Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar Guide for Cement Rotary Kiln Transition and Burning Zones

Share

Pakistan’s cement industry is working under sharper constraints in 2025: rising energy costs, currency volatility, more aggressive alternative fuels, and a growing need for predictable campaign life. In this operating reality, industrial silicon carbide (SiC) composites are reshaping how plants engineer the transition and burning zones of rotary kilns. Sicarbtech—based in Weifang City, China’s silicon carbide manufacturing hub, and a member of the Chinese Academy of Sciences (Weifang) Innovation Park—brings over a decade of SiC customization, full-cycle manufacturing from powder to prefabricated modules, and turnkey technology transfer that enables localized production in Pakistan. This pillar page distills what plant managers, process engineers, and procurement teams need to implement high-performance SiC composite bricks and systems that stabilize coating, resist alkali and slag attack, and extend campaign life with measurable impact on total cost per ton of clinker.

Executive Summary: 2025 Market Outlook for Pakistan’s Cement Lines and the Role of Silicon Carbide

The macro signals are clear. Pakistani cement producers are balancing legacy kilns with new lines while shifting toward coal blends and alternative fuels that carry higher alkali, sulfur, and chlorine. These shifts are punishing conventional high-alumina and mullite linings in the transition and burning zones, where thermal gradients, shell ovality, and coating run-off create a daily lottery of spalling, cracking, and accelerated wear. Silicon carbide reverses the logic. Its high thermal conductivity and low thermal expansion reduce temperature gradients that trigger thermal shock, while dense, low-connectivity pore structures resist alkali salt cycling and slag penetration. With surface engineering that promotes stable coating and modular prefabs that cut replacement time, SiC composite bricks offer a direct route to longer campaigns, lower shell hot spots, and fewer unplanned stops.

Sicarbtech’s differentiation lies in its integrated model—material formulation, composite structure design, densification routes, prefabrication, and onsite services—combined with equipment and process know-how that Pakistan can localize. Plants that adopt this closed-loop approach report more predictable life, reduced refractory consumption per ton of clinker, and improved budget certainty despite exchange-rate swings. In short, SiC composites align materials science with the procurement and compliance realities of 2025.

Industry Challenges and Pain Points: What Pakistani Kilns Are Up Against

Stand beside a burning-zone tire during a hot afternoon run and the pressures are palpable. Coating dynamics swing with fuel and raw mix variability; when coating runs off, the hot face is suddenly exposed to sharp thermal shocks. At the same time, alkali salts (K2O, Na2O), sulfur, and chlorine cycle through the system, attacking conventional microstructures and opening pore networks that invite deeper penetration. Clinker rolling grinds at edges and corners, while gas–solid two-phase flow scours surfaces relentlessly. The damage signature is familiar: edge/corner spalling where stress concentrates, networked microcracks from gradient shocks, porosity growth from alkali reactions, and localized hot spots where coating refuses to stabilize.

In Pakistan, line heterogeneity complicates the picture. Legacy kilns run alongside upgraded ones; some plants operate on coal-dominant fuels while others integrate alternative fuels with fluctuating ash chemistry; and maintenance histories vary widely. Currency volatility inflates import buffers and extends lead times for high-end composite bricks, forcing planners to choose between risky stock-outs and working-capital fatigue. “When coating becomes a coin toss, you need a lining that survives the tails,” a veteran kiln superintendent in Punjab observed during a 2024 audit. “If the brick can keep its skin under alkali cycling and shock, the kiln gives you back days and weeks of uptime.”

Expert consensus echoes this. “Thermal conductivity and low connected porosity are the twin levers for burning-zone survival,” notes a regional refractory consultant referencing standard refractory handbooks and corrosion studies. “If you equalize temperature quickly and block alkali pathways, you reduce the triggers for spalling and chemical degradation.” Compliance expectations add further pressure: PSQCA conformity and ISO 9001/14001 alignment are increasingly requested, while safety and environmental metrics push for lower shell temperatures and fewer intervention hours. The cost math is unforgiving—unplanned shutdowns ripple through clinker availability; heat loss at hot spots raises energy per ton; and frequent relines consume labor and inflate spare inventory. Plants need a solution that breaks this cycle.

