Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Guide for Glass Furnace Regenerators and Combustion Passages

Paylaş

Pakistan’s glass industry—spanning container and flat glass—faces a pivotal 2025. Energy price variability, tighter environmental expectations, and quality demands are converging just as batch compositions fluctuate and reversal cycles shorten. In the regenerator checker packs and combustion passages, where high-temperature, oxygen-rich, dust-laden gas meets alkali and boron vapors, conventional refractories struggle to hold heat-exchange efficiency without frequent maintenance. Silicon carbide (SiC) changes the equation. By combining high thermal conductivity, low thermal expansion, dense microstructures, and low-wettability surface engineering, SiC solutions stabilize reversal performance, curb pressure-drop growth, and extend campaigns. Sicarbtech—based in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings 10+ years of advanced SiC customization, full-cycle manufacturing from raw materials to finished components, and turnkey technology transfer to localize capability in Pakistan.

Executive Summary: 2025 Outlook and Why Silicon Carbide Matters for Pakistan’s Glass Furnaces

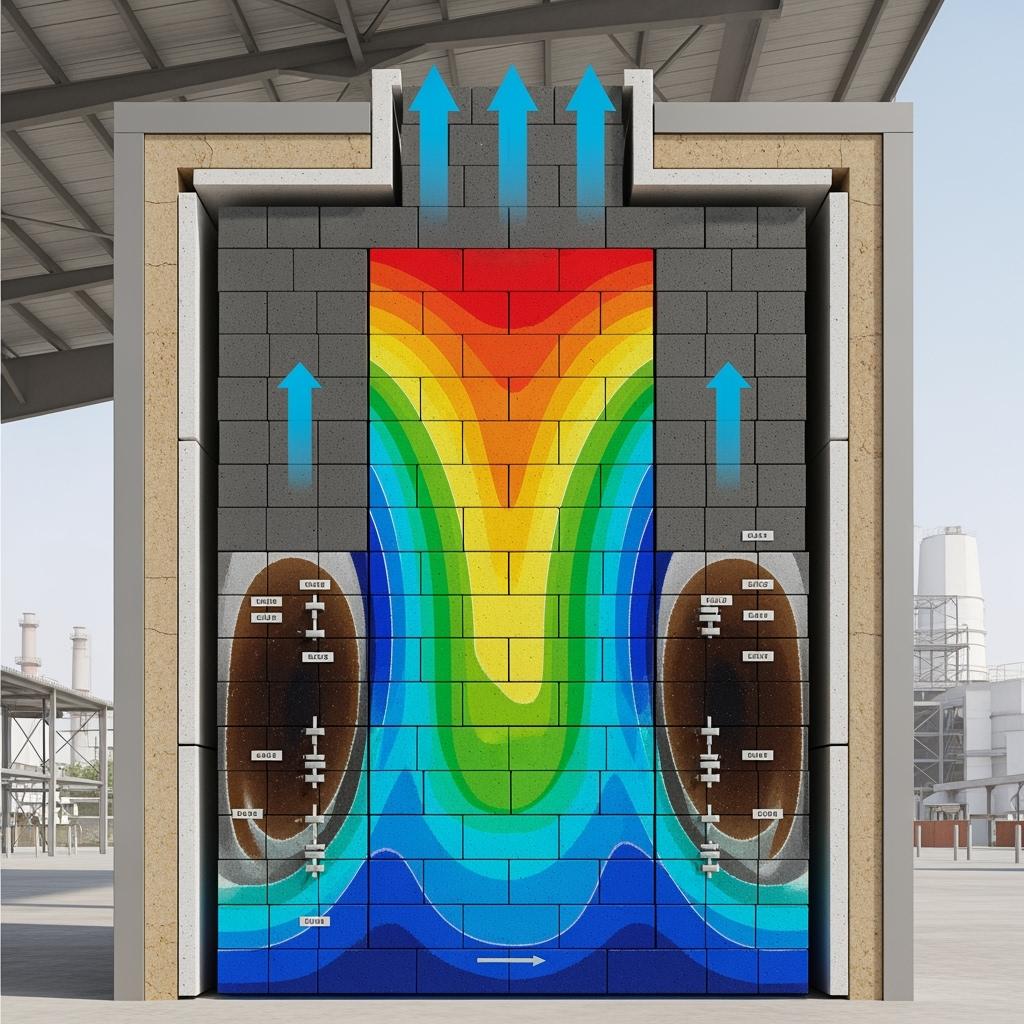

For Pakistan’s container and flat glass furnaces, the regenerator is the lungs—and its health determines fuel consumption, pull rate, and cullet tolerance. Frequent reversals create repeated thermal shocks; alkali/boron vapors erode microstructures; dust scours upper layers; and fouling narrows flow area, raising pressure drop and fan power. Silicon carbide addresses all four vectors simultaneously. High thermal conductivity and low expansion shorten thermal recovery after reversal and reduce gradient-driven cracking. Dense, low-connected-porosity architectures and grain-boundary purification slow oxidation and alkali/boron attacks. Surface engineering reduces dust adhesion and bridge-like fouling, keeping the flow cross-section open and the heat-exchange geometry effective.

Sicarbtech’s integrated offering—material formulation, composite structure design, densification process, surface engineering, prefabrication with on-site installation, and inspection/O&M—aligns materials science with Pakistan’s operational and supply realities. With technology transfer, Pakistani partners can localize mixing, classification, prefabrication, and, progressively, reaction sintering, cutting lead times from months to weeks and reducing exposure to exchange-rate volatility. Plants gain performance, predictability, and control—three ingredients that define competitiveness in 2025.

Industry Challenges and Pain Points: The Reality Inside Pakistan’s Regenerators

