Custom Silicon Carbide Solutions for Industrial Applications in Brazil

Share

Executive Overview: Why Silicon Carbide Will Shape Brazil’s Industrial Efficiency in 2025

Brazil’s industrial backbone—mining in Minas Gerais and Pará, offshore oil and gas in pre-salt basins, and large-scale agribusiness processing from Mato Grosso to Paraná—is under simultaneous pressure to raise throughput, curb maintenance costs, and meet stringent environmental targets. As utilities and operators push equipment harder and regulators tighten standards, materials that thrive under abrasion, corrosion, thermal shock, and high loads are moving from “nice-to-have” to mandatory. That is where engineered silicon carbide (SiC) unlocks measurable, near-term gains.

Sicarbtech, based in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings over a decade of customization experience to Brazil’s operators and OEMs. By combining advanced R-SiC, SSiC, RBSiC, and SiSiC grades with turnkey technology transfer and factory establishment services, Sicarbtech bridges the gap between laboratory-grade material science and field-proven, production-ready components.

In 2025, we expect Brazilian buyers to prioritize lifecycle economics, Brazilian Regulatory Agency for Petroleum, Natural Gas and Biofuels (ANP) compliance in oil and gas, ABNT NBR alignment for industrial equipment, and adherence to IBAMA-backed environmental guidelines. Moreover, currency volatility and CAPEX constraints are driving interest in local manufacturing footprints and knowledge transfer. Against this backdrop, Sicarbtech’s comprehensive approach—materials, design, fabrication, qualification, and ongoing optimization—offers a practical path to improved OEE, lower total cost of ownership, and faster time-to-value.

Industry Challenges and Pain Points in Brazil’s Core Sectors

Most industrial reliability problems in Brazil stem from a common set of stressors. In open-pit and underground mining, abrasive slurries shred conventional steel and alumina ceramics, forcing frequent shutdowns. The ore blending variability typical of Brazilian mines increases particle size and hardness fluctuations, intensifying wear unpredictably. Meanwhile, logistics to remote sites add lead time risk, which raises the cost of spare inventory.

