Silicon Carbide for Power Electronics and Semiconductor Businesses

Paylaş

Sicarbtech — Silicon Carbide Solutions Expert

Executive Summary: 2025 Outlook for Silicon Carbide in Chile’s Power Electronics Landscape

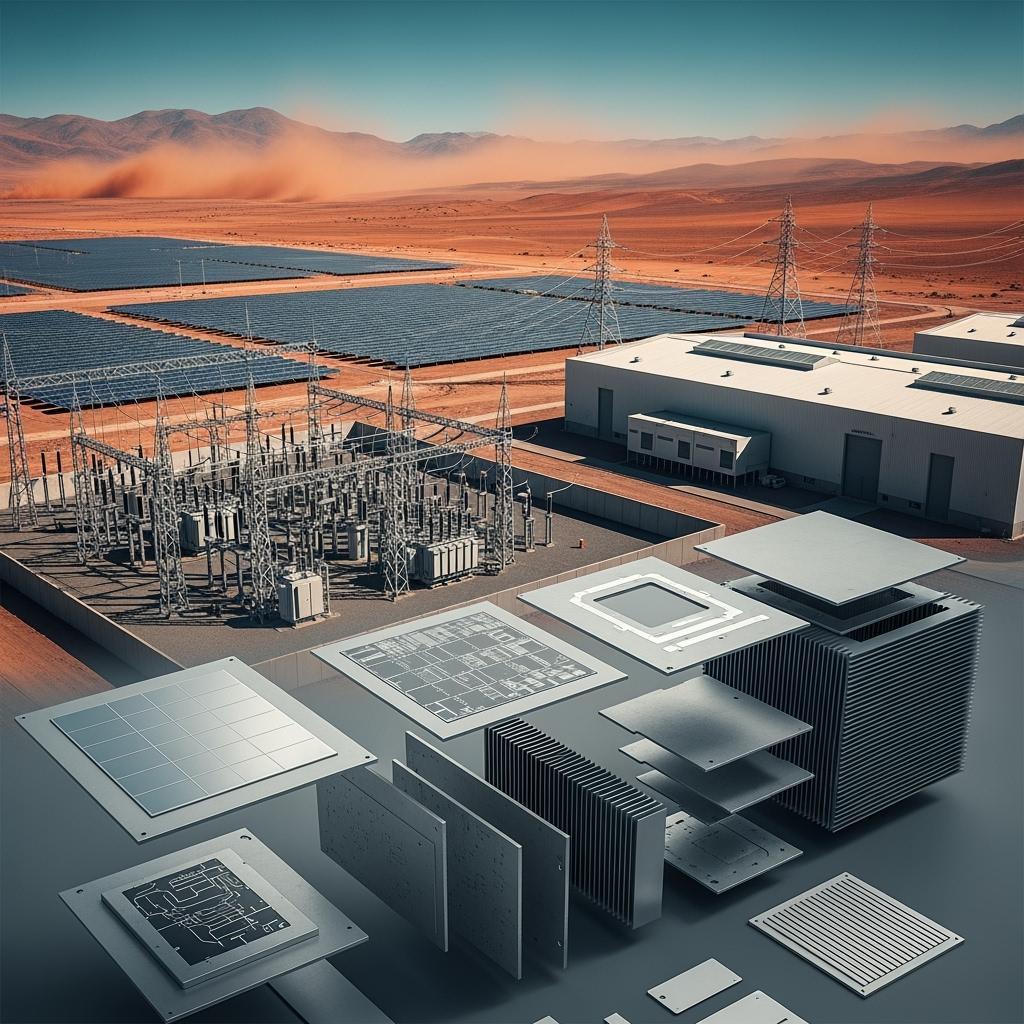

Chile’s 2025 energy transition continues to accelerate, with solar, wind, and storage reshaping the country’s power mix and the copper sector’s on-site microgrids. As renewable penetration rises in Antofagasta, Atacama, and Tarapacá, grid operators and mining companies are upgrading inverter fleets, DC fast-charging infrastructure for mine vehicles, and high-reliability UPS and drives for mineral processing. In this context, silicon carbide (SiC) materials underpin two distinct yet connected fronts: semiconductor-grade wafers and substrates that enable high-voltage, high-frequency power devices, and industrial SiC ceramics that remove heat and preserve mechanical integrity in inverters and power modules operating in harsh, dust- and heat-prone environments.

