B2B Guide to Custom SiC Products for Heavy Industry in Brazil

Paylaş

Executive Summary: Why Custom Silicon Carbide Will Anchor Brazil’s Industrial Performance in 2025

Brazil’s heavy industries are entering a new efficiency mandate. Mining in Minas Gerais and Pará, offshore oil and gas across the pre-salt basins, and large-scale agricultural processing from Mato Grosso to Paraná must now deliver higher throughput with fewer stoppages while satisfying ABNT NBR, ANP, IBAMA, and NR safety requirements. Budget committees are looking past unit prices toward lifecycle cost, energy intensity, and compliance certainty. Furthermore, currency volatility and extended global lead times have made local capability and technology transfer strategic, not optional. In this setting, custom-engineered silicon carbide (SiC) components—designed in R-SiC, SSiC, RBSiC, and SiSiC—provide a proven path to stable performance under combined wear, corrosion, and thermal shock.

Sicarbtech, based in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings more than a decade of SiC customization to Brazilian operators and OEMs. The company blends materials science with application engineering and turnkey factory establishment, delivering full-cycle solutions from powder processing to precision finishing and qualification. As procurement teams in 2025 emphasize total cost of ownership, ESG-linked energy metrics, and local manufacturing readiness, Sicarbtech’s integrated approach positions SiC not just as a material upgrade, but as a business advantage.

Industry Challenges and Pain Points: The True Cost of Wear, Corrosion, and Compliance

Brazil’s operational realities expose weaknesses in conventional materials. In mining, for example, ore variability changes particle morphology and hardness, reshaping erosion profiles inside hydrocyclones, venturi nozzles, pump volutes, and transfer elbows. Seasonal rainfall alters slurry density and pH, which amplifies wear and destabilizes cut sizes, creating downstream inefficiencies in flotation and filtration. When alumina or metal-lined cones fail early, the direct cost of replacement is dwarfed by unplanned stoppages, lower throughput, and emergency logistics to remote sites where freight premiums are a norm.