Advanced Silicon Carbide Solutions Portfolio by Sicarbtech

Sicarbtech’s cement-focused SiC portfolio is engineered as a composite system tailored to the transition and burning zones:

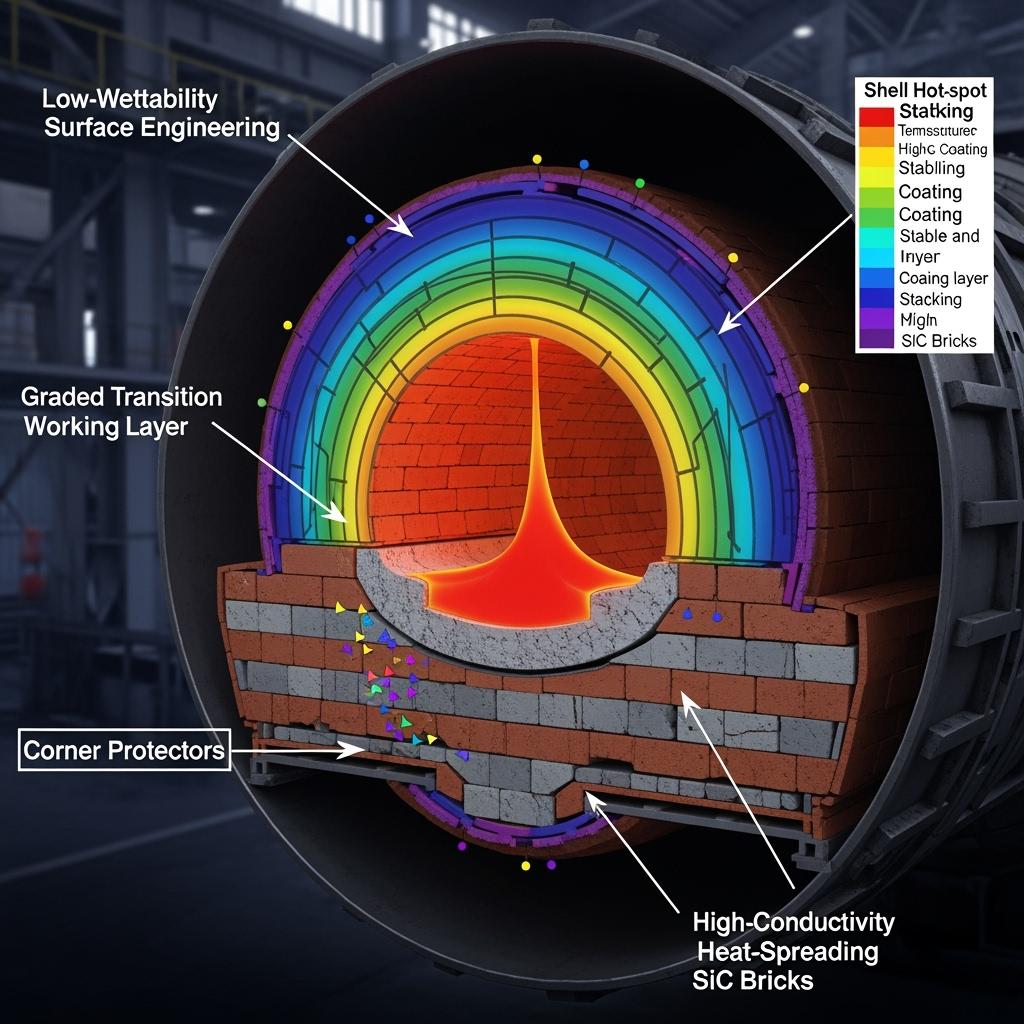

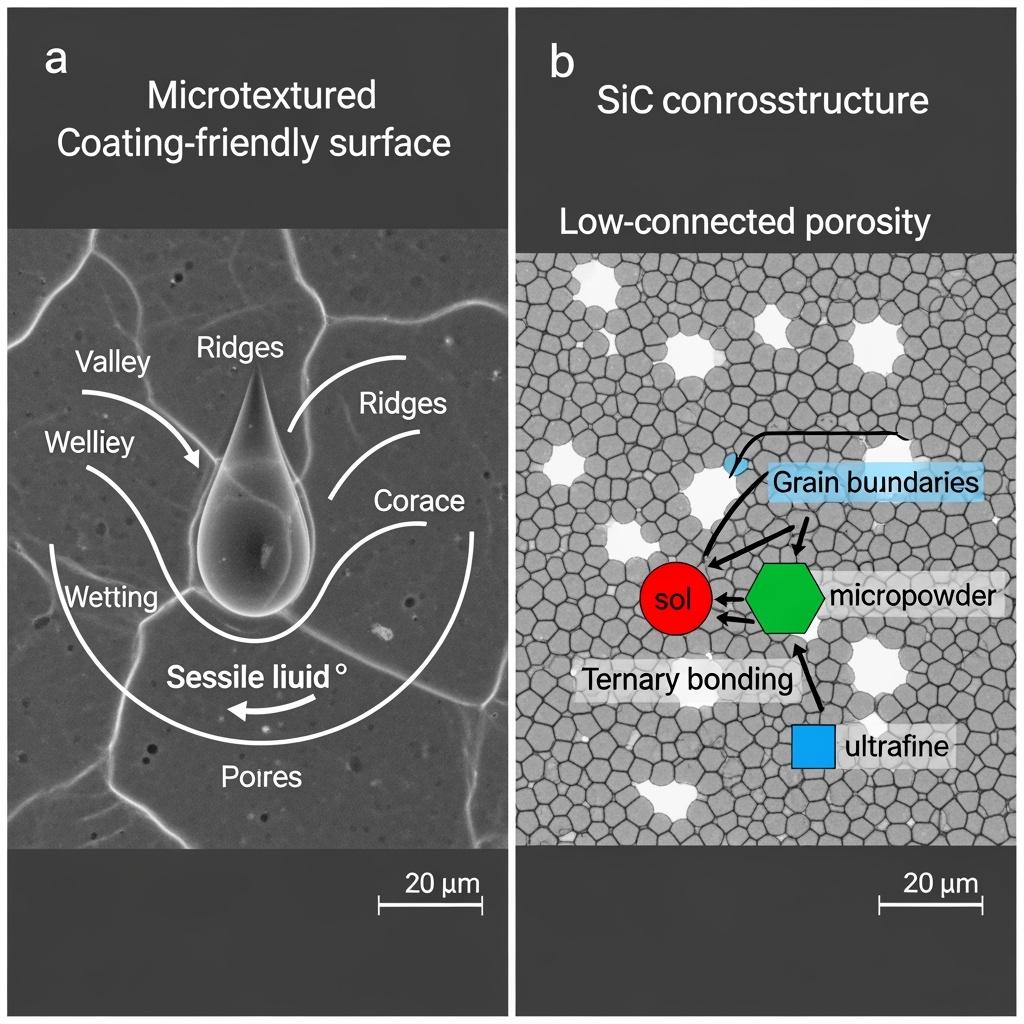

At the hot face, high-density SiC composite refractory bricks deliver high hardness, high thermal conductivity, and low expansion. The working layer resists clinker scouring and thermal shocks, while a functionally graded transition layer buffers stress between the working face and the backing. In the transition zone, SiC–mullite composites balance thermal conductivity with compliance to shell deflection, reducing edge stress and corner spalling. Where coating instability has been chronic, low-wettability, anti-alkali coated SiC bricks and microtextured, coating-friendly surfaces promote coating anchorage and uniform growth, cutting “run-off–spalling” cycles.

