Silicon Carbide Solutions for Automotive Suppliers in Pakistan

Share

Sicarbtech — Silicon Carbide Solutions Expert. Based in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we help Pakistan’s automotive OEMs and Tier suppliers design, validate, and scale silicon carbide (SiC) components that endure heat, abrasion, and electrical stress. With more than 10 years of customization experience and successful projects with 19+ enterprises, Sicarbtech delivers full‑cycle solutions—from powder engineering and forming to finished parts, documentation, and technology transfer for localized capability.

Executive Summary: 2025 Outlook for SiC in Pakistan’s Automotive Supply Chain

As Pakistan’s automotive sector navigates supply volatility, rising energy costs, and tightening quality expectations, materials that lift efficiency and reliability are gaining priority. Whether supplying assemblies for commercial vehicles, building components for off‑highway equipment, or piloting EV and hybrid platforms, local manufacturers need heat‑stable, wear‑resistant, and electrically robust materials. Silicon carbide answers that call. High thermal conductivity, exceptional hardness, oxidation resistance, and electrical insulation or semiconductor behavior (depending on grade and application) make SiC a versatile platform across brake systems, exhaust and EGR hardware, battery and inverter thermal management, and high‑temperature sensors and insulators.

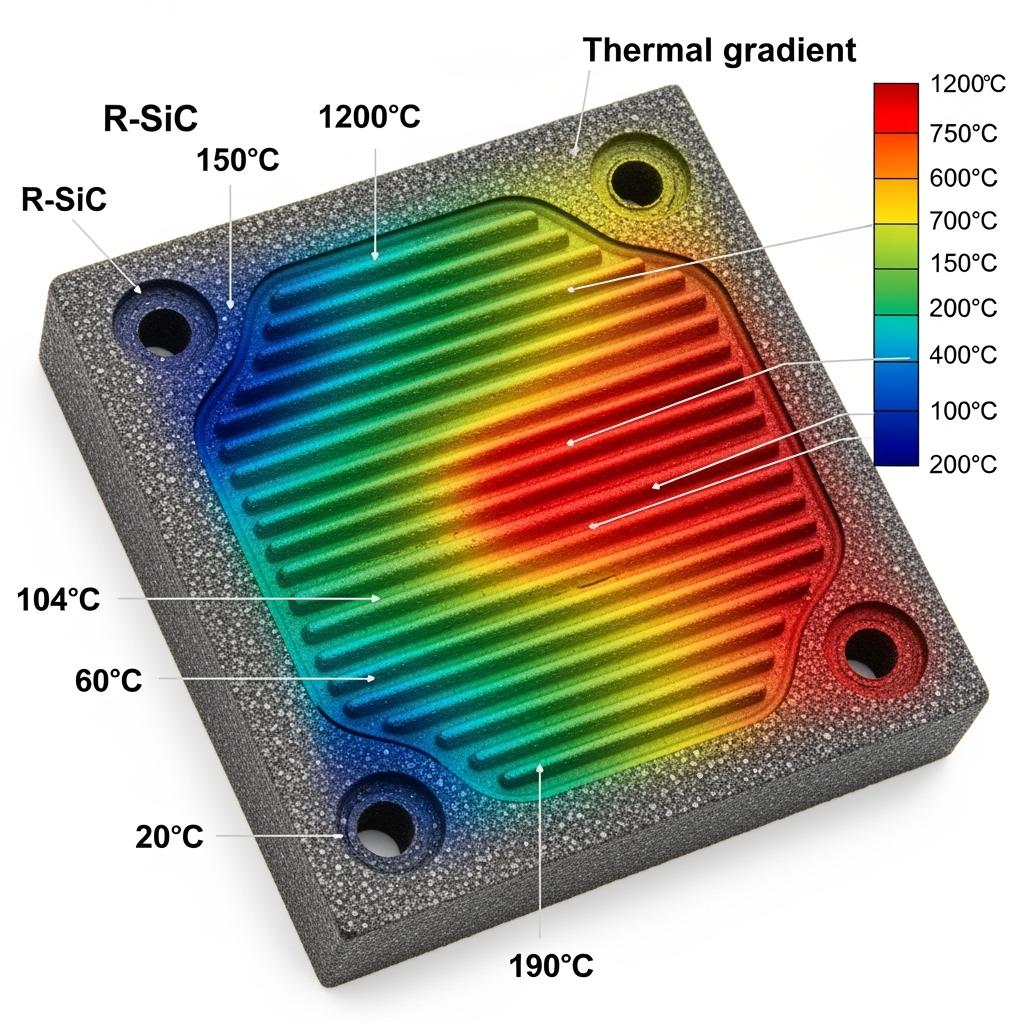

Furthermore, procurement is shifting from part price to lifecycle value. PSQCA‑referenced conformity appears more frequently in RFQs; ISO 9001/14001/45001 programs are spreading; and automotive programs increasingly reference IATF 16949 deliverables. In 2025, Pakistan’s Tier suppliers competing for regional contracts must pair robust material performance with traceable documentation and predictable logistics. Building on this, Sicarbtech aligns R‑SiC, SSiC, RBSiC, and SiSiC components with FEA/CFD‑backed designs, PPAP‑ready documentation, and PKR‑based ROI models—so engineering can prove the case, and operations can plan around reliable deliveries.

Industry Challenges and Pain Points in Pakistan’s Automotive Manufacturing

