary processes for R-SiC, SSiC, RBSiC, and SiSiC grades. This materials depth reinforces power electronics performance through better thermal paths, mechanical robustness, and long-term reliability.

For Pakistani partners—OEMs, EPCs, and industrial operators—Sicarbtech offers comprehensive technology transfer packages that cover process know-how, equipment specifications, and training. Epitaxial growth (CVD) recipes, doping profiles, trench/planar gate options, copper-on-ceramic stack-ups, and sintered silver windows are documented to accelerate line ramp. Equipment specifications include utilities, layout, environmental controls, and maintenance. Training spans operators, process engineers, quality teams, and application engineers, embedding practical tradecraft rather than just shipping machines.

Factory establishment services begin with feasibility studies that reflect Pakistan’s labor pools, utilities, and environmental regulations, then proceed to production line commissioning and initial yield ramp with statistical process control. Quality systems are set up to align with ISO 9001 and ISO 14001, and Sicarbtech advises on IEC/UL component testing pathways and local PQ/safety expectations. The ongoing services layer includes quarterly process audits, reliability data refreshes, EMC/thermal/application engineering support, and continuous improvement loops based on field feedback. Because Sicarbtech has supported more than 19 enterprises through similar journeys, the probability of a smooth, timely ramp is substantially higher.

“Standing up a SiC capability is about disciplined metrology and repeatable processes as much as it is about equipment. We transfer the routine that makes yield reliable,” says a Sicarbtech process transfer leader, emphasizing the company’s commitment to sustained partner success.

Future Market Opportunities and 2025+ Trends: Aligning SiC with Pakistan’s Next Stage

Looking beyond 2025, Pakistan’s demand for C&I UPS and microgrid inverters is set to grow in step with digitalization, cold-chain expansion, and mission-critical telecom upgrades. Hybrid systems that pair PV and storage on microgrids will prioritize bidirectional conversion efficiency and low THD—both strengths of SiC platforms. Time-of-use tariffs and rising fuel costs push the economics toward peak shaving and higher round-trip efficiency, while weak-grid conditions reward fast dynamic response and stable operation at elevated temperatures.

We anticipate SiC penetration in mid-to-high-end UPS and microgrid inverters to rise from a low base toward 30–50% in the next several years. As local assemblers and OEMs consider partial localization to manage FX and logistics risks, integrated suppliers with materials–devices–equipment delivery and proven technology transfer programs will hold a structural advantage. For sectors like textiles, cement, and steel, SiC’s power density and reliability open the door to denser MCC rooms and fewer thermal deratings. EV charging for commercial and industrial sites will value compactness and low acoustic noise—both direct dividends of high-frequency SiC designs.

Sıkça Sorulan Sorular

What efficiency improvements can online double-conversion UPS users expect in Pakistan?

Field projects typically report a 1.0–1.5 percentage point uplift versus older silicon platforms and about 0.5–1.0 percentage points against newer silicon designs, depending on topology and loading. This translates into less heat, quieter cooling, and lower energy bills under TOU tariffs.

How does Sicarbtech address dust and humidity for UPS and microgrids in industrial zones?

We tailor sealing gels, moisture-resistant encapsulants, and corrosion-resistant coatings, and we optimize creepage and enclosure venting. Combined with laminated busbars and controlled edge rates, these measures reduce ingress-related faults and improve PQ stability.

Can SiC inverters help with NEPRA and industrial estate PQ compliance?

Yes. By reducing reverse recovery and module parasitics, we cut EMI at the source; coupled with tuned filters and gate control, systems typically achieve lower THD (around 2–3%) and more stable voltage during disturbances, easing compliance.

Which voltage classes are most relevant for Pakistani UPS and microgrid architectures?

1200 V devices are common for many stages of double-conversion UPS and microgrids, while 1700 V devices are preferred in higher-power or higher-bus-voltage sections. Sicarbtech configures half-bridge/full-bridge and bidirectional modules accordingly.

How does sintered silver improve lifetime compared with solder?

Sintered silver offers higher thermal conductivity and superior mechanical integrity, greatly enhancing power cycling life—particularly valuable when heatsinks are partially dust-fouled and thermal gradients widen.

Can Sicarbtech support local assembly or full manufacturing in Pakistan?

Yes. Through technology transfer and factory establishment services, we provide process recipes, equipment specs, training programs, quality frameworks, and commissioning support, enabling phased localization to match demand and capability.

What reliability testing does Sicarbtech offer for Pakistani conditions?

We provide power cycling, temperature cycling, high-temperature/high-humidity accelerated tests, and salt-mist exposure where applicable. We share acceleration models and collaborate on site-specific test plans to underpin extended warranties.

Will faster switching worsen EMC in sensitive data environments?

If unmanaged, fast edges can stress EMC. However, Sicarbtech’s low-parasitic modules, laminated busbars, controlled gate resistors, and Miller clamping minimize ringing. Properly co-designed SiC systems often need less bulky filtering than legacy designs.

How fast can pilots be executed and evaluated?

Depending on scope, pilots can be set up in weeks to a few months. We recommend A/B trials with clear KPIs: efficiency curves, thermal imaging, THD/PQ logs, transfer-time measurements, and maintenance records.

What total cost of ownership benefits are typical over 10–15 years?

Lower energy consumption, smaller and quieter cooling, reduced maintenance, and extended lifetimes generally yield a lower TCO despite higher device costs—benefits amplified in hot, dusty, and weak-grid environments common in Pakistan.

Operasyonlarınız için Doğru Seçimi Yapmak

The best SiC strategy begins with your operational constraints: heat, dust, room or roof loading, PQ targets, redundancy strategy, and financing requirements. When Sicarbtech co-designs from device physics and gate reliability to busbar geometry, EMI control, and thermal paths, the gains become tangible—higher online efficiency, shorter transfer times, leaner cooling, simpler filters, and stronger reliability narratives for lenders and procurement boards. For Pakistan’s textiles, cement, steel, data centers, cold chain, and telecom, this is a practical pathway to resilient uptime and competitive energy economics.

Uzman Danışmanlığı ve Özel Çözümler Alın

Discuss your UPS or microgrid roadmap with Sicarbtech’s engineering team. Whether you are piloting a modular UPS, retrofitting microgrid inverters, or planning local assembly, we will propose a data-driven plan with milestones for performance, reliability, compliance, and localization. Contact: [email protected] | +86 133 6536 0038.

Makale Meta Verileri

Last updated: 2025-09-17

Próxima revisión programada: 01/12/2025

Content freshness indicators: Includes 2025 Pakistan market outlook; double-conversion UPS and microgrid use cases; 1200/1700 V SiC MOSFETs and 3rd-gen Schottky diodes; sintered silver interconnects; AlN/Si3N4 ceramic substrates; laminated low-parasitic DC busbars; NEPRA/PQ compliance notes; localization, technology transfer, and factory establishment pathways; case narratives in Lahore, Faisalabad, and Karachi.

About Sicarbtech: Silicon Carbide Solutions Expert based in Weifang City, China’s SiC manufacturing hub; member of Chinese Academy of Sciences (Weifang) Innovation Park; over 10 years of SiC customization supporting 19+ enterprises; full-cycle delivery from materials to finished products; specialties include R-SiC, SSiC, RBSiC, and SiSiC grades; services span custom manufacturing, factory establishment, and technology transfer.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.