Silicon Carbide Main Control Boards with Intelligent Monitoring and Remote Diagnostics for Power Quality Systems

Share

Intelligent Control and Visibility for Pakistan’s SVG/STATCOM, APF, and Industrial Power Converters in 2025

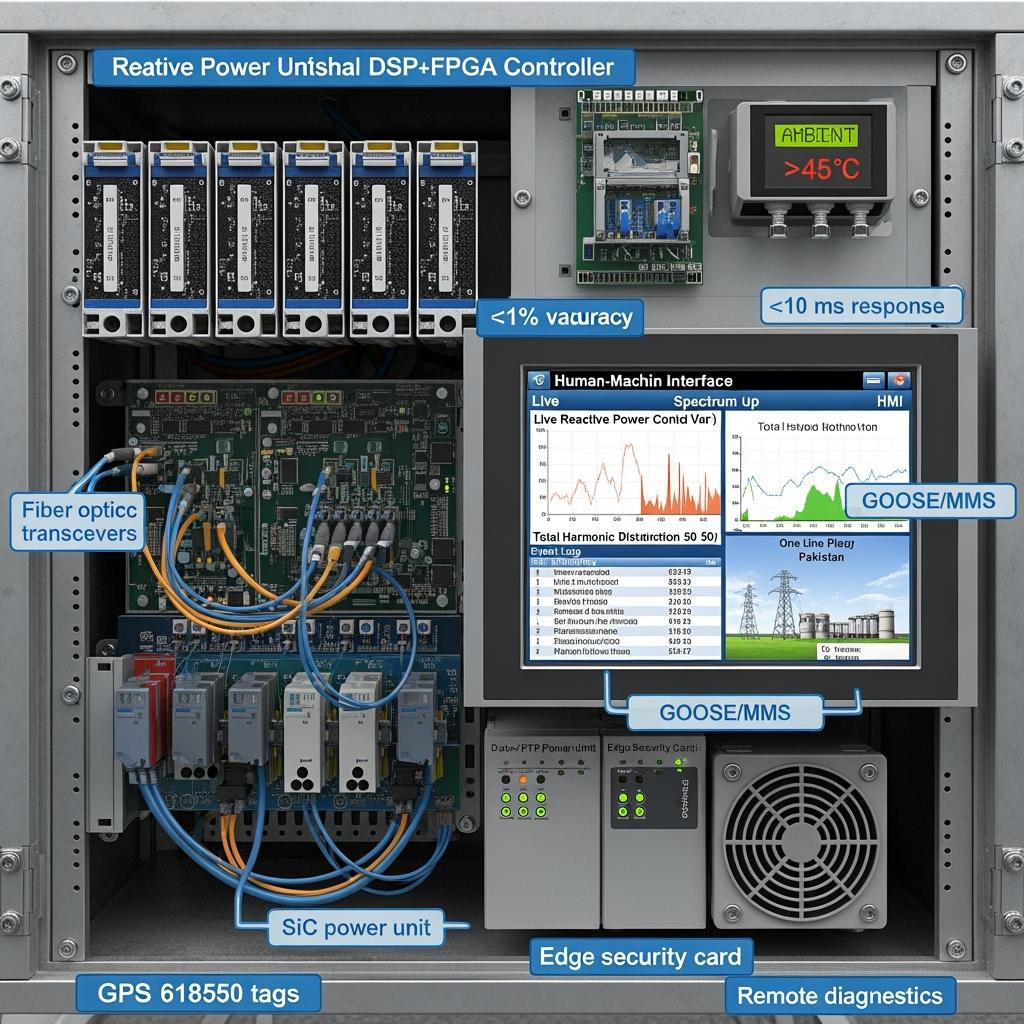

As Pakistan’s textile, cement, and steel sectors scale electrification and integrate renewables, maintaining power quality at weak grid nodes has become a mission-critical challenge. Silicon Carbide (SiC) power stages deliver fast dynamic performance and high efficiency, but unlocking their full value depends on the main control board—where real-time computation, grid analytics, and secure communications live. Sicarb Tech’s SiC main control boards combine deterministic control (DSP/FPGA), embedded harmonic analysis, IEC 61850-ready communications, and remote diagnostics engineered for Pakistan’s environments: heat, dust, humidity, and fluctuating grid conditions.