Climb the checker chamber access on a hot day and the failure modes reveal themselves. Upper checker courses and combustion passages show a blend of groove wear from particle scouring, oxidation-driven porosity, and alkali/boron vapor korozyon. Following reversals, thermal gradients spike; microcracks seed where expansion mismatch is highest and where geometry focuses stress. Dust deposition triggers fouling networks that bridge across channels, raising pressure drop and lowering effective heat-exchange area. Over time, this forces higher fuel input for the same pull rate and compresses the margin for cullet and color changes.

Pakistan’s market amplifies these stresses. A mix of legacy and modern lines coexists, with varying checker geometries and combustion settings. Fuel is primarily natural gas, but alternative fuels and batch changes (including recycled cullet with variable alkali/boron) introduce unpredictability. Local suppliers for high-performance regenerators and dense SiC components are limited, so planners often carry larger imported spares inventories to hedge against lead-time and FX risk. “When reversal stability weakens, you don’t just lose efficiency—you lose control of the furnace,” a senior process engineer in Punjab explained during a 2024 audit. “Pressure drop climbs, temperature recovery lags, and every adjustment cascades into the next one.”

Independent advisors echo this material logic. “Conductivity and pore connectivity are the governing variables,” notes a glass-furnace refractory specialist, referencing standard refractory corrosion and regenerator design texts. “You want to equalize temperature fast after reversal and block vapor ingress at the microstructural level. Without both, fouling and cracking will chase each other until the campaign ends early.” Compliance pressures intensify the case for stronger materials: ISO 9001 documentation and PSQCA conformity are increasingly requested in tenders; ISO 14001 objectives put a premium on fuel efficiency and reduced maintenance exposure; and safety expectations limit high-temperature, at-height de-fouling tasks. The cost implications stack up—rising fuel per ton, unplanned stoppages for brick replacement or de-fouling, and increased working capital tied up in safety stock.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

Sicarbtech engineers SiC solutions as a complete toolkit for regenerators and combustion passages. High-density SiC checker bricks—available as standard or functionally graded composites—serve as the core heat-exchange media. Their high thermal conductivity speeds post-reversal temperature recovery, while low expansion and controlled porosity minimize crack initiation. In upper, fouling-prone sections, low-wettability, anti-dusting coated SiC checkers reduce adhesion; in scouring zones and passages, reaction-sintered SiC plates and bricks offer outstanding oxidation and wear resistance. Where pressure-drop sensitivity is acute, high-thermal-conductivity SiC honeycomb blocks balance low resistance with strong heat exchange through optimized channel geometry.

