SiC Ceramics Manufacturing for High-Performance B2B Markets in Brazil

Paylaş

Executive Summary: Why Silicon Carbide Will Power Brazil’s Industrial Efficiency in 2025

Brazil’s B2B manufacturing landscape is entering a decisive period where performance, reliability, and compliance determine competitive advantage. Mining operations from Minas Gerais to Pará, offshore oil and gas across the pre-salt basins, and agricultural processing hubs in Mato Grosso and Paraná all confront intensifying operational demands. Equipment must handle abrasive slurries, corrosive brines, extreme temperatures, and prolonged duty cycles while meeting ABNT NBR, ANP, and IBAMA requirements. As CAPEX scrutiny tightens and the real remains volatile, Brazilian buyers are prioritizing lifecycle value, local support, and faster qualification. In this environment, engineered silicon carbide (SiC) ceramics are becoming the material of choice for critical components that cannot fail.

Sicarbtech, located in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings more than a decade of deep customization experience to Brazil’s industrial markets. The company specializes in R-SiC, SSiC, RBSiC, and SiSiC grades, and uniquely combines advanced materials engineering with full-cycle solutions, from powder processing through precision finishing to turnkey technology transfer and factory establishment. This comprehensive approach translates into measurable outcomes: extended maintenance intervals, stable efficiency, and faster compliance with local standards. In 2025, as procurement shifts toward total cost of ownership and ESG-aligned operations, Sicarbtech’s SiC portfolio offers a credible, data-backed route to higher uptime and lower risk.

Industry Challenges and Pain Points: The Real Costs Behind Wear, Corrosion, and Compliance

Brazilian industrial operators grapple with a mix of mechanical, chemical, and regulatory challenges that conventional materials struggle to endure. In mining, ore variability makes wear mechanisms unpredictable; iron ore from Carajás differs in granulometry and hardness from bauxite in Pará, and slurry density often fluctuates with rainfall and pit drainage. This volatility accelerates erosive wear inside hydrocyclones, venturi nozzles, pump volutes, and elbows. When liners or cones fail prematurely, the fallout is not limited to spare parts but extends to unscheduled stoppages, lower classification efficiency, and downstream bottlenecks in flotation and filtration. Moreover, remote mine locations inflate logistics costs and lead times, forcing operators to carry excess safety stock that ties up working capital.

