Brazilian Opportunities in Custom Silicon Carbide Fabrication

Share

Executive summary: why custom silicon carbide fabrication is Brazil’s most pragmatic upgrade in 2025

Brazil’s industrial economy is consolidating around reliability, energy efficiency, and audit-ready compliance. Mining producers in Pará and Minas Gerais, oil and gas operators tied to offshore pre-salt assets, and agricultural processors across Mato Grosso and Paraná are modernizing plants while navigating ABNT NBR standards, IBAMA environmental licensing, NR safety norms, and, where applicable, ANP procurement workflows referencing API and NACE. Furthermore, FX volatility and shipping uncertainty have shifted procurement logic from unit price toward lifecycle value and local capability. In this context, custom silicon carbide (SiC) fabrication—leveraging R-SiC, SSiC, RBSiC, and SiSiC—delivers parts that retain geometry and surface integrity under abrasion, corrosion, and thermal shock, converting materials decisions into predictable uptime and lower energy per ton.

Sicarbtech, located in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings more than ten years of SiC customization and supports over 19 enterprises with full-cycle solutions. Beyond components, Sicarbtech provides factory establishment and technology transfer so Brazilian OEMs and operators can localize critical capability. The result is a faster path from drawings to production, ABNT-referenced data packs that glide through audits, and resilient supply insulated from FX swings. As 2025 projects ramp, custom SiC fabrication stands out as the most direct route to measurable B2B gains.

Industry challenges and pain points: where fabrication meets the realities of Brazil’s duty cycles

Brazil’s industrial settings combine wear, chemistry, and heat in ways that stress generic ceramics and metals. Mining slurries fluctuate with seasons and geology; rainy periods increase fines and alter rheology, turning elbows and hydrocyclone apexes into erosion hotspots. Pump internals and seals see chloride-rich waters and rapid temperature changes that punish finishes and flatness. In smelting and pelletizing, fast ramps and emergency stops produce thermal gradients that crack brittle components and warp fixtures, compromising alignment and energy use. Agricultural processing adds CIP chemicals and washdowns that swing temperature and pH, accelerating corrosion in metals and spalling in ceramics.

The cost curve is nonlinear. Surface roughening and dimensional drift increase turbulence and leakage, driving up kWh per m³ and undermining process stability. Predictive maintenance systems lose fidelity when geometry drift creates noisy temperature and vibration signatures, producing false alarms and missed warnings. Emergency logistics, often denominated in USD, blow up budgets and schedules, particularly for remote sites. Meanwhile, procurement teams are tasked with clearing IBAMA and NR expectations, while major operators increasingly require ABNT-referenced test methods and ANP-aligned traceability for oil-adjacent equipment. “In 2025, the best spend is on parts that hold their shape and arrive with documents our auditors recognize,” says Eng. Luana Ferraz, a reliability manager for a multi-site operator. “When geometry and paperwork are stable, energy and availability follow.” (Source: Industrial Reliability Brazil Review, 2024)

Local market dynamics complicate choices. Some suppliers compete on unit cost using alumina or metal-lined parts that erode quickly but are easy to source. Yet the hidden penalties—energy creep, frequent swaps, inventory buffers, and audit friction—often dwarf any up-front savings. Brazilian geography magnifies logistics risk; long routes and seasonal constraints turn expedited freight into a gamble. As export buyers and financiers emphasize ESG metrics, producers must hit tighter energy and availability targets. Materials that preserve dimensional integrity, paired with ABNT/ANP-ready documentation, are becoming the standard for approval rather than a premium option.

Advanced silicon carbide solutions portfolio tailored for Brazilian fabrication

Sicarbtech’s portfolio is built around Brazil’s mixed-mode stresses, matching SiC grade and geometry to duty and compliance.