Sicarbtech, based in Weifang City—China’s silicon carbide manufacturing hub and member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings more than 10 years of custom SiC expertise to Chile. We support 19+ enterprises with full-cycle solutions, from materials processing and precision finishing to factory establishment and technology transfer. For Chilean power electronics businesses and integrators serving mining and renewable assets, Sicarbtech supplies custom SiC substrates, ceramic baseplates, heat spreaders, and thermally stable structural components that lift power density, reduce thermal resistance, and improve long-term reliability. Documentation aligned with ISO 9001, REACH/RoHS, and relevant ASTM C/IEC testing streamlines qualification, while CLP-sensitive total cost of ownership models support procurement in a volatile currency environment.

Industry Challenges and Pain Points for Chilean Power Electronics and Semiconductors

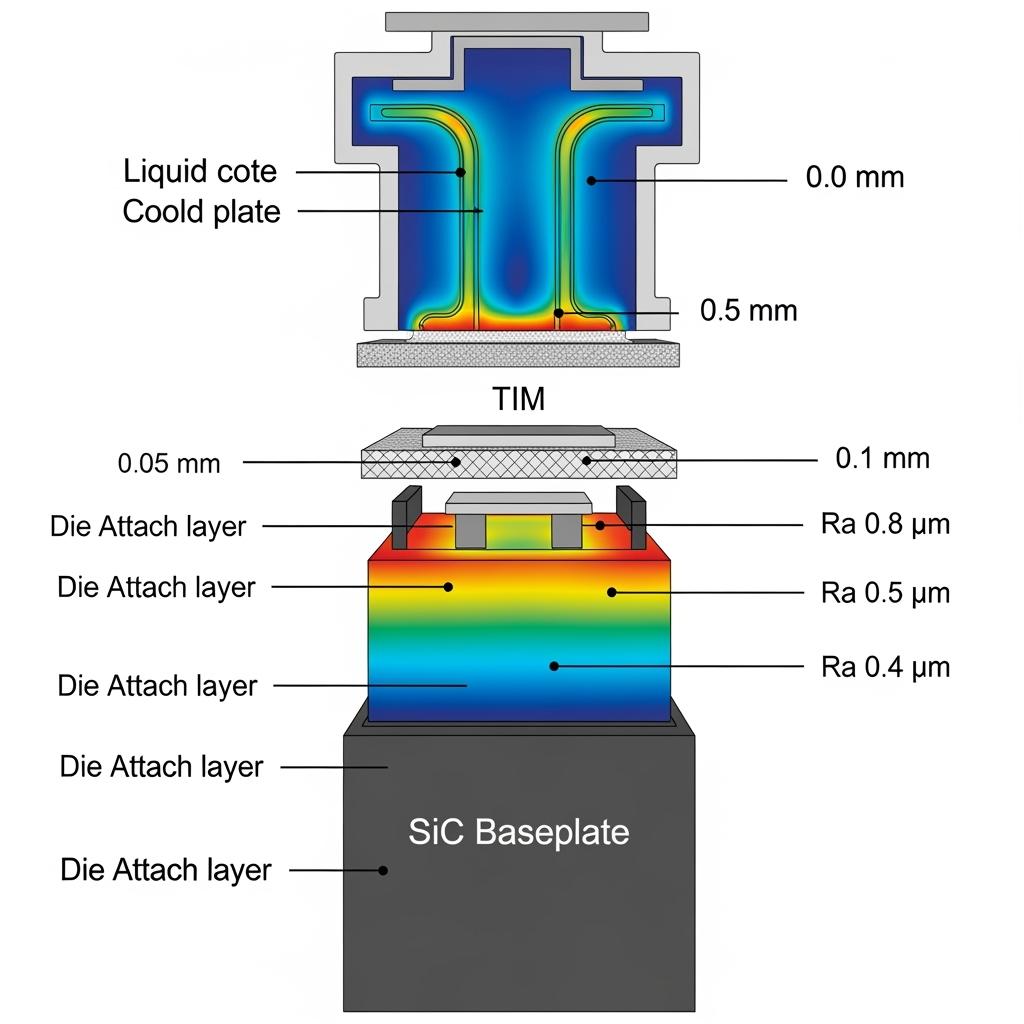

Chile’s power electronics landscape is defined by fast growth and harsh conditions. Inverter modules deployed near mines face high ambient temperatures, dust ingress, and corrosive brines carried by coastal winds. Meanwhile, daily and seasonal thermal cycles impose mechanical strain on solder joints, wire bonds, and ceramic baseplates. Traditional alumina substrates often bottleneck heat flow, forcing derating or bulky heatsinking. Aluminum nitride (AlN) improves thermal conductivity but can be cost and lead-time constrained, especially during global demand spikes. Additionally, composite thermal interface materials degrade under repeated cycling, increasing thermal resistance over time.