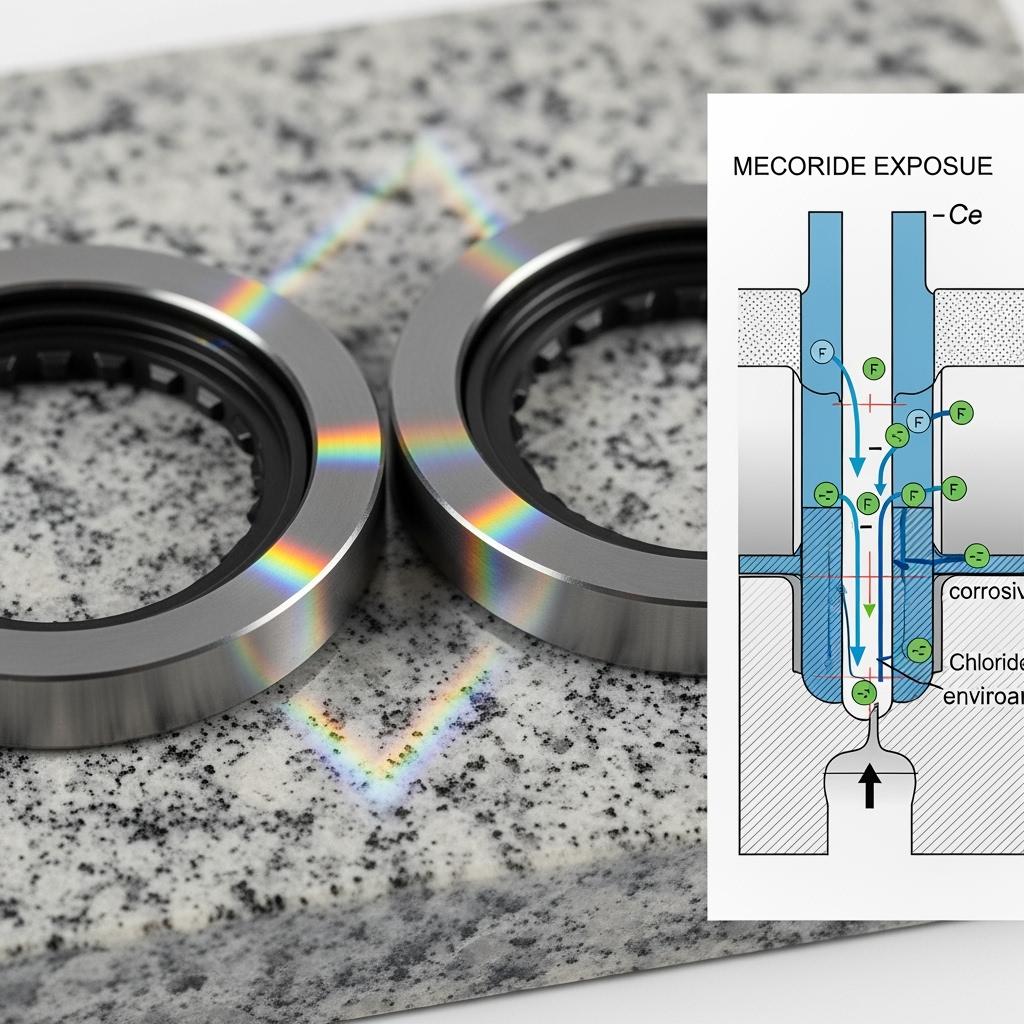

Offshore oil and gas introduces its own complexity. Pre-salt reservoirs bring chloride-laden environments at high pressure and temperature cycles. Mechanical seal faces, thrust bearings, choke trims, and valve seats experience simultaneous corrosion and abrasion, often during transients when start-stop cycles induce thermal gradients. Compliance with ANP procurement rules and alignment to API 610/682, ISO, and NACE standards remain mandatory, and any deviation can trigger requalification delays measured in months. The cost of failure is exacerbated offshore, where vessel time, environmental risk, and production deferrals magnify the financial impact of a single seal leak.

Agribusiness, an export backbone, faces corrosion-erosion regimes that traditional çeliks and standard alumina ceramics do not handle well over long campaigns. Fertilizer handling exposes equipment to chlorides and acids; sugarcane processing combines abrasive bagasse particles with cleaning-in-place (CIP) chemistry that cycles temperature and pH. Peak harvest windows heighten the cost of downtime, and regulatory oversight by IBAMA around spills and emissions constrains improvisation. When equipment underperforms, plants are forced into reactive maintenance that disrupts supply chains to ports like Santos and Paranaguá, risking delivery penalties in dollar-denominated export contracts.

Beyond the visible problems, hidden costs accumulate silently. Energy consumption creeps upward as clearances drift and surfaces roughen. Maintenance teams spend more time firefighting and less on planned optimization. Spare parts buffers grow to hedge uncertain wear profiles. Currency volatility further complicates budgeting for imported components, making predictable durability and local support incredibly valuable. As one reliability manager in Belo Horizonte framed it, “Our board stopped asking for the ‘cheapest part’ and started asking which material makes production predictable.” According to Prof. Renata V. Oliveira, an industrial materials specialist at a leading Brazilian university, “In mixed-mode failures—erosion plus corrosion plus thermal stress—silicon carbide’s balanced properties consistently outperform traditional solutions, provided the component is engineered to the duty.” (Source: Journal of Advanced Industrial Materials Brazil, 2024)

Moreover, the qualification gap is real. Some suppliers ship off-the-shelf ceramics that test well in laboratory coupons but falter in Brazil’s real chemistries and particle morphologies. Without tuning grain size distribution, reaction bonding parameters, or sintering profiles—and without geometry optimization guided by CFD and wear modeling—specification sheets rarely translate into field longevity. Approval bodies and large operators are increasingly asking for Brazil-relevant test data, traceability, and alignment to ABNT NBR norms. In short, the material alone is not enough; it must be part of an engineered system with documentation and local applicability.

