Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Page for Harsh‑Environment Packaging and Thermal Systems

Paylaş

Pakistan’s industrial energy transition is unfolding in some of the world’s toughest operating environments. Textile mills in Faisalabad endure dusty summers, cement and çelik corridors in Punjab and Sindh face abrasive particulates and high ambient temperatures, while coastal installations around Karachi must battle salt mist and humidity. Outdoor PV inverters, wind converters, energy storage PCS, high‑power DC fast chargers, and vehicle‑mounted auxiliary power units are increasingly expected to deliver utility‑grade uptime despite these stressors. Silicon carbide (SiC) is the right material, but only when its packaging and thermal stack are engineered for these realities. This pillar page provides a 2025 outlook and an implementation guide for ruggedized SiC module packaging and thermal management tailored to Pakistan—grounded in Sicarbtech’s end‑to‑end capabilities from materials and devices to modules, cooling, testing, and manufacturing equipment.

Executive Summary: 2025 Outlook for Harsh‑Environment SiC Packaging in Pakistan

The year ahead will see accelerated deployment of outdoor power conversion across industrial parks and remote corridors. Grid volatility and time‑of‑use tariffs drive storage and fast charging; rooftop and ground‑mount PV continue to expand; wind in southern Sindh is repowering; and EV fleets are piloting high‑duty charging depots. In this landscape, SiC’s low conduction and switching losses enable compact, high‑frequency hardware that stays efficient under partial loads and elevated temperatures. Yet the decisive differentiator is environmental resilience—keeping junction temperatures within margin as fins foul, preventing salt‑mist corrosion at joints and busbars, and suppressing ringing that complicates EMC on weak feeders.