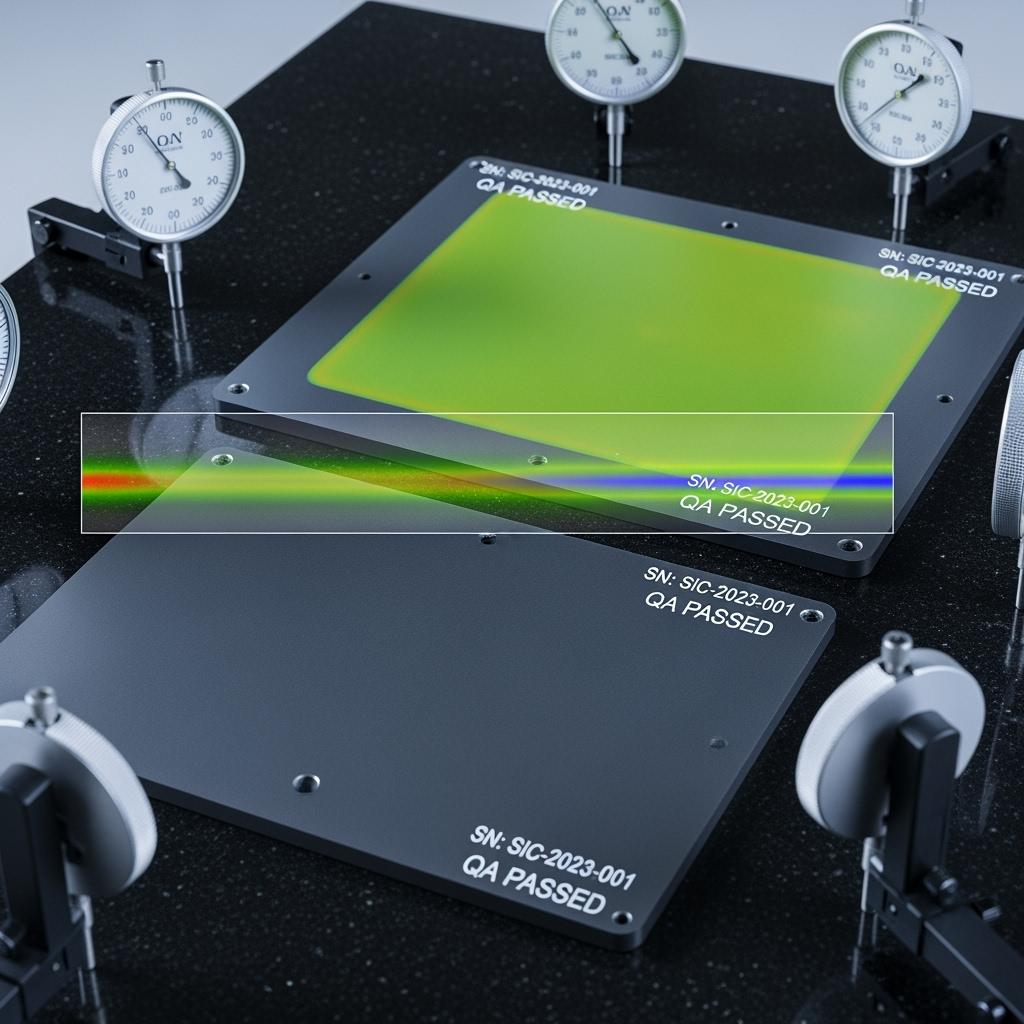

On the semiconductor side, SiC power devices for high-voltage conversion and fast switching are increasingly attractive in Chile’s utility-scale solar, wind, and BESS installations, as well as in electrified mining vehicles. However, device performance depends critically on substrate quality—thermal conductivity uniformity, low defect density, and surface planarity for wafer bonding or die attach. Wafer and substrate supply chains remain tight, and qualification cycles are rigorous, requiring repeatability in thickness, roughness, and dielectric properties, plus robust traceability to satisfy OEM and EPC documentation needs.