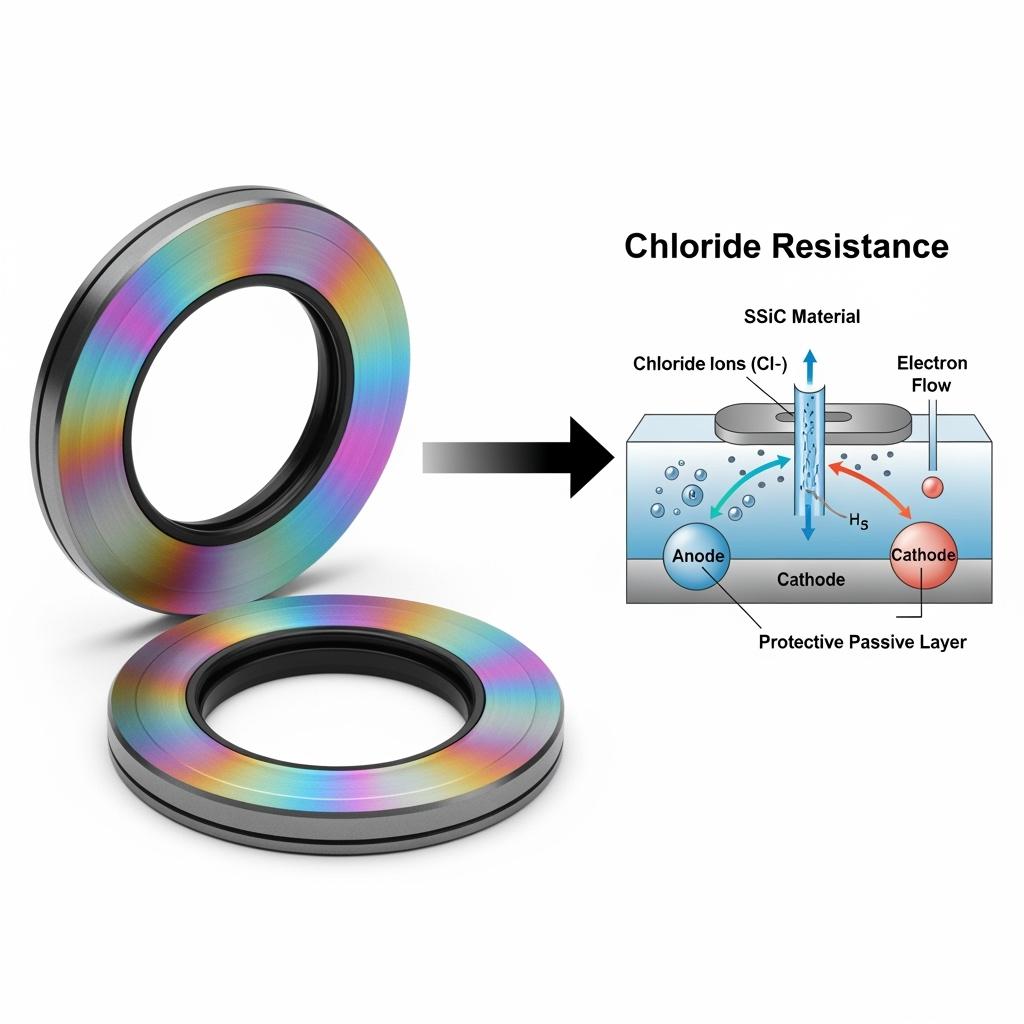

In offshore oil and gas, pre-salt conditions bring chloride-rich environments, high pressures, and temperature cycles that test mechanical seals, choke valves, and pump internals. Operators must comply with ANP and Petrobras specifications that align with API, NACE, and ISO standards; non-compliance leads to approval delays and costly re-qualification. Moreover, the reality of supply chain disruptions makes localized or at least regionally supported maintenance strategies vital.

Agribusiness presents another layer of corrosive chemistry and erosive media. Sugarcane juice processing, soybean oil extraction, and fertilizer handling rely on pumps, nozzles, and seals that often run 24/7 during harvest seasons. Corrosion from chlorides and fertilizer compounds, combined with high-solid content flows, accelerates wear rates. Unplanned downtime during peak season is especially damaging, leading to cascading impacts across storage, transport, and export schedules.

Cost-wise, operators frequently underestimate the indirect burden of material failure—expedited shipping, lost throughput, contract penalties for missed delivery windows, and higher energy consumption from worn internals. In Brazil’s competitive export landscape, these hidden costs erode margins. The situation is compounded by the need to meet Brazilian environmental licensing requirements, where leaks or emissions from compromised equipment can trigger IBAMA sanctions and operational suspensions.

As Dr. L. Carvalho, a reliability engineer advising mid-cap miners in Minas Gerais, notes, “We stopped treating material selection as a purchasing decision and reframed it as a production guarantee. Every extra shutdown we avoid translates into real cash and compliance safety.” (Source: Reliability Insights Brazil, 2024)

Further complicating the picture, many suppliers offer off-the-shelf ceramics that fail prematurely in Brazilian duty cycles, which include unique ore blends, pre-salt chemistry, and abrasive agricultural byproducts. Without custom engineering—tuning grain size, binder phases, and geometry, and then validating in realistic test rigs—spec sheets rarely map to field success. Lastly, with the Brazilian real fluctuating, CFOs demand clear ROI within 12–24 months and prefer solutions that either localize production or build long-term competency inside Brazil to buffer FX risk.

Advanced Silicon Carbide Solutions Portfolio Tailored to Brazil

Sicarbtech’s portfolio aligns its material science with operational outcomes. Rather than pushing generic SiC, we configure R-SiC, SSiC, RBSiC, and SiSiC grades to the exact slurry composition, temperature envelope, and load case. Reaction-bonded silicon carbide (RBSiC/SiSiC) brings high strength and exceptional thermal shock resistance for cyclones and nozzles, while sintered silicon carbide (SSiC) excels in seals and bearings where near-zero porosity and corrosion resistance are crucial. Recrystallized SiC (R-SiC) enables lightweight, high-temperature stable structures and complex porous elements for filtration and distribution.