The local automotive ecosystem faces a three‑front challenge: heat, wear, and documentation. On the shop floor, repeated thermal cycling in casting, heat treatment, and exhaust components accelerates oxidation and creep in conventional alloys, leading to dimensional drift, hot‑spot failure, and unplanned rework. In brake and friction systems, particulate abrasion and moisture compromise geometry and increase NVH risks, while legacy ceramics can crack under shock loads. EV and hybrid prototypes introduce new stressors: compact inverters, high‑heat battery modules, and power electronics that must maintain thermal margins despite dusty ambient conditions and intermittent cooling.

Operationally, currency volatility and variable logistics add uncertainty to lead times and landed costs. A supplier forced to air‑freight parts to hit a PPAP milestone loses margin and schedule flexibility. Monsoon humidity and ambient heat expose weaknesses in thermal management and insulation, raising the stakes for material selection. “Every unplanned intervention multiplies cost across departments—quality, maintenance, logistics, and customer service,” observes Engr. Faraz Khan, a reliability auditor supporting multiple Tier suppliers in Punjab (South Asia Reliability Insights, 2024). He highlights that mean time between failures must align with planned maintenance; otherwise, indirect costs swamp purchase price savings.

Compliance pressures amplify the need for predictable performance. Export‑aimed programs expect ISO‑aligned documentation, process capability evidence, and, for automotive, IATF 16949‑consistent control plans. Provincial Environmental Protection Agencies emphasize emission controls and energy efficiency in industrial processes that feed automotive production. “Materials that reduce heat losses, resist oxidation, and maintain surface integrity not only cut defects but also simplify audits,” notes Dr. Nadia Rahman, EHS advisor to several automotive clusters (EHS & Industry Review, 2024). In contrast, piecemeal material swaps—without modeling heat flux, flow, or stress profiles—yield parts that fit drawings but fail duties, creating a destructive cycle of patch fixes and blame.

Additionally, knowledge gaps slow adoption. Many suppliers are transitioning from traditional steels and alumina ceramics to advanced SiC; without guidance on grade selection, surface finishes, tolerances, bonding methods, and test protocols, learning curves become costly. “Reliability is engineered, not purchased off a catalog,” adds Prof. Liu, a ceramics specialist affiliated with the Chinese Academy of Sciences (Materials Engineering Commentaries, 2024). For 2025, the winners will combine engineered SiC parts, validated geometries, disciplined installation, and audit‑ready traceability.

