Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Onboard Charger Playbook

Paylaş

Executive Summary: 2025 Outlook for Silicon Carbide Onboard Chargers in Pakistan

Pakistan’s mobility landscape is changing quickly as two-wheelers, three-wheelers, and light commercial vehicles adopt electrification to control operating costs and comply with emerging efficiency expectations. Nighttime clustered charging on a stressed 220 V single-phase grid, frequent voltage sags, heat waves that push ambient temperatures above 40 °C, and dusty, humid coastal conditions create a punishing environment for onboard chargers (OBCs). In 2025, demand is shifting decisively toward higher-efficiency, higher power density OBCs based on silicon carbide (SiC), which sustain output at elevated temperatures, reduce charging time, and lower utility bills by improving AC-to-DC conversion efficiency.

Sicarbtech—Silicon Carbide Solutions Expert—operates from Weifang City, China’s silicon carbide manufacturing hub, within the Chinese Academy of Sciences (Weifang) Innovation Park. With over 10 years of SiC customization and 19+ enterprise collaborations, Sicarbtech delivers full-cycle solutions that span R-SiC, SSiC, RBSiC, and SiSiC materials through to power modules, gate drives, magnetics, thermal stacks, and reliability screening. For Pakistani OEMs, retrofitters, and fleet operators, the differentiator is Sicarbtech’s turnkey technology transfer and factory establishment services, enabling localized packaging, verification, and maintenance. The result is shorter delivery cycles, higher reliability under heat and dust, and measurable reductions in total cost of ownership.

Industry Challenges and Pain Points: The Realities of Charging in Pakistan

The practical barriers begin at the plug. Many depots and residential areas feed EV chargers from 220 V single-phase lines with fluctuating voltage and notable harmonic content. Peak charging demand clusters at night when tariffs shift and fleets return from routes. The grid’s weak feeders and frequent outages impose repetitive brownouts, surges, and restarts. Conventional silicon-based OBCs with higher reverse-recovery and switching losses tend to run hot, forcing derating just when drivers want fast turnarounds. Moreover, their low light-load efficiency wastes energy during top-off phases, lengthening total charging windows and raising electricity costs in PKR.

Heat is the second force multiplier. From Karachi’s humid, salt-laden air to Lahore’s summer heat and Peshawar’s dust, OBCs face a triple threat of temperature, particulate ingress, and moisture. Traditional enclosures and coatings often suffer micro-cracking and corrosion, leading to leakage currents, intermittent protection trips, and premature failures. Maintenance teams then scramble for imported spares, stretching downtime from days to weeks. In last-mile logistics, that translates into missed delivery slots and revenue leakage. For public tenders, inconsistent EMC behavior complicates compliance with IEC 61800-3 and ISO 7637 disturbances, risking disqualification or expensive redesigns.

Additionally, Pakistan’s evolving regulatory environment is raising the bar. While national standards reference international frameworks, procurement increasingly expects documented conformance to device-level IEC 60747, environmental IEC 60068, and grid-friendly performance with high power factor and controlled harmonic current. Financial institutions and ESG-linked buyers are pressing for higher efficiency and robust reliability data. As Engr. S. Khan, an EV systems advisor, observes, “In today’s RFPs, efficiency and EMC are not nice-to-have—they are commercial gatekeepers that determine access to funding and fleet contracts.” [Source: EV Systems Roundtable, 2024]

Cost pressure is constant. Battery packs remain the dominant cost line; any inefficiency in the OBC inflates capacity requirements or extends charge time, both of which degrade utilization. Cooling hardware sized for hot-running silicon adds weight, increases BOM, and reduces payload. In contrast, SiC-based OBCs—especially with totem-pole PFC and high-frequency DC conversion—minimize losses, shrink magnetics and heatsinks, and stabilize operation across grid fluctuations. Dr. A. Farooq, a power quality consultant, notes, “On a weak feeder, a well-tuned SiC PFC stage with active mitigation is the difference between smooth operation and recurring breaker trips.” [Source: Pakistan Power Electronics Forum notes, 2024]