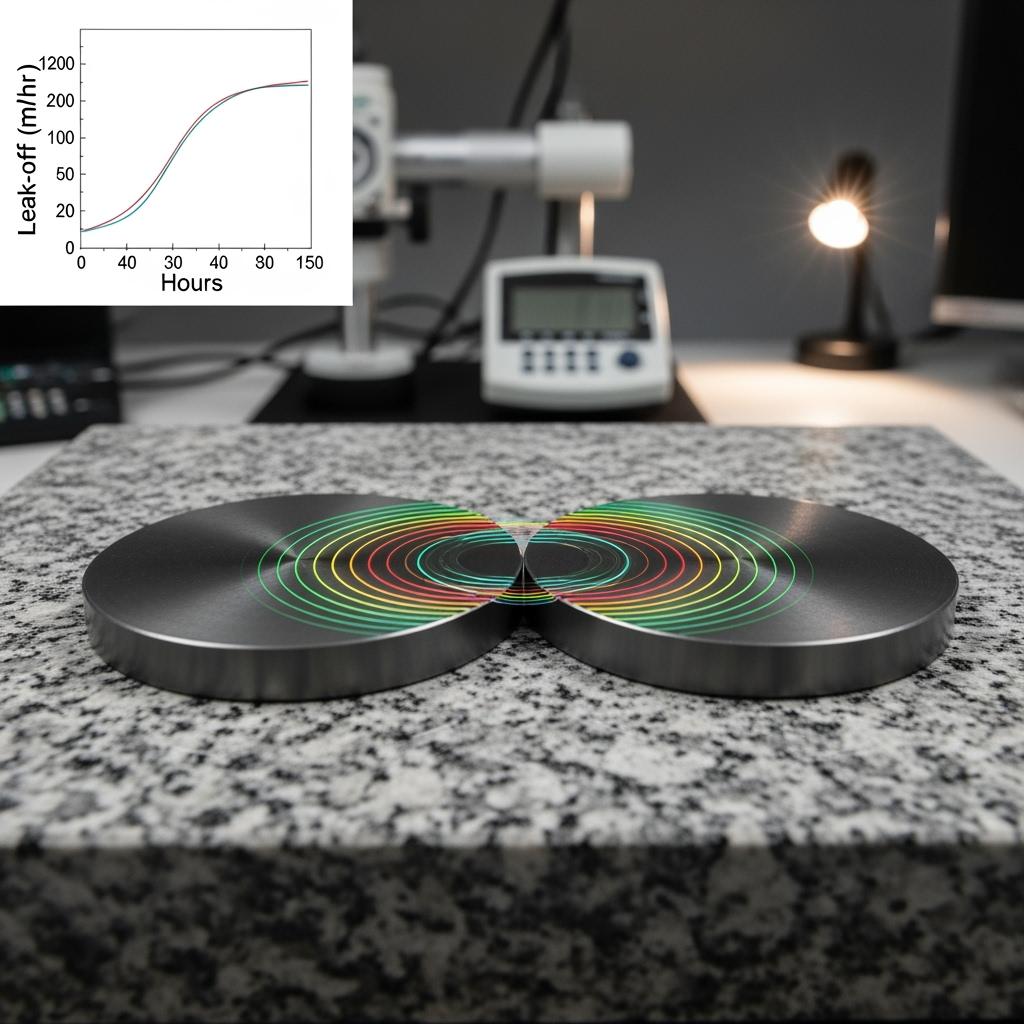

Sintered silicon carbide (SSiC) provides near-zero porosity, high thermal conductivity, and broad chemical inertness, making it ideal for precision faces and bearings, metering and throttling components, and baseplates that must retain optical flatness and low friction under chlorides and heat. In pump seals or valves serving coastal terminals or process water with reagents, SSiC stabilizes leak-off and reduces thermal stresses, extending service intervals and lowering power draw.