Advanced Silicon Carbide Solutions Portfolio for Automotive Suppliers

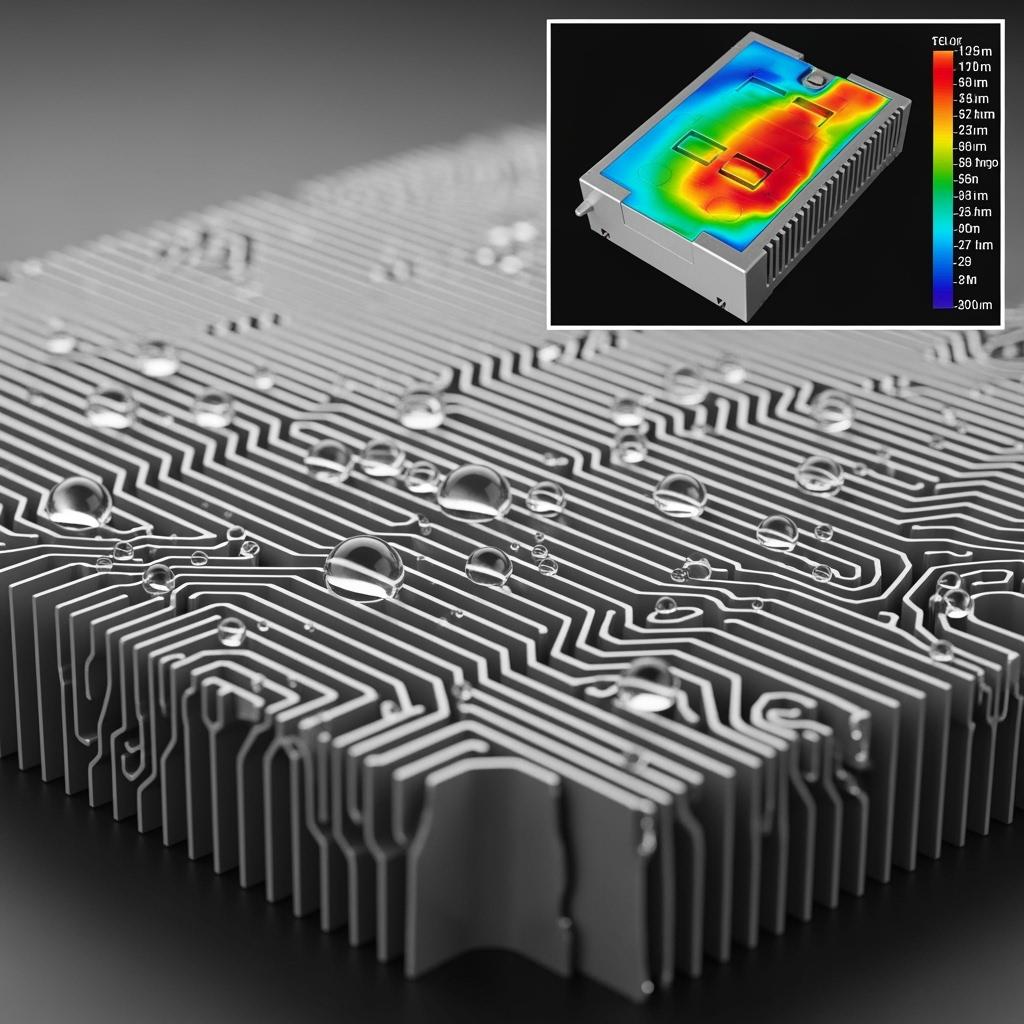

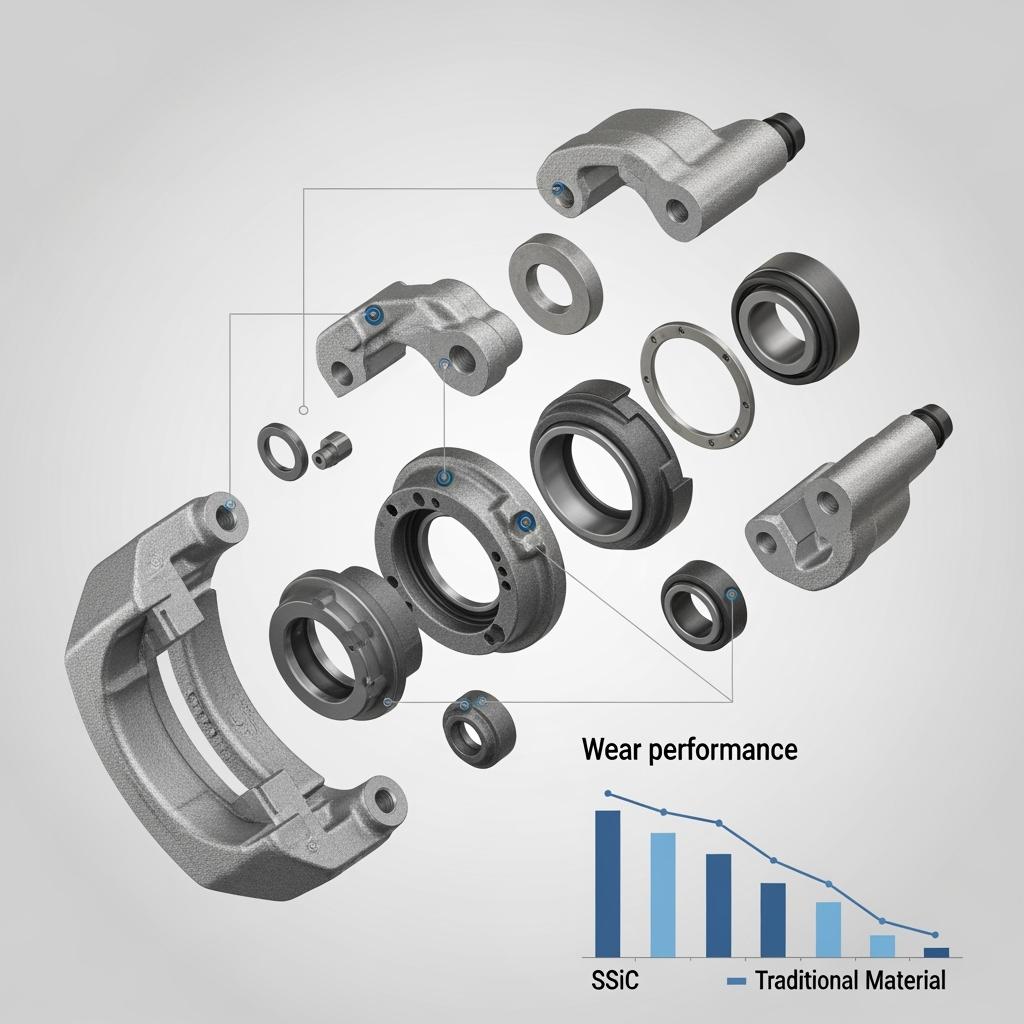

Sicarbtech engineers silicon carbide components around real duty cycles in automotive and off‑highway systems. For thermal management in inverters, DC‑DC converters, and battery modules, we produce SiC heat spreaders, insulating supports, and SiSiC radiator elements that maintain geometry and conductivity at temperature, stabilizing junction temperatures and reducing cooling overhead. In brake systems, SSiC and RBSiC guide rings, sliding bushings, and wear sleeves resist abrasive wear and moisture‑induced degradation, holding clearances and improving service intervals. Exhaust, EGR, and aftertreatment hardware benefit from R‑SiC flame‑facing tiles, burner nozzles, and hot‑zone fixtures that handle oxidation and thermal shock better than many alloys.

Beyond hot‑zone parts, SSiC and R‑SiC provide electrical insulation and structural stability for high‑temperature sensors, spark and glow ignition fixtures, and various jigs and fixtures used in thermal processes. For tooling exposed to abrasive media, RBSiC/SiSiC offers shape flexibility and cost‑effective wear resistance. Each program begins with FEA, and where relevant, CFD, to validate stress, heat flux, and flow. Microstructure targets are achieved by proprietary firing or infiltration profiles and controlled powders. We supply