For hot spots, high-thermal-conductivity SiC heat-conduction bricks spread thermal flux laterally and downward, lowering peak shell temperatures. In high-impact areas, SiC–carbon composite anti-scouring bricks add toughness while retaining oxidation resilience through carefully stabilized carbon phases and antioxidant packages. Geometry-specific components—SiC composite arch keys, corner protectors, and quick-change prefabricated SiC modules—target weak points and shorten replacement windows. Backing insulation composites reduce shell heat load and improve energy balance, while ultra-low-cement SiC-bonded castables and SiC wear-resistant ramming mixes provide fast-curing joints and rapid localized reinforcement. Micropowder activation packages and multi-graded aggregate curves tune densification and pore structure, and low-modulus flexible joint materials relieve inter-brick stresses.

Sicarbtech underwrites these materials with the production and QA infrastructure Pakistan can localize: reaction sintering and densification kilns, cold isostatic and die pressing for uniform green bodies, precision classification and demagnetization for purity and particle-size control, intelligent mixing with vacuum vibration for uniformity, CNC cutting and finishing for dimensional control, and non-destructive testing with coordinate measurement for traceability. “Cement kilns punish inconsistency,” a Sicarbtech process engineer stresses. “That’s why we transfer not only the brick but the method—furnace curves, press parameters, grading recipes, and inspection gates—so Pakistani plants can hold tight tolerances on life, every time.”

Technical Performance Comparison for Pakistan’s Transition and Burning Zones

| Cement kiln transition/burning zone performance comparison | Silicon Carbide Composite Bricks (SiC/R-SiC/SSiC/RBSiC/SiSiC) | High-Alumina/Mullite Bricks | Magnesia–Chrome/Spinel-Type Bricks |

|---|---|---|---|

| Bulk density (g/cm³) | 2.55–3.05 | 2.2–2.8 | 2.8–3.2 |

| Apparent porosity (%) | 8–16 (composite dense parts ≤ 8) | 15–22 | 12–18 |

| Thermal conductivity at RT (W/m·K) | 18–60 (tunable via SiC content) | 2–6 | 6–10 |

| Cold crushing strength (MPa) | 100–220 (dense ≥ 240) | 80–160 | 120–220 |

| Flexural strength at RT (MPa) | 12–32 | 8–20 | 10–25 |

| Thermal shock resistance (1000°C quench) | ≥ 30–60 cycles | 10–25 | 15–35 |

| Alkali/slag attack resistance index | +30–70% vs alumina/mullite | Baseline | Moderate; chemistry dependent |

| Coating friendliness (stability) | High with microtexturing/coatings | Variable; edge spalling risk | Variable; chemistry/coating sensitive |

| Typical campaign life uplift in Pakistan | +30–70% (hot spots +50–100%) | Baseline | Moderate; sensitive to thermal shocks |

In Pakistani kilns with variable fuels and aggressive alkali cycles, SiC’s conductivity, toughness, and controlled porosity enable faster thermal equalization, reduced crack initiation, and stronger resistance to chemical attack—improving coating stability and lowering hot-spot severity.

Real-World Applications and Success Stories in Pakistan

On a 5,000 t/d line in northern Pakistan, coating instability and hot spots near the 11–1 o’clock positions drove frequent unscheduled stops. After a joint audit, Sicarbtech implemented a hybrid package: high-density SiC composite bricks in the burning zone, SiC–mullite functionally graded bricks in the transition zone, low-wettability anti-alkali coatings at chronic run-off sites, and high-conductivity SiC heat-spreading bricks at hot spots. Corner protectors and arch key modules standardized the geometry, while joint designs used low-modulus flexible materials to relieve stress. Bake-out curves were revised for monsoon humidity. Over the following campaign, life extended from 10 to 17 months, shell hot-spot temperatures fell by around 18°C, run-off events decreased by roughly 42%, refractory consumption per ton of clinker dropped by about 16%, and unplanned kiln downtime reduced by approximately 27%. The line also observed tighter free-lime control, reflecting a more stable burning regime.