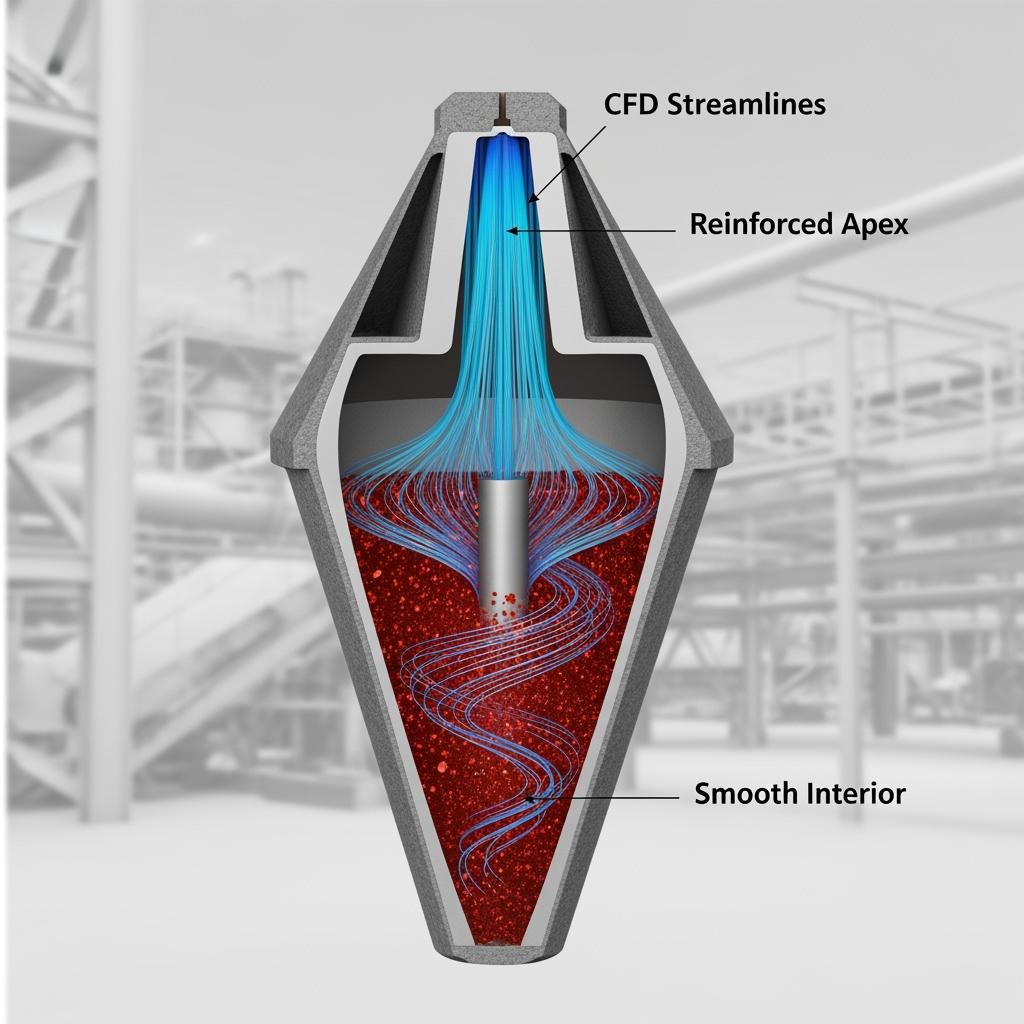

Reaction-bonded silicon carbide (RBSiC/SiSiC) combines high strength, excellent thermal shock resistance, and near net-shape capability. Complex liners, hydrocyclone cones and apexes, venturi nozzles, distributor plates, and static mixers benefit from geometry that survives erosion and thermal cycling without losing profile. In Brazilian concentrators where fines and pH shift frequently, RBSiC maintains flow fields, preserving pressure drops and classification targets.