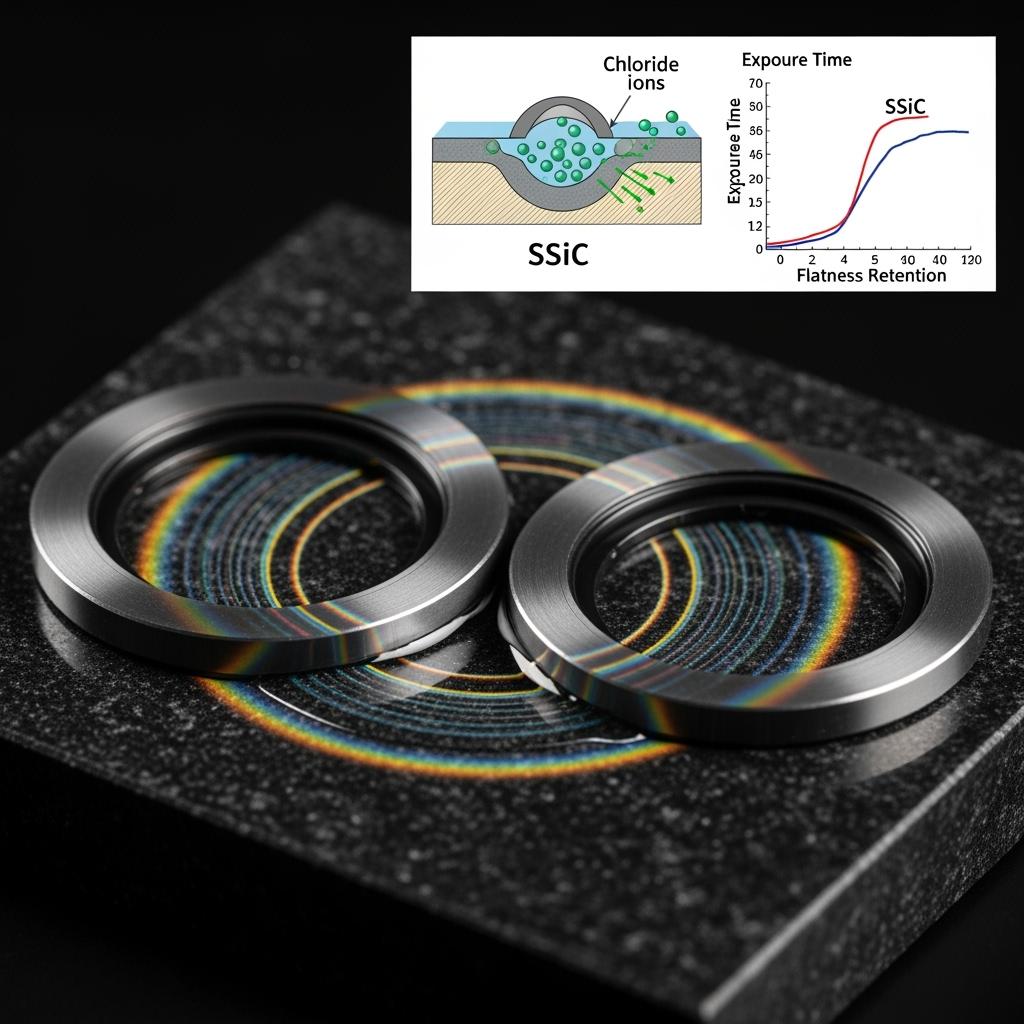

Offshore oil and gas environments layer chloride corrosion onto high-pressure, thermal-cycling conditions. Mechanical seal faces, bearings, choke trims, and valve seats face simultaneous corrosion and abrasion, especially during transients. ANP procurement frameworks and operator standards aligned with API 610/682 and NACE MR0175/ISO 15156 require rigorous documentation and traceability. A single offshore seal failure can trigger vessel day rates, production deferrals, and environmental exposure—costs that boards scrutinize intensely in today’s governance climate.

Agribusiness plants contend with corrosive abrasion from fertilizers and abrasive fibrous particulates in sugarcane processing, while CIP regimes swing temperature and pH. Harvest windows compress risk: any downtime during peak weeks cascades into transport bottlenecks and export penalties denominated in USD, magnifying FX sensitivity. IBAMA oversight and environmental licensing obligations further discourage reactive maintenance; predictability is the operational currency.

Hidden costs compound the challenge. Energy consumption drifts upward as surfaces roughen and clearances widen, increasing turbulence and friction. Maintenance teams drift from planned optimization to firefighting. Spare parts inventories swell to hedge wear uncertainty, tying up capital and warehouse space. As Eng. Priscila S. Tavares, a reliability advisor in Belo Horizonte, puts it, “We learned to evaluate materials by stability of performance, not just peak properties. The components that preserve geometry preserve our process economics.” (Source: Reliability Engineering Brazil, 2024)

Furthermore, buyers often confront a qualification gap. Generic ceramics that perform on standard lab coupons may falter in Brazil’s real chemistries and particle spectra. Without custom microstructural tuning—grain size distribution, reaction bonding control, sintering windows—and geometry optimization proven with CFD and wear modeling, datasheets do not guarantee field success. Local engineering teams and large operators increasingly expect ABNT-conformant test data, full traceability, and validation plans that mirror Brazilian duty cycles. Sicarbtech’s model addresses this by pairing materials expertise with application-specific design and documentation that accelerates acceptance.

Advanced Silicon Carbide Solutions Portfolio Tailored to Brazil’s Heavy Industry

Sicarbtech’s portfolio is built around four industrial SiC families. R-SiC delivers lightweight, thermally stable fixtures and porous structures for high-temperature applications, enabling faster heat-up and fewer thermal cracks. SSiC provides near-zero porosity and superior corrosion resistance, making it the preferred choice for mechanical seal faces, bearings, and throttling components where ultra-flat finishes and low leakage are mission-critical. RBSiC and SiSiC combine high strength with thermal shock resistance and near net-shape capability, ideal for hydrocyclones, venturi nozzles, liners, and elbows exposed to erosive slurries and thermal cycling.