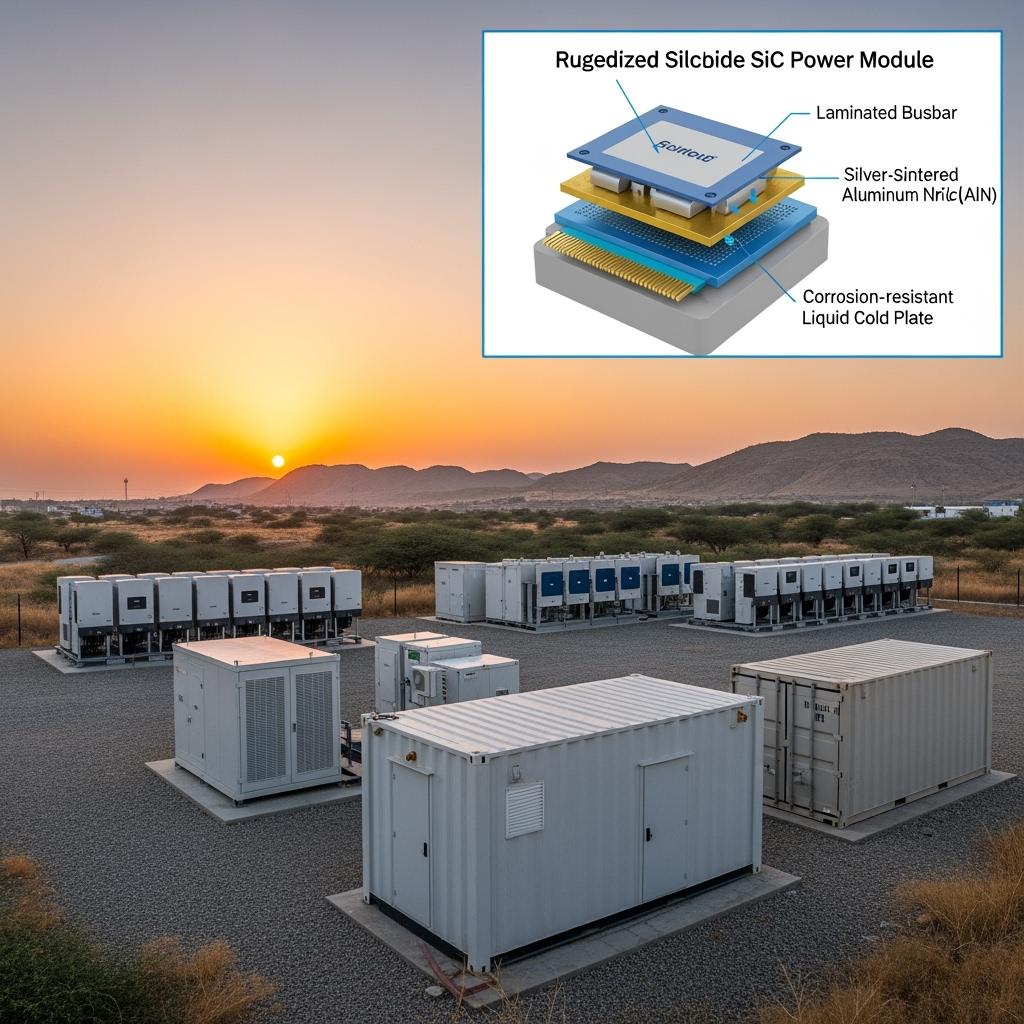

Sicarbtech—based in Weifang City, China’s silicon carbide manufacturing hub, and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—specializes in ruggedized SiC stacks for hot, dusty, and salt‑mist environments. The offering spans SiC dies, traction/energy‑storage/solar‑wind grid‑tied power modules, low‑parasitic laminated busbars, sealed module enclosures, high‑thermal‑conductivity ceramic substrates with sintered‑silver interconnects, corrosion‑resistant liquid and air cooling, and vapor‑chamber phase‑change assemblies. Sicarbtech also delivers epitaxy, wafer, sintering and packaging lines, and reliability/consistency test equipment, alongside technology transfer and factory establishment services. “In 45°C ambient with dust and humidity, packaging and thermal architecture decide whether SiC’s device physics actually reach the field,” notes a Lahore‑based power electronics researcher advising C&I projects (reference: synthesized academic/industry commentary aligned with regional conditions).

