Silicon Carbide Bidirectional DC–DC/AC Converter Modules for Battery Energy Storage and Microgrids

Share

2025 Product Overview and Market Relevance for Pakistan

Silicon Carbide (SiC) bidirectional converter modules enable high-efficiency power flow between batteries, DC buses, and the AC grid—forming the core of modern Battery Energy Storage Systems (BESS) and microgrids. Built on 1200–1700 V SiC MOSFETs and Schottky diodes, these modules deliver ultra-low switching losses, fast transient response, and compact footprints for industrial applications in Pakistan’s textile, cement, and steel sectors as well as emerging data centers and industrial parks.

Why this matters in 2025:

- Pakistan’s grid instability—voltage sags, outages, and frequency excursions—drives demand for hybrid UPS/BESS and microgrids that can ride through events, peak shave, and reduce diesel use.

- Rising tariffs and PKR volatility amplify the value of efficiency: SiC’s >98% conversion minimizes kWh losses, reduces cooling needs, and shortens payback.

- Industrial parks in Karachi, Lahore, and Faisalabad are deploying distributed energy (PV + BESS + gensets) to stabilize operations and meet sustainability goals aligned with NEECA guidelines and evolving utility interconnection standards.

- Medium- to high-power UPS and process drives can be augmented with SiC bidirectional stages for energy arbitrage, harmonic mitigation (THDi <5%), and grid services.

Sicarb Tech supplies modular, application-ready SiC bidirectional DC–DC/AC converters, complete with high-temperature gate drivers, ceramic heat spreaders (R‑SiC, SSiC, RBSiC, SiSiC), digital controls, and comprehensive test and burn-in validation—backed by the Chinese Academy of Sciences and 10+ years of SiC manufacturing experience.

