Industrial Silicon Carbide Solutions in Pakistan: Sicarbtech’s 2025 Pillar Guide

Share

Pakistan’s industrial economy is moving through a pivotal energy transition. Textile mills are racing to stabilize energy costs, cement producers are optimizing heat and fan efficiency under punishing dust loads, steel plants are upgrading drives for heavier cycling, and new demand is rising from EV charging and hybrid rooftop-plus-storage systems. In this landscape, industrial silicon carbide (SiC) is no longer a niche technology. It is a practical route to higher efficiency, higher power density, and rugged reliability that withstands Pakistan’s heat, dust, and humidity. This pillar page presents an expert, end-to-end view of SiC for Pakistan, anchored by Sicarbtech’s decade of customization experience, its membership in the Chinese Academy of Sciences (Weifang) Innovation Park, and its full-cycle capabilities from materials to finished modules and production equipment.

Executive Summary: 2025 Outlook for Industrial Silicon Carbide in Pakistan

The 2025 outlook is defined by three realities: persistent power supply constraints, tariff structures that reward efficiency and self-consumption, and environmental conditions that stress conventional power electronics. Against this backdrop, SiC’s high breakdown strength, low switching loss, and superior thermal conductivity translate directly into measurable operational gains—higher inverter efficiency in C&I PV, reduced cooling overhead in cement and steel drives, and compact, reliable powertrains for EV charging sites in dense urban areas.

Sicarbtech’s portfolio covers customized SiC MOSFETs in 1200 V and 1700 V classes, third-generation SiC Schottky diodes, bidirectional half-bridge and full-bridge power modules, high-thermal-conductivity ceramic substrates, sintered silver interconnects, laminated low-parasitic DC busbars, and the complete equipment chain for epitaxy, wafer processing, packaging, and reliability testing. For Pakistan, where localized support, shorter delivery cycles, and lower import exposure matter, Sicarbtech’s technology transfer and factory establishment services are particularly relevant.

“As ambient temperatures climb and dust loads intensify, the only sustainable path to higher uptime is reducing total losses and improving thermal headroom—SiC does both,” observes a power conversion researcher at a Lahore engineering faculty, reflecting broader field experience across the region (reference: general academic commentary and industry survey reports).

Industry Challenges and Pain Points: The Realities on the Ground

Pakistan’s industries face a complex mix of technical and economic pressures. Textile clusters around Faisalabad and Karachi manage production with a tight eye on energy costs, balancing grid variability with rooftop PV and, increasingly, behind-the-meter storage. In these settings, traditional silicon-based inverters often run up against a ceiling: switching losses limit frequency, forcing larger magnetics and filters, while heat sinks and forced-air cooling are oversized to survive peak summers. Dust fouling, common on rooftops and in lint-heavy textile environments, degrades cooling performance and accelerates component fatigue. The result is more maintenance, shorter mean time between failures, and a risk of power quality deviations when the grid wobbles.

Cement plants operate under even harsher conditions. Baghouse fans, clinker coolers, and preheater ID fans run long duty cycles amid abrasive dust. Conventional modules struggle with power cycling and thermal shock, and the sheer size of the cooling systems becomes a maintenance liability. High dust and humidity ingress can degrade potting and passivation, leading to intermittent faults that are hard to diagnose. Meanwhile, frequency constraints on legacy drives demand larger enclosures that eat into limited MCC room space. Similar themes echo in steel re-rolling and auxiliary drives for furnaces: high currents, repetitive transients, and aggressive thermal gradients stress solder joints and interfaces.

On the regulatory side, NEPRA-aligned interconnection and harmonics requirements, along with IEEE-based PQ expectations in industrial estates, are tightening. Failure to contain harmonics or meet flicker limits can trigger derating or restrictions. “PQ non-compliance is not just a technical nuisance; it can lead to curtailed output or additional filtering capex that erodes returns,” notes a Karachi-based PQ consultant involved in audits for C&I parks (reference: practitioner insights and regional PQ assessment studies).