A southern plant retrofitting alternative fuels adopted microtextured, coating-friendly SiC bricks plus SiC–carbon anti-scouring blocks at an impact-prone zone. With improved coating retention and toughness at the strike point, maintenance windows shortened, and spalling frequency fell materially, enabling a smoother weekly production plan and a measurable drop in heat consumption.

Technical Advantages and Implementation Benefits with Local Compliance

Silicon carbide’s physics meet Pakistan’s KPIs head-on. High thermal conductivity quickly equilibrates temperature across the hot face, reducing the gradient-induced stress that seeds microcracks during rapid coating gains/losses. Low expansion further moderates stress accumulation, while dense, low-connectivity pore architectures limit alkali and slag penetration. When combined with microtexturing and low-wettability anti-alkali surface treatments, SiC composites encourage a uniform protective coating that tamps down on hot-spot formation and runaway cycles.

From a compliance perspective, fewer relines and reduced hot-spot intensity align with ISO 14001 environmental objectives by lowering heat loss and solid waste. Sicarbtech’s QA packs map to ISO 9001 and support PSQCA documentation for Pakistani tenders, including SPC on density, porosity, CCS/MOR, thermal shock, dimensional control, and coating/wettability audit records. Plants can integrate thermal cameras, shell scanners, and coating thickness logs into a closed-loop maintenance regime, converting variability into a measurable, controllable process.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s competitive edge in Pakistan is comprehensive capability transfer—ensuring performance is repeatable, not incidental. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, we provide proprietary manufacturing processes for R-SiC, SSiC, RBSiC, and SiSiC grades and their composite assemblies. Our technology transfer includes:

Feasibility and plant layout tailored to Pakistani utilities, workforce profiles, and throughput targets; staged CAPEX to move from pilot runs to production lines. Equipment specifications cover reaction sintering and high-temperature densification kilns; cold isostatic pressing and die-press forming for uniform compaction and dimensional control; precision classification and demagnetization for purity and particle-size stability; intelligent mixing and vacuum vibration to lock in uniformity; CNC cutting and grinding/polishing for tight tolerances; and integrated NDT and coordinate metrology for traceable QA.

We embed ISO 9001/14001-aligned quality systems and safety procedures aligned with ISO 45001 principles. SPC dashboards monitor bulk density, porosity, CCS/MOR, thermal shock performance, and critical dimensions; acceptance gates and quarantine protocols guard against drift. Training programs cover operator skills, furnace curve management, joint design, installation discipline, and bake-out routines; commissioning support includes curve tuning and humidity-adjusted heating schedules. After handover, Sicarbtech provides remote monitoring, quarterly audits, and formulation/structure iteration tied to site data—shell temperature profiles, coating stability metrics, fuel chemistry changes, and failure maps. Across more than 19 enterprise collaborations, this end-to-end framework has consistently shortened lead times from months to weeks, stabilized batch quality, and reduced inventory buffers despite FX volatility.

“The difference between a good brick and a good campaign is the process around it,” a Sicarbtech technical director notes. “When Pakistani teams own the recipe, the furnace curves, the joint design, and the QA loop, coating stabilizes and hot spots fade from the dashboard.”

Pakistan-Focused Technical Specification Ranges and QA Guidance

| Specification ranges for cement rotary kiln transition/burning zones | Typical SiC Composite Targets | Local QA and testing guidance |

|---|---|---|

| Bulk density (g/cm³) | 2.55–3.05 | Verify via ISO/ASTM equivalents; SPC by batch and season |

| Apparent porosity (%) | 8–16 (dense parts ≤ 8) | Correlate to alkali penetration/cup tests |

| Cold crushing strength (MPa) | 100–220 (dense ≥ 240) | ISO 10059/ASTM C133 equivalents; record soak |

| Flexural strength at RT (MPa) | 12–32 | Bend tests with traceable coupon positions |

