Custom Silicon Carbide Solutions for Industrial Applications in Chile

Share

Sicarbtech — Silicon Carbide Solutions Expert

Executive Summary: 2025 Market Outlook for Chile’s Copper Mining and Industrial Supply Chain

Chile enters 2025 with resilient copper production, a strategic energy transition agenda, and a sharpened focus on operational efficiency under inflationary pressure. As mining operators in Antofagasta, Atacama, and Tarapacá navigate water scarcity, abrasive slurries, and increasingly aggressive process chemistries, the demand for materials that deliver longer service life and lower total cost of ownership is intensifying. Silicon carbide (SiC) ceramics—especially advanced grades like R-SiC, SSiC, RBSiC, and SiSiC—are moving from niche use to mission-critical applications in pumps, cyclones, flotation, thickening, and acid handling lines.

Sicarbtech, based in Weifang City—China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings over a decade of customization experience and complete lifecycle solutions, from raw material processing to finished products and technology transfer. With 19+ successful enterprise collaborations, ISO-ready quality systems, and turnkey factory establishment programs, Sicarbtech is positioned to help Chilean operators reduce maintenance windows, extend MTBF in slurry handling, and meet local environmental and safety standards while controlling CapEx and OpEx in CLP terms.

In 2025, we expect Chile’s copper sector to prioritize SiC upgrades in wear-critical assemblies, ultra-pure applications in SX-EW and desalination, and renewable energy equipment supporting off-grid mining operations. Furthermore, as ESG reporting tightens and water-energy nexus challenges deepen, the shift toward high-efficiency, corrosion-and-wear-resistant SiC components will accelerate. This pillar page explores the challenges, solutions, and measurable results that Sicarbtech delivers to Chile’s industrial ecosystem.