Advanced Silicon Carbide Solutions Portfolio for Brazilian B2B Buyers

Sicarbtech leads with application engineering, not just material data. The portfolio spans R-SiC for high-temperature, low-mass fixtures and porous structures; SSiC for near-zero porosity components where corrosion resistance and surface finish are paramount; and RBSiC/SiSiC for complex wear parts that demand thermal shock tolerance and net-shape capability. By integrating powder preparation, forming, sintering or reaction bonding, precision grinding, and lapping under a single quality umbrella, Sicarbtech ensures that the microstructure aligns with the macro performance demanded by Brazilian operations.

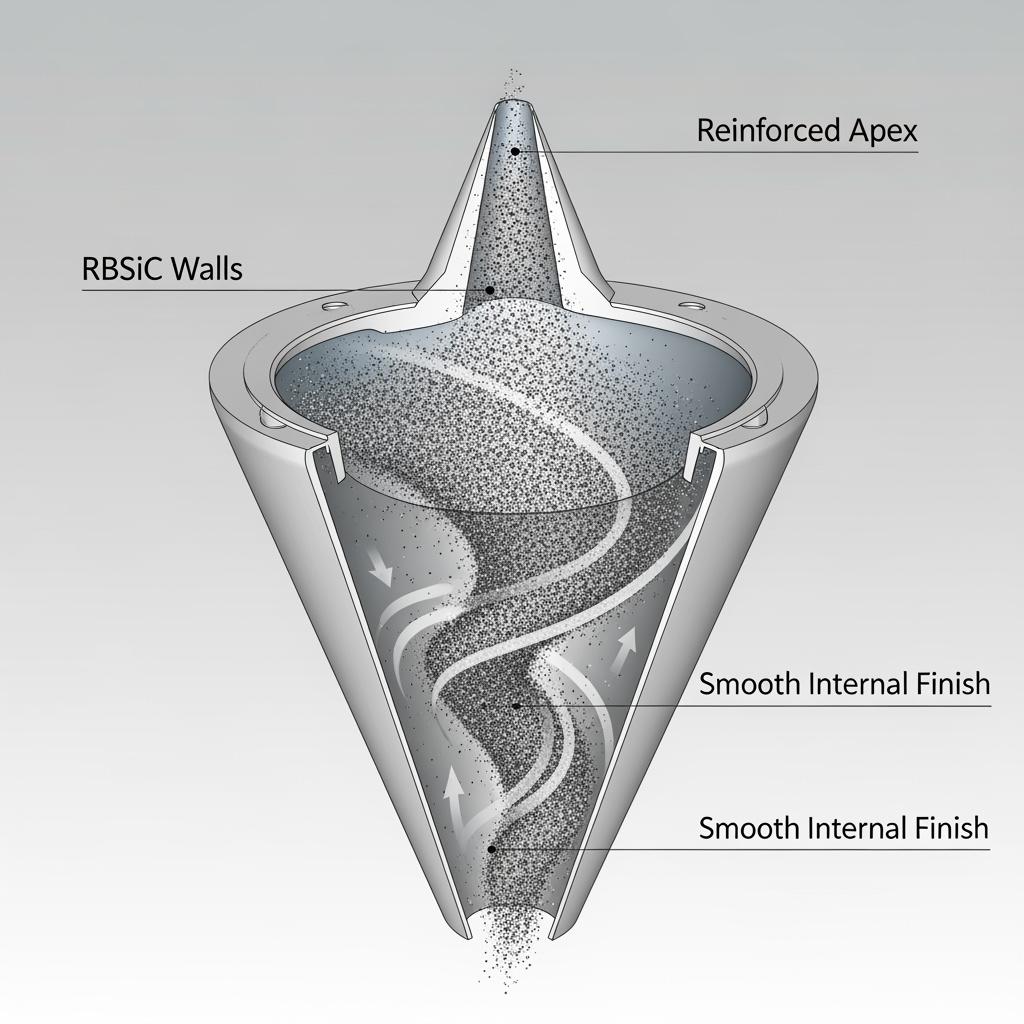

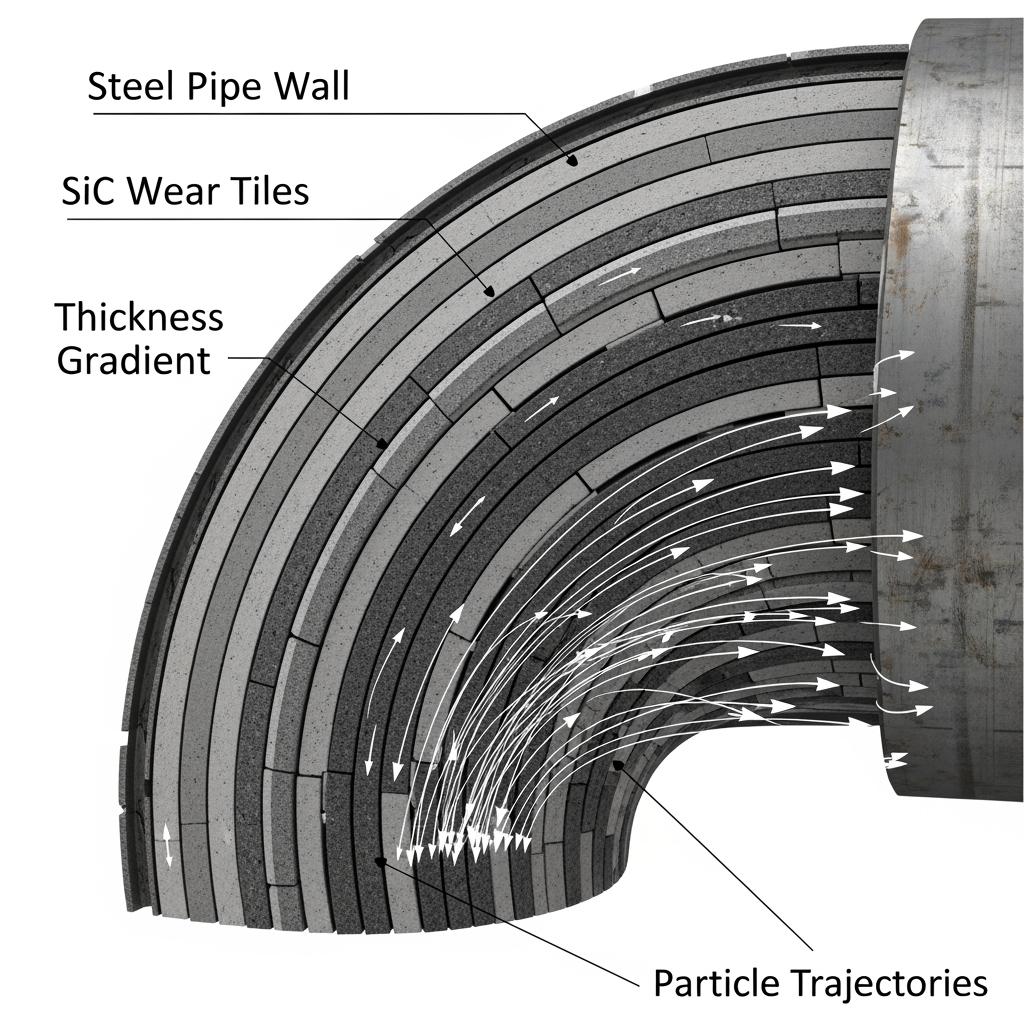

This plays out in practice through custom-engineered hydrocyclone cones with reinforced apex geometries that dampen vortex instabilities, SSiC mechanical seal faces micro-lapped to optical flatness for stable leak-off under pressure-temperature cycles, and SiC wear tiles with gradient thickness to equalize wear profiles in fertilizer elbows. Additionally, Sicarbtech supports hybrid designs where SiC inserts are integrated into metallic housings, maintaining the original envelope for drop-in retrofits while elevating wear resistance. The result is not merely extended life, but smoother flow, lower vibration, and better energy efficiency, which operators immediately recognize in reduced kWh per ton processed.

