Silicon Carbide (SiC) for Foundries and Metalworking in Pakistan

Share

Sicarbtech — Silicon Carbide Solutions Expert. From Weifang City, China’s silicon carbide manufacturing hub, and as a member of the Chinese Academy of Sciences (Weifang) Innovation Park, we help Pakistani foundries and metalworking operations secure predictable uptime, tighter process control, and lower total cost of ownership. With more than a decade of customization experience and proven outcomes across 19+ industrial enterprises, Sicarbtech delivers full‑cycle solutions—spanning R‑SiC, SSiC, RBSiC, and SiSiC products, custom manufacturing, factory establishment, and technology transfer—tailored to the realities of Pakistan’s 2025 market.

Executive Summary: 2025 Outlook for Silicon Carbide in Pakistan’s Foundry and Metalworking Sector

Pakistan’s foundry and metalworking ecosystem is entering a decisive modernization phase. Steel re‑rollers in Punjab, aluminum casters in Sindh, and copper/brass shops serving automotive and appliance supply chains are all rethinking materials and process control. Energy costs remain volatile, PKR fluctuations complicate imports, and provincial environmental enforcement is tightening around particulate emissions and furnace efficiency. In this environment, silicon carbide is moving from optional to essential because it bridges high‑temperature stability, oxidation resistance, and wear performance—exactly where conventional refractories and alloys tend to fail.

Furthermore, export‑oriented foundries are aligning with ISO 9001/14001/45001 and increasingly referencing ISO/SGS certification evidence in their procurement. Automotive‑adjacent suppliers are gravitating toward IATF 16949 practices, which demand traceability, repeatable microstructures, and robust PPAP documentation. Building on this, Sicarbtech’s combination of engineered R‑SiC crucibles and kiln furniture, SiSiC radiant tubes, RBSiC linings, and SSiC precision components delivers measurable savings in fuel, scrap, and downtime, while accelerating audit readiness. With ROI cases expressed in PKR and implementation aligned with planned shutdowns, procurement leaders can justify upgrades even under capital constraints.