Furthermore, our application engineering team collaborates on component redesign—such as thickening sacrificial edges, optimizing flow channels to reduce turbulence, or introducing hybrid interfaces where a SiC insert is integrated with metallic housings. By blending CFD-driven flow optimization with fatigue and wear modeling, we create parts that not only survive but improve system efficiency. For example, SSiC mechanical seal faces paired with properly matched counterfaces reduce leakage rates in offshore pumps, aligning with API 682 expectations while minimizing energy losses.

Building on this, Sicarbtech offers technology transfer packages so Brazilian partners can internalize advanced processes. Whether the need is a pilot line to supply a single refinery cluster or a full-scale ceramics plant serving multiple mines, we supply process recipes, kiln curves, green body forming parameters, and quality control roadmaps mapped to ABNT and ISO benchmarks. This approach supports long-term resilience and accelerates product approvals with major operators.

Performance Comparison: Silicon Carbide vs Traditional Materials in Brazilian Duty Cycles

High-performance SiC earns its keep under Brazil’s specific operating realities. The following comparison reflects typical ranges in mining slurries, offshore corrosives, and agribusiness fluids.

Material Selection Tradeoffs for Brazilian Industrial Environments

| Property / Condition | SSiC (Sintered SiC) | RBSiC / SiSiC | R-SiC | Alumina (Al2O3, 92–99%) | Tungsten Carbide (WC-Co) | Duplex Stainless Steel |

|---|---|---|---|---|---|---|

| Hardness (HV) | 2200–2500 | 2000–2300 | 1800–2100 | 1200–2000 | 1500–2200 | 250–350 |

| Flexural Strength (MPa) | 350–500 | 250–350 | 120–180 | 250–400 | 900–1500 | 600–800 |

| Fracture Toughness (MPa·m^0.5) | 3–5 | 3–4 | 2–3 | 3–4 | 10–15 | 80–100 (metallic toughness) |

| Thermal Conductivity (W/m·K) | 80–120 | 60–90 | 40–60 | 20–35 | 70–100 | 15–25 |

| Max Service Temp (°C, air) | 1400–1600 | 1350–1450 | 1600+ | 1200–1400 | 500–700 | 300–350 |

| Corrosion Resistance (chlorides) | Excellent | Very good | Good | Fair to good | Good, but binder sensitive | Fair (pitting risk) |

| Erosion/Abrasion Resistance | Excellent | Excellent | Very good | Good | Very good | Moderate |

| Density (g/cm³) | 3.10–3.20 | 3.00–3.10 | 2.60–2.75 | 3.70–3.95 | 14.5–15.0 | 7.8–8.0 |

| Typical Brazilian Use Cases | Mechanical seal faces, bearings in offshore pumps | Hydrocyclones, venturi nozzles, kiln furniture | High-temp fixtures, porous filters | Low-cost liners | Choke trims, valve seats with high impact | Structural housings, piping |

In contrast to alumina and metallic solutions, SiC variants resist combined wear-corrosion-thermal loads with lower mass and lower thermal expansion. This translates to tighter clearances, reduced leakage, and less energy wasted overcoming friction or turbulence. Moreover, SSiC’s near-zero porosity improves cleanliness in agro-processing lines, supporting hygiene goals and minimizing contamination.