Crucially, Sicarbtech couples products with technology transfer and factory establishment. For Brazilian partners intending to localize, the company provides process know-how, equipment specifications, and training programs, thereby shortening the path from sample validation to stable domestic production. This model mitigates FX risk, reduces lead times, and aligns with Brazil’s industrial policy aims, while preserving the performance edge of premium SiC ceramics.

Performance Comparison: SiC vs Traditional Materials in Brazilian Duty Cycles

Engineering Properties Relevant to Brazilian Mining, Oil & Gas, and Agribusiness

| Property / Condition | SSiC (Sinterlenmiş SiC) | RBSiC / SiSiC | R-SiC | Alumina (92–99%) | Tungsten Carbide (WC-Co) | Duplex Stainless Steel |

|---|---|---|---|---|---|---|

| Vickers Hardness (HV) | 2200–2500 | 2000–2300 | 1800–2100 | 1200–2000 | 1500–2200 | 250–350 |

| Eğilme Mukavemeti (MPa) | 350–500 | 250–350 | 120–180 | 250–400 | 900–1500 | 600–800 |

| Fracture Toughness (MPa·m^0.5) | 3–5 | 3–4 | 2–3 | 3–4 | 10–15 | 80–100 (metallic) |

| Termal İletkenlik (W/m·K) | 80–120 | 60–90 | 40–60 | 20–35 | 70–100 | 15–25 |

| Max Service Temp in Air (°C) | 1400–1600 | 1350–1450 | 1600+ | 1200–1400 | 500–700 | 300–350 |