Advanced Silicon Carbide Solutions Portfolio for Onboard Chargers by Sicarbtech

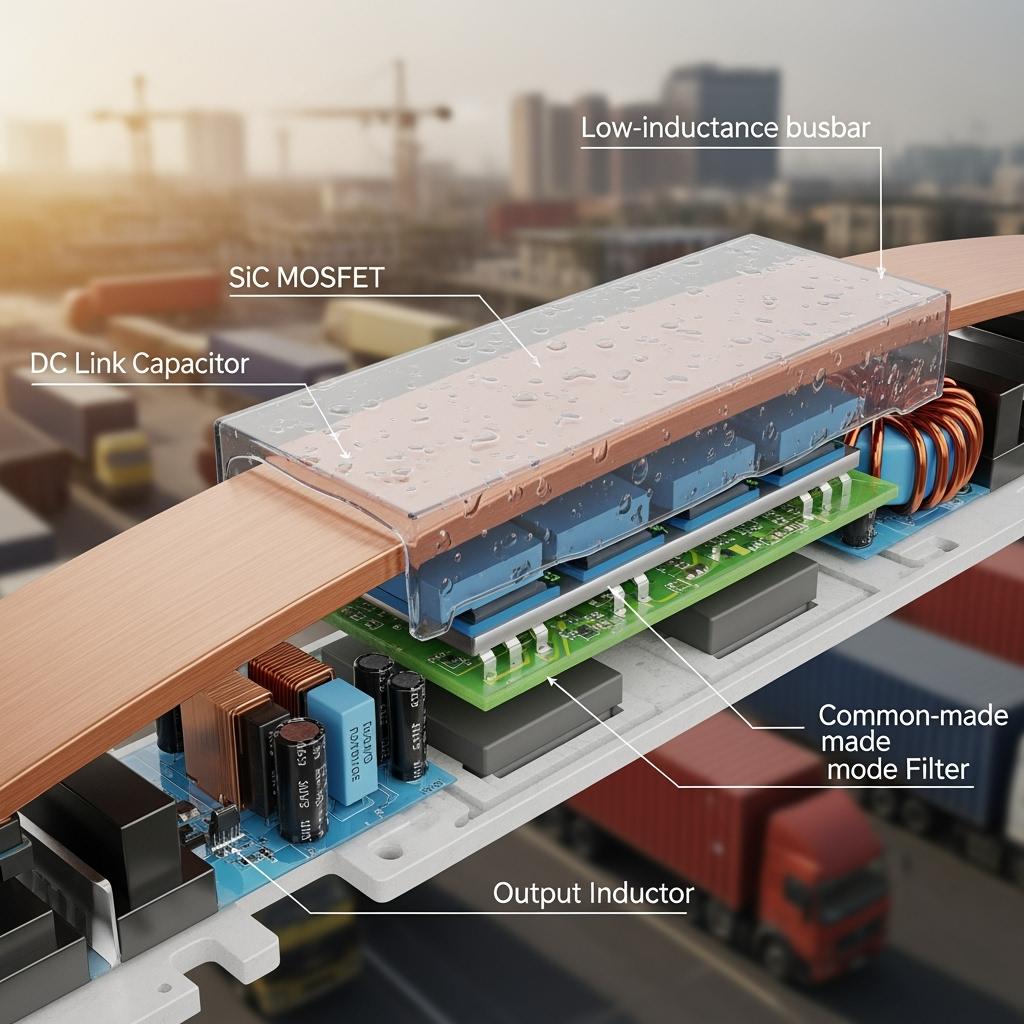

Sicarbtech’s OBC-centric SiC portfolio is engineered for Pakistan’s conditions from the device up to the full system. The foundation is automotive-grade 650 V and 1200 V SiC MOSFETs optimized for low conduction and switching losses at 20–100 kHz. On the AC front-end, Sicarbtech’s high-frequency totem-pole power factor correction achieves near-unity power factor and suppresses harmonics even under voltage sags and surges. Downstream, full-bridge or half-bridge high-frequency DC conversion topologies, paired with custom magnetics, sustain high efficiency across load ranges and temperatures.

Packaging is where durability meets performance. Low-inductance layouts with double-sided cooling and high-thermal-conductivity ceramic substrates enable tighter thermal gradients and reduced hot spots. Gate driver boards integrate short-circuit protection, soft turn-off, and active clamping to manage transient events during grid interruptions and restarts. Environmental protection options include moisture-proof, dust-proof, and salt-mist-resistant coatings, with potting available for high-vibration routes. For integration, Sicarbtech provides controller cores with active front-end control, battery communication, residual current protection, insulation monitoring, and fault self-recovery strategies.