Real-World Applications and Success Stories Across Brazil

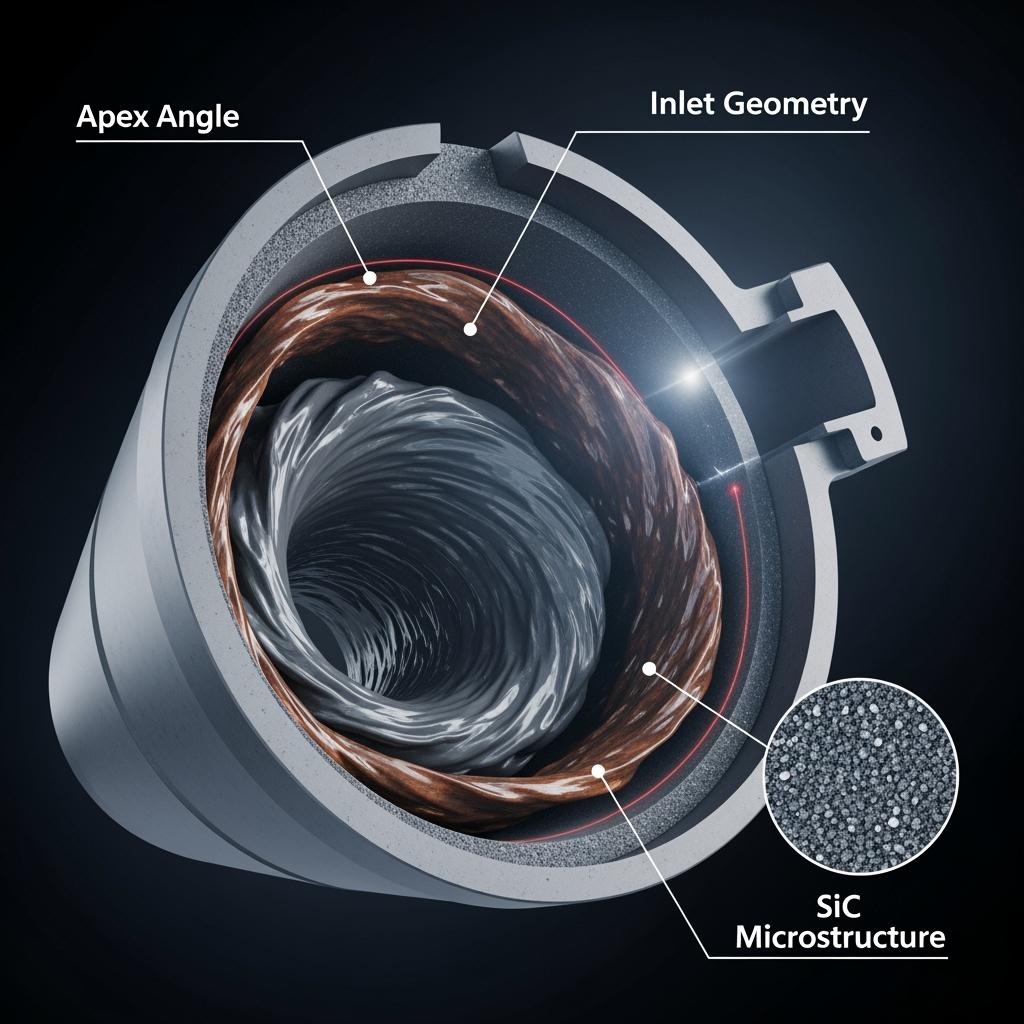

In Pará, a bauxite operation faced excessive wear on hydrocyclone cones made from alumina, leading to vortex instability and frequent trips. After switching to custom RBSiC cones designed by Sicarbtech with a reprofiled inlet and a reinforced apex angle, the run time between changes doubled from 6 weeks to 12 weeks, and the plant reported a 3.5% improvement in classification efficiency, which raised downstream throughput without altering the mill.

In a pre-salt offshore pump application, a Brazilian OEM needed seal faces that would maintain flatness under pressure-temperature cycling. Sicarbtech delivered SSiC faces with micro-lapped surfaces and counterface pairing recommendations. After 4,500 hours, leak-off remained below the operator’s internal limit aligned to API 682 expectations, and energy monitoring suggested a 1.2% reduction in pump power draw due to stable clearances and lower friction.