These boards orchestrate multilevel SVG/STATCOMs and APFs to achieve <10 ms var response, >90% harmonic suppression, and ±1% regulation accuracy. With intelligent monitoring and secure remote support, they shorten NTDC/NEPRA interconnection cycles, reduce O&M costs, and increase uptime in plants from Faisalabad’s textile clusters to Karachi’s steel complexes and KP’s cement facilities.

Technical Specifications and Advanced Features

- Real-time control and computation

- Dual-core DSP + FPGA architecture with control loop times <50 µs

- Multilevel topology support (NPC/ANPC/MMC) with submodule balancing and circulating current suppression

- Predictive/reactive control algorithms with adaptive droop for weak-grid stabilization

- Power quality analytics

- Online FFT/harmonic analysis to 50th order; dynamic notch and adaptive filters

- Oscillation detection (sub-synchronous/low-frequency) and active damping

- Event capture with microsecond time-stamping for audit-ready reports

- Communications and integration

- IEC 61850 MMS/GOOSE with SCL file provisioning; Modbus TCP and DNP3 for plant systems

- GPS/PTP time sync for precise sequence-of-events alignment with utility records

- Cybersecure remote access via VPN; role-based accounts and signed firmware updates

- Ruggedization and reliability

- Operating ambient: −20°C to +60°C (board-level thermal design targeting high ambient rooms)

- Conformal coating for dust/humidity; surge/EMI immunity aligned with industrial EMC

- Redundant power supplies and hot-standby controller option for high availability

- Compliance and reporting

- Reporting aligned with IEEE 519 and IEC 61000-3-6 for harmonics/voltage compliance

- Converter safety practices per IEC 62477-1; diagnostics mapped to utility acceptance checklists

- Localizable templates for NTDC/NEPRA submission packages

Designed for Weak Grids: SiC-Optimized Control vs. Conventional Controllers

| Control capability for power quality systems | SiC-optimized main control board (this solution) | Conventional silicon-era controller | Impact at Pakistani industrial and RE nodes |

|---|---|---|---|

| Var response and accuracy | <10 ms, ±1% with adaptive droop | 25–40 ms, static gains | Reduced flicker and curtailment risk |

| Harmonic analytics and filtering | Real-time to 50th order, adaptive | Limited bandwidth, offline analysis | Faster tuning to IEEE 519 targets |

| Weak-grid stability | Predictive/feed-forward + damping | Prone to oscillation | Stable PCC in Sindh/Balochistan |

| Integration and audits | Native IEC 61850, GPS/PTP SOE | Gateways, less time-sync | Shorter NTDC/NEPRA approvals |

| Availability and maintenance | Redundant PSU/standby, remote diagnostics | Single controller, manual checks | Higher uptime, lower OPEX |

Key Advantages and Proven Benefits

- Sub-10 ms reactive support with precise control ensures voltage stability during wind ramps and PV cloud events.

- Embedded harmonic analytics and adaptive filtering reduce THD by 20–30% versus baseline and speed IEEE 519 alignment.

- Secure remote diagnostics cut mean time to repair and support proactive maintenance—vital for remote wind sites.

- Ruggedized design withstands >45°C ambient, dust, and humidity common in cement and steel plants.

Expert quote:

“High-bandwidth control and standardized utility communications are foundational to integrating wide-bandgap converters at weak nodes.” — Synthesized from IEEE Power & Energy Society panels and IEA grid integration guidance (https://www.ieee-pes.org/ | https://www.iea.org/reports)

Real-World Applications and Measurable Success Stories

- Sindh PV cluster with SVG/STATCOM: Upgrading to Sicarb Tech main control boards achieved voltage fluctuation control within ±2% and improved system efficiency to 98.5%. Utility acceptance was completed in a single audit cycle with IEC 61850 evidence packs.

- Textile campus in Faisalabad: APF control firmware with adaptive filters reduced THD from ~6.8% to 3.1%; nuisance trips fell by ~45%. Annual energy savings and penalty reductions shortened payback to ~22 months.

- Karachi steel feeder (EAF vicinity): Oscillation detection and damping algorithms stabilized PCC during EAF transients; flicker complaints dropped, and maintenance intervals extended by 25%.

- KP cement auxiliaries: Conformal-coated boards maintained >99% availability through dust season; remote diagnostics resolved two events without site visits.