Industry Challenges and Pain Points in Pakistani Foundries and Metal Shops

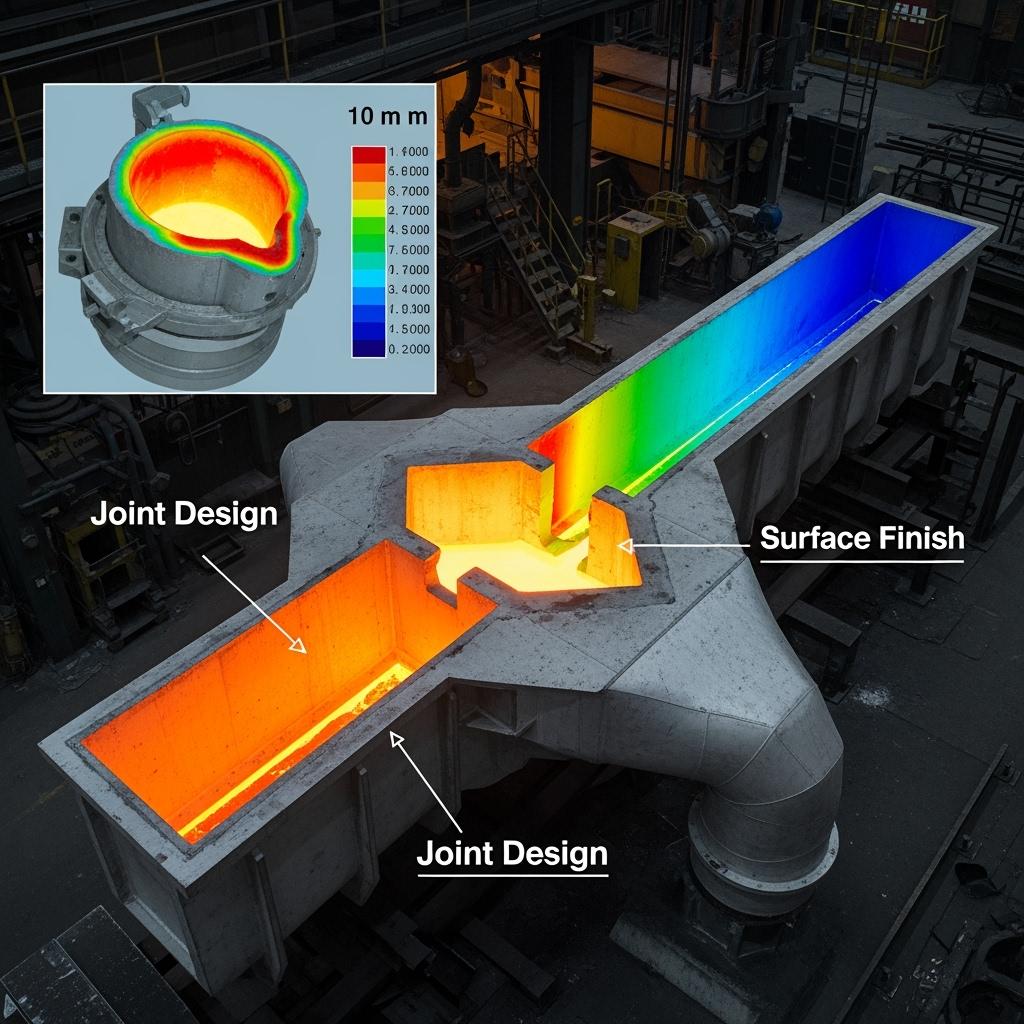

Foundries rarely struggle with a single bottleneck; instead, they face a cluster of issues that compound one another. In ferrous casting, thermal shock and oxidation degrade crucibles and channel linings, while slag chemistry and abrasive dross accelerate wear on troughs and launders. Non‑ferrous aluminum and copper operations wrestle with corrosive melts, fluxes, and thermal cycling that punish conventional refractories and alloy inserts. Ladles lose heat due to low‑conductivity linings that crack under repeated cycles, forcing more superheat and consuming fuel. In reheat furnaces and holding furnaces, alloy radiant tubes creep and oxidize, resulting in temperature non‑uniformity that raises scrap and rework.

These failures do not remain contained. A cracked crucible or spalled launder lining creates inclusions, inflates rejection rates, and triggers reactive maintenance. The cost is not just the part; it is lost output, overtime labor, emergency freight, and sometimes damaged tools or contaminated melts. “The real penalty is not the broken refractory—it is the shift in your quality curve,” notes Engr. Yousaf Gill, a metallurgical consultant active in Punjab’s foundry belt (Pakistan Foundry Forum Briefs, 2024). He emphasizes that consistent thermal environments and material stability at temperature correlate strongly with lower scrap and tighter dimensional control.

Energy is an equally pressing pain point. Many Pakistani furnaces run on expensive fuels or grid‑dependent power with variable quality. Inefficient heat transfer, hot‑spotting from oxidized tubes, and degraded linings can add several percentage points to energy intensity. Even a 1–2% improvement in thermal efficiency can translate into millions of PKR saved annually for medium‑to‑large furnaces. In contrast, poorly performing materials push operators to raise superheat, which increases oxidation, burn‑on defects, and fuel consumption—a negative spiral.

Moreover, compliance and buyer expectations are rising. Provincial Environmental Protection Agencies scrutinize particulate emissions and thermal efficiency; export buyers expect ISO‑aligned documentation and material traceability; and insurers ask for evidence of planned maintenance and reliability measures. “Materials that extend service life while reducing dust and stabilizing heat flows deliver a compliance dividend,” says Dr. Nadia Rahman, EHS advisor to multiple industrial estates (EHS & Industry Review, 2024).