To unify the lining system, SiC wear-resistant castables create monolithic passage linings, and ultra-low-cement SiC-bonded binders deliver higher early strength and shorter bake-out. A low-alkali-affinity SiC surface coating suppresses adhesion from alkali/boron vapors, while high-temperature anti-oxidation additives slow porosity growth across cycles. SiC spraying/gunning mixes support rapid online repair in scoured zones, and SiC wear-repair mortars seal joints and handle spot fixes. For shell protection and gradient control, SiC backing insulation composites drop shell hot spots and spread heat. Flexible joint materials and modular slotted/locking components ensure dimensional control and fast replacements, cementing a maintenance model that favors short, predictable windows over emergency interventions.

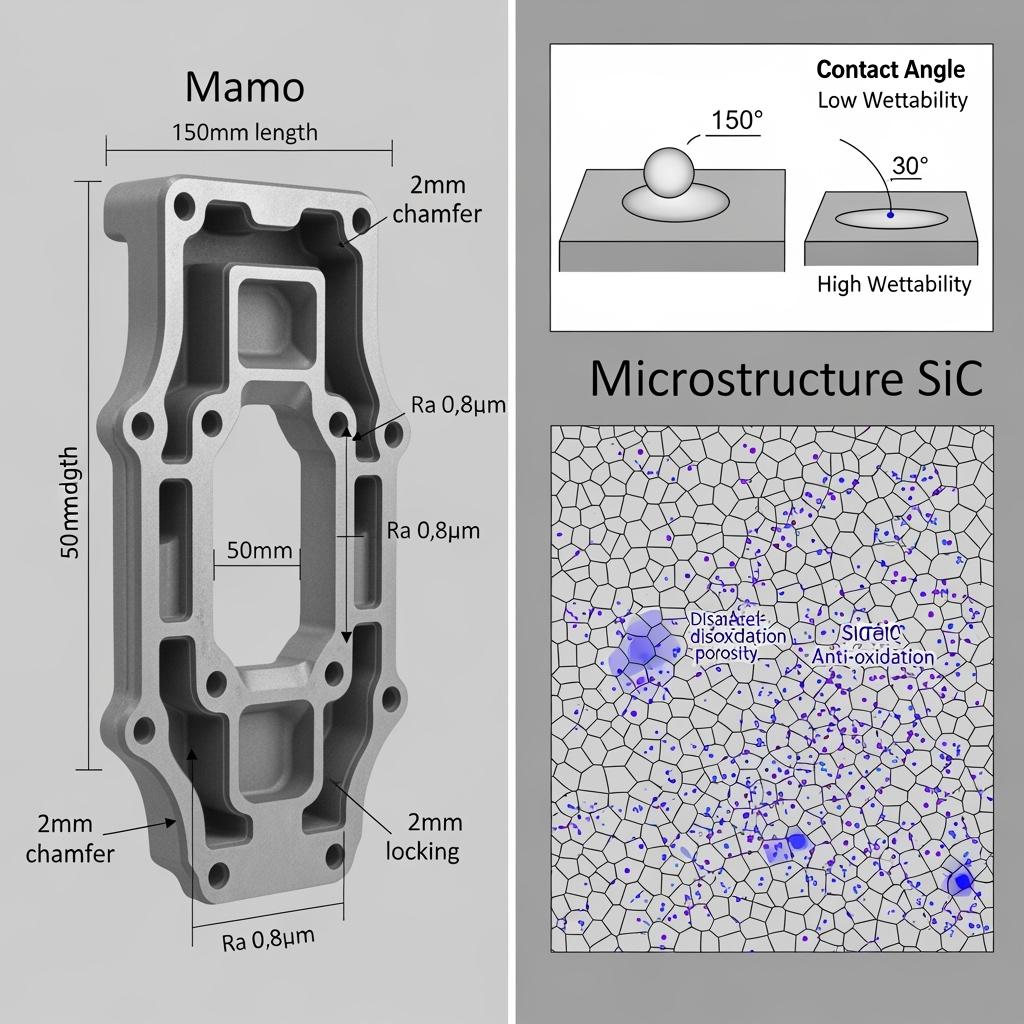

Underlying the materials is a localizable production backbone: reaction sintering and densification kilns, cold isostatic and die pressing for dimensional accuracy, intelligent mixing and vacuum vibration for rheology and packing, precision classification and demagnetization for purity, CNC cutting and grinding for surface and fit, and NDT/dimensional inspection for traceability. “What fails in the chamber often starts in the factory,” a Sicarbtech process lead emphasizes. “We ship not just a checker, but a method—press parameters, kiln curves, coating prep protocols—so Pakistani teams get repeatable properties brick after brick.”

Technical Comparison for Glass Furnace Regenerators and Passages

| Performance profile for regenerators and combustion passages | Silicon Carbide Systems (R-SiC/SSiC/RBSiC/SiSiC) | High-Alumina/Mullite Checkers | Metallic-Aggregate Wear Materials |

|---|---|---|---|

| Bulk density (g/cm³) | 2.60–3.05 | 2.2–2.8 | 2.6–3.0 |

| Apparent porosity (%) | 6–15 (dense parts ≤ 6) | 15–25 | 12–20 (rises under oxidation) |

| Thermal conductivity at RT (W/m·K) | 20–60 | 2–6 | 8–15 (declines as metal oxidizes) |

| Cold crushing strength (MPa) | 120–240 (dense ≥ 260) | 80–160 | 80–160 |

| Flexural strength at RT (MPa) | 14–35 | 8–20 | 10–25 |