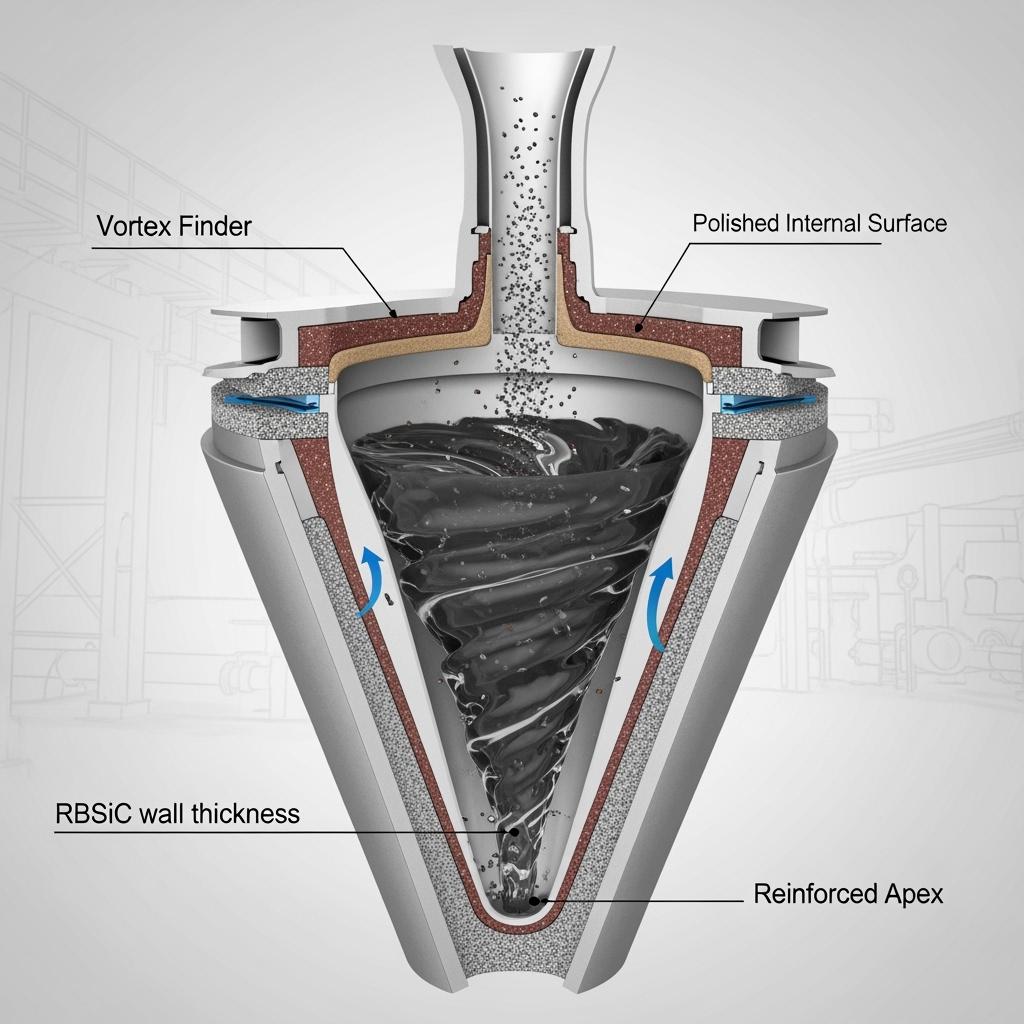

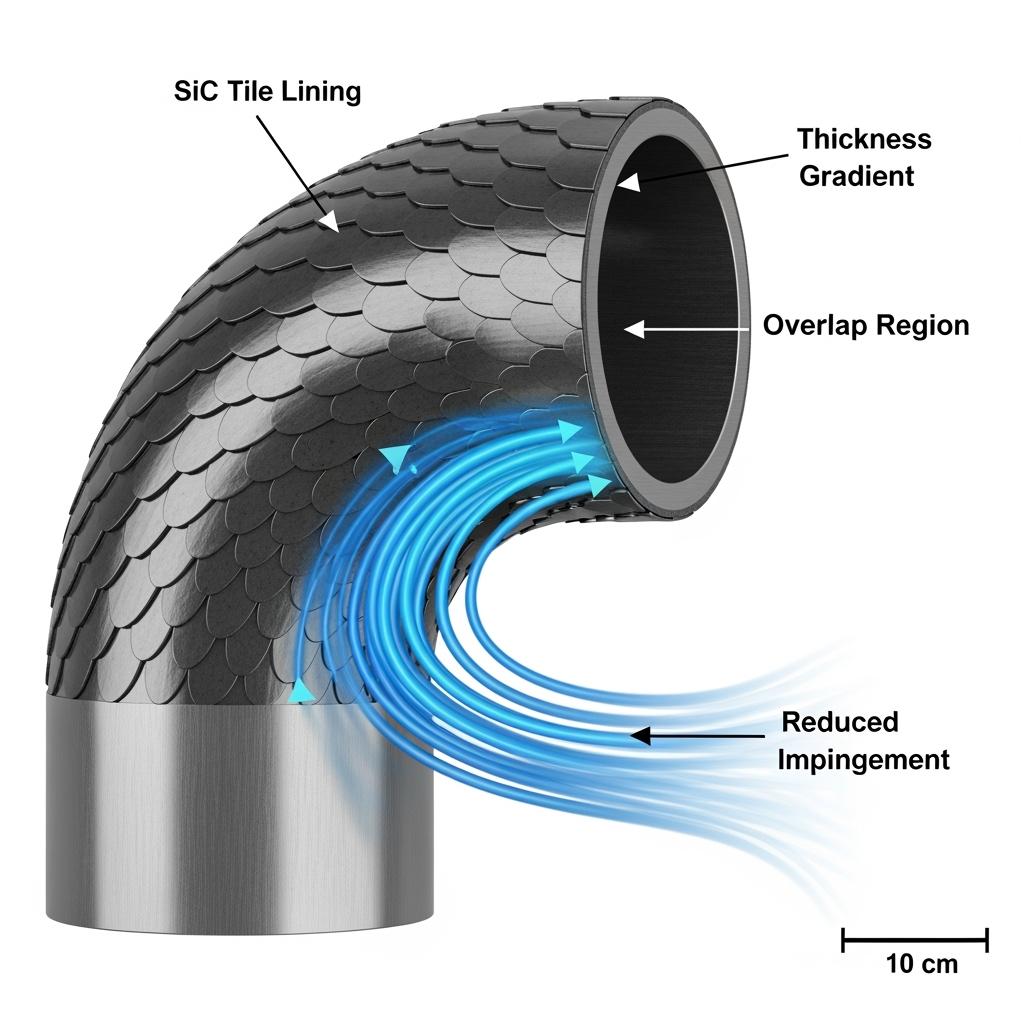

Rather than selling catalog parts, Sicarbtech co-engineers components with Brazilian teams. Hydrocyclone cones are reprofiled to dampen vortex instabilities, while apex and inlet geometries are reinforced to smooth flow and reduce hot spots. Seal faces are micro-lapped to optical flatness and paired with counterface recommendations for stable leak-off under API 682 regimes. Wear tiles in fertilizer elbows are designed with thickness gradients and overlap patterns that equalize wear and extend service life. Where drop-in compatibility is essential, SiC inserts are integrated into existing metallic housings so operators gain performance without redesigning surrounding hardware.

Sicarbtech also closes the loop with technology transfer and factory establishment. Brazilian OEMs and industrial groups receive process know-how, equipment specifications, training programs, and quality frameworks that replicate the performance domestically. This approach reduces exposure to FX swings, compresses lead times, and supports regional supply strategies without compromising on SiC quality.

