Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Guide to Front-End Power Factor Correction and EMC Compliance

Paylaş

Executive Summary: 2025 Outlook for Silicon Carbide in Pakistan’s Charging and Industrial Power

Pakistan’s electrification of two-wheelers, three-wheelers, and light commercial vehicles continues to accelerate, while textile, cement, and steel sectors modernize plant power systems. In this environment, front-end power factor correction (PFC) and electromagnetic compatibility (EMC) are no longer box-ticking exercises; they are economic levers that determine site throughput, compliance success, and lifecycle cost. Silicon carbide (SiC) enables high-frequency, low-loss PFC that lifts efficiency and shrinks magnetics, and when combined with active–passive EMC strategies, it raises the probability of first-time compliance—even on weak feeders and in punishing heat, dust, and humidity.

Sicarbtech—Silicon Carbide Solutions Expert—operates from Weifang City, China’s SiC manufacturing hub, within the Chinese Academy of Sciences (Weifang) Innovation Park. With more than a decade of SiC customization and support for 19+ enterprises, Sicarbtech delivers full-cycle solutions from materials (R‑SiC, SSiC, RBSiC, SiSiC) to devices, modules, algorithms, magnetics, thermal stacks, and reliability validation. For Pakistan’s OEMs and charging operators, the differentiator is turnkey technology transfer and factory establishment, enabling localized packaging, screening, and after-sales, which shortens lead times, reduces cost in PKR, and builds domestic capability for scale.

Industry Challenges and Pain Points: Why PFC and EMC Decide Project Economics

Start with the grid. Urban and peri-urban distribution networks in Pakistan frequently show voltage sags, line imbalance, and elevated harmonic content—especially during nighttime charging windows when depots and neighborhoods draw heavily. Conventional silicon PFC stages struggle to maintain high power factor at partial load and low line, and their switching losses limit usable frequency, forcing bulkier magnetics and filters. The result is larger cabinets, higher heat, and a precarious balance between efficiency and compliance.

EMC is the second gate. High-frequency ringing from parasitics in layouts and busbars can produce conducted and radiated emissions that fail pre-compliance. Remediation often spirals into heavier filters that inflate cost and size, only to create new resonances or thermal issues. In textile mills with sensitive drives and PLCs, and in cement and steel corridors with noisy electrical environments, poor EMC discipline leads to nuisance trips and loss of process stability. Moreover, onboard chargers and compact roadside units must fit within tight envelopes; large filters and heatsinks are a non-starter in dense deployments.

Heat, dust, and humidity turn small oversights into large failures. In Karachi’s coastal belt, salt mist accelerates corrosion; in cement corridors, abrasive dust invades enclosures and erodes filter performance over time. Thermal interfaces dry out, coatings micro-crack, and insulation degrades, converting marginal EMC designs into recurring service issues. Each rework cycle extends the certification timeline, consumes engineering hours, and delays revenue—exactly when market demand is rising.