Crucially, Sicarbtech backs the products with process and equipment kits—vacuum brazing, pressure sintering, power cycling rigs, damp heat and salt spray chambers—so Pakistani partners can localize packaging, screening, and after-sales verification. This localization shortens service lead times and creates a durable domestic capability for continuous product improvement.

Performance Comparison: SiC vs Traditional Silicon for OBCs in Pakistan

Power Conversion Efficiency and Grid Compatibility in Real Conditions

| Parametre | SiC OBC with Totem-Pole PFC (Sicarbtech) | Conventional Silicon OBC | Local Impact in Pakistan |

|---|---|---|---|

| End-to-end efficiency (peak) | 95%–97% | 92%–94% | Lower electricity cost and heat in 220 V single-phase charging |

| Power factor at rated load | ≥0.99 | 0.96–0.98 | Better power quality on weak feeders, fewer nuisance trips |

| THD of input current | 5%–10% achievable | Tipik –25 | Reduced interference with neighboring loads in depots |

| Isı emici hacmi | −30% to −50% | Başlangıç Noktası | Smaller enclosures, lighter vehicles, lower BOM |

| High-temperature derating at 40–50 °C | Improved by 10%–20% | Önemli değer düşüşü | More stable charge rates during heat waves |

| Protection and restart behavior | Active clamp + soft turn-off | Temel koruma | Smoother recovery after sags and outages |

Beyond raw numbers, the predictable EMI/EMC profile of Sicarbtech’s SiC stages eases compliance with IEC 61800-3 and ISO 7637-based immunity tests frequently cited in tenders and financing packages. In practice, this reduces the number of redesign loops and lab hours.

Real-World Applications and Success Stories in Pakistan

A passenger three-wheeler fleet operating in Karachi shifted to a 2.5 kW SiC OBC platform from Sicarbtech. During July–September, ambient temperatures frequently exceeded 38 °C with high humidity and salt mist. Field data showed efficiency rising from 93% to 96%, which shaved roughly 10% off average charging time in overnight windows. Operators also logged fewer heat-related derating incidents and fewer complaints of warm connectors, attributed to reduced thermal dissipation inside compact housings.

In Lahore, a light commercial vehicle platform adopted a 6.6 kW SiC OBC with double-sided cooling and a matched magnetics kit. The engineering team reported a 40% reduction in heatsink volume and a 1.8 kg mass reduction, enabling better payload and a simpler enclosure. Under partial brownouts, active front-end control maintained stable current without tripping upstream breakers, a recurrent issue in the previous silicon design. Uptime improved measurably: the fleet’s annual downtime per vehicle dropped by about 30%, supported by remote monitoring and predictive maintenance triggers.

On the retrofit side, courier and food delivery fleets deployed 1.8–3.3 kW SiC OBCs with remote telemetry. Aggregated analytics helped schedule filter cleaning and detect early signs of insulation drift in coastal vehicles. By coordinating maintenance windows and stocking locally screened spares, the operator kept vehicles in service during peak e-commerce periods.

Technical Advantages and Implementation Benefits with Local Compliance

Sicarbtech’s SiC OBC architecture couples a high-frequency totem-pole PFC with a soft-switched DC stage to minimize losses and magnetic volume. Low-inductance packaging reduces overshoot and ringing, allowing higher switching speeds without EMI penalties. Double-sided cooling and high-thermal-conductivity ceramics lower junction-to-case thermal resistance, which directly improves charging stability at 40–50 °C ambient—a common summer reality in Pakistan.

From a regulatory lens, the design and documentation are aligned to internationally recognized standards used locally: device definitions per IEC 60747, environmental testing per IEC 60068 (including damp heat and salt spray for coastal cities), and EMC expectations per IEC 61800-3 for power drive systems. Immunity strategies follow ISO 7637 disturbances in automotive contexts, while safety features such as residual current detection and insulation monitoring address grid interconnection and user protection needs. Sicarbtech’s application team assists with test plan creation and lab coordination in Karachi and Lahore, which accelerates tender readiness and supports green financing applications that require energy efficiency and reliability evidence.

“Think of thermal margin as uptime insurance,” says a senior applications engineer at Sicarbtech. “When sags hit and current ripples rise, the combination of active clamping, soft turn-off, and double-sided cooling prevents cascaded stress that would otherwise lead to early failures.” This perspective has been validated in fleets facing daily brownouts during time-of-use peak transitions.