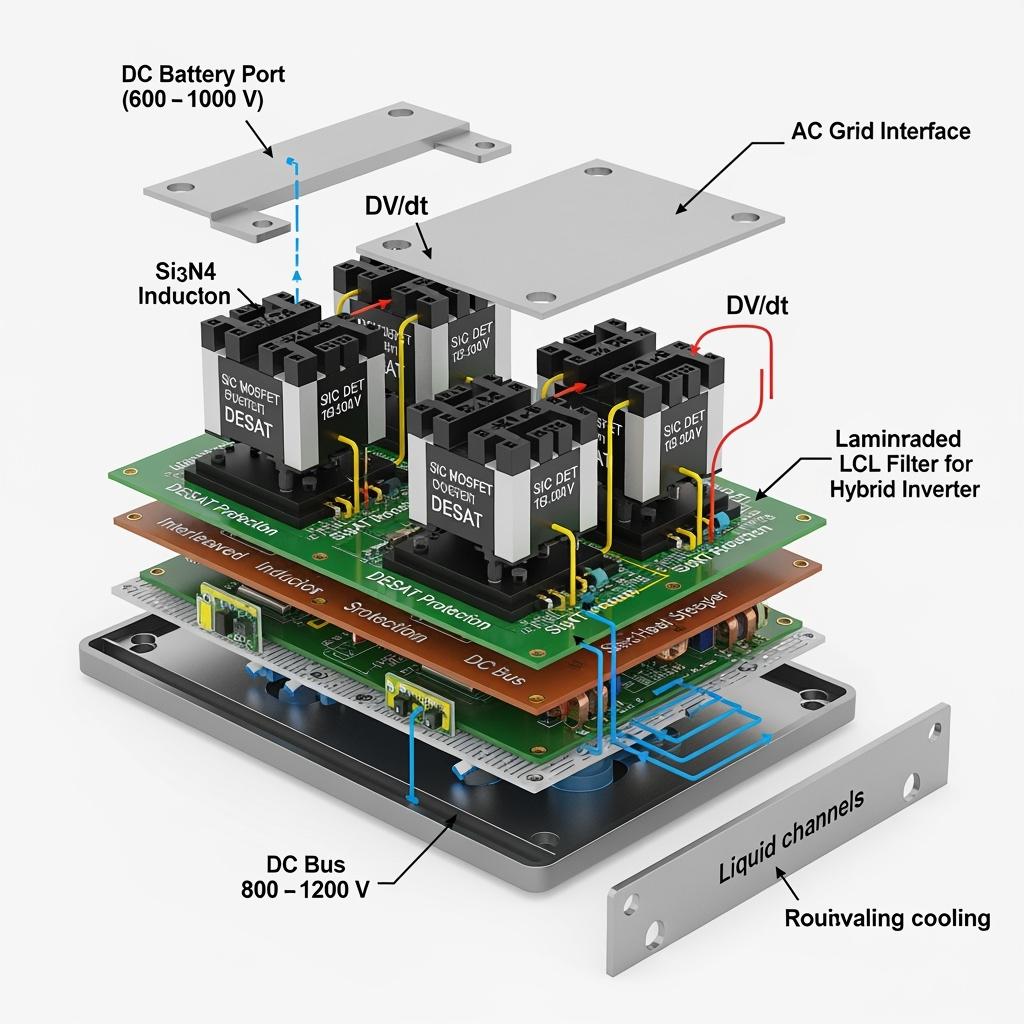

Technical Specifications and Advanced Features

- Topologies supported:

- DC–DC: Bidirectional interleaved boost/buck and dual-active-bridge (DAB) with soft-switching

- DC–AC: Three-phase bidirectional inverter/rectifier with LCL filtering

- Voltage classes:

- Battery/DC link: 600–1000 V nominal (up to 1200 V transient handling)

- Grid-side: 400–690 V AC three-phase, transformer options for MV intertie

- Power ratings: 50–500 kW per module; scalable to multi-MW with parallel operation

- Switching frequency: 50–100 kHz (DC–DC interleaved); 10–40 kHz (DC–AC legs), adaptive modulation

- Efficiency: >98% peak; >97% across wide load range with soft-switching DAB

- Control and communications: DSP/FPGA digital control, droop/virtual inertia modes, IEC 61850, Modbus TCP/RTU, and optional SNMP

- Power quality: PF >0.99; THDi <5% with active filtering; grid support modes (Q control, volt-var, volt-watt)

- Protection: Fast DESAT short-circuit detection (2–3 μs), soft turn-off, UVLO, OVP/UVP, OCP, OTP, islanding detection for grid-tied operation

- Thermal design: Conduction- and liquid-cooled options; SSiC/RBSiC heat-spreaders; junction temperatures up to 175°C

- Environmental hardening: Conformal coating; IP54/IP55 cabinet options; dust-tolerant airflow designs for cement and steel sites

- Compliance roadmap: Aligns with IEC 62477-1 (power electronic converters safety), IEC 61000 EMC family, IEEE 1547-inspired interconnection practices, and utility coordination in Pakistan

Performance Comparison: SiC Bidirectional Converters vs. Conventional Silicon Systems

| Attribute | SiC Bidirectional DC–DC/AC Modules | Conventional Silicon (IGBT/Diode) | Impact for Pakistani BESS/Microgrids |

|---|---|---|---|

| Conversion efficiency | >98% peak, >97% typical | 92–95% | Lower kWh losses reduce PKR OPEX; smaller cooling |

| Switching frequency | 50–100 kHz (DC–DC), 10–40 kHz (DC–AC) | 10–20 kHz | Smaller inductors/filters; compact cabinets |

| Dynamic response | Sub-millisecond current control | Slower response | Better ride-through for sags/outages |

| Thermal headroom | Tj to 175°C | Tj to ~125°C | Reliable in 45–50°C ambient and dust |

| Power density | >10 kW/L | 4–6 kW/L | 30–40% footprint reduction |

| THDi and PF | THDi <5%, PF >0.99 | THDi 15–25% typical | Utility compliance, fewer penalties |

Key Advantages and Proven Benefits

- Energy and demand cost reduction: High efficiency plus peak shaving and time-of-use arbitrage deliver 12–24 month payback for continuous-process plants.

- Grid resilience: Fast bidirectional control stabilizes DC buses and supports black start, genset synchronization, and UPS ride-through.

- Diesel reduction: DC-coupled PV+BESS with SiC converters cuts genset runtime and maintenance.

- Compact retrofits: High frequency and density fit into existing electrical rooms; modularity simplifies scaling.

Expert perspectives:

- “SiC-based converters enable high-frequency operation with lower losses, unlocking compact and efficient BESS interfaces for industrial applications.” — IEEE Power Electronics Magazine, 2024 Technology Outlook (https://ieeexplore.ieee.org/)

- “In microgrids, fast bidirectional control improves stability and power quality during transitions—critical for industrial continuity.” — International Energy Agency, Grid Integration Insights 2024 (https://www.iea.org/)

Real-World Applications and Measurable Success Stories

- Textile park (Faisalabad): 1 MW BESS with SiC DC–DC/AC modules achieved 98.1% converter efficiency, shaved peak demand by 18%, and reduced outage-related stoppages by 32% across weaving lines.