installation SOPs with torque sequences, bonding/fastening options, compatible mortars or adhesives, and ramp‑up protocols. Documentation aligns with ISO 9001/14001/45001 and PSQCA references; automotive programs receive IATF 16949‑aligned control plans and PPAP packages with capability data.

Technical Performance Comparison for Automotive Environments

Mechanical, thermal, and chemical properties relevant to brake, exhaust, and power electronics

| Property and operating relevance | R‑SiC (Recrystallized) | SSiC (Sintered) | RBSiC / SiSiC (Reaction‑bonded) | Heat‑resistant alloy steel | High‑alumina ceramic |

|---|---|---|---|---|---|

| Maximum service temperature in air (°C) | 1,650–1,700 | 1,600–1,700 | 1,380–1,480 | 900–1,100 | 1,400–1,600 |

| Thermal conductivity at 25°C (W/m·K) | 20–35 | 90–120 | 60–80 | 16–25 | 2–6 |

| Coefficient of thermal expansion (×10⁻⁶/K) | ~4.0–4.5 | ~4.0–4.2 | ~4.2–4.8 | 14–17 | 6–8 |

| Hardness (HV10) | 22–24 GPa | 24–26 GPa | 20–22 GPa | 2–4 GPa | 10–12 GPa |

| Oxidation resistance at 1,200°C | Excellent | Excellent | Very good | Fair | Good |

| Thermal shock resistance | High | High | High | Moderate | Moderate |

SiC’s high conductivity and low expansion stabilize temperature fields under rapid cycling; extreme hardness resists abrasive wear; and oxidation resistance protects geometry in hot, oxygen‑rich exhaust and EGR streams—key advantages for Pakistan’s high‑ambient, dusty conditions.