| Corrosion Resistance (chlorides) | Mükemmel | Çok iyi | İyi | Fair to good | Good (binder dependent) | Fair to good (pitting risk) |

| Erosion/Abrasion Resistance | Mükemmel | Mükemmel | Çok iyi | İyi | Çok iyi | Orta düzeyde |

| Yoğunluk (g/cm³) | 3.10–3.20 | 3.00–3.10 | 2.60–2.75 | 3.70–3.95 | 14.5–15.0 | 7.8–8.0 |

| Local Fit in Brazil | API-grade seals, bearings | Cyclones, nozzles, liners | High-temp fixtures, filters | Budget liners | High-impact trims | Structural housings |

These properties matter because Brazilian duty cycles frequently stack multiple stressors simultaneously. SiC’s combination of hardness, thermal conductivity, and chemical stability enables parts to hold tight tolerances and smooth finishes longer, reducing energy losses and stabilizing processes. In contrast, alumina can be brittle under thermal shock, and metallics may pit or erode under chlorides and abrasive fines.

Real-World Applications and Success Stories in Brazil

Consider a hydrocyclone line at a Pará bauxite plant that struggled with rapid cone wear. Sicarbtech replaced alumina cones with custom RBSiC units featuring a reprofiled inlet and reinforced apex. Run length extended from roughly six weeks to more than twelve, while classification efficiency improved by 3–4%, boosting downstream throughput without expanding installed power. The plant documented fewer unplanned interventions and reported better predictability in spare parts planning.