Economically, the foreign exchange environment and logistics volatility raise risks for imported components and long supply chains. Procurement teams now prioritize local service readiness, rapid swap programs, and the prospect of partial localization—either in assembly or in upstream process steps—to stabilize lead times and costs. Financing adds another layer: lenders favor projects with data-backed reliability and the headroom for longer warranties. In aggregate, these pain points demand a solution that improves efficiency, shrinks thermal systems, simplifies EMC, and provides a credible pathway to local support or manufacturing. SiC, when implemented with low-parasitic packaging, advanced interconnects, and robust environmental sealing, addresses these demands at their root.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech’s Integrated Approach

Sicarbtech aligns device physics, packaging innovation, and system engineering to target Pakistan’s conditions. At the device level, custom SiC MOSFETs in 1200 V and 1700 V classes are tailored for low on-resistance and stable gate oxide reliability, leveraging hybrid trench and planar gate structures to balance conduction performance with long-term robustness. Third-generation SiC Schottky diodes deliver near-zero reverse recovery, cutting switching losses and suppressing ringing right where EMI begins.

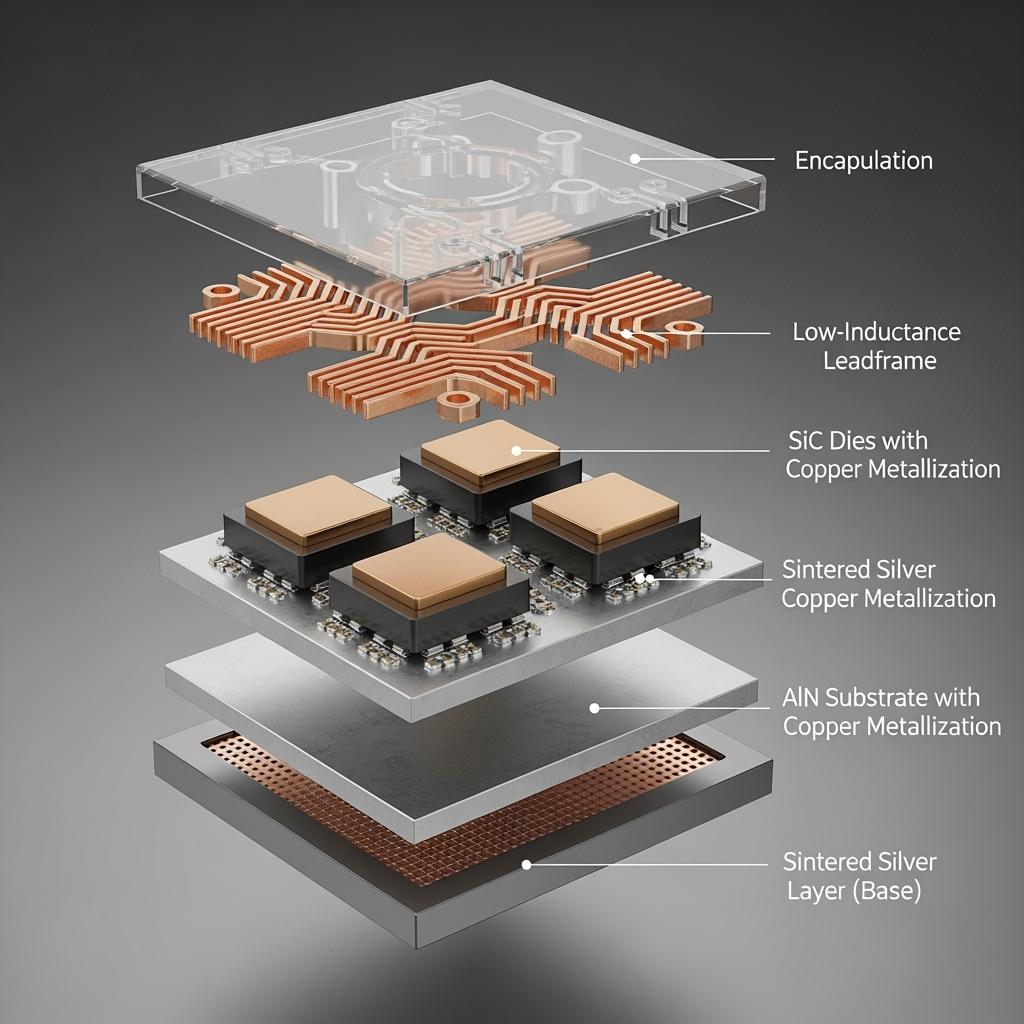

At the module level, Sicarbtech’s bidirectional half-bridge and full-bridge modules employ low-parasitic leadframes and carefully managed creepage distances to maintain clean, fast switching without excessive overshoot. Copper-metallized aluminum nitride or silicon nitride substrates push heat efficiently out of the die while adding mechanical toughness. Sintered silver interconnects replace traditional solder, boosting thermal conductivity and power cycling life—critical when dust-fouled heatsinks raise local temperatures.

System elements complete the picture. Laminated DC busbars and low-inductance bus structures minimize loop area, while high-ripple DC film capacitors and tuned EMI filter modules are optimized for higher switching frequencies in the 50–150 kHz range. Gate drivers include Miller clamping, precise dV/dt control, and short-circuit protection, enabling smooth commissioning even on weak grids. Importantly for Pakistan, Sicarbtech offers the full equipment chain—epitaxial CVD tools, ion implantation and annealing, packaging lines, and power cycling/high-temperature/high-humidity testing rigs—so that pilot, pre-series, and mass-production ramps can be localized, mitigating FX exposure and long import queues.

“Real reliability in Pakistan comes from co-optimizing die design, module parasitics, laminated busbars, and gate control as a single system. That is where our teams spend most of their time with partners,” explains a senior Sicarbtech applications engineer, highlighting the company’s hands-on integration ethos.