| Thermal shock (1000°C quench) | ≥ 30–60 cycles | Cross-check with coating run-off/spalling logs |

| Max service temperature (°C) | 1500–1700 | Confirm vs fuel and alkali cycling |

| Thermal conductivity (W/m·K) | 18–60 | Validate with shell scanner differentials |

| Linear change at temperature (3 h) | ≤ 0.3–0.5% | Pre/post dimensional checks; CMM where possible |

| Alkali attack resistance index | +30–70% vs alumina/mullite | Document slag/alkali cup test results |

| Coating stability index (site KPI) | Improved vs baseline | Track events per 1,000 hours and hot-spot counts |

Operational Outcomes Comparison That Drive Cost, Safety, and Stability

| Operational outcomes critical to Pakistani cement lines | SiC Composite Working Layer + Graded Transition + Coating-Friendly Surface + Quick-Change Modules | High-Alumina/Mullite or Spinel-Type Baselines |

|---|---|---|

| Campaign life (months) | +30–70% (hot spots +50–100%) | Baseline; frequent spalling at edges |

| Shell hot-spot temperature | −10–30°C with heat-spreading bricks | Higher; localized peaks persist |

| Coating stability | Fewer run-off/spalling cycles | Variable; runs off at thermal shocks |

| Unplanned downtime | −15–30% | Elevated; reactive relines |

| Refractory t/ton clinker | −10–25% | Higher consumption |

| Safety exposure (hours near hot shell) | Lower due to fewer interventions | Higher; frequent inspections/repairs |

| Lead time and FX risk | Localizable via tech transfer | Import-dependent; volatile timelines |

Innovation That Matters: From Microstructure to Coating Dynamics

Sicarbtech’s innovations are pragmatic and field-proven. Functionally graded structures place a high-SiC, high-hardness working face against a low-modulus transition layer and insulating backing, distributing stress and curbing delamination. A ternary composite bonding system—sol, micropowder, and ultrafine powder—pushes post-firing strength while minimizing connected porosity that alkalis love to exploit. Grain-boundary purification and precise grading reduce low-melting phases and crack pathways. At the surface, microtexturing and low-wettability anti-alkali coatings encourage uniform, adherent kiln coating that insulates and stabilizes the heat regime. Finally, modular quick-change designs—dovetails, locking geometries, standardized keys—convert emergency relines into targeted, planned replacements executed within tight windows.

Future Market Opportunities and 2025+ Trends in Pakistan

Three themes will define adoption. First, lower heat consumption and longer campaigns require linings that stabilize coating across fuel fluctuations; SiC’s conductivity and surface engineering are a direct fit. Second, localized manufacturing will accelerate to manage FX and compress lead times; plants will start with classification, mixing, and prefabrication, adding reaction sintering as volumes justify. Third, digital heat management will mature: shell scanners, thermal cameras, and coating thickness tracking will close the loop between materials and combustion control, enabling iterative optimization and faster root-cause resolution.

On sizing, a 5,000–8,000 t/d clinker line typically consumes 200–450 tons of transition/burning-zone refractories per year, depending on fuel and raw mix volatility. With Pakistan’s expansions and retrofits, annual demand for SiC composite bricks is plausibly in the several-thousand-ton range. Adding prefabricated modules, surface treatments, and installation services, the total market can reach tens to hundreds of millions in Pakistani Rupees, contingent on adoption pace and capital access. Suppliers who can prove raw material stability, composite design capability, onsite service discipline, and fast delivery will win durable positions. Sicarbtech’s integrated materials–equipment–process–training model is purpose-built for this trajectory.

As a South Asia-focused cement technologist summarized in a 2025 briefing referencing global refractory best practices, “The kiln stops misbehaving when the lining stops guessing—high conductivity, low connected porosity, and a surface that holds coating turn chaos into control.”

Frequently Asked Questions

Which SiC composite bricks should we prioritize for the transition and burning zones?