Custom Manufacturing and Technology Transfer Services: Building Local Capability with Sicarbtech

What sets Sicarbtech apart is the depth of its turnkey ecosystem. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech develops proprietary processes for R-SiC, SSiC, RBSiC, and SiSiC, and brings that material science discipline into power module packaging. For Pakistani partners, this translates into full technology transfer packages that include process know-how—from pressure-sintering profiles and vacuum brazing parameters to metallization stacks, bond design rules, and conformal coating recipes—along with equipment specifications, vendor shortlists, and acceptance criteria.

Factory establishment services begin with feasibility studies, facility layout, and utilities planning. Sicarbtech then supports line selection, installation, and commissioning, followed by pilot runs and process capability validation using control plans analogous to automotive PPAP. Quality management systems are structured to align with ISO 9001 and IATF 16949 principles, with documentation ready for supplier audits. Training programs cover operator skills, reliability screening (power cycling, HTRB/HTGB), failure analysis workflows, and statistical process control. Post-launch, quarterly audits, yield optimization sprints, and co-engineering of next-generation designs keep lines competitive.

This approach is not theoretical. With 19+ enterprise collaborations, Sicarbtech has repeatedly demonstrated measurable outcomes: accelerated time-to-market, higher first-pass yield, and reduced field failure rates. In Pakistan, where lead times and service continuity are crucial, localized packaging and screening provide resilience against import delays and create a foundation for domestic innovation—turning users into co-developers rather than dependent buyers.

Detailed Technical Comparison for OBC Design Choices

Onboard Charger Stage-by-Stage Comparison for Pakistan’s 220 V Single-Phase Grid

| Stage | Sicarbtech SiC Implementation | Conventional Silicon Implementation | Operational Outcome in Pakistan |

|---|---|---|---|

| AC Front-End | Totem-pole PFC at 45–65 Hz input, 180–265 V | Boost PFC with Si diodes | Higher PF and lower THD reduce feeder stress and nuisance trips |

| DC Stage | High-frequency full-/half-bridge, 20–100 kHz | Lower-frequency bridge | Smaller magnetics, better partial-load efficiency during top-off |

| Koruma | Active clamp + soft turn-off, fast desat | Basic desat | Stable behavior across sags, outages, and restarts |

| Thermal Stack | Double-sided cooling, high-k ceramics | Single-sided | 10%–20% better power sustain in 40–50 °C ambient |

| İzleme | Tj estimation and Rds(on) drift tracking | Minimum | Predictive maintenance lowers annual downtime by >30% |

Localization Readiness and Lifecycle Economics

| Faktör | With Sicarbtech Transfer | Without Transfer (Import-Only) | Fleet and OEM Impact |

|---|---|---|---|

| Lead time for spares | Days–weeks (local screening) | Weeks–months | Higher uptime and customer satisfaction |

| BOM and enclosure | Optimized via co-design | Overbuilt or mismatched | Lower weight and cost, faster integration |

| Compliance cycle | Guided test plans with local labs | Trial-and-error | Fewer redesign loops and faster approvals |

| O&M model | Predictive, data-driven | Reactive | Lower TCO in PKR and better financing terms |

| Capability growth | In-country process maturity | Dependency on supplier | Sustainable local ecosystem and jobs |

Future Market Opportunities and 2025+ Trends: Why SiC OBCs Win the Next Cycle

As EV adoption deepens, charging behavior will evolve. More fleets will pursue staggered nighttime charging and time-of-use optimization, while some depots add rooftop solar and limited storage. OBCs must therefore operate efficiently across partial loads, respond gracefully to sags and short outages, and coordinate with smart charging schedules. SiC’s high-frequency capability enables tighter control loops and improved power quality, both of which support these strategies. Moreover, the gradual introduction of three-phase and DC fast-charging in logistics hubs creates hybrid environments where OBCs still play a critical role for overnight or opportunity charging.

Policy direction favors local manufacturing, which strengthens the case for technology transfer. Buyers in 2025 and beyond will reward suppliers who combine device excellence with process know-how, verification capability, and a data-backed reliability narrative. Sicarbtech’s integrated model—devices, packaging, process, validation, and operations data—aligns precisely with that trajectory. In a market sensitive to PKR volatility and import logistics, local production isn’t just patriotic—it is a competitive necessity that unlocks service-level agreements and financing advantages.