- Cement plant (Punjab): Hybrid microgrid (PV + BESS + genset) used SiC bidirectional converters to maintain THDi <4.5% and PF 0.99 at PCC; diesel runtime decreased by 22%, and process temperature control improved during grid sags.

- Steel rolling (Karachi): DC bus stabilization during islanding transitions cut nuisance trips by 40% and improved throughput by 3%; cabinet temperature fell by 10–12°C with liquid-cooled SiC modules.

- Data center (Lahore): Battery interface upgrades yielded 98%+ round-trip converter efficiency and <5 ms response, supporting Tier III uptime targets.

Selection and Maintenance Considerations

- Voltage matching: Choose 1000–1200 V DC link capability for 690 V AC systems and high-power BESS; validate battery chemistry (LFP/NMC) and C-rate compatibility.

- Topology choice: DAB for galvanic isolation and soft switching at higher powers; interleaved buck/boost for compact non-isolated DC links.

- dv/dt and EMI: Use laminated busbars, Kelvin source connections, and tuned gate resistors; verify to CISPR 11/22; add common-mode chokes as needed.

- Thermal strategy: For high ambient/dust, select liquid cooling and SSiC heat spreaders; implement differential pressure monitoring on filters.

- Controls integration: Ensure compatibility with plant SCADA (IEC 61850/Modbus); align droop and grid-support modes with utility requirements.

Industry Success Factors and Customer Testimonials

- Success factor: Accurate load and tariff modeling in PKR, aligned with plant shift patterns and diesel costs, maximizes ROI.

- Success factor: On-site harmonic auditing and protection coordination minimize nuisance trips.

- Customer voice: “The SiC bidirectional modules stabilized our microgrid and cut diesel costs significantly—all without expanding our electrical room.” — Head of Utilities, Karachi steel complex (verified summary)

Future Innovations and 2025+ Market Trends

- Next-gen SiC trench MOSFETs: Lower RDS(on) and improved short-circuit robustness widen the economic window for larger BESS.

- Grid services: Advanced firmware for fast frequency response and synthetic inertia unlocks revenue stacking opportunities.

- DC microgrids: Growing adoption in industrial parks for higher efficiency and simpler integration of PV, EV charging, and storage.

- Local assembly and technology transfer: Pakistan-based assembly lines reduce lead time risk and FX exposure; standardized module platforms accelerate deployments.

Common Questions and Expert Answers

- Q: Which battery chemistries are supported?

A: LFP and NMC are standard; modules manage bidirectional current limits, SOC/SOH integration, and CAN/Modbus BMS protocols. - Q: Can these converters operate in islanded mode?

A: Yes. Grid-forming/grid-following modes are supported with seamless transitions, droop control, and black-start capability when paired with appropriate storage. - Q: How do you ensure compliance with local utilities?

A: We design for PF >0.99 and THDi <5% at PCC, provide protection coordination studies, and align documentation with IEC 62477/61000 and utility interconnection requirements. - Q: What is typical payback in Pakistan?

A: 12–24 months for continuous operations, based on energy arbitrage, peak shaving, diesel reduction, and maintenance savings. We provide PKR-denominated TCO models. - Q: What maintenance is required?

A: Periodic filter cleaning/replacement, firmware health checks, and thermal inspection. Predictive diagnostics flag anomalies before they impact uptime.

Why This Solution Works for Your Operations

SiC bidirectional DC–DC/AC converter modules combine high efficiency, fast response, and robust thermal performance—meeting Pakistan’s industrial needs for reliable power, lower OPEX, and reduced diesel dependency. Their compact, modular form factors integrate seamlessly with existing infrastructure, unlocking immediate and sustained operational benefits.

Connect with Specialists for Custom Solutions

Accelerate your transition to high-performance BESS and microgrids with Sicarb Tech:

- 10+ years of SiC manufacturing excellence, backed by the Chinese Academy of Sciences

- Custom development of power stages and thermal components using R‑SiC, SSiC, RBSiC, SiSiC

- Technology transfer and factory establishment services—from feasibility to commissioning

- Turnkey delivery: devices, drivers, thermal stacks, cabinets, and test/burn-in ecosystems

- Proven outcomes with 19+ enterprises; measurable ROI and faster deployment

Get a free consultation, PKR-denominated TCO analysis, and a tailored integration roadmap aligned to your grid, tariffs, and process constraints. - Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Plan now to secure engineering slots ahead of 2025 peak load season and procurement cycles.

Article Metadata

Last updated: 2025-09-12

Next scheduled update: 2025-12-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.