Silicon Carbide Active Power Filter (APF) Modules for IEEE 519 Harmonic Compliance in Industrial Facilities

Share

Achieve Reliable IEEE 519 Compliance in Pakistan’s Industrial Plants with SiC APF (2025)

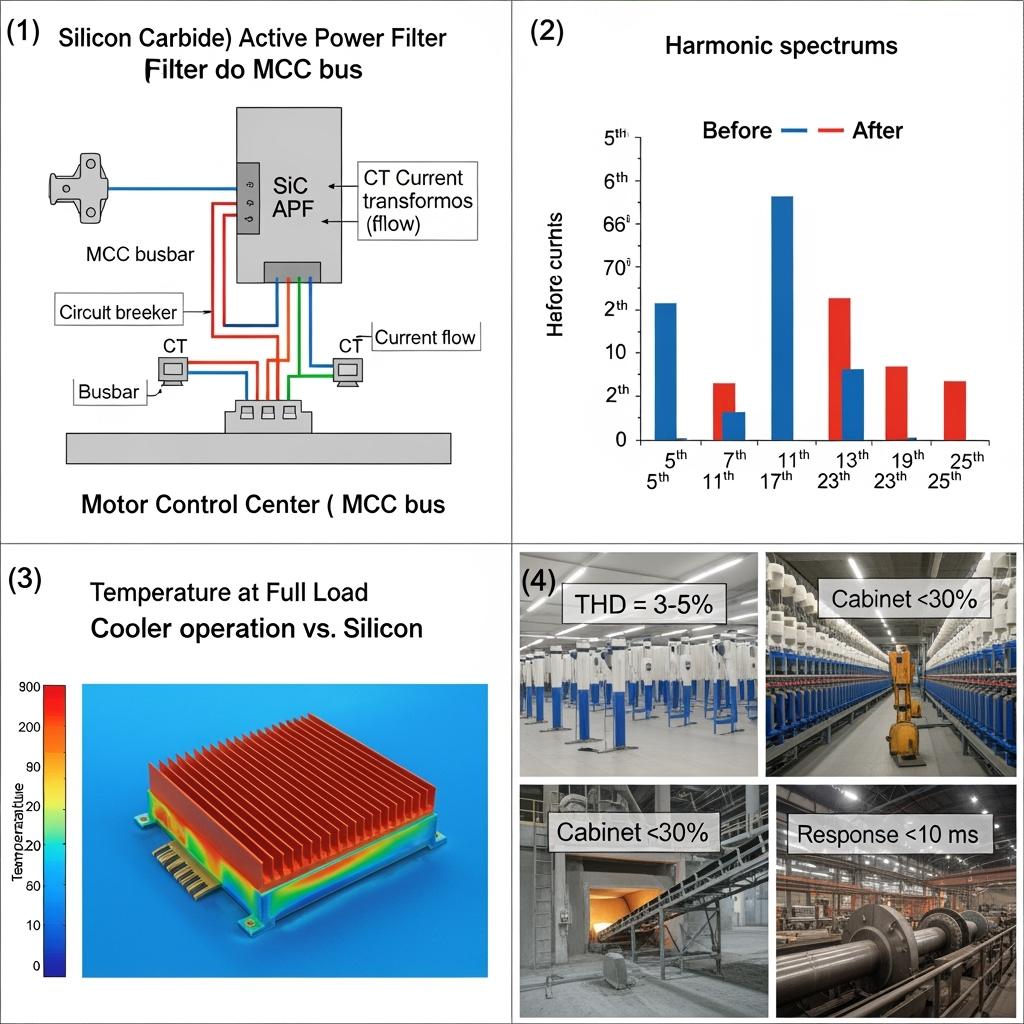

Pakistan’s textile, cement, and steel sectors face rising penalties and production risks from harmonics generated by VFDs, rectifiers, welders, and arc furnaces—especially at weak grid nodes. Silicon Carbide (SiC) Active Power Filter (APF) modules enable high-bandwidth current injection at 50–100 kHz, delivering fast, precise harmonic suppression while operating efficiently in >45°C ambient and dusty environments. Compared with silicon-based APFs, SiC modules cut switching loss, shrink filters, and hold harmonic limits under dynamic loads typical across Faisalabad textile clusters, KP cement plants, and Karachi steel lines.