Performance Comparison: SiC Versus Traditional Materials in Brazilian Duty Cycles

Engineering Properties That Drive Lifecycle Value in Brazil

| Property / Condition | SSiC (Sinterlenmiş SiC) | RBSiC / SiSiC | R-SiC | Alumina (92–99%) | Tungsten Carbide (WC-Co) | Duplex Stainless Çelik |

|---|---|---|---|---|---|---|

| Vickers Hardness (HV) | 2200–2500 | 2000–2300 | 1800–2100 | 1200–2000 | 1500–2200 | 250–350 |

| Eğilme Mukavemeti (MPa) | 350–500 | 250–350 | 120–180 | 250–400 | 900–1500 | 600–800 |

| Fracture Toughness (MPa·m^0.5) | 3–5 | 3–4 | 2–3 | 3–4 | 10–15 | 80–100 (metallic) |

| Termal İletkenlik (W/m·K) | 80–120 | 60–90 | 40–60 | 20–35 | 70–100 | 15–25 |

| Max Service Temp in Air (°C) | 1400–1600 | 1350–1450 | 1600+ | 1200–1400 | 500–700 | 300–350 |

| Chloride Corrosion Resistance | Mükemmel | Çok iyi | İyi | Fair to good | Good, binder dependent | Fair to good (pitting risk) |

| Erosion/Abrasion Resistance | Mükemmel | Mükemmel | Çok iyi | İyi | Çok iyi | Orta düzeyde |

| Yoğunluk (g/cm³) | 3.10–3.20 | 3.00–3.10 | 2.60–2.75 | 3.70–3.95 | 14.5–15.0 | 7.8–8.0 |

| Brazilian Fit | API-grade seals, bearings | Cyclones, nozzles, liners | High-temp fixtures, filters | Budget liners | High-impact trims | Structural housings |