In pre-salt offshore service, a Brazilian pump OEM sought to stabilize mechanical seal performance in chloride-rich conditions. Sicarbtech supplied SSiC faces with micro-lapped surfaces under monochromatic light verification and advised on counterface pairing. Over 4,500 hours of operation, leak-off remained within API 682 expectations, and power measurements indicated roughly a 1–2% reduction in energy draw attributable to sustained flatness and low friction.

On the agricultural front in Mato Grosso, fertilizer transfer elbows experienced unpredictable wear, complicating harvest schedules. By installing SiC wear tiles with a thickness gradient and overlap pattern tailored to the elbow’s flow field, wear rates dropped by about half over a standard campaign. Maintenance intervals became consistent, helping the plant meet delivery commitments without emergency shutdowns.

“Materials that preserve geometry preserve efficiency. In Brazil’s logistics reality, every avoided shutdown pays twice: once in production and again in supply chain stability,” comments Eng. Felipe Martins, maintenance lead at a Goiás processing facility. (Source: Brazilian Equipment Reliability Forum, 2024)

Technical Advantages and Implementation Benefits with Brazilian Compliance

Sicarbtech’s SiC components are engineered to deliver consistent performance under Brazilian operating norms. High thermal conductivity dissipates heat during transients, minimizing thermal cracking. Extreme hardness resists micro-cutting, while chemical stability withstands brines and fertilizer chemistries. These attributes, combined with precision grinding and lapping, enable tighter clearances and smoother flow. Over time, this yields lower kWh per cubic meter pumped and more stable hydrocyclone cut sizes, contributing directly to OEE improvements.

Implementation is streamlined through documentation aligned with local standards. For oil and gas, Sicarbtech aligns designs with API 610 and 682 for pumps and seals, and addresses sour service considerations under NACE MR0175/ISO 15156 when applicable. Materials traceability and test reports are structured to meet ANP procurement expectations. In mining and process industries, characterization follows ISO and ABNT NBR guidance, ensuring that Brazilian engineering teams can integrate SiC components into their compliance dossiers without friction. Environmental and safety documentation supports IBAMA licensing processes, while machining and installation guidelines conform to applicable NR safety norms.

Moreover, Sicarbtech’s quality systems leverage ISO 9001 methodologies, with statistical process control across critical steps. This rigor reduces variability and helps Brazilian operators achieve faster internal approvals.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Brazilian OEMs and industrial groups increasingly seek local capability for strategic components. Sicarbtech’s end-to-end technology transfer and factory establishment services are built for this need. The engagement begins with feasibility studies that assess demand, raw material availability, utilities, and regulatory factors. From there, Sicarbtech delivers complete process packages for R-SiC, SSiC, RBSiC, and SiSiC, including powder selection and preparation, forming methods such as CIP and iso-pressing, sintering and reaction bonding furnace curves, and finishing routines for tight tolerance components like mechanical seal faces.

Equipment specifications are detailed, from mixers and spray dryers to furnaces, grinders, and lapping machines, ensuring procurement teams have a clear, ABNT-aligned roadmap. Training programs cover operator skills, maintenance, metrology, and SPC methods, while documentation sets up ISO 9001 quality systems and can extend to ISO 14001 support for environmental management. Sicarbtech assists through commissioning and ramp-up, embedding ongoing technical support so yields stabilize quickly and cost targets are met.

This turnkey approach is reinforced by Sicarbtech’s R&D link with the Chinese Academy of Sciences (Weifang) Innovation Park, providing access to advanced microstructural characterization and process modeling. Because Sicarbtech controls the entire journey, from powder to finished part, feedback from Brazilian field performance is looped back into process parameters, creating a continuous improvement cycle. Competitors that only sell finished parts cannot easily match this depth. Over the past decade, Sicarbtech has supported more than 19 enterprises with measurable outcomes—extended wear life by 1.8×–3.2×, energy savings in the 1–3% range for critical rotating equipment, and faster qualification with major operators due to robust documentation.