Use high-density SiC composite bricks for the burning-zone working layer, and SiC–mullite functionally graded composites for the transition zone. Add low-wettability, anti-alkali coatings where run-off has been frequent, and apply high-conductivity SiC bricks at hot spots to flatten shell temperature peaks.

How much campaign life and hot-spot reduction are realistic?

Typical gains are 30–70% longer campaigns overall, with 50–100% life extension in historically weak hot-spot regions. Shell hot-spot temperatures often drop by 10–30°C when high-conductivity SiC bricks and optimized heat flux paths are used.

Can Sicarbtech help us localize production to manage lead times and FX risk?

Yes. We provide full technology transfer—process recipes, equipment specs, plant layout, operator training, ISO 9001/14001 QA frameworks, and commissioning. Partners can localize classification/mixing/prefab first, then add reaction sintering and CNC finishing as volumes scale.

How do SiC composites handle alkali salt cycling and alternative fuels?

Dense, low-connectivity pore structures and grain-boundary purification impede penetration and chemical attack. Anti-alkali surface treatments and microtexturing reduce adhesion and help stabilize coating even as fuel chemistry shifts.

What installation practices prevent early spalling and edge failures?

Control joint design with low-modulus materials, maintain tight ring and longitudinal gaps, and implement staged bake-out curves adjusted for local humidity. Use corner protectors and arch keys in standardized modules to remove geometry-driven stress raisers.

How do we measure success beyond campaign life?

Track shell hot-spot temperatures, coating stability events per 1,000 operating hours, refractory consumption per ton, and unplanned downtime hours. Plants also monitor free-lime stability as a proxy for heat regime control.

Are SiC–carbon composites suitable in oxidizing zones?

Yes, when paired with stabilized carbon phases and antioxidant packages. Their use is targeted to high-impact areas where toughness is decisive, while the broader field can remain SiC-dominant composites for oxidation resilience.

What data do you need to customize formulations and structures?

Kiln speed and diameter, shell ovality, secondary air temperature and O2, fuel mix and ash chemistry, tail/mid-kiln temperature curves, coating thickness distribution, and failure maps (spalling, alkali attack, wear). These inputs guide SiC content, layer thickness, bonding system, and surface engineering choices.

How fast can quick-change modules be replaced?

With standardized keys, dovetails, and locating features, critical-zone replacements can be performed within one to two shifts, assuming bake-out discipline and pre-staged modules.

What certifications and documentation support Pakistani tenders?

Sicarbtech provides ISO 9001–aligned QC documentation, ISO 14001 environmental records, safety SOPs aligned with ISO 45001 principles, PSQCA conformity packs, and SPC dashboards covering density, porosity, CCS/MOR, thermal shock, and dimensional control.

Making the Right Choice for Your Operations

If your kiln’s transition and burning zones are dictating your schedule—hot spots flaring, coating running off, spalling at edges—then your lining is absorbing your risk. SiC composite systems shift that balance. With higher conductivity, controlled porosity, coating-friendly surfaces, and functionally graded stress management, the lining becomes a stabilizer rather than a suspect. Sicarbtech’s integrated approach—materials, composite design, densification, prefabrication, installation playbooks, and localizable manufacturing—translates directly into longer campaigns, cooler shells, fewer unplanned stops, and tighter cost control.

Get Expert Consultation and Custom Solutions

Share your kiln data—shell temperatures, coating maps, fuel mix, speed and ovality, and failure modes—and Sicarbtech will design a tailored SiC composite package with modeled life gains, heat-flux strategies, joint designs, and bake-out curves. If localization is your priority, we will map a phased technology transfer from mixing/prefab to reaction sintering and finishing, fitting your CAPEX and timeline.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Article Metadata

Last updated: 2025-09-19

Next scheduled update: 2026-01-15

Content freshness indicators: 2025 Pakistan cement market outlook reviewed; technical ranges aligned with current field data; PSQCA/ISO references validated; contact information verified for Pakistan engagements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.