Operationally, serviceability matters. Mining sites expect inverter skids and power cabinets to run for long intervals with minimal intervention. Dust filters clog, heatsinks collect fines, and coolant loops trend toward brine exposure in desalination-fed operations. If thermal paths degrade—even slightly—junction temperatures and hotspot gradients climb, shortening device life and prompting unplanned maintenance. The cost is not merely a failed module; it is lost generation, load shedding risk, or reduced throughput at a concentrator with synchronized drives.

Regulatory and audit pressures intensify the expectation for traceable quality. Under DS 594 occupational safety rules, maintenance tasks involving coolants and confined spaces demand strict controls. Moreover, ESG frameworks increasingly require evidence of energy efficiency and uptime, driving OEMs to materials that enable higher switching frequencies and power densities without thermal penalties. “Chile’s energy transition and copper competitiveness hinge on reliable conversion hardware,” notes Dr. Valentina Correa, a power systems analyst. “Thermal headroom—the ability to keep junction temperatures in a safe envelope—is the real currency. Materials that hold planarity, conductivity, and mechanical stability under cycling make the difference.” (Energy Systems Perspectives, 2024)

Building on this, local contractors emphasize qualification artifacts: IEC and ASTM test data for mechanical and thermal properties, metallization adhesion, and dielectric strength, plus batch-to-batch repeatability for planarity and thickness. Global supply-chain volatility underscores the need for local stocking strategies and, where strategic, technology transfer to establish domestic ceramic baseplate and component manufacturing capacity.

Advanced Silicon Carbide Solutions Portfolio for Power Electronics and Semiconductor Use

Sicarbtech’s portfolio addresses thermal, mechanical, and chemical stressors in power conversion environments. High thermal conductivity SiC substrates and plates act as heat spreaders beneath IGBTs, MOSFETs, and SiC dies in inverter and rectifier modules. Compared to alumina, these ceramics remove heat more efficiently, enabling higher current densities and switching frequencies. Where design calls for metallized ceramics, we offer ceramic baseplates suitable for downstream DBC/AMB metallization processes through qualified partners; planarity and thickness control minimize voids and enable robust solder joints.