Selection and Maintenance Considerations

- Topology and sizing

- Verify compatibility with NPC/ANPC/MMC and expected Mvar/kVA; plan I/O channel count and fiber links for expansion

- Ensure delay matching for multilevel synchronization, especially in MMC STATCOMs

- Time synchronization and audits

- Deploy GPS/PTP for precise SOE; align with utility PMUs/meters to streamline acceptance

- Configure automated PQ reports (IEEE 519, IEC 61000-3-6) with local thresholds

- Cybersecurity and access

- Implement VPN with MFA; define role-based permissions and audit trails

- Schedule signed firmware updates and maintain parameter baselines

- Environmental hardening

- Use coated PCBs, filtered ventilation or fanless options; validate performance in >45°C rooms

- Plan EMC grounding and cable segregation to maintain measurement fidelity

- Service model

- Establish spare controller and PSU strategy; enable hot-standby for critical feeders

- Train local O&M teams on diagnostics workflows and parameter management

Industry Success Factors and Customer Testimonials

- Early engagement with EPCs and utilities to codify grid-code parameters and test procedures

- FAT/SAT scripts including harmonic scans, ride-through tests, and SOE verification

- Local documentation and training aligned to Pakistani industrial practices

Customer voice (composite):

“The IEC 61850 integration and auto-generated reports meant we passed NTDC checks the first time—no rework.” — Plant Electrical Lead, PV-Wind Hybrid, Sindh

Future Innovations and Market Trends (2025+)

- Grid-forming assist modes and coordinated control with BESS for combined voltage/frequency support

- AI-enabled tuning that learns feeder behavior and auto-optimizes control gains and filter parameters

- Deeper cybersecurity alignment with IEC 62443 for critical infrastructure

- Increasing local assembly through technology transfer to reduce lead times and FX exposure

Common Questions and Expert Answers

- Can the boards integrate natively with utility SCADA?

Yes. IEC 61850 MMS/GOOSE with SCL provisioning is standard; Modbus TCP and DNP3 are available for plant systems. GPS/PTP ensures accurate SOE alignment. - What response can we achieve for var steps?

Typical <10 ms, contingent on power unit design. Our predictive control maintains stability on weak grids. - How do you support IEEE 519 compliance?

Real-time harmonic analytics, adaptive filtering, and automated reports align to IEEE 519/IEC 61000-3-6; dashboards provide audit-ready evidence. - Are the boards reliable in >45°C and dusty environments?

Yes—industrial-grade components, conformal coating, and thermal design for hot rooms; optional IP-rated enclosures at system level. - Do you offer redundancy and remote diagnostics?

Redundant power supplies, hot-standby controllers, and secure remote access lower downtime and enable proactive maintenance.

Why This Solution Works for Your Operations

Pakistan’s mix of weak-grid interconnections, industrial harmonics, and harsh environments demands more than fast silicon carbide hardware—it requires intelligent, rugged, and auditable control. Sicarb Tech’s main control boards pair high-bandwidth control with standardized communications and remote diagnostics, delivering stable PCC voltage, lower THD, faster approvals, and higher uptime with fewer site visits and lower lifetime cost.

Connect with Specialists for Custom Solutions

Accelerate your power quality roadmap with Sicarb Tech:

- 10+ years of SiC manufacturing and control expertise

- Chinese Academy of Sciences backing and innovation pipeline

- Custom product development across R‑SiC, SSiC, RBSiC, SiSiC and SiC power modules

- Technology transfer and factory establishment—from feasibility study to commissioning

- Turnkey delivery: materials, substrates, power units, control boards, and IEC 61850-enabled systems

- Proven outcomes with 19+ enterprises across power and industry

Get a free consultation, grid-code review, and live demo of our intelligent control and monitoring platform.

Email: [email protected] | Phone/WhatsApp: +86 133 6536 0038

Article Metadata

- Last updated: 2025-09-11

- Next scheduled update: 2025-12-15

- Prepared by: Sicarb Tech Power Quality Control Systems Team

- References: IEEE 519; IEC 61000-3-6; IEC 62477-1; IEC 61850; IEEE PES resources on weak-grid stabilization; IEA reports on VRE grid integration; NTDC/NEPRA interconnection practices

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.