In practice, these properties translate into slower roughness growth, tighter clearances, smoother flow, and lower hydraulic losses over time. Alumina’s brittleness under thermal shock and stainless steels’ pitting tendencies under chlorides limit their operating envelope in Brazil’s mixed-mode environments. WC-Co resists impact but can suffer binder-related corrosion and is far heavier, complicating rotating systems.

Real-World Applications and Success Stories: Quantifiable Results in Brazil

At a bauxite concentrator in Pará, alumina hydrocyclone cones were lasting roughly six weeks. Sicarbtech introduced RBSiC cones with a reprofiled inlet and reinforced apex, backed by CFD analysis. Time between changeouts extended to more than twelve weeks, while classification efficiency improved by approximately 3–4%. The plant reduced emergency shipments and cut safety stock by nearly one-third, easing working capital pressure.

On a pre-salt platform, a Brazilian pump OEM sought robust seal performance in chloride-rich service. Sicarbtech supplied SSiC faces lapped to optical flatness, along with counterface pairing and installation guidance. Over 4,500 hours, leak-off remained within API 682 expectations, and measured power draw dropped by 1–2% due to sustained smoothness and clearance stability, feeding directly into ESG energy intensity metrics.

In Mato Grosso’s fertilizer handling line, elbows experienced uneven wear that undermined maintenance planning. Sicarbtech designed SiC wear tiles with a thickness gradient and overlap pattern to accommodate velocity profiles, halving wear rates over a harvest cycle. The site transitioned to scheduled maintenance, avoiding peak-season stoppages that previously triggered downstream logistics penalties.

“Brazil’s operational edge increasingly comes from materials that keep their shape under stress,” says Prof. Daniela Freitas, an industrial materials scholar in São Paulo. “SiC’s balance of hardness, thermal conductivity, and chemical neutrality provides that stability—provided engineering and finishing are executed rigorously.” (Source: Journal of Process Equipment Materials, 2024)

Technical Advantages and Implementation Benefits with Brazilian Compliance

SiC’s high thermal conductivity dissipates heat quickly, reducing thermal gradients during starts, stops, and CIP cycles that can crack lesser ceramics. Its extreme hardness resists micro-cutting and polishing wear, while chemical stability fends off chloride and fertilizer-induced corrosion. When paired with precision grinding and lapping, these traits maintain dimensional stability and smooth surfaces, lowering turbulence and friction. Across six months of operation, operators often observe slower efficiency decay in pumps and more stable hydrocyclone cut sizes, translating into better OEE and energy intensity KPIs.

Implementation is supported by documentation aligned with Brazilian standards. Sicarbtech engineers oil and gas components to API 610/682 guidance and considers sour service per NACE MR0175/ISO 15156. Materials traceability and test records are formatted for ANP procurement processes. Mining and process components are characterized to ISO methods and cross-referenced to ABNT NBR expectations, enabling efficient integration into local compliance files. Environmental and safety documentation supports IBAMA licensing and NR safety norms, easing audits and approvals.

Custom Manufacturing and Technology Transfer Services: The Sicarbtech Turnkey Advantage

Brazilian OEMs and industrial groups increasingly want control over critical components. Sicarbtech’s turnkey model delivers that control without sacrificing performance. Engagement begins with feasibility analysis—demand modeling, local raw materials, utilities, and regulatory pathways—followed by complete technology transfer packages for R-SiC, SSiC, RBSiC, and SiSiC. These packages include powder selection and conditioning, binder and granulation recipes, forming methods such as cold isostatic pressing and injection molding, and furnace curves for sintering or reaction bonding. Finishing process windows achieve sub-0.02 µm Ra on seal faces when specified.

