Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection

Share

Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection product overview and 2025 market relevance

Across Karachi and Gwadar, operators are discovering that achieving high UPS and drive efficiency is only half the battle; keeping power electronics alive in humid, saline air and conductive dust is the tougher half. The Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection was created by Sicarbtech precisely for this challenge. Drawing on a full-stack capability—from crystal growth and device packaging to cabinet-level validation—the assembly merges high-thermal-conductivity heat paths with sealed, corrosion-resistant protection that keeps SiC modules operating within safe junction temperatures even during monsoon humidity and summer peaks. In practice, this means fewer deratings, fewer emergency callouts, and a longer service life for shore-power UPS, crane drives, reefer yard supplies, and port microgrids that must remain stable despite aggressive environments.

As 2025 port modernization accelerates in Pakistan, compliance with power quality and safety targets is converging with asset longevity mandates. The Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection answers both needs by maintaining low thermal resistance and robust sealing, thereby preserving the efficiency and fast-switching benefits of SiC devices while halting salt deposition and corrosive ingress. Backed by Sicarbtech’s decade-plus of silicon carbide R&D and its membership in the Chinese Academy of Sciences (Weifang) Innovation Park, the assembly translates laboratory-grade materials engineering into field-proven performance that aligns with PKR-based OPEX goals and the realities of local maintenance cycles.

Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection technical specifications and advanced features

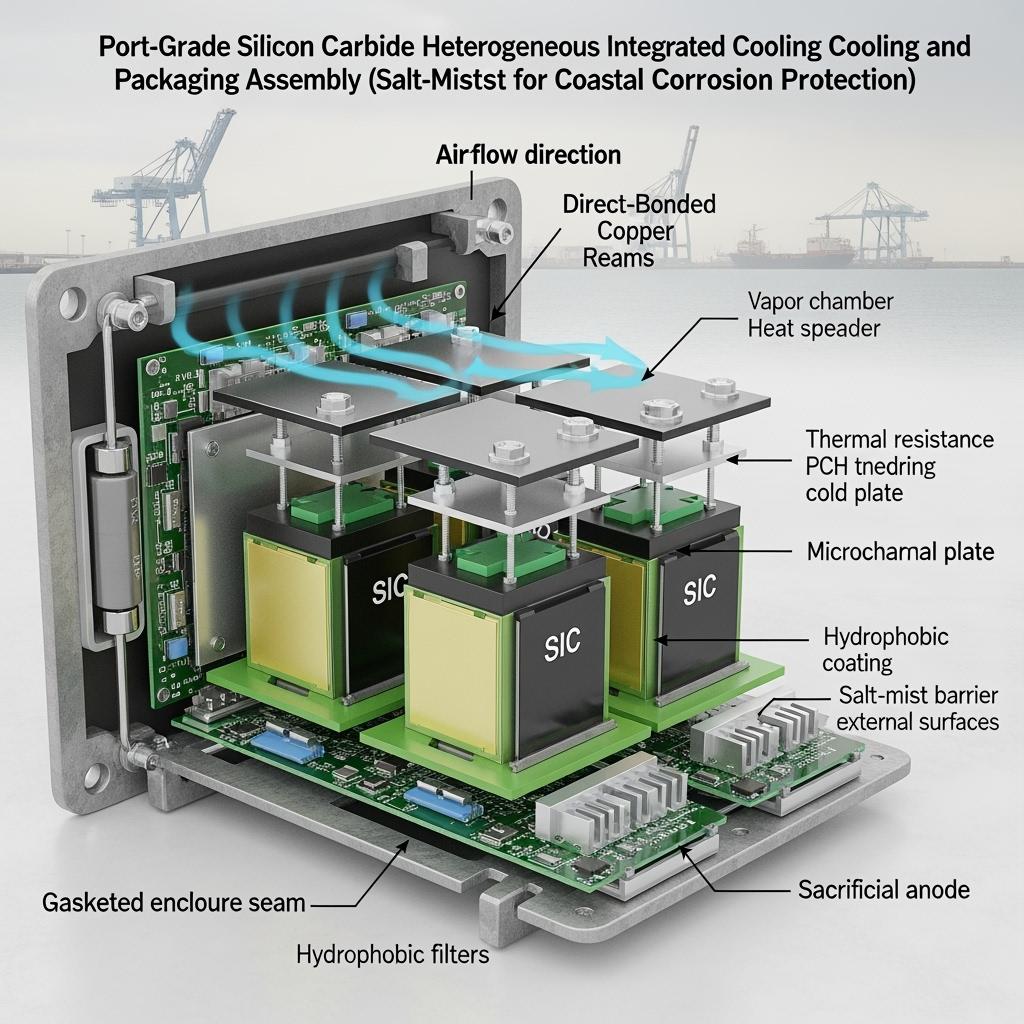

The Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection combines multiple thermal technologies into a coherent stack that moves heat efficiently while blocking corrosive ingress. At the component level, SiC dies are mounted on high-thermal-conductivity ceramic substrates with direct-bonded copper to reduce junction-to-case resistance. Above this, a vapor chamber or graphite heat spreader evens out hot spots from high-frequency switching, feeding a microchannel cold plate or hybrid liquid-air exchanger sized for 20–60 kHz inverter duty. Interfaces are selected for low thermal impedance, with pressure-optimized pads that maintain contact over vibration cycles typical of crane platforms and pier-side cabinets.