Lead time and currency risk also shape decisions. Many foundries import refractory sets and alloy spares with long lead times that do not match outage windows. Stocking large spares ties up working capital, yet going lean risks stockouts. In contrast, a move to longer‑lasting SiC components lowers replacement frequency and allows smarter inventory strategies. “Reliability is engineered, not purchased by the kilo,” argues Prof. Liu, ceramics specialist affiliated with the Chinese Academy of Sciences (Materials Engineering Commentaries, 2024). The conclusion for 2025 is clear: success demands integration of material science, component geometry, and process modeling—not just catalog selection.

Advanced Silicon Carbide Solutions Portfolio for Foundry and Metalworking Use

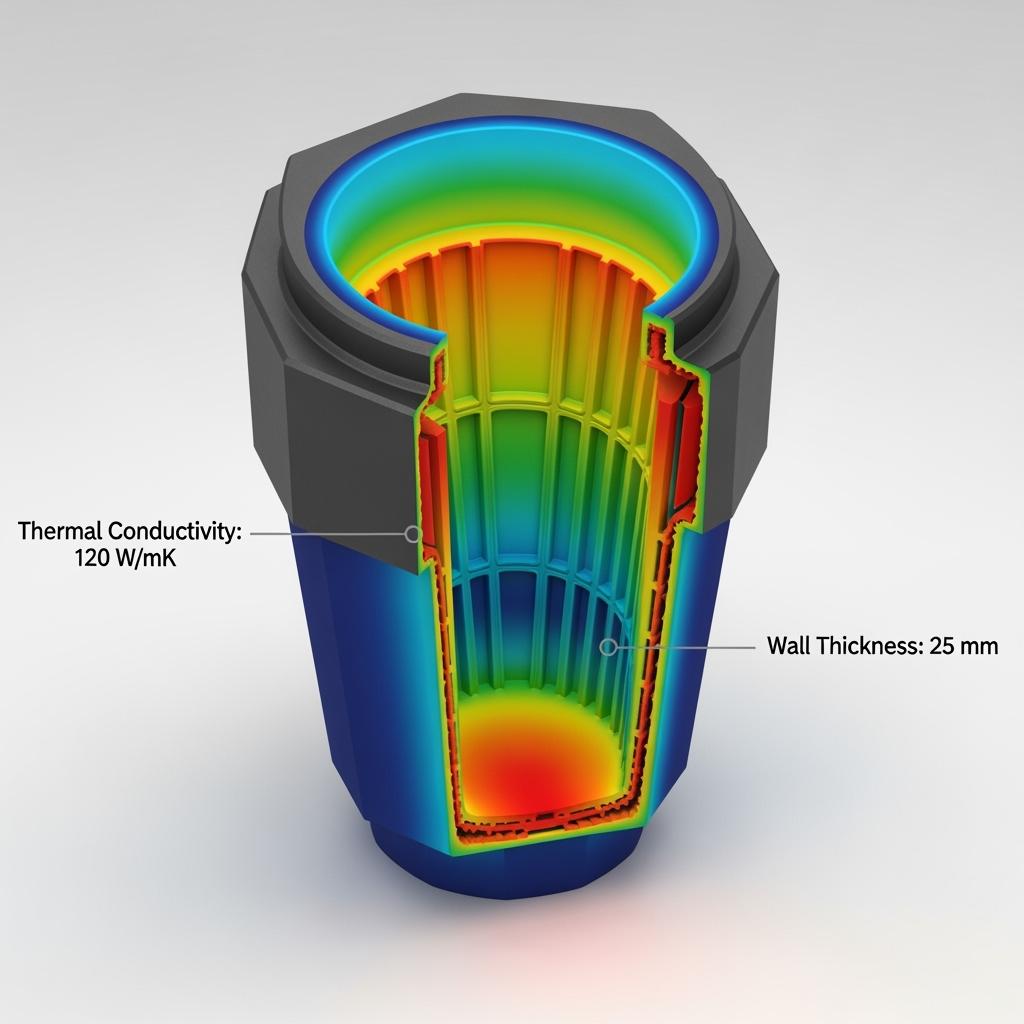

Sicarbtech’s SiC portfolio is engineered to the process realities of Pakistani foundries. For crucibles and ladles where dimensional stability and oxidation resistance at temperature define metal quality, we specify R‑SiC, tailoring wall thickness and rib geometry to manage thermal gradients and reduce thermal shock. For transfer launders, spouts, and slag‑contact zones, we deploy RBSiC/SiSiC linings with high erosion resistance and excellent oxidation behavior, allowing complex shapes and modular segments for targeted maintenance. In reheat and holding furnaces, SiSiC radiant tubes maintain geometry and emissivity under oxidizing atmospheres, improving temperature uniformity and reducing tube‑related outages.

Where corrosion and precision sealing matter—such as degassing systems, pump components for molten aluminum transfer, and valve seats in fluxed environments—SSiC’s near‑theoretical density and corrosion resistance limit leakage and extend service life. We also engineer kiln furniture, flame tubes, and burners for heat‑treatment fixtures, ensuring stable thermal profiles across start‑stop schedules common in small‑to‑mid foundry shops.

Additionally, Sicarbtech integrates application engineering with manufacturability. We model heat flux, thermal expansion, and stress through FEA; then we define microstructural targets achieved via proprietary firing or infiltration profiles. Our documentation supports ISO 9001 and PSQCA‑referenced conformity, while for OEMs we align control plans to IATF 16949 and prepare PPAP evidence where required. Implementation is guided by installation SOPs, preheat protocols, and maintenance instructions that condense qualification time and reduce first‑run risk.