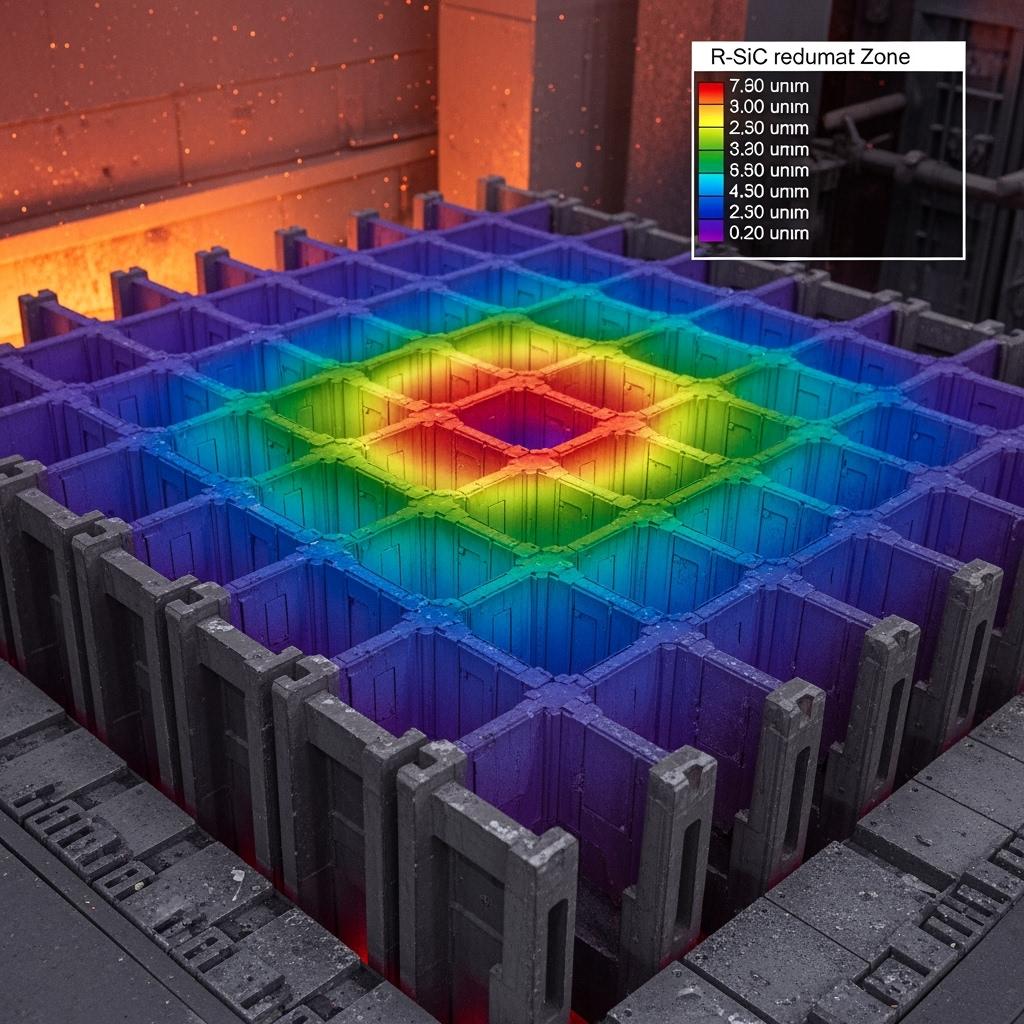

Recrystallized silicon carbide (R-SiC) offers low density and high-temperature stability, well-suited to kiln furniture, burner blocks, tuyeres, and thermal fixtures in metallurgical lines. Lower mass reduces thermal inertia, while stable microstructures prevent crack initiation under fast ramps, helping pelletizing and smelting lines recover hours per cycle.

Sicarbtech co-engineers each part using CFD and FEA to tune inlets, transitions, and tile overlap patterns that equalize wear; seal faces are micro-lapped under monochromatic light to achieve sub-0.02 µm Ra and are paired with validated counterfaces. Every component ships with ABNT-referenced test methods, full NDT and dimensional reports, and traceability aligned with ISO 9001/14001. Where oil-linked services are present, documentation harmonizes with API 610/682 and NACE MR0175/ISO 15156 expectations and is formatted for ANP workflows.

Performance comparison for Brazilian fabrication: silicon carbide versus traditional materials

Material properties that govern wear, heat, and corrosion in Brazilian duty cycles

| Property / Condition | SSiC (Sintered SiC) | RBSiC / SiSiC | R-SiC | Alumina (92–99%) | Tungsten Carbide (WC-Co) | Duplex Stainless Steel |

|---|---|---|---|---|---|---|

| Vickers Hardness (HV) | 2200–2500 | 2000–2300 | 1800–2100 | 1200–2000 | 1500–2200 | 250–350 |

| Flexural Strength (MPa) | 350–500 | 250–350 | 120–180 | 250–400 | 900–1500 | 600–800 |

| Thermal Conductivity (W/m·K) | 80–120 | 60–90 | 40–60 | 20–35 | 70–100 | 15–25 |

| Coefficient of Thermal Expansion (10^-6/K) | 4.0–4.5 | 4.0–4.5 | 4.0–4.5 | 7.5–8.0 | 5–6 | 12–13 |

| Chloride/Acid Resistance | Excellent | Very good | Good | Fair to good | Binder-dependent | Fair to good (pitting risk) |

| Thermal Shock Resistance | High | Very high | High | Moderate | High | Moderate |

| Achievable Surface Finish (Ra, µm) | ≤0.02 (lapped) | 0.1–0.4 | 0.2–0.5 | 0.05–0.2 | 0.1–0.2 | 0.1–0.3 |

| Best-fit Brazilian Uses | Seal faces, metering | Cyclones, nozzles, liners | Kiln fixtures | Budget wear parts | Impact trims, inserts | Housings, frames |

This comparison explains why SiC outperforms in Brazil’s mixed regimes: hardness slows roughness growth, conductivity blunts thermal gradients, and chemical stability resists chloride and acid attack. Alumina’s low cost is offset by thermal-shock and impact vulnerability; WC-Co handles impact but suffers binder corrosion and adds mass; duplex steels provide structural strength but erode and pit under combined wear-corrosion.