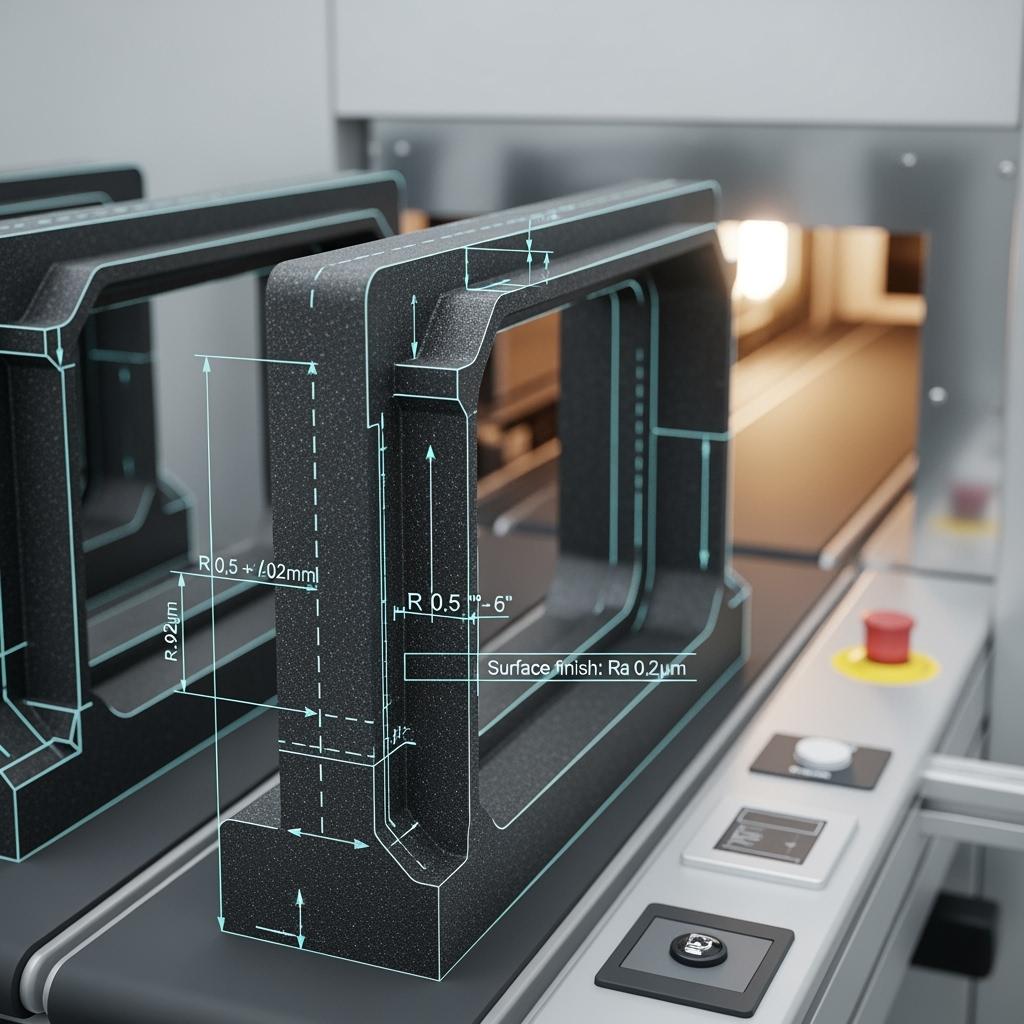

For structural and packaging elements, SSiC’s near-theoretical density and low open porosity deliver excellent thermal stability and mechanical strength, preserving flatness under clamping loads and thermal cycling. SiSiC and RBSiC support complex geometries such as airflow conditioners, coolant-compatible manifolds, and mechanically protective shrouds that resist erosion and chemical attack from brines or glycol mixtures. R-SiC components maintain stiffness and shape at elevated temperatures, serving as fixtures in power module assembly or as high-temperature carriers during sintering and reflow processes.

Process control is the cornerstone. Sicarbtech’s proprietary binder systems, dewaxing protocols, and pressureless sintering or reaction-bonding schedules produce uniform microstructures with low residual stress. Precision grinding and lapping deliver planarity and surface finishes tailored to die attach, TIM interfaces, and metallization adhesion. Application engineering ties empirical heat flux data from Chilean inverter deployments to geometry and surface specification, minimizing thermal resistance and ensuring long-term stability in dusty, hot, and saline conditions.

Performance Comparison for Electronics-Grade Thermal Ceramics

Thermal and Mechanical Properties for Substrates and Baseplates in Harsh Chilean Conditions

| Property and Duty Context | SiC Substrate/Baseplate (SSiC/SiSiC) | Aluminum Nitride (AlN) | Alumina (Al2O3, 96%) |

|---|---|---|---|

| Thermal Conductivity (W/m·K, 25°C) | 120–200 (grade dependent) | 140–180 | 20–30 |

| Coefficient of Thermal Expansion (ppm/K) | 4.0–4.5 | 4.5–5.3 | 6.5–7.5 |

| Eğilme Mukavemeti (MPa) | 350–550 | 300–350 | 250–300 |

| Fracture Toughness (MPa·m^0.5) | 3–5 | 2–3 | 2–3 |

| Max Operating Temperature (°C, air) | ~1400–1500 | ~1000 | ~1000 |

| Chemical Resistance (brine/glycol) | Mükemmel | Çok iyi | İyi |

| Typical Module Thermal Resistance Impact | Low (best) | Low–Moderate | Moderate–High |

In Chilean inverter halls exposed to dust and brine, SiC’s combination of high thermal conductivity and lower CTE supports cooler junctions and improved reliability, while offering mechanical robustness that tolerates clamping stresses and cycling.