Performance Comparison: SiC vs Traditional Foundry Materials in Pakistani Conditions

Technical properties relevant to foundry crucibles, linings, and radiant tubes

| Property and operating relevance | R‑SiC (Recrystallized) | SSiC (Sintered) | RBSiC / SiSiC (Reaction‑bonded) | High‑alumina refractory | Heat‑resistant alloy steel |

|---|---|---|---|---|---|

| Max service temperature in air (°C) | 1,650–1,700 | 1,600–1,700 | 1,380–1,480 | 1,400–1,600 | 900–1,100 |

| Thermal conductivity at 25°C (W/m·K) | 20–35 | 90–120 | 60–80 | 2–6 | 16–25 |

| Flexural strength at RT (MPa) | 100–180 | 350–450 | 280–380 | 30–60 | 150–220 |

| Hardness (HV10) | 22–24 GPa | 24–26 GPa | 20–22 GPa | 10–12 GPa | 2–4 GPa |

| Oxidation resistance at 1,200°C | Excellent | Excellent | Very good | Good | Fair |

| Thermal shock resistance | High | High | High | Moderate | Moderate |

| Erosion/slag resistance | Very high | Very high | Very high | Moderate | Moderate |

In Pakistani foundries using variable scrap and alternate fuels, SiC’s oxidation resistance and high hardness resist slag attack and thermal cycling better than conventional refractories and steels. SiSiC radiant tubes, in particular, maintain geometry and emissivity, improving uniformity and reducing hot‑spotting.

Lifecycle economics and reliability impact for typical Pakistani foundry cases

| Foundry use case | Conventional baseline | Sicarbtech SiC solution | Energy impact | Maintenance impact | Typical payback (months) |

|---|---|---|---|---|---|

| Ferrous crucible for melt/hold | High‑alumina crucible | R‑SiC crucible with rib‑stabilized wall | 1–2% fuel reduction due to better heat transfer | 2–3× life extension | 8–14 |

| Aluminum launder and spout | Castable refractory lining | RBSiC segmented lining | Lower heat loss, less erosion | 3–4× wear life | 6–10 |

| Reheat/holding furnace tubes | Heat‑resistant alloy tubes | SiSiC radiant tubes | Faster heat‑up, tighter uniformity | 2× interval between tube interventions | 10–16 |

| Degassing/pump components | Alloy/Al2O3 mixed parts | SSiC precision components | Reduced leakage and bypass | Longer seal and bearing life | 4–9 |

These ranges reflect Sicarbtech deployments and interviews across Punjab and Sindh foundry clusters. Actual outcomes vary with melt chemistry, flux usage, and duty cycles, yet the direction is consistent: custom SiC reduces fuel, wear, and unplanned outages.