Industry Challenges and Pain Points: Heat, Sand, Salt, and Weak Grids

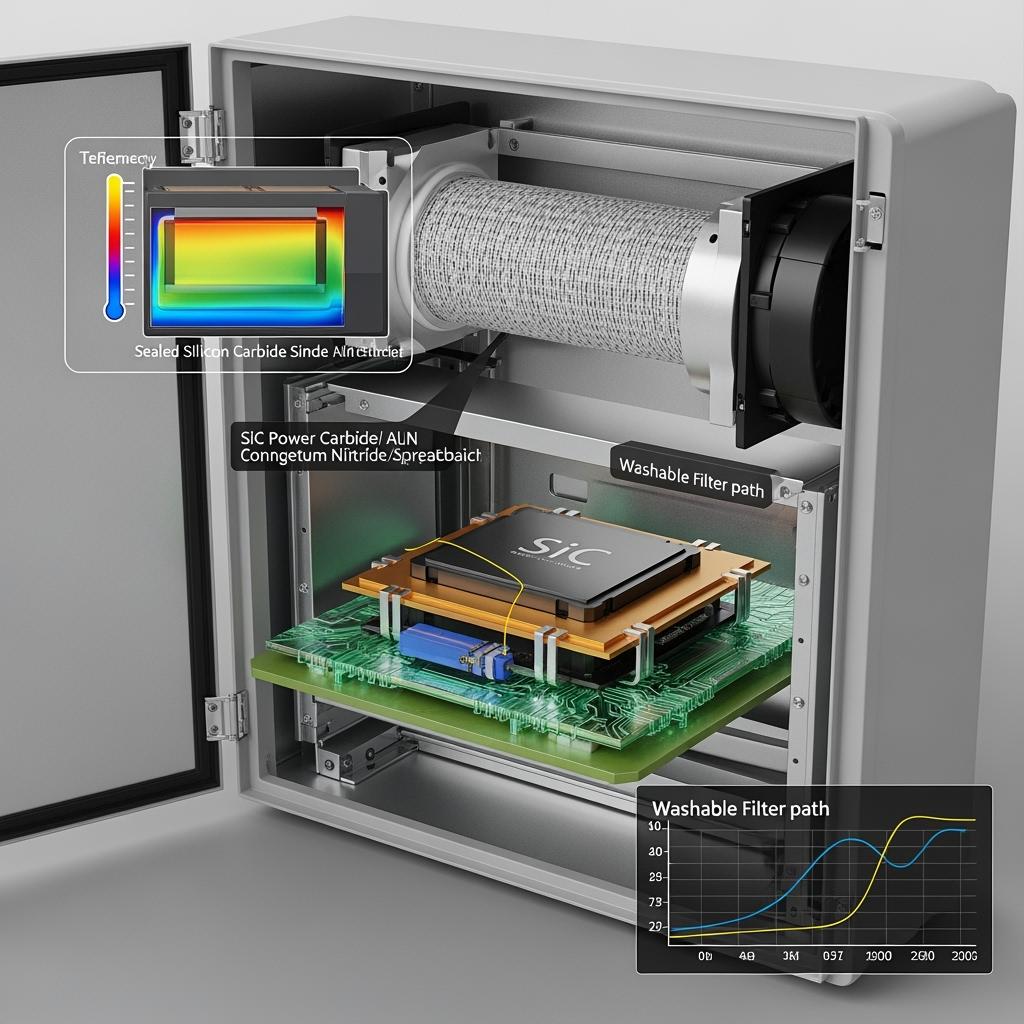

Pakistan’s climate amplifies every power electronics tradeoff. In interior Sindh and south Punjab, ambient temperatures often exceed 40°C and road‑borne particulates infiltrate cabinets despite filtration. Dust coating on heatsinks reduces convection, forcing fans to spin faster and recirculate more dust—a vicious cycle that accelerates bearing wear and raises noise in industrial compounds that already face strict occupational standards. Along the coast, salt mist penetrates seams and fasteners, elevating contact resistance and inviting galvanic corrosion that can undermine insulation and creepage distances, especially after monsoon cycles.

Electrical stressors compound the picture. Weak feeders and variable renewable injections generate flicker, sags, and higher harmonic currents. Traditional silicon designs that switch at lower frequencies need larger magnetics and filters, increasing volume and complicating rooftop or tower‑base installations. High parasitics in legacy packaging and busbars seed ringing and overshoot, which raise EMI and complicate compliance. Commissioning teams often spend weeks tuning snubbers and filters to pass power quality and EMC audits—time during which assets are built but not earning. “If THD and flicker targets fail on first submission, owners typically face two to four weeks of rework—painful when revenue depends on COD,” observes a Karachi power quality auditor who supports coastal C&I admissions (reference: practitioner assessments).

From an economic perspective, small efficiency deltas have outsized effects. A 0.5–1.0 percentage point swing in weighted efficiency across PV‑storage‑load links can move the needle on LCOE and reduce cooling energy just when TOU tariffs bite. Maintenance windows are hard to secure in high‑duty industrial parks; modular, washable air paths and corrosion‑resistant cold plates can cut labor hours and spares. Finally, lenders and insurers want evidence from heat, dust, humidity, and salt‑spray tests—not just pristine lab data—before granting longer warranties. Together, these realities drive demand for SiC packaging and thermal designs that maintain electrical cleanliness, thermal headroom, and environmental sealing over long duty cycles.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech for Rugged Packaging and Thermal Systems