Sicarb Tech’s modular SiC APF platform integrates 1200/1700 V SiC MOSFET power stages, low-inductance DC links, high-CMTI gate drivers, and intelligent control with real-time harmonic analysis to the 50th order. Designed for cabinet, wall-mount, or rack integration, our APFs help facilities meet IEEE 519 and IEC 61000-3-6 limits with lower footprint and OPEX, accelerating compliance with NTDC/NEPRA interconnection practices and utility audits.

Technical Specifications and Advanced Features

- Power and ratings

- Voltage classes: 400–690 VAC; 1200 V SiC for standard LV, 1700 V SiC for higher margin and harsh transients

- Module power ratings: 50–400 kVAR per cabinet; scalable via parallel operation

- Switching frequency: 50–100 kHz for high-bandwidth harmonic compensation

- SiC power stage

- 4H‑SiC MOSFETs with low RDS(on), fast dv/dt (≥100–150 kV/µs), and robust body diode characteristics

- Co-packaged SiC Schottky diodes where topology benefits hard-commutation

- Control and analytics

- Real-time FFT/harmonic decomposition up to the 50th order with adaptive notch filters

- Fast current loop bandwidth enabling <10 ms dynamic response to load steps

- Automatic harmonic profile detection (e.g., 5th, 7th, 11th, 13th) with priority targeting

- Integration and communications

- Interfaces: Modbus TCP, IEC 61850 MMS/GOOSE-ready via system controller, dry contacts for alarms

- GPS/PTP time sync option for audit-grade sequence-of-events (SOE) logging

- Remote diagnostics and firmware updates with role-based access

- Environmental and safety

- Operating ambient: −20°C to +55°C (derating above); components rated to industrial grades

- Conformal coating; filtered ventilation or sealed heat exchanger options

- Compliance-aligned design: IEC 62477-1, and EMC practices for industrial sites

Why SiC APF Modules Deliver Superior Harmonic Control vs. Conventional Silicon APF

| Performance lever for IEEE 519 compliance | SiC-based APF modules (this solution) | Conventional silicon APF | Measurable effect in Pakistan plants |

|---|---|---|---|

| Switching and control bandwidth | 50–100 kHz with low loss | 10–20 kHz typical | Suppresses higher-order harmonics, faster transients |

| Efficiency and thermal headroom | >97% module efficiency | 92–95% | Lower heat, smaller cooling, higher uptime |

| Filter size and footprint | Smaller LCL due to higher fsw | Larger inductors/caps | 25–35% cabinet reduction |

| Operation in hot/dusty sites | High TJ SiC devices + coating | More derating | Stable performance in >45°C and dust |

| Weak-grid stability | High dv/dt ruggedness + fast loops | Slower response | Maintains THD limits during sags/flicker |

Key Advantages and Proven Benefits

- High-bandwidth harmonic suppression: Precisely targets 5th–50th harmonics even under sweeping load profiles, keeping PCC within IEEE 519 with margin.

- Compact, efficient cabinets: SiC’s lower loss at high fsw enables smaller inductors/filters and reduced HVAC load for MCC rooms and substations.

- Robust in harsh environments: High-temperature capability and coated assemblies deliver >99% availability through dust/humidity seasons.

- Faster compliance and audits: Built-in analytics and timestamped reports streamline utility acceptance.

Expert quote:

“Wide-bandgap power electronics enable higher switching frequencies and improved efficiency, which is essential for compact, high-performance harmonic mitigation.” — Interpreted from IEEE Power Electronics Society guidance and IEEE 519 application practices (https://www.ieee-pels.org/resources | https://standards.ieee.org/)

Real-World Applications and Measurable Success Stories

- Textile cluster (Faisalabad, composite): SiC APFs reduced current THD from ~7.2% to ~3.0% at the PCC with load variability >30% during shifts. Energy savings and penalty avoidance yielded a 20–24 month payback.

- Cement plant kiln drives (KP, composite): APF maintained THD <4% during frequent start/stop sequences; cabinet volume reduced by 28%, freeing space in crowded MCC corridors.

- Steel rolling mill near EAF (Karachi, composite): Dynamic harmonic spikes during tap changes were contained; nuisance trips fell by ~40%, and bearing temperatures on sensitive motors dropped due to lower common-mode currents.