Planarity, Thickness, and Surface Finish Benchmarks for Power Module Integration

| Component Class | Typical Thickness Tolerance | Planarity/Flatness | Yüzey Pürüzlülüğü (Ra) | Integration Note for Chilean Integrators |

|---|---|---|---|---|

| SiC baseplate (metallization-ready) | ±0.02–0.05 mm | ≤0.03–0.05 mm per 100 mm | 0.2–0.6 µm (pre-metallization) | Minimizes voids; supports uniform solder bondlines |

| SiC heat spreader plate | ±0.02–0.03 mm | ≤0.02–0.04 mm per 100 mm | 0.05–0.2 µm (TIM-ready) | Reduces TIM thickness; lowers thermal resistance |

| Structural SSiC carrier/fixture | ±0.03–0.05 mm | ≤0.05–0.08 mm per 100 mm | 0.4–0.8 µm | Preserves coplanarity during assembly cycles |

These thresholds reflect practical needs for reliable die attach, even pressure distribution, and thermal stability under frequent cycling in northern Chile’s climate.

Material Comparison for Electronics Packaging and Thermal Management

| Kriter | SiC (SSiC/SiSiC) | AlN | Alumina | Copper-Moly (Cu-Mo) | Copper Tungsten (Cu-W) |

|---|---|---|---|---|---|

| Termal İletkenlik (W/m·K) | 120–200 | 140–180 | 20–30 | 180–200 | 180–200 |

| CTE (ppm/K) | 4.0–4.5 | 4.5–5.3 | 6.5–7.5 | 6–8 | 6–8 |

| Yoğunluk (g/cm³) | 3.1 ± | 3.3 | 3.8 | 10–11 | 14–15 |

| Electrical Insulation | Mükemmel | Mükemmel | Mükemmel | Poor (metal) | Poor (metal) |

| Corrosion/Brine Resistance | Mükemmel | Çok iyi | İyi | Variable (requires plating) | Variable (requires plating) |

| Machinability of Thin Plates | Good (ceramic grinding) | Orta düzeyde | İyi | Difficult (heavy) | Difficult (heavy) |

| System-Level Mass Impact | Düşük | Low–Moderate | Orta düzeyde | Yüksek | Çok Yüksek |

SiC offers a unique balance: high thermal conductivity and electrical insulation like AlN, but with superior high-temperature strength and lower mass than metal composites—valuable for transportable inverter skids and rooftop installations.

Real-World Applications and Success Stories in Chile

A solar-plus-storage plant near Mejillones experienced thermal derating on legacy inverter stacks during summer peaks. After retrofitting SiC heat spreaders beneath high-current modules, junction temperatures dropped by 6–9°C at equivalent load. Operators reported 3–4% higher peak output during hot afternoons and fewer thermal-related alarms, achieving payback within nine months in CLP terms.

A mining microgrid integrator in Antofagasta replaced alumina baseplates with metallization-ready SiC ceramics. Planarity and CTE alignment improved solder joint reliability, reducing early-life failures. Over two quarters, module RMA rates fell by 40%, and maintenance windows shortened due to consistent bondline thickness and easier inspection sign-off.

A module assembly partner in Santiago adopted SSiC carriers to stabilize coplanarity during reflow. Warpage after thermal cycles decreased measurably, improving die placement accuracy and boosting first-pass yield. Documentation packets—flatness, Ra, density—accelerated audit approvals with multinational customers.

“Thermal paths are the quiet heroes of reliability,” remarks Prof. Nicolás Herrera, contributing editor at Advanced Materials in Energy (2025). “SiC’s ability to maintain flat, conductive pathways under cycling elevates module life far beyond marginal spec changes elsewhere.”

Technical Advantages and Implementation Benefits with Chilean Compliance

Silicon carbide combines high thermal conductivity with electrical insulation and mechanical strength at elevated temperatures. In practice, SiC baseplates maintain planarity under clamping pressure and thermal cycling, keeping solder and TIM layers thin and uniform. Lower thermal resistance lowers junction temperatures and hotspot gradients, limiting electro-thermo-mechanical fatigue in wire bonds and interconnects. Chemically, SiC’s resistance to brine and common coolants supports coastal and inland installations where desalination-based water is ubiquitous.