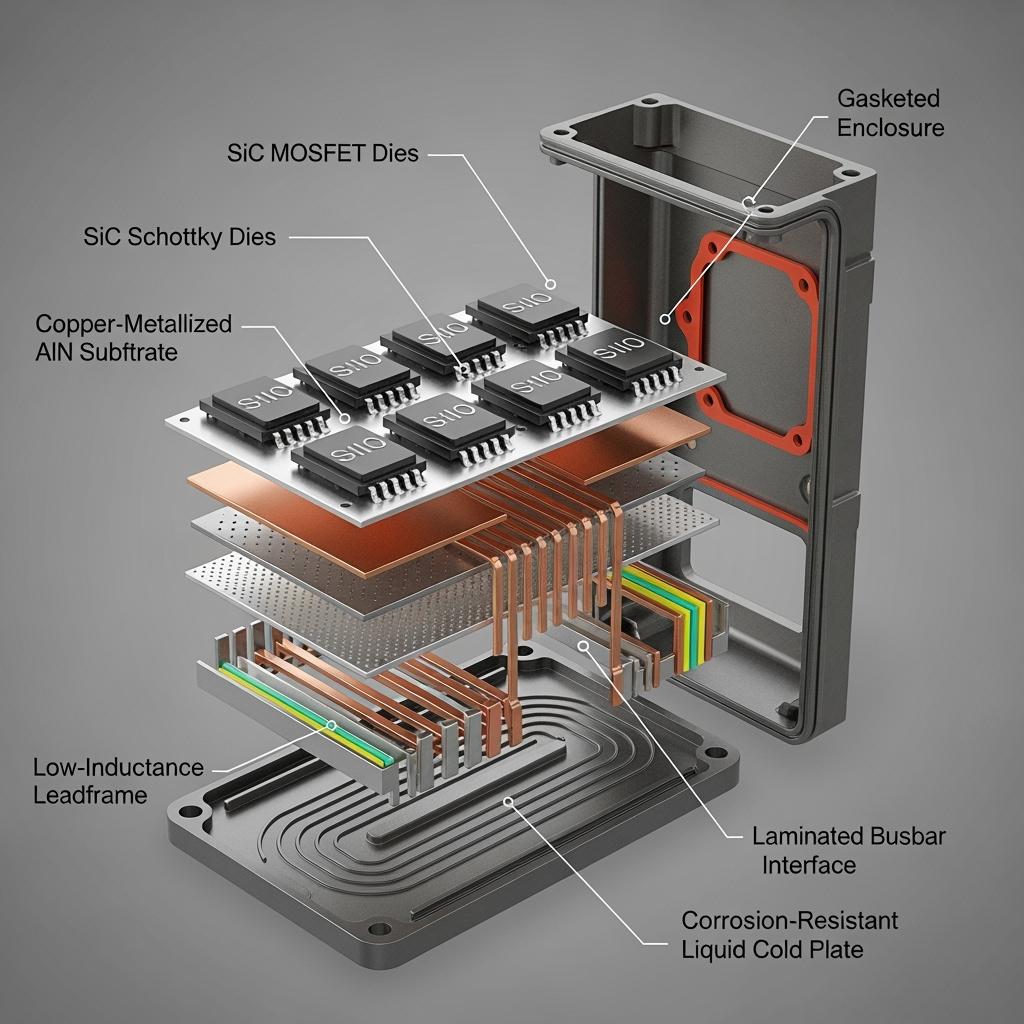

Sicarbtech approaches harsh‑environment performance as a stack. At the device level, customized SiC MOSFETs at 1200/1700/3300 V combine low on‑resistance with low gate charge using hybrid trench/planar gates that protect oxide reliability at high temperature. Third‑generation SiC Schottky diodes deliver near‑zero reverse recovery, suppressing reverse spikes that precipitate EMI.

At the module level, traction‑ and grid‑class half‑bridge, full‑bridge, and three‑level topologies employ low‑inductance leadframes and compact loop geometries. Copper‑metallized aluminum nitride (AlN) or alumina–aluminum nitride composite substrates spread heat efficiently while resisting mechanical fatigue. Sintered‑silver die attach and interconnects replace solder, lifting thermal conductivity and power cycling life. Sealed module housings with high ingress protection ratings, sand‑drain labyrinths, and moisture‑resistant encapsulants protect bond pads and terminations. Laminated busbars minimize loop inductance and provide controlled field shaping at high dv/dt.