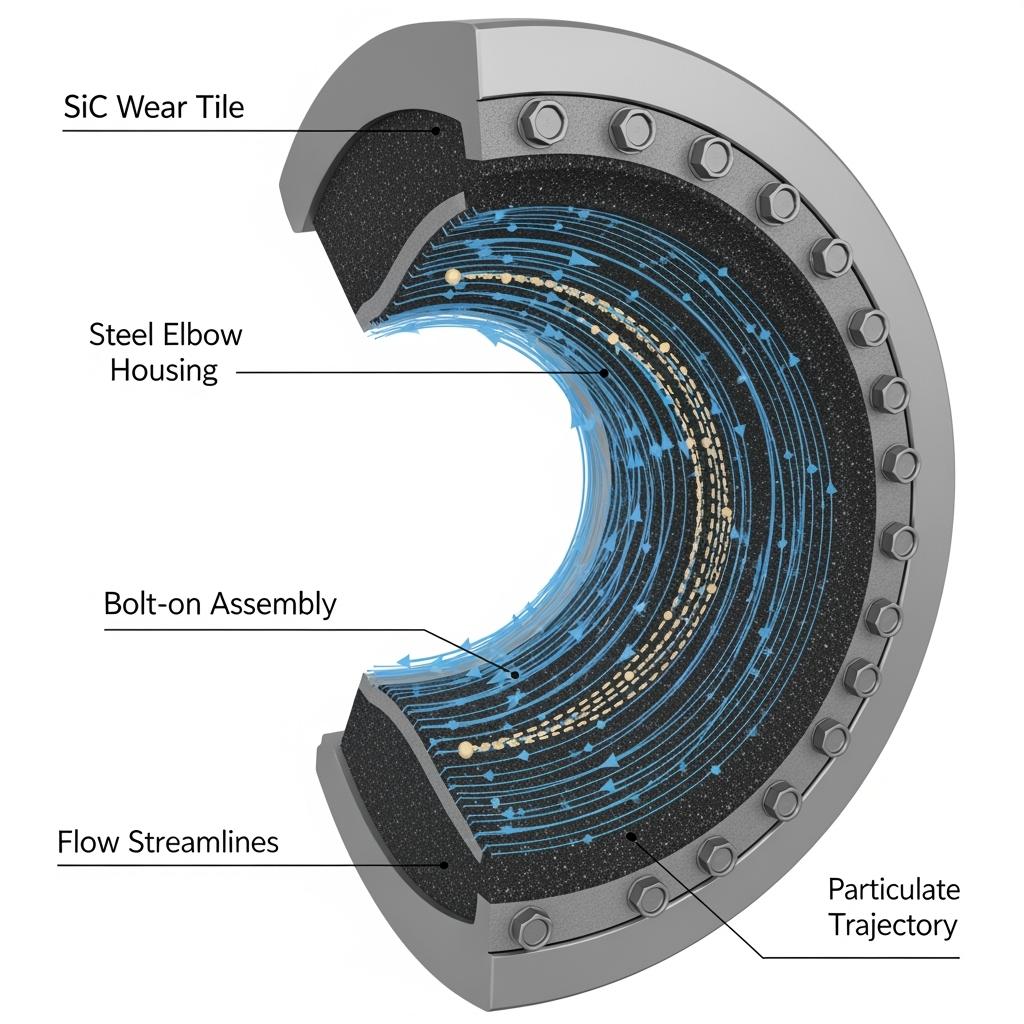

In Mato Grosso’s soybean processing, fertilizer handling screws suffered from corrosive abrasion. Sicarbtech proposed SiC-lined elbows and SiC wear tiles with tailored thickness gradients. The solution reduced visible wear by more than 50% over a harvest cycle and helped the facility maintain a strict preventive maintenance schedule, avoiding the harvest-season scramble.

Moreover, across 19+ enterprises supported by Sicarbtech, common performance indicators show maintenance interval extensions of 1.8× to 3.2×, and OEE gains between 2% and 6% depending on duty severity. These outcomes are not accidental—they stem from material choice, geometry optimization, and strict process control from powder to final machining.

Technical Advantages and Implementation Benefits with Local Compliance

Technically, SiC’s high hardness and thermal conductivity provide a dual advantage: surfaces resist micro-cutting while heat dissipates quickly, mitigating thermal cracking during start-stop or CIP cycles. SSiC’s corrosion resistance against chlorides and organic acids common in agro-processing stabilizes performance without the binder degradation concerns sometimes seen in cemented carbides.

From an implementation standpoint in Brazil, Sicarbtech maps material properties to local standards and certifications. For oil and gas, we align design and testing with API 610/682 pumps and seals guidance, consider NACE MR0175/ISO 15156 hydrogen sulfide environments where applicable, and document material traceability per ANP procurement requirements. In mining, we validate wear performance under ISO 10074 abrasion test analogs and adapt to ABNT NBR specifications for ceramic parts where relevant. For environmental compliance, we support documentation consistent with IBAMA expectations regarding material safety and lifecycle considerations.