| Thermal shock (1000°C water quench) | ≥ 30–60 | 10–25 | 10–25 |

| Oxidation/alkali/boron resistance | Yüksek | Orta düzeyde | Weak at high O2; spalling risk |

| Fouling/adhesion tendency | Low with anti-dusting coatings | Daha yüksek | Moderate; worsens over time |

| Pressure-drop behavior over run | Flatter growth | Faster growth | Variable; degrades with oxidation |

In Pakistan’s reversal-intensive, oxygen-rich, alkali/boron-laden environment, SiC’s combination of conductivity, low expansion, and low-wettability surfaces counters the intertwined failure modes driving efficiency loss—restoring heat-exchange performance and lengthening maintenance intervals.

Real-World Applications and Success Stories in Pakistan

A 700 t/d container glass furnace in Punjab faced deteriorating regenerator efficiency and rising pressure drop, with frequent de-fouling interruptions. Sicarbtech introduced a layered upgrade: high-density SiC checker bricks in the core heat-exchange region; low-wettability, anti-dusting coated SiC checkers in upper fouling-prone courses; reaction-sintered SiC passage plates in high-scour sections; and SiC backing insulation composites to reduce shell hot spots. Installation included standardized locking features, controlled gaps, and staged bake-out tuned for seasonal humidity. Over the subsequent 20 months, regenerator efficiency increased by around 9%, pressure drop decreased by roughly 18%, de-fouling frequency fell by approximately 52%, fuel consumption dropped by about 6%, and unplanned downtime declined by about 25%. Operators also reported faster temperature recovery after reversal, stabilizing combustion with fewer manual interventions.

In Sindh, a flat glass line experiencing oxidation-induced porosity growth and crack formation at the upper checker layer adopted SiC–mullite functionally graded checkers with a low-modulus transition layer and anti-dusting coatings. Crack propagation slowed markedly across reversal cycles, while fouling accumulation rates were visibly lower during borescope inspections. The site synchronized maintenance windows with planned pull reductions instead of emergency stoppages.