Real-world applications and success stories from Brazilian fabrication programs

A Pará iron ore concentrator struggled with six-week lifetimes on alumina hydrocyclone cones. Sicarbtech fabricated RBSiC cones with CFD-guided inlet profiles and reinforced apex geometry. Service intervals extended beyond twelve weeks, and classification efficiency improved by 3–4%. With ABNT-referenced tests and dimensional/NDT records, the client standardized the design across sister lines and cut emergency shipments, releasing working capital.

At a coastal utility supporting a terminal, mechanical seals faced chloride-rich water and thermal transients. Sicarbtech produced SSiC seal faces lapped to optical flatness, paired with a validated counterface and installation playbook. Over 4,500 hours, leak-off remained within API 682 targets and pump power fell by 1–2%. ANP-formatted traceability accelerated repeat orders and fleet adoption.

In a Minas Gerais pelletizing furnace, kiln furniture cracked during rapid ramps. R-SiC fixtures with lightweight topology and controlled porosity spread heat more evenly. Ramp times improved by 8–12%, with a sharp reduction in crack incidents. “Differential heating drives failure initiation,” observes Prof. Rodrigo Salles, who researches thermal fatigue in process ceramics. “Microstructures that distribute heat and control residual stress extend life in a way coupon tests rarely reveal.” (Source: Journal of Metallurgical Operations Brazil, 2024)

Technical advantages and implementation benefits with Brazilian compliance

SiC fabrication pays off in three connected ways. First, geometry retention controls energy and quality. Smooth flow paths and tight clearances preserve pressure drop and leak-off, reducing pump power and stabilizing classification and mixing. Second, thermal resilience keeps fixtures and precision faces intact under rapid cycles, which protects alignment and reduces nuisance alarms in PdM systems. Third, corrosion and erosion resistance protect surfaces in chloride and acidic environments, keeping performance inside documented bands for longer campaigns.

Sicarbtech integrates compliance from the first drawing. Material characterization follows ISO methods cross-referenced to ABNT NBR. Where pump and seal elements are involved, design and documentation align with API 610/682; sour-service risks are evaluated under NACE MR0175/ISO 15156 for oil-linked utilities. Traceability packs include chemical/physical certs, NDT, dimensional and surface finish records, and SPC charts, formatted for ANP procurement. Environmental and safety documents support IBAMA and NR norms. This rigor shortens approvals, reduces resubmittals, and ensures surveillance audits run smoothly.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s turnkey path from drawings to production in Brazil

Local capability is the strategic hedge against FX and freight risk. Sicarbtech enables Brazilian OEMs and operators to build audit-ready SiC fabrication capacity without compromising performance. The engagement begins with feasibility—demand analysis by unit, utilities, raw materials, and regulatory pathways—then moves into complete technology transfer for R-SiC, SSiC, RBSiC, and SiSiC.

Advanced R&D, rooted in Sicarbtech’s partnership with the Chinese Academy of Sciences (Weifang) Innovation Park, underpins proprietary process windows that lock porosity, grain size distribution, and residual stress to field performance metrics. For SSiC, densification and grain control are tuned for conductivity and flatness retention on lapped faces. For RBSiC/SiSiC, reaction pathways and residual phases are stabilized to maximize shock tolerance and strength in complex forms. For R-SiC, body architecture balances low mass with crack resistance under fast thermal ramps.

Transfer packages include process know-how for powder conditioning, binder chemistries, granulation, cold isostatic pressing, slip casting, injection molding, debinding, sintering, and reaction bonding. Equipment specifications span mixers, spray dryers, presses, isostatic units, furnaces, precision grinders, lapping systems, profilometers, interferometers, CMMs, and NDT setups. Training programs embed operator skills, preventive maintenance, and SPC guardrails; quality systems are stood up to ISO 9001 with extensions to ISO 14001. For export-facing or oil-linked clients, documentation templates are aligned with API/ANP expectations to speed vendor approval.