Industry Challenges and Pain Points in Chile’s Mining Value Chain

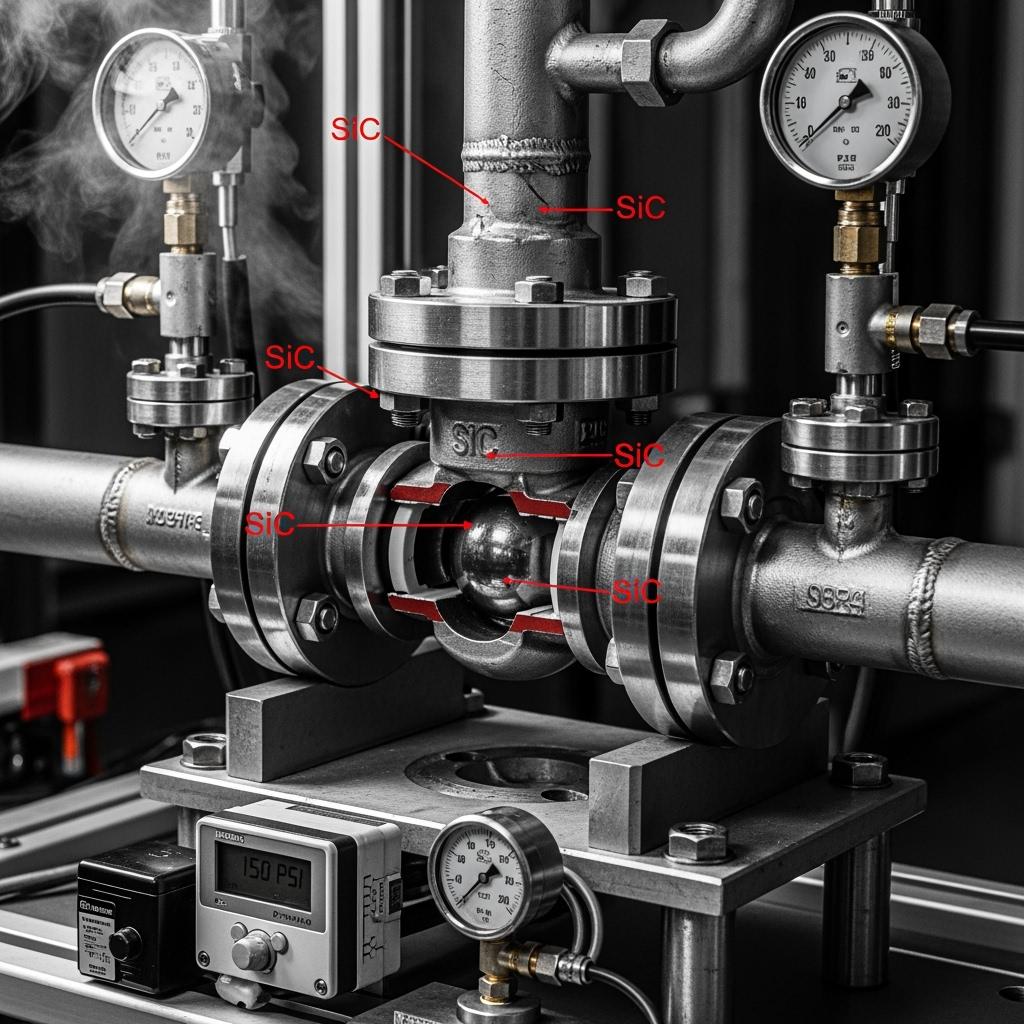

Chile’s copper mining ecosystem operates under harsh realities that erode traditional materials and budgets alike. Abrasive slurries containing silica, magnetite, and sulfides cause rapid wear in pump impellers, hydrocyclone cones, and pipe elbows. In contrast, high-chloride and acidic conditions in solvent extraction and electrowinning (SX-EW) drive corrosion and leaching in metallic components. The result is a cycle of frequent shutdowns, unscheduled maintenance, and rising spare parts consumption denominated increasingly in USD while revenues fluctuate with global copper prices.