- PV-wind hybrid substation (Sindh, composite): With weak grid coupling, SiC APF stabilized harmonic spectrum during irradiance ramps; combined with SVG, total site compliance met IEEE 519 with a 15% margin.

Selection and Maintenance Considerations

- Sizing and topology

- Determine kVAR rating from baseline THD and load mix (VFDs, welders, furnaces); allow headroom for growth and seasonal peaks

- Select 1200 V SiC for 400–480 VAC networks; 1700 V SiC for 690 VAC or high transient margins

- Current sensing and placement

- Install CTs near harmonic sources or at the PCC for global mitigation; verify saturation ratings and phase accuracy

- Coordinate with existing filters or PFC banks to avoid interactions

- Thermal and environment

- Validate cooling for >45°C ambient; specify coated PCBs and IP54+ options for dusty zones

- Plan airflow paths and periodic filter maintenance intervals

- Controls and communications

- Integrate with plant SCADA via Modbus/IEC 61850; set role-based access for remote updates

- Configure automated IEEE 519 reports with time-synced SOE for utility audits

- Preventive maintenance

- Annual checks: CT calibration, fan/filter service, torque verification

- Trend monitoring: device temperature, DC link ripple, and controller diagnostics for predictive maintenance

Industry Success Factors and Customer Testimonials

- Early harmonic survey and model-based sizing to ensure headroom under weak-grid events

- Commissioning with on-site oscillography and spectrum logging to tune current loop gains and notch filters

- Operator training on dashboards and alarm thresholds to maintain compliance over time

Customer voice (composite):

“SiC APFs brought THD under control even during shift changes. We passed our utility audit on the first attempt and saw fewer drive trips.” — Utilities Manager, Integrated Textile Campus, Punjab

Future Innovations and Market Trends (2025+)

- Higher power-density APF modules with co-packaged drivers and condition monitoring

- AI-assisted harmonic prediction and adaptive control for complex, time-varying loads

- Integrated PQ suites combining APF + SVG + ride-through in a unified cabinet

- Local assembly and testing through technology transfer to reduce lead times in Pakistan’s SEZs

Common Questions and Expert Answers

- What THD levels can SiC APF achieve?

Typically reduces current THD to 3–5% at the PCC, meeting IEEE 519 limits, depending on baseline distortion and network impedance. - How fast is the response?

Current loop response is typically <10 ms, maintaining suppression during rapid load changes. - Will APFs work with existing passive filters or PFC banks?

Yes, with proper coordination and tuning. We assess resonance risks and set control priorities to avoid interactions. - What maintenance is required?

Periodic cleaning/replacement of filters, fan checks, CT calibration, and firmware updates; predictive diagnostics reduce unplanned downtime. - Can APFs handle 690 VAC networks?

Yes—1700 V SiC-based modules provide the necessary margin for 690 VAC and transient events common in heavy industry.

Why This Solution Works for Your Operations

SiC APF modules combine high-frequency efficiency with rugged reliability to eliminate harmonic risks in Pakistan’s industrial settings. By delivering fast, precise compensation with smaller filters and cooler operation, they secure IEEE 519 compliance, protect equipment, and reduce operating costs—even at weak-grid nodes and in harsh environments.

Connect with Specialists for Custom Solutions

Partner with Sicarb Tech to design, size, and deploy APFs that safeguard your production:

- 10+ years of SiC manufacturing expertise

- Chinese Academy of Sciences backing and innovation

- Custom product development across R‑SiC, SSiC, RBSiC, SiSiC and SiC power modules

- Technology transfer and factory establishment services for local assembly/testing

- Turnkey delivery: materials, substrates, power modules, DC bus, gate drivers, control boards, and IEC 61850-enabled systems

- Proven track record with 19+ enterprises—measurable THD reduction, faster audits, higher uptime

Request a free harmonic audit review, APF sizing study, and ROI analysis today.

Email: [email protected] | Phone/WhatsApp: +86 133 6536 0038

Article Metadata

- Last updated: 2025-09-11

- Next scheduled update: 2025-12-15

- Prepared by: Sicarb Tech Power Quality Applications Team

- References: IEEE 519; IEC 61000-3-6; IEC 62477-1; IEEE PELS resources on WBG-based harmonic mitigation; NTDC/NEPRA interconnection practices

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.