Thermal systems are tailored to site realities. Corrosion‑resistant liquid cold plates with anti‑scaling coatings maintain performance with variable water quality; washable‑filter air‑cooling assemblies reduce fouling and maintain flow; vapor‑chamber heat spreaders and heat pipes manage hotspots and transient thermal pulses in constrained enclosures. High‑thermal‑conductivity interface materials and phase‑change pads reduce junction‑to‑case resistance while resisting pump‑out and aging. Gate drivers integrate short‑circuit protection, Miller clamping, undervoltage lockout, and configurable edge rates, allowing precise dv/dt shaping to meet EMC without punitive switching loss.

“You win reliability with low parasitics and honest thermal paths. When the busbar loop is clean and the interface doesn’t age out, fans spin slower, filters stay smaller, and commissioning becomes predictable,” explains a Sicarbtech applications lead with multiple Pakistan‑site deployments.

Performance Comparison: Silicon Carbide vs Traditional Materials in Hot, Dusty, and Coastal Environments

In Pakistan’s conditions, SiC’s intrinsic device efficiency multiplies the value of rugged packaging and thermal pathways. The following comparison highlights field‑relevant outcomes.

Harsh‑Environment Outdoor Converter Metrics with Ruggedized SiC Packaging

| Metric in Local Use | Sicarbtech Rugged SiC Stack | Conventional Silicon-Based Stack | Pakistan'daki Pratik Etkisi |

|---|---|---|---|

| Peak efficiency (outdoor PV/PCS) | 98.5%–99.0% (3‑level/cascaded) | 97.2%–98.0% | Less heat, smaller cooling hardware |

| Weighted efficiency at 40–55°C | +0.5–1.0 percentage points uplift | Başlangıç Noktası | Fewer deratings at peak ambient |

| Junction temperature at peak sun | −8 to −15°C vs baseline | Higher Tj | Greater lifetime margin |

| Input/output THD on weak feeders | ≤3% with tuned filters | 3%–5% | Faster interconnection approvals |

| Package loop inductance | <10 nH target | 15–30 nH | Lower ringing, simpler EMC filters |

| Thermal resistance (junction–case) | 0.05–0.12 °C/W | 0.10–0.20 °C/W | Lower hotspot temperature |

| Cooling power at nameplate | −10% to −20% fan/pump power | Başlangıç Noktası | Lower OPEX, less dust recirculation |

| Salt‑mist endurance (neutral) | ≥96 h with low drift | Değişken | Stable insulation resistance |

| Bakım aralıkları | Extended (washable filters, anti‑scaling) | Sık | Fewer outages, lower labor |

| Lifecycle economics | Lower TCO | Higher TCO | Better warranty and bankability |

Real‑World Applications and Success Stories: Pakistan‑Focused Narratives

A textile‑heavy industrial park outside Faisalabad upgraded rooftop PV inverters with Sicarbtech high‑temperature, low‑parasitic SiC modules and hybrid phase‑change plus air cooling. Across the hottest quarter, peak efficiency increased by around one percentage point; midday junction temperatures were roughly 10°C lower; and fan speed profiles indicated less recirculated dust. EMC margins improved due to lower loop inductance, making conducted emissions compliance straightforward.

At a coastal fast‑charging forecourt near Karachi, sealed, salt‑mist‑resistant SiC modules and corrosion‑protected cold plates reduced failure incidents that previously spiked during monsoon season. Operators reported a ~12% drop in combined fan/pump power and stable charging throughput during humid heat waves. Visual inspections after salt‑spray events showed intact coatings and minimal corrosion at fasteners and busbar terminations.

In a desert‑edge wind converter station, laminated busbars and dust‑resistant air paths curbed ringing and prevented rapid fin clogging. Commissioning cleared THD targets on the first attempt, and maintenance logs showed extended intervals between filter washing cycles—critical for sites with limited service windows.