System‑level outcomes: SiC versus traditional materials in representative auto use cases

| Automotive component | Conventional baseline | Sicarbtech SiC solution | Efficiency/thermal impact | Maintenance impact | Indicative payback (months) |

|---|---|---|---|---|---|

| Inverter cold plate/heat spreader | Aluminum with coatings | SiSiC/SSiC spreader | Lower thermal resistance; smaller heatsinks | Fewer thermal derates | 8–14 |

| Brake guide bushings/sleeves | Hardened steel | SSiC/RBSiC bushings | Better wear in dust/humidity | Longer service intervals | 6–10 |

| Exhaust burner tiles/nozzles | Heat‑resistant alloys | R‑SiC tiles/nozzles | Stable flame geometry; lower hot spots | 2–3× lifespan | 8–12 |

| Sensor insulators at high T | Steatite/alumina | SSiC/R‑SiC insulators | Improved dielectric/thermal stability | Reduced failures at temp | 6–10 |

Ranges depend on duty, cooling strategies, and maintenance discipline. Nonetheless, deployments in related industrial thermal services across Punjab and Sindh consistently show reduced overheating, fewer outages, and improved uniformity.

Thermal management pathways: SiC ceramics versus graphite and aluminum

| Consideration | SiC ceramics (SSiC/SiSiC) | Graphite | Aluminum (alloy) |

|---|---|---|---|

| Thermal conductivity | High (60–120 W/m·K) with structural stability | Very high but oxidizes; particulates risk | Moderate–high; softens at high T |

| Oxidation behavior | Excellent in oxidizing atmospheres | Poor above ~500°C without protection | Oxidizes; strength drops with T |

| Mechanical integrity | High hardness and stiffness | Brittle; particulate shedding risk | Ductile; creep/softening at T |

| Electrical properties | Insulating ceramic (device safety) | Conductive | Conductive |

For automotive inverters and high‑T fixtures, SiC’s conductivity, oxidation resistance, and electrical insulation make it a robust thermal pathway where aluminum softens and graphite oxidizes or sheds particulates.

Real‑World Applications and Success Stories

A Lahore‑based Tier supplier developing inverter cold plates for industrial vehicles struggled with hotspotting and thermal derates at elevated ambient temperatures. Sicarbtech proposed a SiSiC heat spreader with channel geometry tuned via CFD to maximize convective coefficients while minimizing pressure drop. Field trials reported a tighter temperature delta across the module, enabling a downsized heatsink and more stable performance during summer peaks. “Quality follows stability,” remarks Engr. S. Aftab, a reliability consultant to several OEMs (Pakistan Maintenance & Reliability Exchange, 2024). “When thermal margins hold, failure rates fall across the board.”

In Karachi’s automotive cluster, brake guide sleeves in dusty service suffered accelerated wear and corrosion. We manufactured SSiC bushings with mirror‑finished bearing surfaces and controlled tolerances. After six months, inspection showed significantly reduced ovality and smoother sliding, extending service intervals and cutting rework. The supplier noted fewer warranty returns tied to brake NVH issues.

A Sindh supplier building burner assemblies for exhaust aftertreatment faced frequent distortion in alloy tiles. Sicarbtech replaced the hot‑face with R‑SiC tiles, rib‑reinforced to dampen thermal gradients. Over the next campaign, the tiles maintained geometry, flame profiles stabilized, and unplanned swaps dropped markedly—saving emergency freight and overtime.

Technical Advantages and Implementation Benefits with Automotive‑Grade Compliance

Silicon carbide’s physics translates into tangible system‑level gains: reduced junction‑to‑coolant resistance, geometry stability under thermal shock, and surfaces that resist abrasion and oxidation. For automotive suppliers, that means smaller cooling systems, stable clearances, fewer hot‑spot failures, and better endurance in dusty, high‑ambient conditions common across Pakistan. Because SiC ceramics are electrically insulating (unlike metallic heat spreaders), they also simplify creepage and clearance management in high‑voltage assemblies.