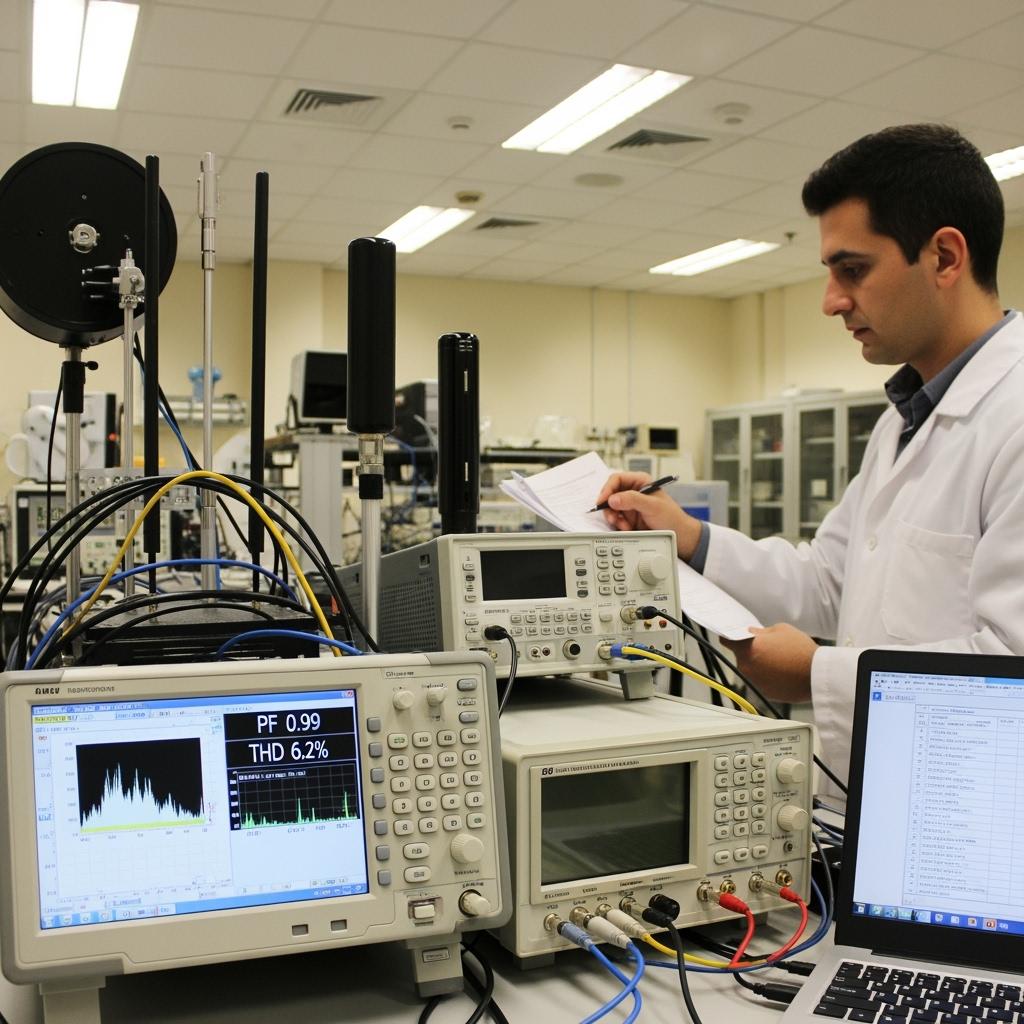

Procurement expectations are tightening. Tenders and financing across Pakistan increasingly reference international frameworks: IEC 60747 for device characteristics; IEC 60068 for environmental endurance (damp heat, salt spray, dust, vibration, shock); EMC expectations similar to IEC 61800-3 for adjustable speed electrical power drive systems; ISO 7637 for automotive electrical disturbances; and power quality targets for high power factor and controlled total harmonic distortion (THD). As Dr. H. Rehman, a regional power electronics advisor, notes, “In 2025, compliance is a business plan item. Projects that bring PF, THD, and EMC evidence to the table get faster approvals and better financing terms.” [Source: Regional Power Electronics Forum proceedings, 2024]