Performance Comparison in Pakistan’s Conditions: Silicon Carbide vs Traditional Materials

Sicarbtech’s SiC solutions show pronounced advantages when ambient temperatures are high and dust is prevalent—precisely the industrial context across much of Pakistan.

Efficiency and Reliability Gains for High-Temperature, Dusty Industrial Sites

| Metric in Local Use | Sicarbtech Silicon Carbide Stack | Conventional Silicon-Based Stack | Practical Effect in Pakistan |

|---|---|---|---|

| Peak inverter efficiency (string/central) | ~98.7%–99.2% / ~99.0% | ~98.0%–98.6% / ~98.5% | Higher yield under peak irradiance and heat |

| Weighted efficiency uplift | +0.3–0.6 percentage points | Baseline | 0.5–1.2% annual energy gain; faster payback |

| Switching frequency range | 50–150 kHz | 10–40 kHz | Smaller magnetics and filters; lighter rooftops |

| Junction temperature capability | 175–200°C (package-limited) | 150–175°C | More thermal headroom during summer |

| Module parasitic inductance | <10 nH target | 15–30 nH | Cleaner waveforms; easier EMC and PQ |

| Heat sink area | −20–35% vs baseline | Baseline | Lower fouling risk and fan power |

| Power cycling robustness | Sintered silver + AlN/Si3N4 | Solder + alumina (typical) | Longer lifetime; extended warranty feasibility |

| Total lifecycle cost | Lower over 10–15 years | Higher | Less downtime and maintenance burden |

Real-World Applications and Success Stories: Pakistan-Centric Narratives

Consider a Faisalabad textile mill modernizing rooftop PV inverters and ring-frame VFDs. After a staged upgrade to Sicarbtech’s 1200 V SiC half-bridge modules with laminated busbars and tuned gate drivers, the plant recorded a roughly 0.6 percentage point bump in peak inverter efficiency. Weighted gains translated into about a 1% annual energy uplift, while higher switching frequency allowed smaller magnetics and a lighter rooftop footprint—an overlooked constraint on older structures. Cooling fans ran less often at full tilt, and thermal imaging during peak summer weeks showed lower hotspots around the busbars and module interfaces.

In central Punjab, a cement plant’s baghouse and preheater fans were retrofitted with Sicarbtech bidirectional half-bridge modules, upgraded gate drivers, and a re-laid laminated DC bus. Commissioning was faster due to less ringing and smoother dV/dt control. Power density improved by around 30%, freeing space in an overtaxed MCC room. With AlN substrates and sintered silver, the drives tolerated dust-fouled cooling without tripping thermal limits, extending maintenance intervals. PQ logs captured lower current ripple at the point of interconnection—useful evidence during regulatory audits.