As Dr. Joana S. Ribeiro, a consultant on ceramic manufacturing scale-ups, notes, “Successful localization depends less on the furnace brand and more on the reproducibility of green body quality and thermal profiles. When those are transferred as ‘living documents’ with SPC, the learning curve compresses dramatically.” (Source: Industrial Ceramics Scale-Up Review, 2024)

Comparative Use-Case Mapping for Brazilian Operations

Application-Driven Material Selection and Expected Outcomes

| Brazilian Scenario | Dominant Risks | Recommended SiC Grade | Engineering Focus | Tipik Sonuç |

|---|---|---|---|---|

| Carajás iron ore hydrocyclones | Erosion, turbulence | RBSiC / SiSiC | Inlet reprofile, apex reinforcement | 2× wear life, stable cut size |

| Pre-salt pump mechanical seals | Chloride corrosion, P–T cycling | SSiC | Micro-lapped faces, flatness control | Lower leak-off, API compliance |

| Fertilizer elbows and chutes | Corrosive abrasion | RBSiC liners | Thickness gradient, tile overlap | 50% wear reduction, predictable PM |

| High-temp kiln fixtures | Thermal shock | R-SiC | Low mass, thermal stability | Faster cycles, fewer cracks |

This mapping is the practical distillation of lab data into field success, tailored to Brazil’s environments and regulations.

Detailed SiC Grade Comparison for Local Specification Teams

Engineering Properties of R-SiC, SSiC, and RBSiC/SiSiC for Brazilian Buyers

| Parametre | SSiC | RBSiC / SiSiC | R-SiC |

|---|---|---|---|

| Open Porosity (%) | <0.5 | 10–16 | 10–20 |

| Elastik Modül (GPa) | 390–420 | 320–350 | 240–280 |

| Coefficient of Thermal Expansion (10^-6/K) | 4.0–4.5 | 4.0–4.5 | 4.0–4.5 |

| Termal Şok Direnci | Yüksek | Çok yüksek | Yüksek |

| Korozyon Direnci | Mükemmel | Çok iyi | İyi |

| Finish Capability (Ra, µm) | ≤0.02 with lapping | 0.1–0.4 typical | 0.2–0.5 typical |

| Typical Brazilian Applications | API-grade seals, precision bearings | Wear parts in mining, agro | Kiln furniture, filters |

| Cost-to-Value in Brazil | Premium, critical services | Balanced, high-wear | Efficient for thermal/structural |

The choice is rarely one-size-fits-all. Sicarbtech helps Brazilian engineers balance porosity, toughness, cost, and finish requirements against actual duty cycles and compliance constraints.

Future Market Opportunities and 2025+ Trends in Brazil

The next cycle of growth in Brazil will prioritize energy efficiency, reliability, and ESG outcomes. Mining majors are pursuing lower energy per ton metrics and exploring dry processing routes where feasible, intensifying demands on wear components. Offshore oil and gas is focusing on equipment that prevents emissions events and unplanned deferrals, while new FPSOs will specify tighter reliability targets in procurement. Agribusiness is scaling throughput with stricter hygiene and waste reduction, incentivizing materials that maintain smooth surfaces and dimensional stability across CIP cycles.

Macroeconomic dynamics will also steer decisions. Currency volatility encourages local content and process know-how transfer to reduce import exposure. Government incentives for reindustrialization and technology partnerships create an opening for Brazil-based SiC production cells serving regional clusters. Concurrently, digitalization and IIoT will accelerate predictive maintenance. Materials like SiC that hold tolerances and surface finish provide cleaner signals and longer warning times, enhancing the value of condition monitoring investments.

Analysts expect Brazil’s advanced technical ceramics market to grow in the mid-single digits annually through 2027, with SiC outpacing the average thanks to expansion in mining and sustained pre-salt development. Buyers will reward suppliers that pair demonstrable performance with documentation, training, and local readiness. In this context, Sicarbtech’s turnkey manufacturing, technology transfer, and application engineering are not just differentiators—they are prerequisites for capturing value in the 2025 procurement mindset.