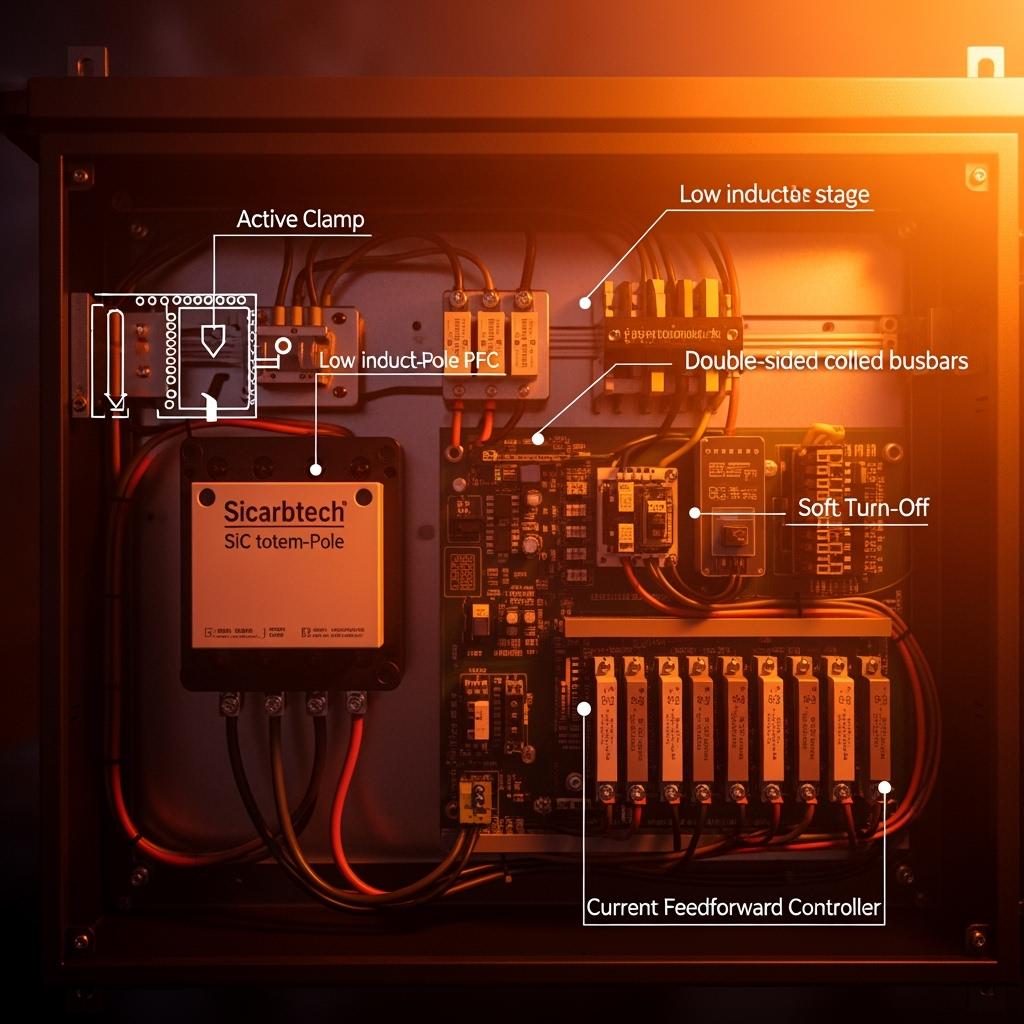

Against this backdrop, SiC-based totem-pole PFC (TPPFC) stands out. By operating efficiently at higher switching frequencies with lower dead-time penalties, it generates near-sinusoidal current, trims filter size, and opens EMC headroom. When combined with low-inductance, double-sided-cooled packaging and active snubbing, it suppresses ringing at the source—reducing reliance on oversized passive filters and improving thermal behavior in the process.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech PFC and EMC Designed for Pakistan

Sicarbtech’s front-end portfolio is engineered as a cohesive stack. Automotive-grade 650 V and 1200 V SiC MOSFETs power continuous conduction mode (CCM) and critical conduction mode (CrCM) TPPFC stages, paired with high-frequency AC–DC rectification and synchronous rectification. The digital control library includes current feedforward, nonlinear inductance compensation, dead-time adaptation, and zero-crossing finesse that sustains high PF and low THD under low line, light load, and grid disturbance.