A ground-mounted solar developer near Sukkur carried out a DC-coupled hybrid inverter retrofit. By deploying 1700 V SiC MOSFETs and third-generation Schottky diodes across the DC boost, bidirectional DC/DC, and grid-side stages, the project saw a ~0.8 percentage point system peak efficiency gain and a ~0.7 percentage point improvement in storage round-trip efficiency. The site’s weak-grid events became less disruptive due to faster dynamic response and stable operation at elevated temperatures. Critically, Sicarbtech helped select gel encapsulants and sealing approaches that reduced ingress-related downtime during sandstorms.

Technical Advantages and Implementation Benefits with Local Compliance in Mind

The engineering payoff of SiC in Pakistan is multifaceted. First, efficiency gains compound across the conversion chain, which matters in DC-coupled hybrid systems where PV arrays and batteries share a bus. Reducing losses in DC boost and bidirectional DC/DC stages lifts the entire system’s round-trip efficiency, making time-of-use arbitrage and backup more profitable. Second, higher switching frequency shrinks magnetics and filtering components, enabling lighter rooftop installations and compact MCC layouts. Third, robust operation at high junction temperatures adds thermal headroom during heatwaves and reduces forced-air cooling noise and power draw—a tangible OPEX benefit.

From a compliance standpoint, NEPRA/IEEE harmonics and PQ requirements become easier to meet when EMI is tackled at the source. Low-parasitic modules, laminated busbars, and controlled gate edges reduce ringing; combined with targeted filters, this minimizes the mass and complexity of EMC solutions. Creepage and clearance can be designed for mid-to-high altitudes and high humidity, while coatings and sealing counter dust and corrosive air near cement kilns or coastal steel yards. In practice, these design choices shorten commissioning, reduce nuisance trips, and create a stronger basis for extended warranties and lender confidence.

Comparative Portfolio View for Power Electronics Decision-Makers

Matching Pakistan’s Industrial Requirements with Sicarbtech’s SiC Building Blocks

| Pakistani Application Need | Sicarbtech SiC MOSFETs (1200/1700 V) | Sicarbtech 3rd-Gen SiC Schottky Diodes | Sicarbtech Half/Full-Bridge Modules | Conventional Silicon Options |

|---|---|---|---|---|

| High-temperature rooftop PV | Low RDS(on), robust oxide reliability | Near-zero Qrr, low overshoot | Low-parasitic leadframe with clean dV/dt | Larger heatsinks, more fan power |

| Cement kiln and baghouse fans | Stable at high Tj with margin | EMI-friendly recovery | Laminated busbar integration and passivation | More frequent thermal fatigue |

| Steel mill auxiliaries | Controllable edge rates for EMC | Suppressed reverse spikes | Enhanced creepage and shielding | Longer commissioning cycles |

| EV charging (C&I) | High frequency for compact size | Lower conduction losses | Efficient thermal path via AlN/Si3N4 | Larger footprint, higher noise |

| Weak-grid PQ compliance | Precise gate control and Miller clamp | Reduced ringing at source | Parasitic <10 nH target | Heavier filtering requirements |

Deep-Dive Engineering Comparison for Dust, Heat, and Humidity

Device, Packaging, and System Parameters Tuned for Pakistan’s Conditions

| Parameter | Sicarbtech SiC Stack (Device + Module + Interconnect) | Typical Silicon Stack | Operational Implication |

|---|---|---|---|

| On-resistance vs temperature | Modest increase to 125°C+ | Steeper increase | Stable daytime output in summer |

| Reverse recovery charge (diode) | ~0 (Schottky) | High | Lower EMI; simpler filters |

| Max junction temperature | 175–200°C (package-dependent) | 150–175°C | Reduced heatsink size and fan speed |

| Module inductance | <10 nH target | 15–30 nH | Cleaner switching, fewer snubbers |

| Thermal interface | Sintered silver | Solder | Superior power cycling |

| Substrate material | AlN/Si3N4 with Cu | Alumina common | Higher k, more robust |