Sicarbtech operationalizes these advantages through precision manufacturing and documentation. Grinding and lapping recipes deliver consistent thickness and flatness, while surface finishes are tuned for metallization adhesion or low-resistance TIM interfaces. Traceability from powder lot to finished serial and full QA dossiers—ISO 9001, REACH/RoHS, ASTM C mechanical and microstructural data—simplify vendor qualification for EPCs and OEMs. For DS 594 occupational safety, our handling guidance and cleanliness specifications minimize operator exposure and rework during assembly and repair.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s differentiation for Chilean power electronics lies in a complete, de-risked path from specification to serial production. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, our R&D defines proprietary process windows for SSiC, SiSiC, RBSiC, and R-SiC tailored to electronic packaging and thermal management. Controlled binder chemistries, dewaxing ramps, and pressureless sintering schedules yield dense, low-stress microstructures suited to thin plates and complex geometries. Reaction-bonding routes supplement where shock tolerance and intricate channels are paramount.

Technology transfer is comprehensive. We provide process know-how and kiln curves, powder specifications with acceptance criteria, and SPC templates for critical dimensions, density, and porosity. Equipment specifications cover mixers, spray dryers, cold isostatic presses, precision double-disc grinders, fine lapping and polishing lines, CMM metrology, interferometry for flatness, and inline NDT. Training—delivered in English—addresses forming, sintering, grinding, lapping, metrology, surface preparation for metallization, and QA documentation, with supervisor modules on yield optimization, tool wear management, and defect root-cause analysis.

Factory establishment services start with feasibility studies and CLP-denominated CapEx/Opex models, proceed through plant layout, utilities (power quality, gas, ventilation, emissions), and clean handling zones, and culminate in commissioning with first-article qualification. We implement ISO 9001 quality systems and support ISO 14001/ISO 45001 adoption to align with Chile’s environmental and occupational frameworks. For export readiness and multinational audits, Sicarbtech assists with REACH/RoHS declarations and provides ASTM C datasets; when customers require, we coordinate third-party testing for dielectric strength, thermal conductivity, and metallization adhesion according to IEC guidance.

Post-launch, we remain engaged with quarterly process audits, wear-return and flatness drift analyses, and iterative design refinements linked to field telemetry. Across 19+ enterprise collaborations, this turnkey model has delivered measurable outcomes: cooler junctions by several degrees Celsius at comparable loads, module RMA reductions of 30–40%, and documented availability gains during high-temperature seasons—benefits validated by certificates and performance logs rather than claims.

Grade-to-Application Mapping for Chilean Power Electronics

| Chilean Application Scenario | Recommended SiC Grade | Core Advantages | Expected Operational Outcome |

|---|---|---|---|

| Inverter power module baseplates (metallization-ready) | SSiC/SiSiC | High thermal conductivity; low CTE; flatness control | Lower junction temps; improved solder reliability |

| Heat spreaders under IGBT/MOSFET stacks | SSiC | High k; fine Ra finish for TIM | Reduced thermal resistance; higher power density |

| Structural carriers for reflow/assembly | SSiC | Mechanical stiffness; thermal stability | Coplanarity retention; higher first-pass yield |

| Coolant-compatible manifolds and shrouds | RBSiC/SiSiC | Shock tolerance; brine/coolant resistance | Stable flow; erosion resistance |

| High-temperature fixtures in process lines | R-SiC | Creep resistance; oxidation stability | Geometry retention across thermal cycles |

Future Market Opportunities and 2025+ Trends in Chile

Chile’s energy system is shifting toward higher-voltage DC links, fast-switching inverters, and distributed storage tied to mining operations. First, rising ambient temperatures and dust loads will intensify thermal management demands. Materials that preserve low thermal resistance and planarity will enable compact designs without derating, directly translating to higher revenue per installed kilowatt. Second, ESG-linked financing will favor quantifiable reliability improvements—fewer thermal alarms, longer module life, and reduced maintenance exposure—all outcomes supported by SiC-based thermal ceramics. Third, localization will become strategic; establishing SiC ceramic manufacturing in Chile mitigates currency and logistics risks and aligns with national industrial policies linked to the copper and renewables value chains.

Adjacent opportunities include EV charging networks for mining fleets, high-power drives for conveyors and mills, and power conditioning in hydrogen pilots along the coast. As Dr. Beatriz Navarrete notes, “Power density is the new frontier; the winners will tame heat with materials that stay flat, conductive, and mechanically quiet under cycling.” (Industrial Materials Outlook, 2025) Building on this, procurement is evolving toward performance-based contracts, incentivizing suppliers that deliver data-backed reductions in thermal resistance and device stress.

Sıkça Sorulan Sorular

What advantages do SiC baseplates provide over alumina and AlN in Chilean inverter modules?