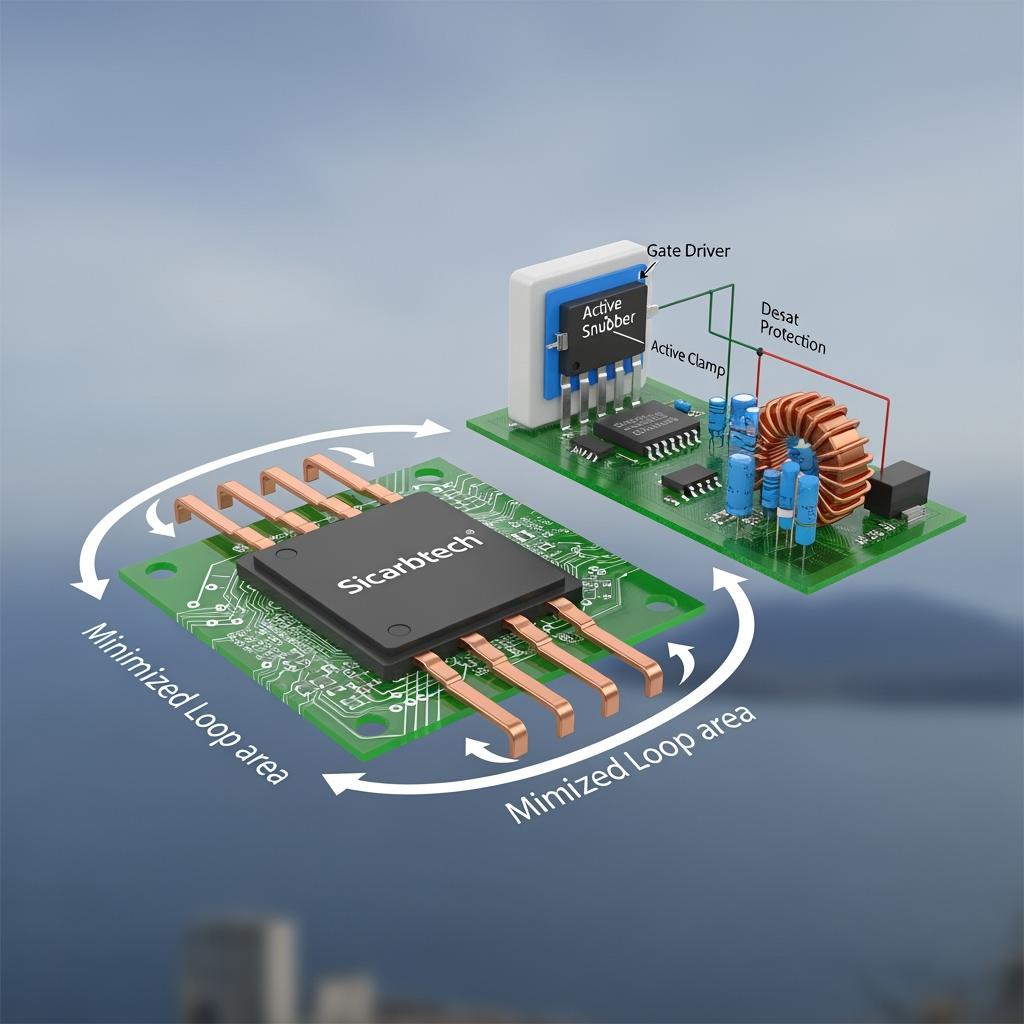

Packaging focuses on first principles. Low-inductance busbars minimize loop area and parasitic coupling; double-sided cooling on high-thermal-conductivity ceramic substrates shortens heat paths and stabilizes hotspot behavior. Gate driver boards integrate soft turn-off and active clamping with fast desaturation protection, preventing avalanche stress during sags, surges, and transient overloads. Magnetics and filters are delivered as plug-in assemblies with measured impedance characteristics, tuned to avoid resonances in real enclosures.

Environmental durability completes the picture. Conformal coating, selective potting of high-stress regions, and salt-mist-resistant hardware extend life in dusty and coastal regions. An online monitoring and data unit with edge analytics captures voltage, current, harmonic spectra, leakage currents, and temperature, feeding into health assessment and parameter trace playback—critical for fast root-cause analysis in both lab and field.

Crucially, Sicarbtech’s process kits and equipment—vacuum brazing, pressure sintering, power cycling rigs, and IEC 60068 chambers—enable localized packaging and pre-compliance screening in Pakistan, lifting first-pass EMC success and shrinking the prototype-to-certification timeline.