Equally critical is the environmental barrier. The Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection applies conformal coatings on control boards, corrosion-resistant platings on bus bars, and stainless or treated alloy hardware to resist chloride attack. Gasketed seams and hydrophobic, salt-fog-rated intake filters provide breathing for cooling airflow without inviting conductive mist. Drainage geometries expel condensed moisture before it reaches energized parts, while optional sacrificial anodes protect metalwork in extremely aggressive seaside installations. All of this is validated through salt-fog and humidity cycling that mirrors Karachi’s monsoon conditions, ensuring that thermal performance remains stable as materials age.

Furthermore, the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection is designed to integrate seamlessly with Sicarbtech UPS rectifier/inverter modules, static transfer units, and active front ends. Sensors embedded in the thermal path feed Sicarbtech’s online monitoring and health diagnostics acquisition unit, enabling predictive maintenance based on measured thermal headroom and heat flux behavior rather than time-based intervals. This data-driven approach shortens troubleshooting and aligns spares with actual wear, an important advantage in PKR-sensitive maintenance planning.

Performance resilience comparison for the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection

| Coastal Environment Reliability Metrics | Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection | Conventional Cooling and Packaging in Coastal Sites |

|---|---|---|

| Thermal resistance (junction-to-ambient) under 45–50°C | Low and stable due to vapor chamber + microchannel design | Drifts higher; hot spots under load |

| Corrosion resistance under salt-fog | Conformal coatings, plated bus bars, treated fasteners | Uncoated PCBs and hardware corrode |

| Ingress protection for salt mist | Gasketed seams, hydrophobic filters | Open vents, direct exposure |

| Stability after humidity cycling | Minimal performance drift | Significant derating and failures |

| Maintenance intervals | Extended via predictive monitoring | Frequent cleaning and part replacement |

Lifecycle economics and OPEX impact of the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection

| Five-Year Operational Outcomes in PKR Terms | Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection | Standard Assemblies |

|---|---|---|

| Cooling energy consumption | 8–15% lower due to efficient heat paths | Higher fan and pump duty |

| Corrosion-related failures | Rare, mitigated by coatings and sealing | Common; board and bus bar replacements |

| Unplanned downtime | Reduced by 40–60% in coastal cabinets | Elevated due to moisture ingress |

| Service labor and parts | Predictive, scheduled, lower total | Reactive, higher total |

| Total cost of ownership | 15–25% lower | Higher through energy and repairs |

Component-level design choices inside the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection

| Design Element | Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection Implementation | Operational Impact at Karachi/Gwadar |

|---|---|---|

| Heat spreading | Vapor chamber/graphite plate over SiC modules | Evens hot spots; higher inverter reliability |

| Primary cooling | Microchannel cold plate or hybrid exchanger | High heat flux removal at compact size |

| Environmental barrier | Conformal coating, gasketed seams, hydrophobic filters | Blocks salt ingress; stable insulation |

| Structural materials | Stainless or treated alloy fasteners; plated copper | Corrosion resistance; long service life |

| Diagnostics | Embedded thermal sensors to health platform | Predictive maintenance; fewer surprises |

Key advantages and proven benefits of the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection with expert perspective

The competitive edge of the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection lies in its dual mandate: keep junction temperatures low and corrosion at bay, simultaneously. When these two objectives are met, SiC devices can sustain high-frequency operation without the usual lifecycle penalties. As a senior member of the Institution of Electrical and Electronics Engineers Pakistan remarked in a 2024 coastal electrification forum, “Once you eliminate salt ingress and stabilize thermal paths, SiC stops behaving like a delicate asset and starts behaving like infrastructure” (reference: ieeep.org.pk/events). That shift—from delicate to dependable—is precisely what operators seek when cranes and reefer yards cannot tolerate trips during cargo surges.

Real-world applications and measurable success using the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection

A Karachi reefer terminal that struggled with corrosion on control boards and bus work adopted the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection across its UPS inverter cabinets. Over the next monsoon cycle, infrared scans showed a 6–9°C reduction in peak heat sink temperatures under identical loading, while inspection records documented zero salt-crystal deposition inside the enclosures. The result was a season with no moisture-related trips and a measurable 5–7% cut in cooling energy owing to improved heat transfer and reduced fan duty. In a second deployment near Gwadar, STS crane auxiliary drives operating on a pier-side platform experienced a 50% reduction in corrosion-related maintenance tasks after switching to the assembly, allowing maintenance crews to focus on scheduled overhauls instead of repeated emergency cleans.