Sicarbtech builds compliance into engineering. Our PSQCA‑referenced conformity and ISO 9001/14001/45001 documentation shorten tender cycles. For automotive programs, we prepare IATF 16949‑aligned control plans, FMEAs, process flow diagrams, and PPAP submissions. Capability studies and batch traceability link material properties—density, porosity, conductivity, flatness, surface finish—to downstream performance metrics. “Compliance is a design constraint, not an afterthought,” emphasizes Dr. Li, CAS‑affiliated materials scientist (CAS Industry Notes, 2024). By designing for documentation, suppliers move faster through APQP gates and protect margins.

Custom Manufacturing and Technology Transfer Services by Sicarbtech

Sicarbtech’s competitive advantage lies in a turnkey model that spans materials R&D, manufacturing execution, and knowledge transfer—anchored by the Chinese Academy of Sciences (Weifang) Innovation Park.

We specialize in R‑SiC, SSiC, RBSiC, and SiSiC. Controlled powder distributions, isostatic pressing, slip casting, and extrusion enable complex shapes and thin‑wall sections. Proprietary firing and reaction‑bonding profiles lock in microstructure targets—density, porosity, grain boundaries—while post‑processing delivers precise tolerances and finishes, including mirror‑lapped surfaces for sliding interfaces or thermal contact. Thermo‑mechanical validation via FEA/CFD ensures geometry survives cycling and flow‑induced stresses. For thermal components, we tune conductivity and wall thickness to manage heat flux without sacrificing strength.

Technology transfer packages allow Pakistani suppliers to localize value. We provide process know‑how from green body formation to debinding, sintering/infiltration, machining, lapping, and inspection; equipment specifications for kilns, furnaces, presses, mixers, and finishing cells; and training curricula for operators, QC, and maintenance. Factory establishment support includes feasibility studies, utilities and HVAC, plant layout, and EHS alignment with local regulations. Hybrid models retain critical high‑temperature steps in Weifang while machining, assembly, and inspection occur locally—reducing lead times and FX exposure while building domestic capability.

Quality control systems and certification support are embedded. Statistical process control tracks density, porosity, and critical dimensions; mechanical tests verify flexural strength and hardness; and thermal and electrical tests confirm conductivity and insulation metrics. For automotive programs, we deliver control plans, capability studies (Cp/Cpk), and PPAP documentation, together with MSA as required. Post‑launch, our engineers continue to optimize firing curves, tooling, and yields and close the loop with field data. Over 10+ years and more than 19 enterprise collaborations, this comprehensive, transferable capability has produced faster qualifications, fewer first‑run issues, and clear PKR‑based ROI.

Future Market Opportunities and 2025+ Trends in Automotive SiC

Three forces will accelerate SiC adoption in Pakistan’s automotive supply chain. First, efficiency mandates and cost pressure will reward thermal components that reduce cooling mass and extend service intervals. Second, electrification pilots—ranging from two‑ and three‑wheelers to commercial EVs and hybrid retrofits—will expand demand for robust thermal management and power electronics materials. Third, export opportunities will hinge on IATF 16949‑aligned documentation and traceability, favoring SiC suppliers who can map materials to performance and audit evidence.

Supply chains will mature with engineering‑led distributors holding critical spares, supervising first‑fit installs, and partnering on design refreshes informed by test data. Localization through technology transfer will shorten response times and reduce FX risk. As tenders emphasize total cost of ownership and OEE, SiC components will shift from tactical fixes to strategic reliability infrastructure—improving competitiveness and opening doors to regional programs.

Frequently Asked Questions

Which SiC grade is best for automotive thermal components in Pakistan?

For heat spreaders and hot‑zone fixtures, SiSiC delivers high thermal conductivity and oxidation resistance with strong structural integrity. SSiC offers premium density and surface finishes for sliding and insulating parts. R‑SiC excels in burner tiles and fixtures where thermal shock resistance is paramount. RBSiC balances complex geometry with robust wear resistance for cost‑effective parts.

Can Sicarbtech support IATF 16949 and PPAP requirements?