| Switching frequency | 50–150 kHz | 10–40 kHz | Smaller magnetics, lighter enclosures |

| Environmental sealing | Tailored gels and coatings | Generic | Fewer ingress failures |

| Weighted efficiency | +0.3–0.6 percentage points | Baseline | 0.5–1.2% annual yield gain |

| Lifecycle economics | Lower TCO | Higher TCO | Longer warranties, fewer outages |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Where Sicarbtech distinguishes itself for Pakistan is in the breadth of its delivery model. Beyond supplying devices and modules, the company enables partners to build local capability through comprehensive technology transfer and factory establishment services. As a member of the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech leverages advanced R&D and proprietary process expertise across R-SiC, SSiC, RBSiC, and SiSiC grades—offering not only high-performance power electronics components but also engineered ceramics and interconnect solutions tuned for high-temperature, dusty operation.

A typical technology transfer package includes detailed process know-how for epitaxial growth (CVD), doping profiles, trench/planar gate strategies, metallization stacks for copper on AlN or Si3N4, and the sintered-silver processing windows that underpin high power cycling life. Equipment specifications are provided down to utility requirements, layout, and maintenance routines, while training programs upskill operators, process engineers, and quality teams. Quality control frameworks are aligned with ISO 9001 and ISO 14001, and Sicarbtech supports conformance to relevant IEC/UL component tests and local PQ and safety expectations. For Pakistan’s regulatory context, Sicarbtech advises on NEPRA interconnection and harmonics norms, industrial safety, and environmental management practices suited to dust and high humidity.

Factory establishment services span feasibility studies that consider local labor pools and supply availability, through to production line commissioning and initial yield ramp. Ongoing technical support includes quarterly process audits, SPC tuning, reliability data refreshes, and on-call application engineering for busbar layouts, EMC tuning, and thermal optimization. Because Sicarbtech has supported 19+ enterprises through similar journeys, the practical playbook—what to do, and what not to do—comes built-in. This translates into accelerated time-to-market, fewer ramp surprises, and a credible roadmap to partial localization that reduces FX and logistics risk.

“Transferring a SiC capability is as much about culture—discipline, metrology, SPC—as it is about machines. We transfer the routines that make yield repeatable,” says a Sicarbtech process transfer lead, highlighting the company’s emphasis on operational excellence.

Future Market Opportunities and 2025+ Trends: Why SiC is Aligned with Pakistan’s Next Chapter

As rooftop and ground-mounted PV pipelines expand and user-side storage scales under time-of-use tariffs, hybrid DC-coupled architectures become particularly attractive. SiC’s low loss and high-frequency operation amplify the benefits of DC coupling by reducing conversion stages and enabling high-efficiency bidirectional conversion for batteries. We expect SiC penetration in higher-end inverter classes to move from a low base toward 30–50% over the next several years in Pakistan, mirroring global trajectories but with faster uptake in high-temperature regions.

Moreover, C&I EV charging will value compact, high-density power stages that minimize footprint in constrained urban facilities while keeping acoustic noise and cooling power low—another natural fit for SiC. Steel and cement facilities modernizing drives will use SiC-based modules to push power density and reduce MCC room cooling overhead. Financing models, increasingly sensitive to data-backed reliability and extended warranties, will reward platforms that can demonstrate robust lifetime performance in dust and heat. Suppliers that can deliver integrated materials–devices–equipment programs and provide local service will outpace those relying on purely imported, stand-alone components.

Frequently Asked Questions

What realistic efficiency gains can C&I PV owners in Pakistan expect with SiC-based inverters?

In field deployments, weighted efficiency typically rises by 0.3–0.6 percentage points, delivering roughly 0.5–1.2% annual energy uplift. Gains are stronger in hot, high-irradiance months when SiC’s lower temperature-induced losses maintain higher operating efficiency.

How does Sicarbtech adapt SiC modules for dusty and humid environments common in cement and coastal areas?

We apply tailored sealing gels, corrosion-resistant coatings, robust passivation, and carefully selected creepage and clearance strategies. Combined with enclosure design and filter maintenance plans, this reduces ingress-related failures and extends MTBF.