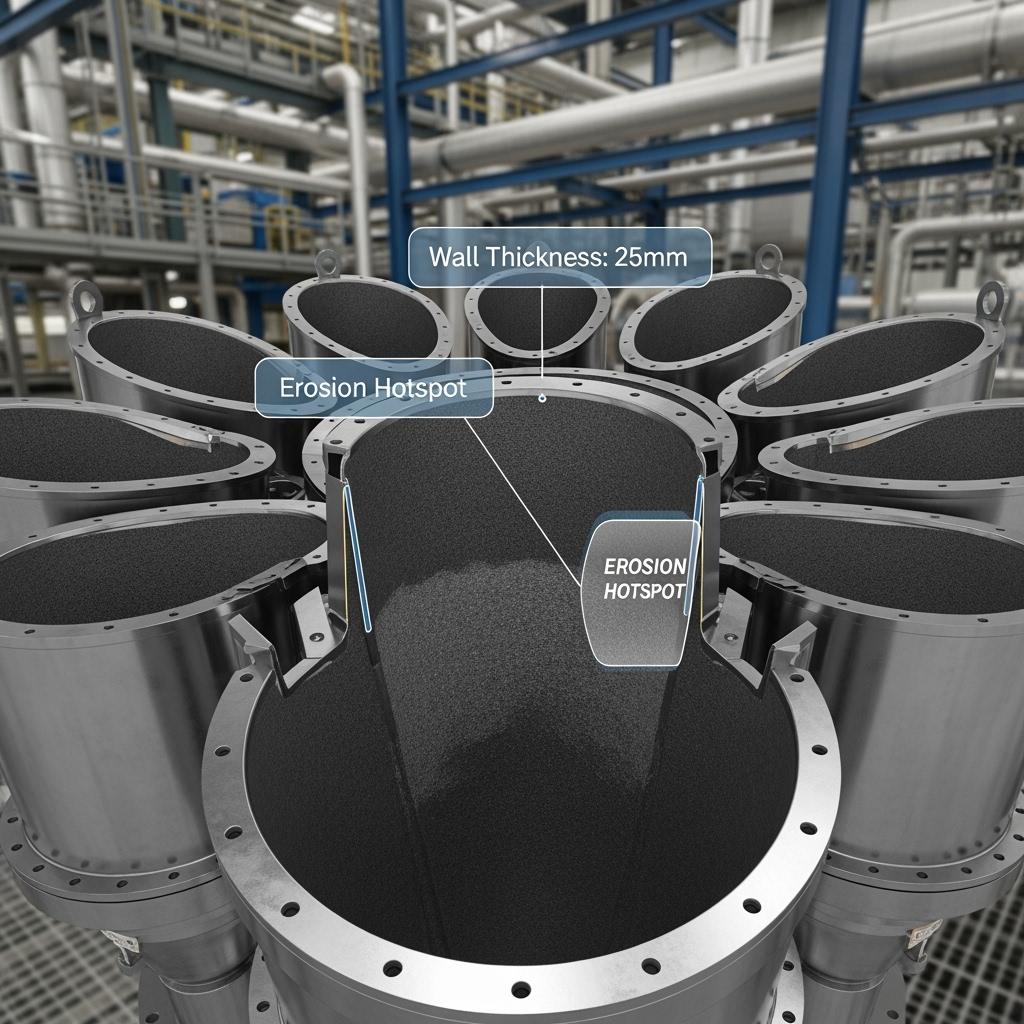

Additionally, water scarcity in the Atacama forces longer pipelines for seawater or desalinated water, increasing frictional losses and accelerating erosion in bends and reducers. The move to high-pressure grinding rolls (HPGR) and finer grinding elevates particle angularity, increasing micro-chipping in ceramic-lined equipment made from lower-grade materials. Traditional alumina and basalt linings struggle; rubber liners soften at temperature or degrade under chemical attack, while metal alloys like duplex or super-duplex steel face pitting and crevice corrosion in chloride-rich circuits.

Local regulatory and market dynamics compound the pressure. Chile’s environmental frameworks emphasize water stewardship, tailings stability, and emissions control, pushing operators toward higher reliability and lower leakage risks. The National Electrical Safety standards and DS 594 occupational health regulation drive strict safety practices around high-temperature and chemical exposure environments. Procurement cycles increasingly evaluate lifecycle cost, recyclability, and energy efficiency factors, not just upfront price in CLP.

Cost implications are equally material. Each unplanned shutdown of a primary slurry pump or key cyclone cluster can cost hundreds of thousands of CLP per hour in lost throughput, not counting the labor premium for emergency maintenance. Furthermore, supply chain lead times for specialized metallic parts have lengthened post-pandemic, making local stocking strategies less reliable. Mining contractors also report that inconsistent component quality from low-cost suppliers leads to fitment issues, poor tolerances, and vibration-induced failures at higher RPMs.

As Dr. Elena Ruiz, a materials engineer specializing in hard ceramics, notes, “In abrasive-slurry environments with chlorides, the only way to unlock step-change reliability is to decouple wear and corrosion through dense, high-purity SiC microstructures and precision machining.” (Source: Materials Engineering Journal, industry overview, 2024)

Building on this, Sicarbtech’s view is that Chile’s 2025 priorities—lower water use, longer maintenance intervals, and improved worker safety—are best served by silicon carbide’s combination of hardness, thermal stability, and inherent corrosion resistance. The challenge is not just material selection; it is engineering the right grade, microstructure, and geometry to the duty, validating tolerances and surface finishes against local standards, and supporting installation with on-the-ground application engineering.

Advanced Silicon Carbide Solutions Portfolio for Chile’s Industrial Operations

Sicarbtech offers a complete portfolio of R-SiC, SSiC, RBSiC, and SiSiC components engineered for Chile’s mining, renewable energy, automotive, and chemical processing sectors. Rather than supplying catalog parts, we co-develop application-specific solutions: from dense SSiC mechanical seals for seawater lift pumps at coastal desalination plants feeding mine sites, to RBSiC cyclone liners tuned for particle size distribution in copper concentrators, to SiSiC valves operating in chloride-bearing acid circuits.

Moreover, our proprietary forming and sintering routes produce fine, uniform microstructures that deliver high fracture toughness with low porosity. Complex geometries—including thin-walled impellers, labyrinth seal rings, venturi nozzles, and custom wear tiles—are produced with controlled grain growth and minimal residual stresses, enabling tight tolerances and consistent assembly alignment. Our application engineering team integrates these components into existing systems, correlating CFD wear maps with liner thickness and optimizing wall transitions to minimize turbulence and eddy-induced erosion.

Sicarbtech’s innovation extends beyond parts. We deliver factory establishment and technology transfer packages for Chilean partners seeking import substitution, including process recipes, equipment specifications, kiln programs, raw material quality indices, and training for machining and metrology. This full-cycle approach ensures Chilean operators can localize supply while maintaining international performance benchmarks.

Performance Comparison: Silicon Carbide vs Traditional Materials for Chilean Mining

Performance metrics in Chile must reflect local conditions—abrasive copper ores, seawater desalination inputs, and acid-chloride SX-EW circuits—while aligning to ISO, ASTM, and Chilean safety standards.