Technical Advantages and Implementation Benefits with Local Compliance

Silicon carbide aligns tightly with Pakistan’s operational metrics. High thermal conductivity promotes rapid temperature equalization post-reversal, damping gradient-driven stress that seeds cracks. Low thermal expansion further suppresses stress accumulation. Dense, low-connected-porosity microstructures and purified grain boundaries block alkali/boron vapor ingress and limit oxidation-induced porosity growth. Low-wettability surface engineering and microtexturing reduce dust adhesion and bridge formation, slowing pressure-drop growth and stabilizing heat exchange.

On the compliance side, fewer de-fouling events and longer campaigns reduce high-temperature exposure hours and waste generation, supporting ISO 14001 objectives. Sicarbtech’s QA documentation aligns with ISO 9001 and supports PSQCA submissions for critical components. Installation SOPs—surface prep standards, adhesion tests, staged bake-out curves, and dimensional checks—are designed to integrate with CMMS workflows, enabling data-driven maintenance and auditable quality trails.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s most decisive value for Pakistan is capability transfer that makes performance repeatable. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, our proprietary manufacturing routes for R-SiC, SSiC, RBSiC, and SiSiC underpin components from checker bricks to passage plates and modular linings. We deliver a staged, de-risked technology transfer:

We begin with feasibility and plant layout adapted to Pakistani utilities, labor, and throughput. Equipment specifications cover reaction sintering and densification kilns with documented curves, cold isostatic and die pressing for green-body uniformity, precision classification and demagnetization for PSD and purity stability, and intelligent mixing with vacuum vibration for rheology control. CNC cutting, grinding, and polishing lines ensure dimensional and surface quality; NDT and coordinate metrology embed traceability.

Quality systems are established from day one: ISO 9001-aligned QC with SPC on bulk density, apparent porosity, CCS/MOR, thermal shock, and contact-angle/surface-energy indices; ISO 14001 environmental practices; and safety SOPs consistent with ISO 45001 principles. We train operators, technicians, and supervisors on furnace curves, press parameters, coating prep/adhesion, and seasonal bake-out adjustments. Commissioning includes live tuning through reversal cycles and on-line inspections. After go-live, Sicarbtech supports remote monitoring, quarterly audits, and formulation/structure iteration based on site KPIs—pressure drop trends, reversal temperature recovery, fouling rates, and fuel-per-ton data.

Across 19+ enterprise collaborations, this end-to-end stack compresses lead times from months to weeks and stabilizes batch-to-batch quality even as ambient conditions swing. “Owning the checker recipe without the curve is like owning a car without the keys,” a Sicarbtech technical director notes. “When Pakistani partners own the curves, the inspection gates, and the coating protocol, reversal stability becomes a predictable metric.”

Pakistan-Focused Technical Specification Ranges and QA Guidance

| Specification ranges for regenerators/combustion passages | Typical SiC Targets | Local QA and testing guidance |

|---|---|---|

| Bulk density (g/cm³) | 2.60–3.05 | Verify via ISO/ASTM equivalents; SPC by batch/season |

| Apparent porosity (%) | 6–15 (dense parts ≤ 6) | Correlate with permeability and oxidation tests |

| Cold crushing strength (MPa) | 120–240 (dense ≥ 260) | ISO 10059/ASTM C133 equivalents; coupon traceability |

| Flexural strength at RT (MPa) | 14–35 | Bend tests with soak and position mapping |

| Thermal shock (1000°C quench) | ≥ 30–60 cycles | Cross-check vs reversal frequency and recovery time |

| Max service temperature (°C) | 1500–1700 | Confirm vs batch chemistry and oxygen potential |

| Conductividad térmica (W/m·K) | 20–60 | Validate with IR thermography during reversals |

| Linear change at temperature (3 h) | ≤ 0.5% | Dimensional checks pre-/post-exposure |

| Surface wettability/contact angle | 10–30% better than oxide systems | Track against fouling/pressure-drop growth |