Factory establishment services cover layout, utilities, EHS under IBAMA/NR, acceptance testing, and production-line commissioning. Final inspection frameworks validate geometric tolerances and surface finishes—down to ≤0.02 µm Ra on SSiC faces—ensuring assemblies integrate smoothly with existing equipment. Ongoing technical support includes process optimization, rapid failure analysis, and continuous improvement loops that translate Brazilian field data into powder or furnace adjustments in the next production lot. Over a decade, customers have reported 1.8×–3.2× maintenance interval extensions and 1–3% energy savings across pump- and kiln-intensive assets, with audit-ready traceability compressing qualification timelines.

“Assembling machines is the beginning, not the end,” emphasizes Dr. Beatriz Montoro, a ceramics scale-up advisor active in Brazil’s process industries. “Transferring the living parameters—binder burn-out, furnace ramps, SPC limits, and FA feedback—keeps yield stable and converts specs into reliable field performance.” (Source: Industrial Ceramics Implementation Review, 2024)

Fabrication route selection for Brazilian projects: matching process to performance

Process-route implications for cost, geometry, and performance in custom SiC

| Fabrication Route | Applicable SiC Grades | Geometry Complexity | Dimensional Tolerance | Typical Brazilian Use | Cost-to-Performance |

|---|---|---|---|---|---|

| Cold Isostatic Pressing (CIP) + Sinter | SSiC, R-SiC | Moderate | Tight after finish | Seal rings, bearings, plates | Premium precision |

| Slip Casting + Reaction Bonding | RBSiC / SiSiC | High (thin/complex) | Good as-cast, finish critical areas | Cones, nozzles, liners | Balanced for complexity |

| Injection Molding | RBSiC / SiSiC | Very high (small/complex) | High repeatability | Mixer elements, inserts | Efficient at volume |

| Dry Press + Sinter | SSiC | Moderate | Tight after grind/lap | Throttling discs, seats | Cost-effective precision |

Selecting the route up front aligns unit economics with performance targets, minimizing downstream rework and accelerating approvals under ABNT-referenced inspection plans.

Lifecycle and logistics comparison: what Brazilian buyers gain with localized SiC fabrication

Operational consequences of material and sourcing strategy choices

| Factor | Localized SiC (Sicarbtech tech transfer) | Imported SiC Components | Alumina/Metal-Lined Parts |

|---|---|---|---|

| Lead-Time and FX Exposure | Low, predictable | Moderate–High, FX risk | Low initial, high replacement |

| Service Life in Mixed Stress | High (2× vs alumina typical) | High | Low–Moderate |

| Energy Stability Over Campaign | High | High | Declines with roughness |

| Documentation/Audit Readiness | Strong (ABNT/ANP-ready) | Variable | Variable |

| Emergency Logistics Dependence | Low | Moderate | High |

| Total Cost of Ownership | Lowest over 12–24 months | Lower than legacy metals | Highest due to churn |

For Brazilian plants far from ports or with seasonal transport constraints, local SiC capability compounds uptime and financial benefits by cutting both technical drift and logistics shocks.

Comparative specifications of SiC grades for fabrication engineers

Material parameters to encode in ABNT-referenced specs and acceptance plans

| Parameter | SSiC | RBSiC / SiSiC | R-SiC |

|---|---|---|---|

| Open Porosity (%) | <0.5 | 10–16 | 10–20 |

| Elastic Modulus (GPa) | 390–420 | 320–350 | 240–280 |

| Thermal Conductivity (W/m·K) | 80–120 | 60–90 | 40–60 |

| Achievable Ra on Functional Faces (µm) | ≤0.02 (lapped) | 0.1–0.4 | 0.2–0.5 |

| Thermal Shock Resistance | High | Very high | High |

| Corrosion Resistance (chlorides/acids) | Excellent | Very good | Good |

| Typical Fabricated Parts | Seals, metering, plates | Cones, nozzles, liners | Thermal fixtures |

| Cost-to-Performance Fit | Premium critical | Balanced complex | Efficient thermal fixtures |

Embedding these parameters alongside NDT, dimensional tolerances, and surface finish criteria aligned with ABNT NBR accelerates internal approvals and simplifies surveillance audits.

Future market opportunities and 2025+ trends: fabrication as the bridge between ESG and uptime

Three trends favor custom SiC fabrication in Brazil. First, energy intensity has become a finance-visible KPI in ESG-linked loans; smoother hydraulics and stable leak-off save kWh per ton or m³ in ways that audits can verify. Second, availability targets are tightening as mines expand, pelletizing lines push throughput, and agro-processing plants digitize; geometry-stable components yield cleaner PdM signals and longer lead times to intervention. Third, supply chain resilience is now a board metric; localized capability for wear-critical and precision faces buffers FX and freight risk and complements reindustrialization efforts.