Compliance, documentation, and qualification aligned to local and export needs

| Buyer requirement in Pakistan | Conventional approach | Sicarbtech approach | Outcome for audits and tenders |

|---|---|---|---|

| PSQCA‑referenced conformity | Generic datasheets | Application‑specific conformity packs | Faster local tender qualification |

| ISO 9001/14001/45001 documentation | Variable | Full traceability and EHS procedures | Smoother buyer/insurer audits |

| ISO/SGS certification evidence | Sporadic | Structured test reports and certificates | Higher confidence for export buyers |

| IATF 16949 readiness for OEMs | Limited | PPAP support, control plans, SPC | Easier supplier onboarding |

| Reliability modeling (MTBF) | Rare | FEA‑backed validation and SOPs | Predictable shutdown planning |

Real‑World Applications and Success Stories from Pakistani Foundries

A steel foundry in Central Punjab experienced frequent crucible spalling and metal inclusions during peak production. Sicarbtech designed an R‑SiC crucible with optimized ribbing to damp thermal gradients during fast heat‑up cycles. Over the next 12 months, the foundry reported a 1.8% reduction in fuel per ton and a 2.6× increase in crucible life. Scrap from inclusion‑related defects fell by 22%, and unplanned outages tied to crucible failures were eliminated.

In Karachi’s non‑ferrous cluster, an aluminum caster struggled with launder erosion and heat loss that forced higher superheat. We supplied RBSiC segmented linings with precision‑matched joints and a surface finish that reduced dross adhesion. Heat loss across the launder dropped measurably, allowing a 10–15°C reduction in superheat at equivalent flow. Liner life tripled, and maintenance shifted to planned, segment‑based replacements during scheduled stops.