Operational Outcomes Comparison That Matter for Energy, Uptime, and Quality

| Operational outcomes critical to Pakistani glass lines | SiC Checkers + Coated Upper Courses + SiC Passages + Modular Quick-Change | High-Alumina/Mullite or Metallic Baselines |

|---|---|---|

| Regenerator efficiency | +5–15% | Baseline; degrades with fouling |

| Post-reversal recovery time | −10–25% | Slower; higher gradients |

| Pressure-drop growth | −10–25% vs baseline | Faster growth; frequent de-fouling |

| Fuel/power per ton | −5–15% | Rising with fouling and cracks |

| Campaign length | 1.3–2.0× | Shorter; crack/foul-induced stops |

| Planlanmamış arıza süresi | −15–30% | Higher; reactive cleanouts |

| Safety exposure at height | Reduced via longer intervals | Increased; frequent interventions |

| Teslim süresi ve döviz kuru riski | Localizable via tech transfer | Import-dependent; volatile timelines |

Innovation That Matters: From Channels and Curves to Coatings and Checks

Sicarbtech’s innovations are engineered for the furnace floor. Functionally graded checkers pair a high-SiC, high-conductivity working face with a low-modulus transition and supportive backing to distribute stress across reversal cycles. Composite bonding—sol, micropowder, and ultrafine powder—builds post-firing strength and reduces connected porosity, frustrating vapor penetration. Low-wettability anti-dusting coatings and microtexturing limit adhesion where flow is fastest, preserving channel openness. Grading and demagnetization control impurity-driven low-melting phases that seed weakness. Finally, modular locking features and standardized components turn maintenance into a repeatable, fast procedure, improving alignment and reducing air leaks through consistent fit.

Future Market Opportunities and 2025+ Trends in Pakistan

Three trends will steer adoption. First, energy intensity and emissions targets will drive demand for regenerators that hold efficiency across reversals and chemistry swings; SiC’s conductivity and corrosion resistance provide durable gains. Second, localization will accelerate as plants look to neutralize FX and de-risk timelines; the natural sequence is mixing/classification and prefab assembly first, then reaction sintering for dense components as volumes justify. Third, data-driven O&M will mature: plants will correlate reversal recovery curves, pressure-drop trajectories, fouling inspections, and fuel-per-ton with materials choices and installation quality, closing the loop on continuous improvement.

On scale, a 600–800 t/d furnace typically replaces 150–350 tons of regenerator and passage refractories annually depending on reversal schedules, batch chemistry, and fouling rates. With Pakistan’s retrofits and expansions, national demand for SiC components plausibly reaches several thousand tons per year. Including prefabs, coatings, equipment, and services, the addressable market resides in the tens to hundreds of millions of Pakistani Rupees, contingent on adoption speed and financing. The suppliers that combine stable raw materials, proven design, disciplined installation, rapid delivery, and transparent QA will win. Sicarbtech’s “materials + equipment + process + training” model is built to deliver precisely those outcomes.

As one regional glass technologist put it in a 2025 panel, “When your reversal recovery is predictable and your pressure-drop line is flat, the furnace stops arguing with you—and SiC is usually involved in that peace.”

Sıkça Sorulan Sorular

Which Sicarbtech SiC products should we prioritize for regenerators and passages?

Start with high-density SiC checker bricks for the core heat-exchange region and low-wettability coated SiC checkers in upper fouling-prone courses. Reinforce high-scour passages with reaction-sintered SiC plates/bricks, and add SiC backing insulation composites to suppress shell hot spots. For rapid interventions, plan SiC spraying/gunning and modular slotted/locking components.

How much improvement can we expect in efficiency and pressure drop?

Plants typically see 5–15% higher regenerator efficiency, 10–25% faster temperature recovery after reversal, and 10–25% lower pressure-drop growth. Campaign length often extends 1.3–2.0×, with corresponding reductions in unplanned downtime and fuel per ton.