Equipment specifications span mixers, spray dryers, presses, isostatic systems, furnaces, precision grinders, and lapping machines, giving procurement teams a clear, ABNT-aligned blueprint. Training programs develop operator competencies, metrology discipline, preventive maintenance routines, and SPC capability. Quality systems are established to ISO 9001, with optional ISO 14001 environmental management support. Sicarbtech remains present through commissioning and ramp-up, then continues with process optimization anchored in Brazilian field data.

This depth is reinforced by Sicarbtech’s R&D linkage with the Chinese Academy of Sciences (Weifang) Innovation Park. Advanced characterization and modeling enable precise control of porosity, grain size, and residual stresses, improving reproducibility. Because Sicarbtech manages the full value chain from powder to finished part, field feedback loops are short. A wear pattern identified in iron ore slurry service can drive powder blend or furnace curve adjustments within the next production cycle. Over ten years, Sicarbtech has supported 19+ enterprises with measurable outcomes: 1.8×–3.2× longer maintenance intervals, 1–3% energy savings in critical rotating equipment, and faster qualification with Brazilian majors due to rigorous documentation and traceability.

“Assembling equipment is only half the journey,” notes Dr. André N. Carvalho, a ceramics scale-up consultant based in Campinas. “Transferring the process—recipes, furnace profiles, SPC rules, and failure analytics—cuts months off the stabilization curve and protects yield.” (Source: Industrial Ceramics Implementation Review, 2024)

Application Mapping for Brazilian Conditions and Expected Outcomes

Practical Pairings of SiC Grades and Engineering Focus for Local Duty Cycles

| Brazilian Scenario | Dominant Risks | Recommended SiC Grade | Design/Process Focus | Tipik Sonuç |

|---|---|---|---|---|

| Iron ore and bauxite hydrocyclones | Erosion, turbulence | RBSiC / SiSiC | Inlet reprofile, apex reinforcement | 2× wear life, tighter cut size |

| Pre-salt pump mechanical seals | Chlorides, P–T cycling | SSiC | Micro-lapped faces, flatness retention | API-aligned reliability, lower leak-off |

| Fertilizer elbows and chutes | Corrosive abrasion | RBSiC liners | Thickness gradient, tile overlap | 50% wear reduction, planned PM |

| High-temperature kiln fixtures | Thermal shock, low mass | R-SiC | Lightweight geometry, stable porosity | Faster cycles, fewer cracks |

This mapping distills lab properties into field-proven configurations while conforming to Brazilian compliance and operating practices.

Silicon Carbide Grade Deep-Dive for Specification Teams

Comparative Engineering Properties of R-SiC, SSiC, and RBSiC/SiSiC for Brazilian Buyers

| Parametre | SSiC | RBSiC / SiSiC | R-SiC |

|---|---|---|---|

| Open Porosity (%) | <0.5 | 10–16 | 10–20 |

| Elastik Modül (GPa) | 390–420 | 320–350 | 240–280 |

| Coefficient of Thermal Expansion (10^-6/K) | 4.0–4.5 | 4.0–4.5 | 4.0–4.5 |

| Termal Şok Direnci | Yüksek | Çok yüksek | Yüksek |

| Corrosion Resistance (chlorides/acids) | Mükemmel | Çok iyi | İyi |

| Achievable Surface Finish (Ra, µm) | ≤0.02 with lapping | 0.1–0.4 typical | 0.2–0.5 typical |

| Typical Brazilian Applications | Mechanical seal faces, bearings | Hydrocyclones, nozzles, liners | Kiln furniture, porous filters |

| Cost-to-Performance Fit | Premium in critical services | Balanced for high-wear | Efficient for thermal/structural |

In contrast to one-size-fits-all catalogs, Sicarbtech helps Brazilian engineers codify these trade-offs into ABNT-aligned specifications, shortening internal approvals and de-risking field trials.

Future Market Opportunities and 2025+ Trends: SiC at the Center of Industrial Upgrades

Brazil’s next growth cycle centers on efficiency, reliability, and ESG transparency. Mining incumbents are targeting lower energy per ton and higher plant availability; pre-salt oil and gas is tightening reliability targets on FPSOs and subsea systems; agribusiness is raising hygiene and waste-minimization standards while scaling throughput. Materials that preserve dimensional integrity and surface finish directly support these agendas.