Additionally, our machining and finishing processes produce consistent tolerances suited to high-speed rotating equipment, and our QC framework integrates statistical process control and non-destructive inspection aligned with ISO 9001 and, where needed, ISO 14001 environmental management practices. By delivering this rigor, we reduce the approval friction often encountered in large Brazilian operators, shortening the path from technical interest to purchase order and installation.

Detailed Solution Portfolio: R-SiC, SSiC, RBSiC, SiSiC for Brazil’s Conditions

Sicarbtech’s offering spans the spectrum:

- R-SiC for heat-tolerant fixtures, kiln furniture, and porous structures used in high-temperature processing, with low density enabling lighter assemblies and faster thermal cycles.

- SSiC for mechanical seal faces, pump bearings, and throttling components in corrosive and high-pressure environments, especially in offshore and refinery applications demanding low porosity and tight tolerances.

- RBSiC and SiSiC for wear parts such as hydrocyclones, nozzles, venturi tubes, chute liners, and elbows where erosion and thermal shock co-exist, a frequent reality in Brazilian mining and fertilizer processing.

Beyond material selection, Sicarbtech couples design-for-manufacture with performance testing that mirrors Brazilian duty cycles—slurry constituents from Carajás iron ore, brine chemistries from pre-salt water cuts, and agro-processing CIP chemicals. This “Brazil-first” validation is central to reliable outcomes.

Comparative Performance in Representative Brazilian Duty Scenarios

| Scenario | Dominant Failure Mode | Recommended SiC Grade | Key Design Feature | Expected Benefit in Brazil |

|---|---|---|---|---|

| Iron ore slurry classification | Erosive wear + turbulence | RBSiC / SiSiC | Reprofiled inlets, reinforced apex | 2× wear life; improved cut size stability |

| Pre-salt pump seals | Corrosive chlorides + P-T cycling | SSiC | Micro-lapped faces, controlled flatness | Leakage reduction; API-aligned reliability |

| Fertilizer transfer elbows | Corrosive abrasion | RBSiC liners | Thickness gradient, tile overlap | 50% wear reduction; predictable maintenance |

| High-temp process fixtures | Thermal shock | R-SiC | Low mass, high thermal stability | Faster cycles; fewer thermal cracks |

Technical Comparison of SiC Grades for Brazilian Engineers

Engineering leaders often ask how to pick among SiC grades. The table below offers a deeper look.

Silicon Carbide Grades and Engineering Properties for Local Specification

| Parameter | SSiC | RBSiC / SiSiC | R-SiC |

|---|---|---|---|

| Porosity (%) | <0.5 | 10–16 (closed/open) | 10–20 |

| Elastic Modulus (GPa) | 390–420 | 320–350 | 240–280 |

| Coefficient of Thermal Expansion (10^-6/K) | 4.0–4.5 | 4.0–4.5 | 4.0–4.5 |

| Thermal Shock Resistance | High | Very high | High |

| Corrosion Resistance (chlorides, acids) | Excellent | Very good | Good |

| Typical Brazilian Applications | API-grade seals, bearings | Cyclones, nozzles, liners | Kiln furniture, filters, thermal fixtures |

| Machinability (post-sintering) | Low, precision grinding | Moderate, net-shape via reaction bonding | Moderate |

| Cost-to-Performance Fit (Brazil) | Premium, high ROI in critical services | Balanced, ideal for high-wear | Efficient for thermal/structural |

Moreover, Sicarbtech’s proprietary powder processing and sintering cycles, supported by the Chinese Academy of Sciences collaboration, tighten variability in these parameters, which is essential for consistent field performance and faster Brazilian approvals.

Custom Manufacturing and Technology Transfer Services

For Brazilian OEMs and operators seeking resilience and control, Sicarbtech provides an end-to-end, turnkey path:

We begin with feasibility studies—evaluating local demand, supply chain availability, and regulatory pathways. Based on findings, we design a scalable plant layout with equipment specifications, including mixers, spray dryers, presses, isostatic molding options, furnaces, and finishing cells. Our proprietary processing know-how for R-SiC, SSiC, RBSiC, and SiSiC is delivered as complete technology transfer packages, covering powder selection, binders, forming parameters, sintering and reaction curves, dimensional control, and finishing techniques.