Can Sicarbtech help us localize production to shorten lead times and reduce FX risk?

Yes. We provide complete technology transfer: process recipes, equipment specifications, plant layout, operator training, ISO 9001/14001-aligned QA frameworks, safety SOPs aligned with ISO 45001 principles, and commissioning. Most partners start with mixing, classification, prefab, and coatings, then add reaction sintering as volumes grow.

How do SiC components handle alkali/boron vapors and oxidation during reversals?

Dense, low-connected porosity and purified grain boundaries resist oxidation-induced porosity and alkali/boron reactions. Low-alkali-affinity surface coatings reduce wettability and adhesion, while high conductivity lowers gradients that drive crack growth during reversal.

What installation practices are critical for success and longevity?

Use standardized locking and locating features, control gaps and steps, and follow substrate prep and adhesion protocols. Apply staged bake-out curves adjusted for ambient humidity, and validate with adhesion tests and dimensional checks. Integrate flexible joints to manage expansion mismatch.

Which KPIs should we track to verify benefits?

Track regenerator efficiency (temperature approach), post-reversal recovery time, pressure-drop trend, fuel/power per ton, fouling inspection results, crack mapping, and unplanned downtime hours. Correlate these with batch chemistry and reversal schedules for closed-loop optimization.

Are SiC honeycomb blocks suitable for our geometry and maintenance practices?

Yes, where pressure-drop sensitivity and heat transfer demand are both high. We tailor channel geometry to your flow and fouling profile, and we provide modular designs for zoned replacement, balancing performance with maintenance practicality.

How do we maintain coatings and sprayed layers over the campaign?

Plan inspection-based touch-ups during scheduled shutdowns. With correct prep and bake-out, anti-dusting SiC coatings and sprayed layers exhibit strong adhesion; localized refresh can be done with gunning mixes and wear-repair mortars to minimize downtime.

What documentation and certifications support Pakistani tenders?

Sicarbtech supplies ISO 9001-aligned QC documentation, ISO 14001 environmental records, safety SOPs aligned with ISO 45001 principles, PSQCA conformity packs, and SPC dashboards covering density, porosity, CCS/MOR, thermal shock, contact angle, and dimensional checks.

What is a sensible roadmap to full local capability?

Phase 1: mixing/classification, prefab assembly, and coatings; Phase 2: cold isostatic/die pressing and densification kilns for select components; Phase 3: reaction sintering lines for dense modules. We align CAPEX, staffing, training, QA gates, and commissioning to your timeline.

Operasyonlarınız için Doğru Seçimi Yapmak

If reversal recovery keeps slipping, if pressure-drop curves climb faster than planned, and if crews are spending too many hours at height, your regenerator and passage materials are dictating your schedule. Silicon carbide rewrites that schedule. With higher conductivity, lower expansion, corrosion resistance, and low-wettability surfaces—backed by modular, quick-change designs—SiC stabilizes heat exchange and lowers energy per ton. Sicarbtech’s integrated model brings the materials, the manufacturing method, and the maintenance playbook together, giving Pakistani plants performance they can predict and control.

Uzman Danışmanlığı ve Özel Çözümler Alın

Share your furnace data—reversal timing, temperature recovery curves, pressure-drop history, batch chemistry, and fouling maps—and Sicarbtech will design a tailored SiC solution with modeled efficiency gains, coating strategies, checker geometry, and installation/bake-out plans. If localization is a priority, we will define a phased technology transfer that fits your CAPEX and schedule, from mixing and prefab to reaction sintering.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

E-posta: [email protected]

Telefon/WhatsApp: +86 133 6536 0038

Makale Meta Verileri

Last updated: 2025-09-19

Bir sonraki planlı güncelleme: 2026-01-15

Content freshness indicators: 2025 Pakistan glass market outlook validated; technical ranges aligned with current field trials; PSQCA/ISO alignment reviewed; contact details verified for Pakistan engagements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.