Performance Comparison: Silicon Carbide Front-End vs Conventional Silicon for Pakistan Sites

Efficiency, Power Quality, and EMC Margin under Heat and Grid Fluctuations

| Parametre | Sicarbtech SiC Totem-Pole PFC Front-End | Conventional Silicon Front-End | Pakistan'da Operasyonel Etki |

|---|---|---|---|

| Combined front-end efficiency (PFC + rectification) | 95%–97% | 92%–95% | Lower PKR energy use and cabinet heat |

| Power factor at rated load | 0.98–0.99+ | 0.95–0.98 | Fewer feeder penalties and trips |

| Giriş akımı THD | 5%–8% achievable | Tipik –25 | Reduced interference with nearby loads |

| Magnetics/filter volume | −20% to −40% | Başlangıç Noktası | Smaller cabinets, higher deployment density |

| High-temp derating at 40–50 °C | 10%–20% fewer events | Sık | Stable summer operation |

| EMC pre-compliance first-pass rate | 85%–90% typical | 50%–70% | Shorter time-to-certification and lower rework cost |

The combination of high PF, low THD, and tighter thermal behavior not only eases approvals but also improves depot harmony where multiple chargers and drives operate side by side.

Real-World Applications and Success Stories in Pakistan

A two-wheeler fast-charging terminal in Lahore upgraded to a SiC TPPFC front end. The station’s measured PF reached 0.99 at rated load, while front-end efficiency improved by about 3%. Conducted EMC passed in the first pre-compliance attempt, and cabinet volume fell by roughly 25% due to smaller magnetics and filters—allowing more bays per site without expanding the footprint.

In Karachi’s coastal district, a light commercial onboard charger adopted Sicarbtech’s high-frequency front end with low-inductance busbars, selective potting, and conformal coating. Over the summer, high-temperature derating events dropped by approximately 30%. Operators reported significantly fewer EMC-related alarms, and annual return rates declined as damp-heat endurance improved.

A centralized charging yard supplying textile logistics near Faisalabad implemented active snubbing and a symmetric loop busbar redesign. Radiated EMC remediation cycles were cut in half, and batch-to-batch consistency tightened after local screening introduced power cycling and damp-heat tests before deployment. Uptime improved during peak nighttime windows, stabilizing queue times and revenue.

Technical Advantages and Implementation Benefits with Local Regulatory Compliance

SiC’s low switching loss enables usable switching frequencies in the 20–80 kHz range without sacrificing efficiency, which directly reduces magnetics and filter size. Sicarbtech’s digital library stabilizes PF and THD across low line and partial load, while dead-time adaptation keeps current sinusoidal under real-world mains distortion. Active snubbing and soft turn-off, working with low-inductance busbars, suppress the root causes of ringing and overshoot rather than masking them with oversized passive filters—an approach that improves thermal performance and EMC simultaneously.

Compliance is engineered, not assumed. Device behavior maps to IEC 60747; environmental endurance follows IEC 60068 damp-heat, salt-spray, dust, vibration, and shock profiles; EMC behavior aligns with expectations similar to IEC 61800-3 for power drive systems, with ISO 7637 informing automotive disturbance immunity for onboard applications. Safety is addressed through insulation monitoring, surge protection, and controlled discharge paths. Sicarbtech packages documentation and coordinates with labs in Karachi and Lahore to shorten certification and support green financing that rewards high efficiency and power quality. As Engr. S. Khan observes, “When PF, THD, and conducted limits are proven upfront, tender negotiations shift to delivery and scale.” [Source: EV Systems Roundtable, 2024]

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Edge for Pakistan

Sicarbtech translates its R&D pedigree into transferable capability. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech holds proprietary processes across R‑SiC, SSiC, RBSiC, and SiSiC, informing thermally robust substrates and rugged fixtures. The technology transfer package includes:

Process know-how: pressure-sintered die attach profiles, vacuum brazing parameters, metallization/passivation stacks, low-inductance busbar geometry rules, gate-drive tuning for soft turn-off and active clamping, and validated conformal coating/potting recipes for damp-heat and salt-spray.

Equipment specifications and vendor lists: vacuum brazing furnaces, pressure sintering presses, inline electrical testers, power cycling rigs, HTRB/HTGB setups, and environmental chambers with acceptance tests and calibration.