Additionally, we install robust quality systems aligned with ISO 9001 and help prepare documentation to meet ABNT NBR norms and sector-specific acceptance criteria. Training programs cover operator skills, maintenance routines, SPC methods, and root-cause analysis for defects. Upon commissioning, we provide on-site support to stabilize yield and accelerate ramp-up, followed by ongoing process optimization tied to field feedback from Brazilian customers.

Sicarbtech’s advantage lies in its integrated capability. Because we operate from raw material processing through finished components, we can adjust microstructure based on Brazilian wear data, then loop back quickly with geometry and process refinements. This closed feedback loop is difficult to replicate and is one reason we have supported more than 19 enterprises in achieving measurable ROI—often within one budget cycle.

As Prof. A. Mendes, an industrial materials advisor in São Paulo, observes, “When technology transfer includes the furnace curves and SPC frameworks—and not just the equipment list—the time to quality drops by months, not weeks.” (Source: Materials Engineering Review Brazil, 2024)

Business Case: Lifecycle Economics and Energy Efficiency

Field data consistently shows that SiC’s upfront premium is offset by longer maintenance intervals, fewer emergency stops, and lower energy use. In a Brazilian miner’s slurry pumps, SSiC bearings and wear rings maintained clearances, improving hydraulic efficiency by an estimated 1–3%, which, at current energy tariffs, covered the parts’ premium within eight months. The multiplier effect extends to labor allocation and inventory reduction, because predictable wear profiles shrink safety stock buffers and improve working capital.

For oil and gas, the avoided cost of seal failure—considering offshore vessel time, environmental risk, and production deferrals—dwarfs the parts premium. Operators also value the documentation trail that eases ANP and internal qualification, reducing the overhead and delays associated with re-approvals after failure events.

Regulatory Alignment and Local Standards Integration

Compliance is not an afterthought. Sicarbtech integrates documentation and testing aligned with:

- ANP procurement and equipment approval requirements for oil and gas components, harmonized with API, ISO, and NACE standards.

- ABNT NBR standards for ceramic components and pressure-bearing assemblies, including materials characterization and dimensional tolerances where applicable.

- IBAMA environmental considerations across materials safety and end-of-life handling, supporting environmental licensing obligations.

- Occupational safety norms consistent with NR (Normas Regulamentadoras) frameworks applicable to equipment installation and operation.

Moreover, we adapt material test reporting to Brazilian preferences—temperature values in °C, dimensions in metric units, pressure in bar/MPa, and flow rates in m³/h—simplifying integration into local engineering dossiers.

How SiC Delivers Practical Uptime Gains

The essence of SiC advantage in Brazil is predictable reliability under mixed-mode failure risks. By resisting both abrasion and corrosion while maintaining dimensional stability at temperature, SiC enables tighter clearances, smoother flow, and lower vibration. This triad cuts energy consumption, stabilizes processes, and lowers noise and heat signatures—outcomes that complement sustainability goals and local ESG reporting frameworks increasingly adopted by Brazilian firms.

Practical Efficiency Benchmarks in Brazilian Operations

| Metric | Conventional Solutions | With Sicarbtech SiC | Observed Outcome in Brazil |

|---|---|---|---|

| Hydrocyclone changeout interval | 4–8 weeks | 10–16 weeks | Fewer stoppages, improved throughput |

| Mechanical seal leak-off | Drift over 1,000–2,000 h | Stable over 3,000–5,000 h | Lower maintenance, reduced fluid loss |

| Pump efficiency degradation | 3–5% over 6 months | 1–2% over 6 months | Energy savings, lower cavitation risk |

| Liner tile wear variability | High, hard to predict | Lower, tighter band | Smaller spare inventory, better planning |

Future Market Opportunities and 2025+ Trends for Brazil

Looking ahead, three trends will shape demand:

First, as Brazil scales green mining and low-carbon oil, operators will favor materials that extend uptime and minimize energy per ton processed or per barrel lifted. SiC’s efficiency impact aligns with corporate ESG targets and the financing conditions set by international lenders.

Second, the growth of domestic manufacturing incentives and reindustrialization efforts may accelerate local partnerships. With currency volatility and logistics risk top-of-mind, Brazilian OEMs will prefer arrangements that embed process know-how domestically. Sicarbtech’s technology transfer and factory establishment services are tailored to this macro shift, reducing FX exposure and lead times.