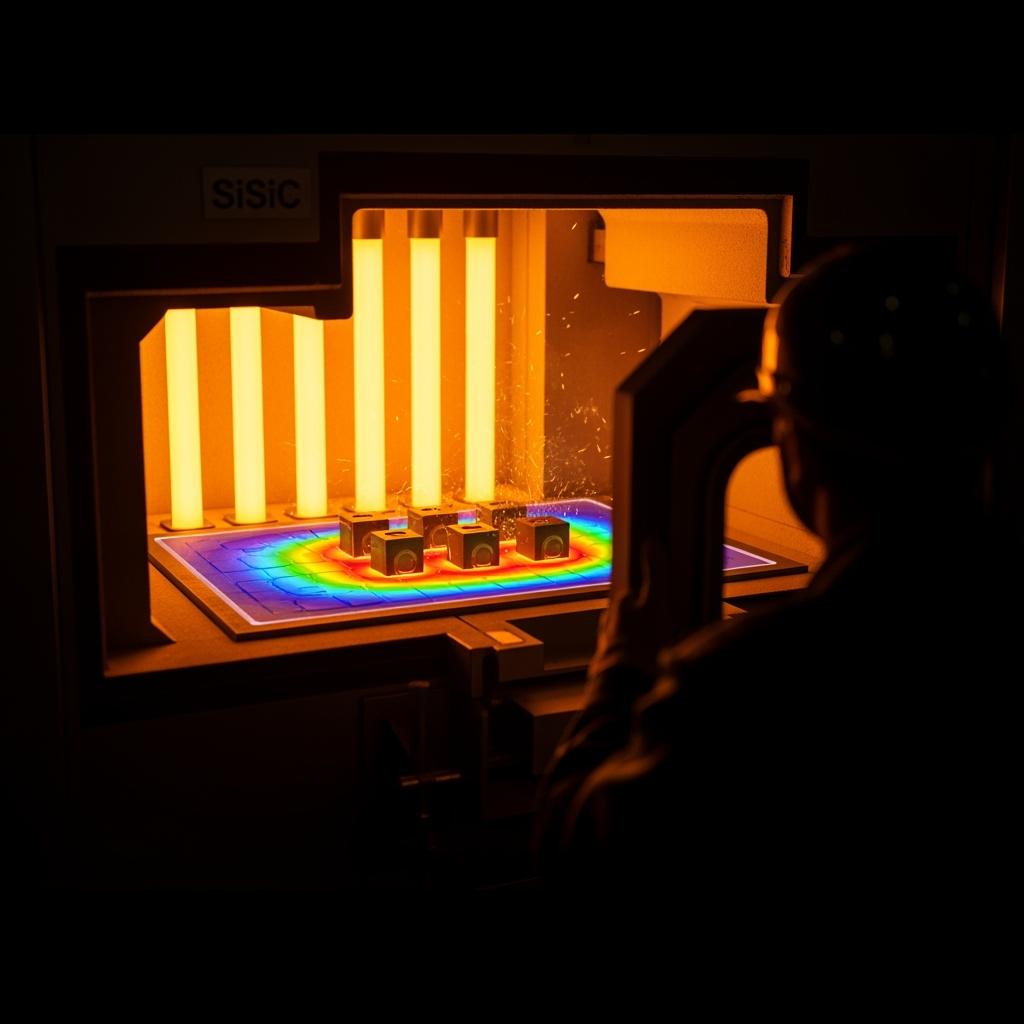

A heat‑treatment facility serving automotive stampings faced uneven soak temperatures due to oxidized alloy radiant tubes. Sicarbtech replaced them with SiSiC radiant tubes matched to atmosphere and load profile. Soak uniformity improved within ±5°C across the work zone, energy use declined by roughly 1.1%, and tube‑related downtime was effectively zero for the first operating year.

“Quality follows stability,” remarks Engr. S. Aftab, a reliability consultant to multiple OEMs (Pakistan Maintenance & Reliability Exchange, 2024). “When your hot‑zone geometry stays constant, your metallurgy becomes predictable—and scrap falls.”

Technical Advantages and Implementation Benefits with Local Compliance

The practical value of SiC arises from its physics and how those properties are engineered into the process. High thermal conductivity reduces energy to reach target temperatures and stabilizes heat flow, while low thermal expansion and robust oxidation resistance protect geometry through rapid cycles. In foundry service, that means fewer thermal shock cracks, less slag adhesion, more uniform heat profiles, and reduced superheat requirements.

Sicarbtech’s implementation approach is equally important. We validate drop‑in designs through FEA, define tolerances and surface finishes that match Pakistani OEM hardware, and provide installation SOPs and preheat curves to avoid early‑life damage. For launders and linings, we specify segment joints, mortars, and expansion allowances. For radiant tubes, we provide start‑up protocols to prevent thermal shock during first heat. Our documentation is organized to satisfy ISO 9001 and ISO 14001 auditors, with EHS procedures consistent with ISO 45001. Where needed, PSQCA‑referenced conformity is prepared for local tenders, and for OEM supply chains we support IATF 16949‑aligned control plans and PPAP submissions.

“Compliance is a design input,” emphasizes Dr. Li, CAS‑affiliated materials scientist (CAS Industry Notes, 2024). By embedding documentation and safety considerations into the engineering package, Sicarbtech shortens acceptance cycles and de‑risks adoption for Pakistani foundries.