Sıkça Sorulan Sorular

How does Sicarbtech align with Brazilian standards like ABNT NBR, ANP, and environmental requirements?

Sicarbtech structures material characterization and dimensional control to ABNT NBR norms and formats all test reports and traceability records to meet ANP procurement expectations, while oil and gas components are designed with API 610/682 and NACE MR0175/ISO 15156 in mind. Environmental and safety documentation supports IBAMA licensing and relevant NR workplace safety norms.

Can Sicarbtech support local production in Brazil through technology transfer?

Yes. We provide complete process recipes, equipment specifications, operator training, SPC frameworks, and commissioning support for R-SiC, SSiC, RBSiC, and SiSiC. The result is faster ramp-up, stable yields, and consistent quality aligned to Brazilian market needs.

What is the typical ROI timeline for upgrading to SiC components in mining?

Most mines see payback within 6–12 months due to longer wear life, fewer stoppages, and incremental energy savings. Exact timelines depend on slurry characteristics, baseline materials, and maintenance practices.

Which SiC grade is best for mechanical seal faces in pre-salt conditions?

SSiC typically offers the best balance of near-zero porosity, corrosion resistance, and surface finish capability. Final selection considers pressure-temperature cycles, counterface materials, and required flatness retention under load.

How does Sicarbtech handle documentation for vendor qualification with Brazilian operators?

We deliver comprehensive data packs, including chemical/physical property reports, NDT results, dimensional inspection, and process certifications. Documents are formatted for ABNT and ANP expectations, reducing approval lead time.

Can SiC components be integrated as drop-in replacements without system redesign?

Often yes. Sicarbtech frequently engineers SiC inserts and liners to match existing envelopes, while proposing minor geometry optimizations that improve performance without altering surrounding hardware.

What about maintenance and after-sales support within Brazil?

We offer remote engineering support, on-site assistance through local partners, and periodic performance reviews. Spare parts strategies are co-developed to mitigate logistics risk and align with harvest or shutdown windows.

Are there balanced-cost options for non-critical services?

RBSiC and R-SiC can deliver strong value in non-critical applications by trading some premium properties for cost efficiency. We model total cost of ownership to recommend the best fit.

What data is needed to start a custom SiC design?

Process media composition, particle size distribution, temperature and pressure ranges, current failure modes, target service life, and assembly drawings. We operate under NDA and follow a structured DfM workflow.

Does Sicarbtech support ISO certifications for newly established plants?

Yes. We help implement ISO 9001-aligned quality systems and can support ISO 14001 environmental management frameworks, including documentation, audits preparation, and continuous improvement protocols.

Operasyonlarınız için Doğru Seçimi Yapmak

Choosing SiC is fundamentally a decision to stabilize process economics and compliance. Sicarbtech brings the materials, the engineering discipline, and the turnkey manufacturing playbook needed to translate specifications into field results in Brazil’s exacting conditions. Whether your focus is hydrocyclones in Pará, mechanical seals on pre-salt platforms, or fertilizer handling in Mato Grosso, the combination of R-SiC, SSiC, RBSiC, and SiSiC—engineered and documented for local duty—delivers measurable, defensible value.

Uzman Danışmanlığı ve Özel Çözümler Alın

Speak with Sicarbtech’s engineering team to map a path from today’s wear and corrosion challenges to tomorrow’s predictable performance. We will align material selection, component design, and qualification documentation to ABNT, ANP, and IBAMA requirements while building a credible ROI case for your board.

Sicarbtech – Silicon Carbide Solutions Expert

E-posta: [email protected]

Phone: +86 133 6536 0038

Makale Meta Verileri

Last updated: 2025-09-22

Bir sonraki planlanan güncelleme: 2025-12-15

Content freshness indicators: 2025 Brazil market outlook integrated; ABNT/ANP/IBAMA references reviewed; three comparison tables updated; new Brazil-specific case insights added; technology transfer section expanded with ISO alignment.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.