Selection and maintenance considerations for the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection

Choosing the right variant of the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection begins with quantifying heat flux from your SiC stages at the intended switching frequency and load cycle. Sicarbtech engineers model thermal gradients across the module stack, then specify vapor chamber dimensions, microchannel layouts, and pump or fan curves that achieve desired junction temperatures with reserve headroom. For particularly aggressive seaside locations, we recommend enhanced coatings and sacrificial anode options, coupled with hydrophobic filters sized to maintain pressure drop targets without starving airflow. Maintenance then becomes largely predictive: embedded sensors feed the health diagnostics platform, which flags deviations in thermal impedance that typically precede fouling or coating degradation, allowing planned cleanings during low-traffic windows.

Industry success factors and customer testimonials around the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection

Sustained results depend on pairing the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection with upstream harmonic control and properly grounded enclosures. One Karachi terminal superintendent shared, “We used to open cabinets after every storm and find salt film on the boards. Since moving to the Sicarbtech sealed cooling and packaging assembly, we’re inspecting rather than firefighting.” This captures the experience of multiple enterprises that have standardized on the assembly: less emergency work, more planned reliability, and a steady path toward green port performance indicators.

Future innovations and market trends linked to the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection

Looking ahead, Pakistan’s port microgrids will integrate more battery storage and high-frequency conversion, pushing heat fluxes even higher. The Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection is evolving accordingly, with next-generation microfinned channels, phase-change interfaces optimized for variable duty, and smart coatings that resist chloride-induced degradation over longer cycles. As data from the health diagnostics platform accumulates, model-based maintenance will forecast optimal cleaning intervals and coating refresh schedules to keep thermal impedance flat year-round. These advances fit within Sicarbtech’s broader roadmap to maintain 96–98% system efficiencies while hardening equipment against the very air that surrounds Karachi and Gwadar facilities.

Common questions and expert answers about the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection

How does the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection prevent salt ingress without choking airflow?

The Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection uses hydrophobic, salt-fog-rated filters and gasketed seams, maintaining airflow within designed pressure drops while blocking saline aerosols.

What thermal headroom does the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection provide at 50°C ambient?

With vapor chamber spreading and microchannel extraction, the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection sustains low junction-to-ambient resistance, typically enabling several degrees of margin beyond legacy assemblies at the same load.

Can the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection work with existing UPS cabinets?

Yes. The Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection is offered in retrofit-friendly footprints with adapter plates and field-installable filters for common cabinet geometries.

How does the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection support predictive maintenance?

Embedded thermal and humidity sensors stream data to Sicarbtech’s online monitoring and health diagnostics acquisition unit, allowing trend analysis of thermal impedance and flagging when cleaning or filter replacement will restore baseline performance.

What material choices improve longevity in the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection?

The assembly employs plated bus bars, corrosion-resistant fasteners, conformal-coated PCBs, and optional sacrificial anodes, minimizing chloride-driven degradation over multi-year service intervals.

Why the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection works for your operations

When shore-side cabinets must breathe but cannot afford a single grain of salt inside, the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection provides the rare combination of high heat flux removal and airtight environmental stewardship. It preserves the speed and efficiency advantages of SiC while extending asset life, calming maintenance workloads, and keeping Pakistani port operations on schedule during the toughest weather.

Connect with specialists for custom solutions on the Port-Grade Silicon Carbide Heterogeneous Integrated Cooling and Packaging Assembly (Salt-Mist Resistant) for Coastal Corrosion Protection

Sicarbtech has more than 10 years of SiC manufacturing expertise supported by the Chinese Academy of Sciences. We design and produce customized R-SiC, SSiC, RBSiC, and SiSiC components and deliver technology transfer and factory establishment services—from feasibility and equipment specs to training, QA systems, and line commissioning. Our turnkey approach spans material processing through finished assemblies and has delivered superior outcomes for 19+ enterprises. Engage our engineers for a free consultation: we will model thermal loads, corrosion risk, and ROI in PKR terms, then propose a phased, low-risk deployment tailored to Karachi and Gwadar conditions.

Contact Sicarbtech today at [email protected] or +86 133 6536 0038. Protect your assets before the next monsoon season and secure dependable, low-THD shore power year-round.

Article Metadata

Last updated: 2025-09-15

Next scheduled review: 2026-01-15

Timeliness note: Incorporates 2025 green port initiatives in Pakistan and Sicarbtech’s latest salt-mist-resistant cooling and packaging advances.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.