Training and quality systems: operator and maintenance qualification, failure analysis workflows, SPC-driven yield optimization, and PPAP-like control plans aligned with ISO 9001 and IATF 16949 principles.

Factory establishment: feasibility studies, facility layout and utilities, installation and commissioning, pilot runs, and capability validation, followed by quarterly audits and yield improvement sprints.

Across 19+ enterprise collaborations, this model has delivered shorter time-to-market, higher first-pass yield, and lower field failure rates. For Pakistan, localized packaging and pre-compliance screening compress spare lead times to days or weeks, stabilize site uptime during peak seasons, and build domestic skill bases that compound competitive advantage over import-only strategies.

Comparative Engineering Choices and Lifecycle Economics

Front-End Architecture and EMC Discipline for Pakistan’s Grids

| Design Area | Sicarbtech SiC Implementation | Conventional Silicon Implementation | Practical Outcome in Pakistan |

|---|---|---|---|

| PFC topology | Totem-pole PFC (CCM/CrCM) at 20–80 kHz | Boost PFC with silicon diodes at lower kHz | Higher PF/THD control with smaller magnetics |

| Gate and protection | Soft turn-off, fast desat, active clamp | Basic desat, no active snub | Fewer trips during sags/surges, better EMC |

| Layout and busbars | Low-inductance, symmetric loops | Higher loop inductance | Reduced ringing, smaller filters |

| Termal yığın | Double-sided cooling, high-k ceramics | Single-sided, larger sinks | Fewer derates at 40–50 °C |

| Control library | Current feedforward, dead-time adapt, nonlinear comp | PI-heavy with fixed dead-time | Stable PF/THD at low line/partial load |

Localization and TCO: From Compliance Risk to Competitive Advantage

| Business Factor | With Sicarbtech Technology Transfer | Import-Only Strategy | Outcome for Pakistani Operations |

|---|---|---|---|

| Pre-compliance cycle | Local scans with data playback | Ship-return loops | Faster approvals, lower rework cost |

| Spare turnaround | Days–weeks via local screening | Weeks–months | Higher uptime and SLA adherence |

| Footprint and density | Co-designed filters/magnetics | Oversized safety margins | More bays per site, lower rent/HVAC |

| Energy and penalties | Higher efficiency, higher PF | Lower PF, higher losses | Lower PKR OPEX, fewer penalties |

| Capability growth | In-country process/QA | Vendor dependency | Stronger ecosystem and talent base |

Future Market Opportunities and 2025+ Trends: Why SiC PFC Becomes Standard

As Pakistan deploys more charging points for two-/three-wheelers and light commercial vehicles, substation constraints and feeder quality will push sites toward grid-friendly front ends. High PF and low THD will move from “nice-to-have” to gate conditions, while cabinet density and thermal behavior determine viable site throughput. Data-driven O&M will extend from vehicle telematics to charger analytics, making pre-compliance logs, harmonic spectra, and thermal histories part of contractual SLAs. In this setting, SiC TPPFC becomes the pragmatic standard: efficient at frequency, compact, and controllable, with EMC engineered into the power path rather than pasted on afterward.

For industrial corridors, plant upgrades will prioritize drives and rectifiers that respect power quality while surviving heat and dust. Local manufacturing capacity, supported by process transfer and pre-compliance labs, will shape supplier selection. Sicarbtech’s integrated stack—devices, packaging, magnetics, algorithms, validation, and factory establishment—aligns with these trends, enabling Pakistani partners to move from assembling products to mastering capability.

Extended Technical Specifications and Local Standards Alignment

Sicarbtech’s front-end solutions target single- and three-phase inputs with wide-voltage adaptation, DC buses from 200–800 V, and rated powers spanning 3–20 kW with scalable options above. Switching frequencies of 20–80 kHz are selected based on acoustic and thermal constraints. Combined PFC + rectification efficiencies of 95%–97% are achievable, with PF ≥0.98 at rated load and input current THD in the 5%–8% range, depending on filter configuration and operating conditions. Protections include over/under-voltage, overcurrent, overtemperature, short circuit with soft turn-off, surge protection, and insulation monitoring. Environmental hardening covers dust, moisture, salt mist, vibration, and shock, with optional potting and coating.