Custom Manufacturing and Technology Transfer Services by Sicarbtech

Sicarbtech’s competitive advantage is a turnkey model that integrates materials science, manufacturing, and knowledge transfer. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, our proprietary processes span R‑SiC, SSiC, RBSiC, and SiSiC. Controlled powder sizing, advanced forming (isostatic pressing, slip casting, extrusion), tailored binders, and precisely profiled firing or infiltration cycles yield repeatable microstructures with narrow porosity and strength distributions—crucial for stable foundry performance.

For Pakistani investors and industrial groups, we offer complete technology transfer packages. These include process know‑how from green body formation through debinding, sintering/infiltration, machining, and lapping; detailed equipment specifications for kilns, furnaces, presses, mixers, and finishing cells; and operator, QC, and maintenance training curricula. We support the full factory establishment journey: feasibility studies, utilities planning, plant layout, EHS alignment with local regulations, and production line commissioning.

Hybrid models can localize machining, assembly, and inspection in Pakistan while retaining critical high‑temperature steps in Weifang. This reduces FX exposure and lead times, while building domestic capability and enabling faster service. Our quality system implements SPC on density, porosity, and critical dimensions; mechanical testing for flexural strength and hardness; and leak/pressure testing for sealed components. For OEMs, we align with IATF 16949 expectations, preparing control plans and PPAP documentation that streamline supplier onboarding. After commissioning, Sicarbtech engineers continue to optimize firing curves, tooling, and yields, ensuring stable cost structures and field performance.

This comprehensive, transferable capability is difficult for catalog‑only vendors to match. It gives Pakistani foundries a partner able to move from prototype to serial production, integrate with existing furnaces and handling systems, and internalize know‑how that endures. Over 10+ years and 19+ enterprise collaborations, this approach has produced faster qualifications, fewer first‑run issues, and clearer ROI.

Future Market Opportunities and 2025+ Trends for Pakistani Foundries

Three forces will shape adoption beyond 2025. First, energy economics and ESG pressures will continue to favor heat‑stable, low‑loss materials. SiC crucibles, launders, and radiant tubes are poised to spread from early adopters to mainstream, as evidence of fuel savings and quality gains accumulates. Second, export‑oriented manufacturers will heighten certification expectations, making SiC’s traceable, repeatable performance a practical route to meet audit demands and reduce customer complaints. Third, as Pakistan explores waste‑to‑energy and alternative fuels in industrial heating, the ability of SiC to tolerate variable atmospheres and thermal cycling will become a structural advantage.

We also anticipate more localized finishing and assembly for SiC components as distributors and engineering houses in Pakistan deepen partnerships with specialist manufacturers. This shift will shorten response times for spares and enable more frequent refreshes of process‑specific designs. In parallel, the cost of poor quality will rise as buyers enforce tighter tolerances and delivery schedules; in that environment, the stability provided by SiC translates directly into lower scrap and steadier throughput.

Ultimately, SiC is no longer a tactical replacement. It is a strategic lever for reliability, energy intensity, and compliance in Pakistani foundries and metalworking lines. Early movers will bank structural cost advantages as standards and competition intensify.

Frequently Asked Questions

Which SiC grade is best for crucibles and launders in Pakistan?

R‑SiC is typically preferred for crucibles and ladles because of its high‑temperature dimensional stability and oxidation resistance. For launders, spouts, and erosion‑prone zones, RBSiC/SiSiC offers strong wear resistance and design flexibility, especially in segmented configurations for targeted maintenance.

Can Sicarbtech’s SiC components help pass ISO and SGS audits?

Yes. We provide ISO 9001/14001/45001‑aligned documentation, structured test reports, and SGS/third‑party certificate evidence where required. For OEM supply chains, we support IATF 16949‑aligned control plans and PPAP submissions to accelerate onboarding.

What payback can a Pakistani foundry expect when switching to SiC?

Most projects show a 6–14 month payback for crucibles and launders, and 10–16 months for radiant tube upgrades, depending on energy prices, duty cycle, flux usage, and baseline failure modes. We model ROI in PKR and align deliveries with planned shutdowns.