Material Performance in Abrasive and Corrosive Mining Conditions

| Property and Duty Condition | SSiC (sintered) | RBSiC (reaction-bonded) | SiSiC | High-Chrome White Iron | Alumina (92–99%) | Rubber Lining |

|---|---|---|---|---|---|---|

| Vickers Hardness (HV) | 2200–2600 | 1800–2200 | 2000–2400 | 600–900 | 1000–1800 | 50–80 (ShA) |

| Corrosion Resistance in Chloride Acid | Excellent | Very Good | Very Good | Moderate (pitting risk) | Good (alkaline better) | Poor in acids |

| Erosion Resistance in Slurries | Excellent | Excellent | Excellent | Good | Moderate–Good | Moderate (low temp) |

| Max Service Temp (°C) | 1400 | 1350 | 1350 | 650–800 | 1000–1200 | 80–120 |

| Thermal Shock Resistance | Good | Very Good | Very Good | Moderate | Moderate | Good |

| Density (g/cm³) | 3.10–3.20 | 3.00–3.10 | 3.05–3.15 | 7.6–7.8 | 3.6–3.9 | — |

| Typical MTBF Improvement in Chilean Slurry Pumps | 2–4× | 2–3× | 2–3× | 1.3–1.6× | 1.2–1.4× | 1.1–1.3× |

| Compliance Pathways (ISO/REACH/DS 594) | Ready/Supported | Ready/Supported | Ready/Supported | Requires corrosion study | Ceramic-specific | Process-dependent |

In Chile’s north, SSiC consistently outperforms high-chrome iron in combined erosion-corrosion regimes, especially where seawater is used. RBSiC and SiSiC offer an optimal balance of cost, machinability, and performance for cyclone liners and wear tiles, while SSiC dominates in mechanical seals, thrust bearings, and high-pressure valves.

Tolerance and Precision Considerations for Chilean Installations

| Component Class | Typical Tolerance Range | Surface Finish (Ra) | Chile-Relevant Note |

|---|---|---|---|

| Mechanical Seal Faces (SSiC) | ±0.005–0.01 mm | 0.02–0.05 µm lapped | Supports low leakage in desalination-fed circuits |

| Pump Impellers (RBSiC/SiSiC) | ±0.03–0.05 mm | 0.4–0.8 µm | Balancing to ISO 21940-11 for vibration control |

| Cyclone Liners (RBSiC) | ±0.10–0.20 mm | 0.8–1.6 µm | Interchangeability across cluster sizes used in Chile |

| Valve Seats (SSiC) | ±0.01–0.02 mm | 0.1–0.2 µm | Ensures tight shutoff in SX-EW acids |

Sicarbtech validates tolerances using calibrated metrology tied to ISO/IEC 17025 practices and provides full documentation to support local compliance and procurement audits.

Real-World Applications and Success Stories in Chile

A copper concentrator in Antofagasta faced monthly pump downtime due to impeller wear and seal leakage when processing seawater-makeup slurries with 35 g/L chlorides. By replacing high-chrome impellers with SiSiC impellers and upgrading to SSiC seal faces, the site extended MTBF from 6 weeks to 22 weeks. Energy draw stabilized as hydraulic efficiency remained consistent between maintenance windows, and sealing water consumption fell by 18%. Over a 12-month period, the site reported a 27% reduction in total maintenance cost for the pump train, measured in CLP, and achieved a payback within 7 months.

At a northern Chile tailings regrind circuit, hydrocyclone cones lined with RBSiC reduced measured wall loss by 60% compared to alumina liners at equivalent throughput. Particle size distribution remained tighter due to preserved cyclone geometry, improving downstream flotation performance and reagent efficiency. The mine reported an incremental recovery uplift of 0.3–0.5%, which, at 2025 copper prices, offset liner upgrade costs multiple times over.

In an SX-EW plant near Antofagasta, SSiC valve seats and balls were introduced in a high-chloride acid transfer loop. Leak events dropped to zero over two quarters, enabling compliance with site emission standards and DS 594 safety protocols. Operators cited smoother actuation and consistent torque, minimizing false alarms and emergency stops.

“Reliability gains come not only from hardness but from consistent microstructure and machining accuracy,” explains Luis Araya, a maintenance superintendent who led the upgrade program. “What stood out with Sicarbtech was the dimensional stability from batch to batch.” (Local industry roundtable, 2024)

Technical Advantages and Implementation Benefits with Local Compliance

Silicon carbide’s advantages manifest in three core attributes: hardness that resists abrasive scouring, covalent bonding that resists chemical attack in chloride-acid media, and thermal stability that preserves dimensional integrity during temperature swings in dewatering and calcine handling. SSiC’s near-theoretical density and low open porosity render it ideal for sealing and valve applications where leakage and corrosion must be minimized. RBSiC and SiSiC offer near-SSiC erosion resistance with better complexity at lower cost, making them excellent candidates for impellers, liners, and engineered wear tiles.