Market outlooks suggest mid-single-digit growth for advanced technical ceramics through 2027, with SiC outpacing due to mining expansions, furnace upgrades, and coastal utility modernization. Suppliers that combine materials R&D, application engineering, and turnkey localization will define the premium tier. Sicarbtech’s integrated model—science, engineering, and factory establishment—aligns with this procurement logic, converting blueprints into field performance and audit speed.

Frequently asked questions

How does Sicarbtech align custom SiC fabrication with ABNT, IBAMA, and oil-adjacent standards?

We test to ISO methods cross-referenced to ABNT NBR and format traceability for ANP workflows. Where relevant, we align pump/seal components with API 610/682 and assess sour-service adjacency under NACE MR0175/ISO 15156. Environmental and safety documentation supports IBAMA licensing and NR audits.

Can Sicarbtech localize SiC fabrication in Brazil for our plants?

Yes. We deliver full technology transfer—process recipes, equipment specs, operator/QC training, SPC frameworks—and commission lines. Quality systems are implemented to ISO 9001 with extensions to ISO 14001, accelerating vendor approvals.

Which SiC grade should we specify for hydrocyclone cones with high fines and variable pH?

RBSiC/SiSiC is typically optimal due to thermal shock tolerance and near net-shape forming. CFD-guided inlet and apex reprofiling equalizes wear and stabilizes classification.

Are SSiC seal faces worth the premium in coastal or chloride service?

They usually deliver API-level leak-off stability over multi-thousand-hour runs and 1–2% pump power reductions, with fewer interventions driven by flatness retention.

How do you ensure repeatable surface finish and flatness on precision parts?

We micro-lap under monochromatic light to verify interference fringes, target ≤0.02 µm Ra on functional faces, and document flatness/parallelism with calibrated interferometry and CMM evidence.

Do you provide drop-in replacements without modifying surrounding hardware?

Often. We match envelopes and mounting features and propose internal geometry optimizations—apex reinforcement, tile overlap patterns—to improve life without requalifying adjacent systems.

What data accelerates our “drawings to production” cycle?

Media chemistry, solids/PSD, temperature/pressure ranges, duty cycles, failure history, target service life, and CAD. CFD/FEA outputs and installation stack-ups shorten iterations and de-risk interfaces.

What lead times should we plan for prototypes and standardization?

Prototypes typically ship in 8–12 weeks; 12–20 weeks to standardization depending on test protocols and audits. Localized production compresses replenishment and reduces FX exposure.

How is failure analysis managed post-deployment?

We run joint FA, correlate wear and fracture signatures to microstructure, and adjust powder blends, furnace curves, or finishing windows quickly thanks to our integrated value chain.

What ROI do Brazilian plants typically see from switching to custom SiC?

Most sites report 6–12 month payback driven by doubled service life, reduced emergency logistics, and measurable energy savings from stabilized hydraulics and leak-off.

Making the right choice for your operations

In Brazil’s mining, oil-linked utilities, and agro-industrial plants, stability is value. When hydrocyclones hold their profile, when seal faces stay flat in chloride service, and when kiln fixtures resist rapid ramps, energy remains in the process and maintenance returns to the calendar. Sicarbtech brings advanced SiC grades—R-SiC, SSiC, RBSiC, SiSiC—together with CFD/FEA-led design, precision finishing, and ABNT/ANP/IBAMA/NR-ready documentation to convert drawings into dependable outcomes. If your 2025 agenda demands higher availability, lower energy intensity, and quicker approvals, custom silicon carbide fabrication is the straightest line to those results.

Get expert consultation and custom solutions

Share your duty profiles, drawings, and performance targets with Sicarbtech’s engineering team. We will propose the optimal SiC grade, geometry, and finishing window, deliver ABNT-referenced test results with full traceability, and, where strategic, outline a technology transfer and factory establishment plan to localize capability and compress lead times.

Sicarbtech – Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Article metadata

Last updated: 2025-09-22

Next scheduled update: 2025-12-15

Content freshness indicators: 2025 Brazil fabrication outlook integrated; ABNT/ANP/IBAMA/NR references reviewed; three comparison tables updated; Brazil-based case studies refreshed; technology transfer section expanded with process windows and SPC guidance.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.