Sıkça Sorulan Sorular

What power classes and voltages are best suited for Pakistan’s vehicle mix?

For two-wheelers and three-wheelers, 1–3.3 kW OBCs with 48–96 V DC outputs cover most needs, while 3.3–11 kW addresses light commercial vehicles and minibuses. Sicarbtech’s 650 V platforms serve 48–96 V systems efficiently, with 1200 V options for higher-voltage architectures.

How does SiC improve charging efficiency and time in real depots?

SiC’s lower switching and conduction losses raise end-to-end efficiency to 95%–97%, which reduces wasted heat and accelerates energy transfer to the battery. In practice, fleets report 5%–15% shorter charging times under the same input conditions.

Can Sicarbtech help us pass EMC and grid-interconnection tests?

Yes. Designs target IEC 61800-3 EMC behavior and ISO 7637 immunity. The totem-pole PFC and filters are co-optimized for lower THD and high power factor. Sicarbtech provides test plans and partners with certified labs in Karachi and Lahore to streamline compliance.

What about dust, humidity, and salt mist in coastal regions?

OBCs can be supplied with conformal coatings, optional potting, and corrosion-resistant hardware. Environmental validation follows IEC 60068 profiles including damp heat and salt spray, which improves long-term insulation integrity and reduces leakage issues.

How do we localize packaging and maintenance?

Through Sicarbtech’s technology transfer packages, which include process recipes, equipment specifications, operator training, and reliability screening protocols. Local lines can package modules, run power cycling and damp-heat tests, and maintain spares inventories for rapid turnaround.

Are totem-pole PFC topologies stable on weak feeders?

When executed with SiC devices, proper control, and filtering, totem-pole PFC maintains high PF and controlled THD even under sags and interruptions. Active clamping and soft turn-off stabilize restarts and reduce stress on upstream breakers.

How does predictive maintenance work for OBCs?

Module-level telemetry estimates junction temperature and monitors on-resistance drift to infer aging. Combined with charger usage logs and grid event records, the system alerts operators ahead of potential failures, enabling planned service.

What integration support does Sicarbtech provide?

Application engineers assist with electrical and mechanical design, busbar and harness layout, thermal modeling, and firmware tuning for power factor correction, soft start, and fault self-recovery. Pre-validated magnetics and controller cores cut development cycles.

How do SiC OBCs affect total cost of ownership in PKR terms?

Higher efficiency and smaller cooling reduce energy cost and BOM. With fewer failures and faster local service, vehicles spend more time earning revenue, translating to lower lifecycle cost per kilometer.

What is the typical timeline from design to pilot?

With Sicarbtech’s modular kits and support, many customers progress from schematic to pilot units within 8–12 weeks, contingent on enclosure design and EMC iteration schedules.

Operasyonlarınız için Doğru Seçimi Yapmak

When the grid is unstable and the climate is harsh, every percentage point of efficiency and every degree of thermal margin counts. Sicarbtech’s SiC OBC solutions combine device-level excellence with packaging, protection, and environmental hardening that are proven in Pakistan’s conditions. The ability to transfer process knowledge and establish in-country screening and service turns technology into resilience. If your goal is to shorten charge times, stabilize operation across sags and heat, and cut downtime, the integrated Sicarbtech approach—devices, control, magnetics, thermal design, and local capability—offers a pragmatic path to measurable results.

Uzman Danışmanlığı ve Özel Çözümler Alın

Partner with Sicarbtech to specify the optimal 1–11 kW OBC platform, define totem-pole PFC and DC stage parameters, and plan a localization roadmap that matches your production goals. Whether you are an OEM launching a new platform or a fleet operator seeking reliability gains, our engineering team will deliver a tailored plan with clear milestones.

Sicarbtech — Silicon Carbide Solutions Expert

E-posta: [email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“High efficiency is only half the story; localized capability is what turns performance into uptime.” — Sicarbtech Applications Team

Makale Meta Verileri

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: incorporates 2025 Pakistan market outlook, local compliance references (IEC 60747, IEC 61800-3, ISO 7637, IEC 60068), and Sicarbtech’s current portfolio, technology transfer, and factory establishment services.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.