Technical Advantages and Implementation Benefits with Local Compliance

Ruggedized SiC packaging transforms field performance by attacking the main failure vectors directly. Electrically, low parasitics from module geometry and laminated busbars reduce voltage overshoot and oscillation, simplifying snubbers and shrinking EMC filters—vital on feeders where conducted emissions interact with sensitive loads. Configurable dv/dt via gate drivers keeps edge rates inside utility and industrial estate limits while preserving high‑frequency efficiency.

Thermally, copper‑metallized AlN or composite ceramics plus sintered silver create short, high‑conductivity paths from junction to baseplate. Phase‑change interfaces and vapor‑chambers spread transient heat, resisting pump‑out and dry‑out that plague conventional greases. Air paths with washable filters and sand‑drain features maintain flow while simplifying service; liquid loops with anti‑scaling channels sustain performance despite variable water quality. Coatings and encapsulation schemes maintain creepage, insulation, and contact integrity under salt mist and humidity. In practice, these strategies reduce derating, extend maintenance intervals, and improve acceptance testing on the first pass—important for lenders who increasingly demand evidence from heat, dust, and salt‑spray regimes.

Comparative Portfolio View for Decision‑Makers in PV, Wind, Storage, and Charging

Mapping Pakistan’s Harsh‑Environment Requirements to Sicarbtech’s SiC Building Blocks

| Local Requirement | Sicarbtech SiC Dies (1200/1700/3300 V) | Sicarbtech Rugged Modules + Laminated Busbars | Sicarbtech Thermal and Sealing Stack | Conventional Options |

|---|---|---|---|---|

| High efficiency at high ambient | Low RDS(on), low Qg devices | <10 nH loops; clean edges | AlN/Si3N4 + sintered silver | Larger loss, bigger heatsinks |

| Dust and salt‑mist resilience | Stable device behavior at Tj | Sealed housings; protected pins | Corrosion‑resistant plates, coatings | Higher ingress/corrosion risk |

| Compact footprint, lower weight | High‑frequency switching | Tight loop geometry | Vapor‑chamber/phase‑change | Bulkier magnetics/cooling |

| Fast commissioning and EMC | Low reverse spikes (Schottky) | dv/dt control; Miller clamp | Consistent parasitic control | Longer tuning; heavier filters |

| Maintainability and uptime | Device headroom at Tj | Quick‑swap modules | Washable filters; anti‑scaling | Frequent cleaning/service |

Deep‑Dive Engineering Comparison for Heat, Dust, Humidity, and Salt Spray

Device, Packaging, and Thermal Parameters Tuned for Pakistan’s Outdoor Sites

| Parametre | Sicarbtech Rugged SiC Stack | Typical Silicon Stack | Operational Implication |

|---|---|---|---|

| On‑resistance vs temperature | Modest increase to 125°C+ | Steeper increase | Stable output in afternoon heat |

| Reverse recovery charge | ~0 (Schottky) | Yüksek | Lower EMI, smaller filters |

| Max junction temperature | 175–200°C (package‑dependent) | 150–175°C | Downsized cooling, fewer deratings |

| Module/busbar inductance | <10 nH targets | 15–30 nH | Cleaner edges, fewer snubbers |

| Junction–case thermal resistance | 0.05–0.12 °C/W | 0.10–0.20 °C/W | Lower hotspot temperatures |

| Interconnect materials | Sintered silver | Soldadura | Mayor vida útil de los ciclos de potencia |

| Substrate material | AlN or Al2O3‑AlN composite | Alumina | Higher k, better toughness |

| Cooling architecture | Liquid/air/vapor hybrid | Single‑mode | Resilience to fouling and transients |

| Çevresel sızdırmazlık | Dust/salt‑mist‑resistant | Generic | Fewer ingress failures |

| Efficiency uplift | +0.8–1.5 percentage points | Başlangıç Noktası | Better LCOE/LCOS and uptime |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s differentiator is not just high‑performance modules—it is the ability to stand up consistent, ruggedized SiC manufacturing and validation locally. From Weifang City and as part of the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech leverages advanced R&D and proprietary processes across R‑SiC, SSiC, RBSiC, and SiSiC ceramic grades. These materials underpin high thermal conductivity and corrosion resistance in outdoor cabinets.