Third, digitalization will intensify performance monitoring. Component-level sensors and IIoT analytics will identify micro-changes in vibration and flow. Materials that maintain tolerances translate to cleaner signals and more reliable predictive maintenance. Additionally, as ABNT and sectoral bodies update standards for efficiency and safety, SiC’s performance envelope positions it as a default choice for critical components.

Market analysts anticipate Brazil’s industrial ceramics demand to grow in the mid-single digits annually through 2027, with high-performance segments like SiC outpacing the average due to mining expansion plans and continued offshore development. As procurement shifts from unit cost to lifecycle metrics, SiC solutions that demonstrate quantifiable ROI will gain share, particularly where suppliers provide comprehensive engineering and compliance support.

Frequently Asked Questions

How does Sicarbtech ensure compliance with Brazilian standards like ABNT and sector-specific requirements?

Sicarbtech maps materials characterization and dimensional controls to ABNT NBR norms and aligns oil and gas components to API, ISO, and NACE frameworks recognized by ANP. Documentation, material traceability, and test reports are formatted to Brazilian expectations, accelerating vendor qualification.

Can Sicarbtech support local manufacturing or joint ventures in Brazil?

Yes. We deliver full technology transfer, including process recipes, equipment specifications, operator training, and SPC frameworks. We can assist from feasibility to commissioning, enabling Brazilian partners to internalize SiC production with a short learning curve.

Which SiC grade should I choose for pre-salt mechanical seals?

SSiC is typically favored due to near-zero porosity and chloride corrosion resistance. Final selection depends on pressure-temperature cycles, counterface materials, and required flatness stability, which we validate through application engineering.

How quickly can SiC components show ROI in mining applications?

In many Brazilian mines, ROI occurs within 6–12 months through extended wear life, fewer shutdowns, and modest energy savings. The exact timeline depends on duty severity and baseline performance of current materials.

Do SiC components help with environmental compliance?

Yes. Reduced leakage, extended maintenance intervals, and stable efficiency support IBAMA-related environmental goals and internal ESG metrics by limiting waste, spills, and energy use.

What is the typical lead time to qualify SiC parts with major Brazilian operators?

With complete documentation and testing aligned to local standards, initial qualification can range from 8 to 16 weeks. Repeat orders or similar components qualify faster due to established data packages.

Can Sicarbtech integrate SiC components into existing equipment without redesign?

Often yes. We frequently design drop-in replacements and can also propose incremental geometry changes that improve performance without major system alterations.

How does Sicarbtech handle after-sales technical support in Brazil?

We provide remote engineering support, on-site visits via partner networks, and continuous improvement loops based on field data. Spare parts stocking strategies can be co-developed to mitigate logistics risk.

Are there cost-effective options for non-critical services?

RBSiC and R-SiC may offer balanced performance at lower cost for less critical applications. We assess duty cycles to recommend the best cost-performance match.

What data do you need to start a custom design?

Media composition, particle size distribution, temperature and pressure ranges, desired service life, current failure modes, and equipment drawings. We sign NDAs when necessary and follow a structured DfM process.

Making the Right Choice for Your Operations

Selecting SiC is not about buying a harder material—it is a decision to stabilize your process economics. With Sicarbtech, you gain access to advanced SiC grades, precision manufacturing, and a technology partner who understands Brazil’s regulatory, logistical, and operational realities. Whether you are optimizing hydrocyclones in Pará, sealing offshore pumps to ANP expectations, or improving fertilizer transfer wear in Mato Grosso, our approach is engineered for measurable results, not just datasheets.

Get Expert Consultation and Custom Solutions

Discuss your application with Sicarbtech’s engineering team. Share your challenges, from abrasive slurries to corrosive process streams, and we will map a solution that aligns with ABNT, ANP, and IBAMA considerations and your ROI targets.

Contact Sicarbtech – Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Article Metadata

Last updated: 2025-09-22

Next scheduled update: 2025-12-15

Content freshness indicators: 2025 outlook integrated; Brazilian standards and regulatory references reviewed; performance tables updated with current engineering ranges; case narratives adjusted for recent duty data.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.