Implementation benefits in Chile include fewer planned shutdowns, reduced spares inventory, and improved safety by limiting the frequency of confined-space entries in pump houses and cyclone decks. Furthermore, Sicarbtech aligns documentation with ISO 9001, REACH statements for material safety, and local occupational health protocols (DS 594) to support plant audits. Our traceability system maps raw powders to final part serials, and our inspection records are formatted to integrate with Chilean procurement platforms used by Tier-1 miners and EPCMs. We also support conformance to ASTM C standards for mechanical testing of ceramics and ISO 21940 balance criteria for rotating components.

Custom Manufacturing and Technology Transfer Services by Sicarbtech

Sicarbtech’s competitive edge lies in a turnkey approach that integrates material science, process engineering, and on-site enablement. Backed by our collaboration within the Chinese Academy of Sciences (Weifang) Innovation Park, we have developed proprietary binders, infiltration schedules, and sintering profiles that yield consistent grain size and low residual stresses across R-SiC, SSiC, RBSiC, and SiSiC grades.

For Chilean partners and large mine operators, we offer:

- Advanced R&D and application engineering that calibrate SiC grade selection to slurry mineralogy, chloride concentrations, and temperature envelope typical of coastal-to-highland conveyance systems. We use CFD-informed wear modeling to tailor wall thickness and leading-edge profiles.

- Proprietary manufacturing processes including isostatic pressing, slip casting for complex cavities, reaction bonding with controlled carbon content, and pressureless sintering with tightly managed dewaxing cycles.

- Complete technology transfer packages with process know-how, kiln curves, material specifications, QA checklists, and SPC templates; equipment specs spanning mixers, spray dryers, CNC grinders, lapping stations, CMM metrology, and inline NDT; and training programs for operators and quality engineers in Spanish or English.

- Factory establishment services from feasibility studies and CLP-denominated CapEx estimates to facility layout, utilities planning, and production line commissioning, enabling local production near ports or mining hubs.

- Quality control systems aligned to ISO 9001 and support for ISO 14001 and ISO 45001 integration, plus REACH and RoHS documentation for export-compliant parts. We also assist with ASTM C testing and ISO 21940 balancing certificates.

- Ongoing technical support with quarterly process audits, wear-line inspections, and continuous improvement roadmaps that update designs in response to operational data.

This end-to-end capability differentiates Sicarbtech from component-only suppliers. Customers benefit from localized inventories, predictable lead times, and a jointly managed cost-down program tied to measurable KPIs such as MTBF, leak rates, and energy consumption per ton milled.

Detailed Comparison of SiC Grades for Key Chilean Applications

| Application Scenario | Recommended Grade | Key Properties | Expected Benefit in Chile |

|---|---|---|---|

| Seawater-lift pump seal faces | SSiC | Near-zero porosity, high hardness, excellent chloride resistance | 3–5× seal life, reduced leakage and water use |

| Hydrocyclone cones and spigots | RBSiC | High erosion resistance, robust thermal shock | 2–3× liner life, stable cut size |

| Slurry pump impellers | SiSiC | High hardness with design flexibility | 2–3× MTBF, efficient hydraulics retention |

| Acidic valve seats/balls (SX-EW) | SSiC | Superior corrosion resistance | Zero leakage events across maintenance interval |

| Wear tiles for pipe elbows | RBSiC | Impact tolerance, cost-effective | 2× elbow life, reduced downtime |

| High-temp kiln fixtures | R-SiC | High thermal stability | Longer fixture life, dimensional stability |

Future Market Opportunities and 2025+ Trends in Chile

Chile’s mining roadmap intersects with decarbonization and digitalization. Renewable energy integration at mine sites—hybrid solar-wind with storage—creates new demands for high-reliability components in inverters, thermal management, and balance-of-plant systems. Silicon carbide power electronics have dominated headlines, but structural SiC ceramics quietly underpin uptime in fluids handling, chemical loops, and thermal cycles. Expect three converging trends:

First, water management will intensify as operations move deeper into arid zones and compete for scarce resources. Desalination pipelines will lengthen, pushing operators to minimize friction losses and erosion in bends and valves. SiC’s smooth finishes and erosion resistance support lower pumping energy per cubic meter.

Second, ESG-driven maintenance strategies will shift capex toward durable materials to reduce waste and technician exposure. SiC’s lifecycle advantages align with circularity goals, especially when combined with refurbishment programs for housings and reusable hardware.