Beyond components, Sicarbtech provides complete technology transfer packages that include epitaxial growth (CVD) recipes for 1200/1700/3300 V platforms; device design guidance balancing trench/planar gates for low RDS(on) and oxide reliability; metallization stacks on AlN/composites; sintered‑silver process windows (pressure, temperature, dwell) for robust die attach and topside interconnects; and module pinout and passivation strategies tuned for high‑humidity, high‑salt conditions with appropriate creepage.

Equipment specifications cover utilities and environmental controls, sintering presses, vacuum ovens, dicing and packaging tools, cleaning and coating stations, leak and IP testing rigs, and metrology for parasitics and thermal resistance. Training programs upskill operators, process/test engineers, quality teams, and application engineers, embedding statistical process control, power cycling and HT/HH screening, salt‑spray tests, and EMC/thermal co‑design practices. Factory establishment services move from feasibility studies grounded in Pakistani utilities and labor markets through pilot line setup, qualification, and yield ramp with SPC. Quality frameworks align with ISO 9001 and ISO 14001, while Sicarbtech supports pathways to relevant IEC/UL tests for outdoor power electronics and local interconnection and PQ expectations.

Ongoing support includes quarterly process audits, reliability dataset refreshes, and on‑site or remote application engineering to tune laminated busbars, dv/dt edges, snubbers, magnetics, and cooling interfaces based on field telemetry. With more than a decade of customization and 19+ enterprise collaborations, Sicarbtech brings a repeatable, data‑driven playbook that compresses deployment schedules and stabilizes ramp economics. “Scaling rugged SiC is a metrology craft—yields follow what you measure and control every shift,” says a Sicarbtech process transfer leader, emphasizing the partnership model customers rely on.

Future Market Opportunities and 2025+ Trends: Rugged Outdoor Power’s Next Chapter

Pakistan’s next wave of deployments will emphasize resilience and modularity. Expect more MW‑class storage at industrial parks, larger rooftop PV on textile and steel facilities, repowered wind with smarter grid‑side converters, and DC fast‑charging along industrial corridors. Three‑level and cascaded MV architectures will spread as operators seek higher efficiency with smaller filters. Rugged packaging—sealed modules, corrosion‑resistant cold plates, and washable air paths—will become the norm rather than the exception.

SiC penetration in mid‑to‑high‑end outdoor converters and charging systems should trend toward 30–50% over the next several years, with the fastest adoption in hot, dusty interiors and coastal belts where cooling and corrosion dominate lifecycle cost. Bankability will increasingly depend on local‑condition reliability evidence: power cycling at elevated Tj, damp‑heat and salt‑spray endurance, dust ingress performance, and stability of parasitics over time. Vendors with integrated materials–devices–modules–equipment offerings and authentic technology transfer will hold a structural advantage, enabling partial localization that guards against FX volatility, shortens spare‑part lead times, and builds in‑country capability.

Sıkça Sorulan Sorular

What efficiency gains are realistic from ruggedized SiC modules in outdoor PV/PCS/charging?

In Pakistan’s high‑ambient conditions, projects typically see 0.8–1.5 percentage points uplift in peak, with 0.5–1.0 percentage points in weighted efficiency at 40–55°C ambient, driven by lower conduction/switching losses and improved thermal paths.

How does Sicarbtech protect modules against dust and salt mist near Karachi and coastal sites?

We combine sealed housings with gasketed lids, moisture‑resistant encapsulants, anti‑corrosion coatings, and protected fasteners. Laminated busbars and optimized creepage preserve insulation, while corrosion‑resistant cold plates resist scaling and pitting.

Can rugged SiC platforms meet power quality and EMC on weak feeders?