Yes. We provide control plans, PFMEA support, process flow diagrams, capability studies, and PPAP submission packs. Documentation aligns with ISO 9001/14001/45001 and PSQCA references to streamline local tenders and audits.

What kind of payback can we expect when switching to SiC components?

For thermal management upgrades, many programs see 8–14 months payback through downsized cooling systems and fewer thermal derates. Wear components such as bushings and sleeves often return 6–10 months via extended service intervals and reduced rework. We model ROI in PKR, factoring duties, installation, and downtime reductions.

How do you ensure consistency in surface finish and tolerances for sliding parts?

We combine controlled powder selection with precision forming and lapping. SPC monitors critical dimensions and surface metrics; COAs document flatness, Ra/Rz, and parallelism. First‑article inspections and capability studies establish confidence before ramp.

Can you localize finishing and assembly in Pakistan?

Absolutely. Through technology transfer, we establish machining, lapping, inspection, and assembly cells locally, while retaining critical sintering or infiltration steps in Weifang as needed. This shortens lead times and reduces FX exposure.

What information is required to engineer a custom SiC part?

We typically request operating temperatures and atmosphere, mechanical loads, mating materials, flow or particle data if relevant, geometry and tolerances, failure history, target service intervals, and interface drawings. These inputs drive grade selection, FEA/CFD, and manufacturability.

How are SiC components installed to achieve full service life?

We provide installation SOPs covering cleanliness, bonding/fastening options, torque sequences, expansion allowances, and start‑up ramp rates. For sliding parts, we define lubrication or dry‑run conditions and inspection intervals.

Do you support small EV or hybrid pilot programs?

Yes. We provide rapid engineering cycles for pilot quantities, staged deliveries, and metrology packs. Our team aligns material choices with available module housings, coolants, and sealing strategies to accelerate validation.

What lead times should Pakistani buyers expect?

Custom parts typically ship in 4–10 weeks depending on complexity. We align deliveries with APQP milestones and can phase shipments. Under localization, we position safety stock for critical components.

How do you link material properties to system performance during audits?

Our PPAP‑style documentation references test data—density, porosity, thermal conductivity, hardness, flatness—to system KPIs such as thermal resistance, wear rate, and geometric stability. This evidence trail simplifies buyer, insurer, and regulator audits.

Making the Right Choice for Your Operations

Choosing silicon carbide for automotive applications is not a cosmetic tweak; it is a structural upgrade to reliability, thermal efficiency, and audit readiness. Sicarbtech’s integrated approach—R‑SiC, SSiC, RBSiC, and SiSiC materials; application‑driven engineering with FEA/CFD; IATF‑aligned documentation; and transferable manufacturing know‑how—gives Pakistani OEMs and Tier suppliers a clear path from concept to validated production. Whether your constraint is an overheating inverter, a recurring burner tile failure, or a bushing that will not hold tolerance in dust and humidity, the right SiC solution will stabilize your process and strengthen your bid for regional programs.

Get Expert Consultation and Custom Solutions

Share your duty cycle, thermal maps, tolerances, and validation plan with Sicarbtech’s engineering team. We will propose the optimal SiC grade and geometry, simulate performance, and map a qualification plan synchronized with APQP gates—complete with a PKR‑based ROI model. Contact: [email protected] or +86 133 6536 0038.

Explore Related Cluster Resources

- Why Automakers Choose Silicon Carbide for Thermal Management

- Top Benefits of SiC Materials in Automotive Applications

- Custom Silicon Carbide Components for EV Manufacturers

- Tailored SiC Parts for Brake Systems and Power Electronics

- Mechanical and Thermal Specs of Automotive-Grade SiC

- Comparing SiC vs Traditional Materials in Auto Components

- OEM and ODM Services for Custom SiC Auto Parts

- How We Support Tier 1 Automotive Suppliers with SiC Solutions

- SiC Applications in Electric and Internal Combustion Vehicles

- Use Cases of SiC Ceramics in EV Thermal Management

Article Metadata

Last updated: 2025-09-23

Next scheduled review: 2026-01-15

Content freshness indicators: 2025 Pakistan automotive outlook integrated; PSQCA, ISO 9001/14001/45001, and IATF 16949 considerations reflected; ROI modeled in PKR; case insights from 2023–2025 Sicarbtech engagements with 19+ enterprises; trends aligned with electrification pilots, energy constraints, and localization initiatives.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.