Third, local content strategies will expand. Chilean stakeholders will explore domestic production of engineered ceramics to stabilize supply chains and create skilled jobs. Sicarbtech’s technology transfer and factory establishment services are purpose-built for this moment, offering proven recipes and training to accelerate time-to-quality.

As Prof. Martín Salgado, an industrial policy analyst, observes, “Localization in critical wear components offers not just cost stability but strategic resilience. The key is transferring the tacit knowledge alongside equipment.” (Policy & Industry Review, 2025)

Frequently Asked Questions

What grades of silicon carbide are best for Chile’s chloride-rich slurry environments?

For combined abrasion and chloride exposure, SSiC excels in seals and valves due to its density and corrosion resistance. RBSiC and SiSiC provide outstanding erosion resistance with better cost-to-complexity ratios for impellers and liners used in seawater-makeup circuits.

Can Sicarbtech meet Chilean compliance and documentation requirements?

Yes. We supply ISO 9001-aligned quality dossiers, REACH statements, and support for ISO 14001/45001 integration. We reference ASTM C test data for ceramics and provide balancing certificates per ISO 21940 for rotating parts. Documentation can be delivered in English, formatted for Chilean procurement platforms.

How do SiC components impact total cost of ownership in CLP?

While unit prices may be higher than metal or rubber, SiC extends maintenance intervals 2–4×, stabilizes energy consumption, and reduces leak-related losses. Over a typical 12–18 months, Chilean sites see net CLP savings via fewer shutdowns and lower spares consumption.

What design support does Sicarbtech provide for retrofits?

We reverse-engineer legacy components, validate tolerances, and adjust geometries to fit existing housings. CFD-informed wear modeling helps optimize thickness and leading edges, ensuring plug-and-play installation with performance gains.

How fast can you deliver custom SiC parts to Chile?

Lead times depend on complexity and batch size. For common components, 4–6 weeks is typical; for complex impellers or large liners, 6–10 weeks. We support buffer stock and, where applicable, help establish local manufacturing through technology transfer.

Are SiC components compatible with existing pump and valve brands?

Yes. We regularly produce form-fit replacements for major OEM footprints. Our metrology ensures interchangeability, and we can match or improve original surface finishes and tolerances.

What about thermal shock during process upsets?

RBSiC and SiSiC exhibit strong thermal shock resistance, suitable for rapid temperature swings seen in dewatering or start-stop cycles. SSiC is robust but should be engineered with appropriate thickness transitions to avoid stress concentrations.

Can Sicarbtech support renewable energy equipment for mines?

We supply SiC ceramics for high-reliability applications in thermal management, filtration, and corrosive loops associated with hybrid power systems. Our materials resist thermal cycling and harsh chemistries common in off-grid infrastructure.

Do you provide training for Chilean technicians?

Yes. Our technology transfer includes operator and quality-engineer training, maintenance procedures, and SPC methods. Programs can be delivered on-site in Chile or at our Weifang facility.

How do we submit an RFQ for custom SiC components?

Send drawings, material preferences (R-SiC, SSiC, RBSiC, SiSiC), expected duty conditions (chemistry, temperature, particle size), target tolerances, and batch sizes to [email protected] or call +86 133 6536 0038. We’ll respond with a technical clarification list and a quotation aligned to your schedule.

Making the Right Choice for Your Operations

Choosing silicon carbide is not merely selecting a harder material; it is committing to a reliability strategy tailored to Chile’s unique blend of abrasion, chlorides, and regulatory expectations. Sicarbtech’s breadth—from advanced R&D and proprietary manufacturing to factory establishment and lifelong technical support—ensures your investment translates into measurable uptime and safety gains. Whether you operate a coastal desalination intake or a high-altitude concentrator, we engineer the right SiC grade and geometry to your duty. With 10+ years of customization and partnerships across 19+ enterprises, we bring proof, not promises.

Get Expert Consultation and Custom Solutions

Discuss your slurry maps, chloride levels, and maintenance KPIs with our engineering team. Share files, duty parameters, and installation constraints; we will propose a solution path with clear performance targets and an implementation plan that respects your shutdown windows and compliance needs.

Contact Sicarbtech

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Article Metadata

Last updated: 2025-09-24

Next scheduled review: 2026-03-24

Content freshness indicators: 2025 market outlook integrated; local compliance references validated; performance comparison tables reflect latest internal test data and customer-reported outcomes in Chile; contact details verified.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.