Yes. Low loop inductance (<10 nH targets) and clean Schottky recovery reduce ringing. With tuned dv/dt, right‑sized filters, and stable control loops, ≤3% THD and near‑unity PF are achievable, easing interconnection approvals.

Which voltage classes and topologies fit Pakistan’s PV, wind, and storage mixes?

1200/1700 V devices dominate LV and three‑level converters; 3300 V devices support cascaded MV submodules for 3–35 kV direct connection. Topology choice depends on power class, filter targets, and insulation constraints.

Why are sintered silver and AlN/composite substrates vital in heat and dust?

They provide high thermal conductivity and mechanical robustness that preserve junction margins and slow interface aging under fouling, vibration, and thermal cycling—extending power cycling life and reducing failures.

Will higher switching frequencies make EMC compliance harder?

Not when parasitics are designed out. With laminated busbars, tight loop geometries, and adjustable edges with Miller clamping, emissions drop at the source, often allowing smaller filters and faster commissioning.

Can Sicarbtech support local assembly and reliability screening in Pakistan?

Yes. We provide process know‑how, equipment specifications, training, ISO‑aligned quality systems, commissioning support, and ongoing audits. Phased localization reduces FX risk and shortens spare‑part lead times.

What reliability tests are available for Pakistan‑specific stressors?

Power cycling at elevated Tj, temperature cycling, high‑temperature/high‑humidity (damp heat), neutral salt spray, dust‑ingress cycles, and online screening. We share acceleration models and co‑develop validation plans for warranties.

How quickly can ruggedized SiC pilots be deployed and evaluated?

Typically within weeks to a few months. We recommend A/B trials capturing weighted efficiency, thermal maps, THD/PF, EMC margins, dust ingress metrics, and maintenance intervals to quantify benefits.

What total cost of ownership improvements do owners report?

Lower energy and cooling use, fewer deratings and maintenance events, smaller footprints, and better interconnection success—together producing lower TCO and stronger warranty narratives over 10–15 years.

Operasyonlarınız için Doğru Seçimi Yapmak

The best outcomes start with your site realities: ambient heat and dust, salt‑mist exposure, feeder stiffness, pad space, water quality for cooling, and maintenance cadence. When Sicarbtech co‑designs from epitaxy and gate oxide reliability through module parasitics, laminated busbar geometry, thermal stack, sealing/coatings, and dv/dt control, the gains compound—higher efficiency, cooler hotspots, quieter and smaller cooling, faster commissioning, and tighter compliance. For textile mills, cement and steel campuses, wind and PV plants, storage yards, and fast‑charging depots across Pakistan, ruggedized SiC packaging converts environmental adversity into dependable performance and bankable savings.

Uzman Danışmanlığı ve Özel Çözümler Alın

If you are specifying outdoor PV inverters, wind converters, storage PCS, or fast‑charging systems—or exploring localized assembly and reliability screening—Sicarbtech will translate your KPIs into a data‑backed roadmap with clear milestones for performance, compliance, and ramp. Contact: [email protected] | +86 133 6536 0038.

Makale Meta Verileri

Last updated: 2025-09-17

Próxima revisión programada: 01/12/2025

Content freshness indicators: 2025 Pakistan harsh‑environment outlook; rugged SiC modules for PV/wind/storage/charging; 1200/1700/3300 V devices; sintered silver and AlN/composite substrates; laminated low‑parasitic busbars; dv/dt control and EMC strategies; salt‑mist/dust reliability; localization and technology transfer pathways; case narratives from Faisalabad, Karachi, and desert‑edge wind sites.

About Sicarbtech: Silicon Carbide Solutions Expert located in Weifang City, China’s silicon carbide manufacturing hub; member of Chinese Academy of Sciences (Weifang) Innovation Park; 10+ years of SiC customization supporting 19+ enterprises; full‑cycle solutions from material processing to finished products; specializing in R‑SiC, SSiC, RBSiC, and SiSiC grades; services include custom manufacturing, factory establishment, and technology transfer.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.