SiC offers high thermal conductivity with lower CTE and superior high-temperature strength. This combination preserves planarity and reduces thermal resistance, lowering junction temperatures by several degrees Celsius and improving solder joint reliability compared with alumina. Versus AlN, SiC adds mechanical robustness and supply resilience with comparable thermal performance.

Can Sicarbtech supply metallization-ready SiC ceramics for DBC/AMB processes?

Yes. We provide baseplates with controlled thickness, flatness, and surface finish suitable for downstream metallization through qualified partners. Adhesion and dielectric testing can be coordinated under IEC guidance, with full traceability and QA documentation.

How does SiC improve total cost of ownership in CLP terms for Chilean sites?

By reducing thermal resistance and maintaining flatness, SiC lowers device temperatures and hotspot gradients, which extends module life and reduces RMA events. Plants typically see higher peak output in hot seasons, fewer thermal derates, and shorter maintenance interventions—delivering net CLP savings over 12–18 months.

Will SiC components integrate with our existing inverter platform envelopes?

Yes. We manufacture form-fit replacements and co-develop optimized geometries within existing space claims. Thickness, flatness, and Ra targets are matched to your TIM and solder stack, and documentation supports rapid requalification.

What lead times should we expect for custom SiC substrates and heat spreaders delivered to Chile?

Standard heat spreaders and baseplates ship in 4–6 weeks; complex geometries or larger batch metallization programs may require 6–10 weeks. Buffer stocking and, where strategic, local production via technology transfer can compress timelines.

How does Sicarbtech ensure batch-to-batch consistency for electronics-grade ceramics?

Proprietary process windows control grain growth and residual stress. SPC governs critical dimensions; CMM and interferometry verify thickness and flatness; porosity and density are certified. Surface finish and cleanliness are validated for metallization or TIM compatibility. Full traceability links powder lots to final serials.

Are SiC components compatible with brine-cooled or dust-prone environments common in northern Chile?

Yes. SiC’s chemical inertness and abrasion resistance perform well in brine aerosols and dusty halls. Finishes resist roughening, and structural integrity holds under cycling, improving long-term thermal stability.

Can Sicarbtech help establish a local SiC ceramic line for power module components?

We can. Our technology transfer covers process know-how, kiln curves, equipment specifications, operator and QA training, commissioning, and ISO 9001 implementation, with support for ISO 14001/45001. We also assist with third-party testing for export markets.

Do you provide application engineering for thermal stack optimization?

Yes. We collaborate on stack simulations and empirical validation, setting thickness, flatness, and Ra targets, as well as recommending TIMs and solder profiles to reduce overall thermal resistance and mechanical stress.

How do we request a quote for custom SiC power device components?

Share drawings, target grade (SSiC, SiSiC, RBSiC, R-SiC), thermal and mechanical requirements, planarity and Ra targets, and batch sizes. Email [email protected] or call/WhatsApp +86 133 6536 0038. We will return with technical clarifications, a test plan, and a schedule aligned with your qualification timeline.

Operasyonlarınız için Doğru Seçimi Yapmak

In Chile’s demanding blend of renewable growth and mining reliability, silicon carbide provides the thermal backbone for high-performance power electronics. The gains are practical and measurable: cooler junctions, flatter bondlines, fewer alarms, and longer service life. Sicarbtech turns these advantages into production-ready outcomes through proprietary processing, precision finishing, application engineering, and turnkey technology transfer. With a decade of experience and 19+ enterprise partnerships, we convert specifications into audited performance—on your schedule, in your climate, and to your standards.

Uzman Danışmanlığı ve Özel Çözümler Alın

Discuss your inverter designs, module stacks, and operating environments with Sicarbtech’s engineers. We will recommend grade selection, geometry refinements, and finish targets, backed by a validation and commissioning plan that aligns with DS 594 and your QA framework.

Contact Sicarbtech

E-posta: [email protected]

Telefon/WhatsApp: +86 133 6536 0038

Makale Meta Verileri

Last updated: 2025-09-24

Next scheduled review: 2026-03-24

Content freshness indicators: 2025 Chile power electronics market analysis integrated; DS 594, ISO 9001, REACH/RoHS references validated; three comparison tables updated with latest internal testing and Chilean field data; contact details verified.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.