Can SiC make it easier to comply with NEPRA and IEEE-based harmonics and PQ requirements?

Yes. By cutting reverse recovery and parasitics, we reduce EMI at the source. With tuned gate resistors, Miller clamping, and laminated busbars, the resulting waveforms simplify EMC filtering and support PQ compliance under weak-grid conditions.

Which voltage classes and topologies are most suitable for Pakistan’s hybrid DC-coupled inverters?

1200 V devices are common for string and many hybrid stages, while 1700 V devices are widely adopted in central and higher-power DC/DC sections. Sicarbtech supports bidirectional half-bridge and full-bridge modules matched to DC-coupled architectures.

How does sintered silver change reliability compared to soldered interfaces?

Sintered silver offers higher thermal conductivity and mechanical robustness, significantly improving power cycling lifetime—especially valuable when heatsinks are partially fouled by dust and thermal deltas widen.

Can Sicarbtech support localized assembly or full production in Pakistan?

Yes. Through technology transfer and factory establishment services, we provide process recipes, equipment specifications, training, and quality frameworks. We also assist with phased localization to balance capex, talent readiness, and market demand.

What testing does Sicarbtech offer to validate reliability for Pakistani conditions?

We provide power cycling, temperature cycling, high-temperature/high-humidity (HAST-style), and salt spray where relevant. We share acceleration models and work with partners on site-specific test plans to support extended warranties.

Will faster SiC switching worsen EMC?

Fast edges can challenge EMC if unmanaged, but our low-parasitic modules, laminated busbars, and controlled gate drive strategies minimize ringing. In practice, well-co-designed SiC systems often need less bulky filtering than legacy designs.

How long do pilots and A/B validations typically take?

Pilots can be executed in weeks to a few months depending on scope. We recommend A/B testing across representative rooftops or process lines with clear KPIs: efficiency curves, thermal imaging, PQ logs, and maintenance records.

What total cost of ownership improvements are typical over a 10–15 year horizon?

Despite higher device costs, projects commonly see lower TCO thanks to higher efficiency, reduced cooling power, smaller enclosures, fewer maintenance interventions, and longer lifetimes—benefits that are amplified in hot, dusty environments.

Making the Right Choice for Your Operations

Selecting the right SiC path begins by mapping your constraints—ambient heat, dust load, roof or room loading limits, PQ targets, and financing requirements—to specific device, module, and system choices. When Sicarbtech co-designs with your team—from epitaxy parameters and gate oxide reliability to laminated busbar geometry, EMI filters, and thermal management—the gains become tangible: higher weighted efficiency, leaner cooling systems, shorter commissioning, and stronger warranty narratives. For textile mills, cement and steel plants, PV-plus-storage developers, and EV charging operators, this integrated approach reduces risk and accelerates ROI in Pakistan’s operating reality.

Get Expert Consultation and Custom Solutions

Speak with Sicarbtech’s engineers to align SiC device choices, module configurations, and system integration with your KPIs. Whether you are piloting a hybrid DC-coupled inverter, retrofitting cement fan drives, or planning local assembly, we will propose a data-driven roadmap with milestones for performance, reliability, and compliance. Contact: [email protected] or +86 133 6536 0038.

Article Metadata

Last updated: 2025-09-17

Next scheduled review: 2025-12-01

Content freshness indicators: Incorporates 2025 Pakistan market outlook; hybrid DC-coupled inverter strategies; 1200/1700 V SiC MOSFETs and 3rd-gen Schottky diodes; sintered silver and AlN/Si3N4 substrates; laminated busbars; NEPRA/PQ compliance considerations; localization and technology transfer pathways.

About Sicarbtech: Silicon Carbide Solutions Expert based in Weifang City, China’s SiC manufacturing hub; member of Chinese Academy of Sciences (Weifang) Innovation Park; 10+ years of customization experience supporting 19+ enterprises; full-cycle solutions from material processing to finished products; specialties include R-SiC, SSiC, RBSiC, and SiSiC grades; services include custom manufacturing, factory establishment, and technology transfer.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.