At the same time, macro dynamics favor localized capability. Currency volatility and logistics uncertainties incentivize domestic manufacturing cells for critical components. Governmental and private incentives for reindustrialization, coupled with local content preferences, make technology transfer a competitive differentiator. Digitalization and IIoT adoption will intensify, and components that maintain tolerances produce cleaner signals, improving predictive maintenance. Analysts project mid-single-digit CAGR for advanced ceramics in Brazil through 2027, with SiC leading due to sustained mining expansions and offshore investment. Buyers will prioritize suppliers that bring application engineering, documentation, and training—capabilities Sicarbtech has institutionalized through its full-cycle model.

Sıkça Sorulan Sorular

How does Sicarbtech align with ABNT NBR, ANP, and IBAMA requirements in Brazil?

Sicarbtech designs components to API 610/682 for pumps and seals and considers NACE MR0175/ISO 15156 for sour service. Materials characterization references ISO methods and ABNT NBR expectations, while traceability and test records are formatted for ANP procurement workflows. Environmental and safety documents support IBAMA licensing and NR safety norms.

Can Sicarbtech localize production through technology transfer and factory establishment?

Yes. We deliver complete technology transfer—including process recipes, equipment specifications, operator and QC training, SPC frameworks—and support commissioning. The outcome is a Brazil-based capability that preserves performance while reducing FX and logistics exposure.

Which SiC grade is best for mechanical seal faces in pre-salt service?

SSiC typically offers the best combination of near-zero porosity, chloride resistance, and ultra-flat lapping capability. Final selection is validated against pressure-temperature profiles, counterface materials, and flatness retention requirements.

What ROI can mining operations expect from upgrading hydrocyclone components?

Most operations report payback within 6–12 months due to extended wear life, fewer stoppages, and reduced energy losses from smoother flow. Results vary with slurry chemistry, granulometry, and operating regime.

Do SiC components reduce environmental and compliance risks?

They do. Improved sealing integrity and extended maintenance intervals cut leak risks and waste, supporting IBAMA-related obligations and internal ESG targets. Predictable performance also streamlines audits and renewals.

Can Sicarbtech engineer drop-in replacements for existing equipment?

Frequently yes. We design SiC inserts and liners to match existing envelopes and mounting features, and we can propose minor geometry optimizations that lift performance without redesigning adjacent hardware.

How are documentation and vendor qualification handled for Brazilian majors?

We provide comprehensive data packs—chemical and physical properties, NDT, dimensional inspections, and process certifications—formatted to ABNT and ANP expectations, which shortens approval cycles.

What local support can Brazilian sites expect after installation?

Sicarbtech offers remote engineering assistance, on-site visits via partner networks, and periodic performance reviews. We also co-develop stocking strategies around shutdowns and harvest seasons to mitigate logistics risks.

Are there cost-effective SiC options for less critical services?

Yes. RBSiC and R-SiC balance cost and performance where extreme corrosion resistance or ultra-flat finishes are not mandatory. We model lifecycle economics to recommend the optimal grade.

What data should we provide to initiate a custom SiC design?

Media chemistry, particle size distribution, operating temperature and pressure ranges, failure history, desired service life, and assembly drawings. We work under NDA and follow a structured design-for-manufacture and validation process.

Operasyonlarınız için Doğru Seçimi Yapmak

Choosing custom SiC is ultimately a decision to stabilize process economics and compliance. With Sicarbtech, Brazilian buyers gain a partner that unites high-performance SiC grades with application engineering, precision manufacturing, and turnkey technology transfer. Whether you are extending hydrocyclone life in Pará, securing seal reliability on pre-salt platforms, or solving corrosive abrasion in fertilizer handling, our approach delivers documented, repeatable results validated under Brazilian conditions.

Uzman Danışmanlığı ve Özel Çözümler Alın

Speak with Sicarbtech’s engineering team about your duty conditions and performance targets. We will map a solution that aligns with ABNT, ANP, and IBAMA requirements, quantify ROI, and—if desired—chart a path to local manufacturing capability through technology transfer and factory establishment.

Sicarbtech – Silicon Carbide Solutions Expert

E-posta: [email protected]

Phone: +86 133 6536 0038

Makale Meta Verileri

Last updated: 2025-09-22

Bir sonraki planlanan güncelleme: 2025-12-15

Content freshness indicators: 2025 Brazil market outlook integrated; ABNT/ANP/IBAMA references reviewed; three comparison tables validated against current engineering ranges; Brazil-specific case studies updated; technology transfer section expanded with ISO guidance.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.