Documentation maps to IEC 60747 (devices), IEC 60068 (environmental endurance), EMC expectations akin to IEC 61800-3, and ISO 7637 for automotive disturbances where onboard usage applies. Sicarbtech supports third-party testing with Karachi and Lahore labs, providing test plans, pre-compliance data, and parameter trace playback to shorten certification cycles.

Sıkça Sorulan Sorular

How much can SiC-based PFC improve efficiency and PF in Pakistani sites?

Expect 2%–4% higher front-end efficiency and PF of 0.98–0.99+ at rated load, with input current THD commonly in the 5%–8% range when filters are correctly tuned.

Will SiC PFC reduce cabinet size meaningfully?

Yes. Higher switching frequency allows magnetics and filters to shrink by roughly 20%–40%, enabling denser deployments or smaller onboard chargers.

How does Sicarbtech help pass EMC on the first attempt?

By combining low-inductance busbars, symmetric loop layout, active snubbing, and digital dead-time adaptation, then validating with local pre-compliance scans and data playback to target issues before formal testing.

Can the design survive Karachi humidity and cement-corridor dust?

Conformal coating, selective potting, and salt-mist-resistant hardware are validated under IEC 60068 (damp heat, salt spray, dust), with vibration/shock coverage for roadside and onboard use.

What is the typical timeline from design to pilot with pre-compliance?

With modular stages and control libraries, pilots often emerge in 8–12 weeks, aided by local pre-compliance scans to de-risk formal certification.

Does totem-pole PFC stay stable on weak feeders and during sags?

Yes. Current feedforward, soft turn-off, and active clamping stabilize behavior through sags, while low-inductance packaging minimizes ringing. Filters are co-designed to avoid resonances.

How does localization change total cost of ownership?

Local packaging and screening shorten spares lead time to days–weeks, improve batch consistency, and reduce rework and certification retests—lowering PKR OPEX and raising uptime.

Are these modules suitable for both chargers and onboard power?

Yes. The architecture scales from compact onboard front ends to multi-kilowatt charger inputs, with parameterization for line conditions and enclosure constraints.

What standards and quality systems does Sicarbtech support?

ISO 9001 and IATF 16949-aligned quality systems, with documentation bundles supporting IEC 60747, IEC 60068, and EMC/ISO 7637 expectations. PPAP-like validation and control plans are available.

Can we monitor PF, THD, and health in the field?

The remote monitoring unit captures voltage, current, harmonic spectra, temperatures, and leakage, enabling health assessment, trend analysis, and closed-loop improvements.

Operasyonlarınız için Doğru Seçimi Yapmak

In Pakistan’s mix of weak feeders, hot summers, and dusty roadside conditions, front-end PFC and EMC are decisive. Sicarbtech’s SiC-based totem-pole PFC brings higher efficiency, smaller size, and stronger EMC discipline—backed by double-sided-cooled, low-inductance packaging and active snubbing to suppress problems at their source. Combined with technology transfer and local pre-compliance labs, it converts compliance risk into a competitive edge: faster approvals, denser sites, lower PKR OPEX, and higher uptime.

Uzman Danışmanlığı ve Özel Çözümler Alın

Partner with Sicarbtech to select the right SiC device class, tune CCM/CrCM control, and co-design magnetics, filters, and busbars for Pakistan’s grid and enclosure realities. Explore technology transfer and factory establishment to localize packaging, screening, and spares, building resilient, in-country capability.

Sicarbtech — Silicon Carbide Solutions Expert

E-posta: [email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“Efficiency wins approvals; EMC wins neighbors; localization wins uptime.” — Sicarbtech Applications Team

Makale Meta Verileri

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: integrates 2025 Pakistan market outlook; aligns with IEC 60747, IEC 60068, ISO 7637, and EMC expectations similar to IEC 61800-3; reflects Sicarbtech’s current SiC portfolio, technology transfer, and factory establishment services.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.