How does SiC improve metal quality and reduce scrap?

Stable geometry and oxidation resistance preserve uniform heat transfer, lowering the need for superheat and reducing burn‑on defects. Smooth, erosion‑resistant surfaces reduce inclusions. Tighter thermal control reduces dimensional variance, cutting scrap and rework.

Can Sicarbtech localize parts or transfer manufacturing know‑how to Pakistan?

Absolutely. We offer technology transfer covering process know‑how, equipment specifications, SOPs, QC protocols, and training. Hybrid setups can place machining and assembly in Pakistan while retaining high‑temperature processing in Weifang, balancing lead time and quality.

What information is needed to design a custom SiC component?

We typically require melt chemistry and temperature, furnace atmosphere, cycle times, fluxes used, mechanical loads, geometry and tolerances, and target service interval. With this, we perform FEA, choose grade, and optimize microstructure and geometry.

How are SiC crucibles and radiant tubes installed for long life?

We supply SOPs and preheat protocols. Crucibles benefit from gradual ramp‑up and correct seating to avoid point loads; radiant tubes require controlled start‑up to limit thermal shock. We specify compatible mortars, expansion allowances, and support designs.

What lead times and delivery options does Sicarbtech offer for Pakistan?

Custom lead times usually run 4–10 weeks depending on complexity. We schedule deliveries around planned outages and can phase shipments. Under technology transfer or local finishing, we reduce lead times and FX exposure while maintaining quality.

Do you provide after‑sales technical support on site?

Yes. We offer remote diagnostics, on‑site commissioning, performance audits, and continuous improvement services. We also co‑develop spare strategies and inspection schedules aligned with your shutdown calendar.

How does Sicarbtech ensure consistent quality across batches?

Proprietary forming and firing/infiltration profiles, SPC on density/porosity/dimensions, mechanical and leak testing, and full traceability underpin batch consistency. For OEMs, we align with IATF 16949 and provide PPAP documentation when required.

Making the Right Choice for Your Operations

Adopting silicon carbide is not just a material upgrade; it is a decision to stabilize thermal processes, protect quality, and regain control over maintenance windows. Sicarbtech’s blend of R‑SiC, SSiC, RBSiC, and SiSiC grades; application‑driven design; complete documentation; and the option to internalize capability through technology transfer provides a de‑risked path to modernization. Whether the bottleneck is a crucible, launder, or radiant tube set, the right SiC solution can deliver predictable uptime and dependable ROI in Pakistani foundries.

Get Expert Consultation and Custom Solutions

Discuss your melt chemistry, duty cycle, and pain points with Sicarbtech’s engineering team. We will recommend an optimal grade and geometry, simulate performance against your process envelope, and map an implementation plan synchronized with your shutdown schedule—complete with a PKR‑based ROI model. Contact: [email protected] or +86 133 6536 0038.

Explore Related Cluster Resources

- Benefits of Silicon Carbide in High-Temperature Foundry Applications

- Why SiC Materials Are Ideal for Metalworking Environments

- Custom Silicon Carbide Crucibles and Linings for Foundries

- Designing Tailored SiC Parts for Foundry and Casting Use

- High-Performance SiC for Steel, Aluminum, and Copper Casting

- Technical Specifications for Foundry-Grade SiC Ceramics

- Downloadable Data Sheets for Custom SiC Foundry Products

- ISO and SGS Certified Silicon Carbide for Industrial Use

- Local Supply Chain for Silicon Carbide Products in Pakistan

- Shipping and Delivery Options for SiC Foundry Components

Article Metadata

Last updated: 2025-09-23

Next scheduled review: 2026-01-15

Content freshness indicators: 2025 Pakistan foundry outlook integrated; compliance aligned with PSQCA, ISO 9001/14001/45001, IATF 16949 considerations; ROI modeled in PKR; case insights drawn from 2023–2025 deployments; trends calibrated to energy volatility, ESG pressures, and localization initiatives.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.