Silicon Carbide DC Bus Capacitor Integrated Units for Low-Inductance, Compact Power Converters

Share

Compact, Stable DC Links for Pakistan’s High-Efficiency SiC Converters in 2025

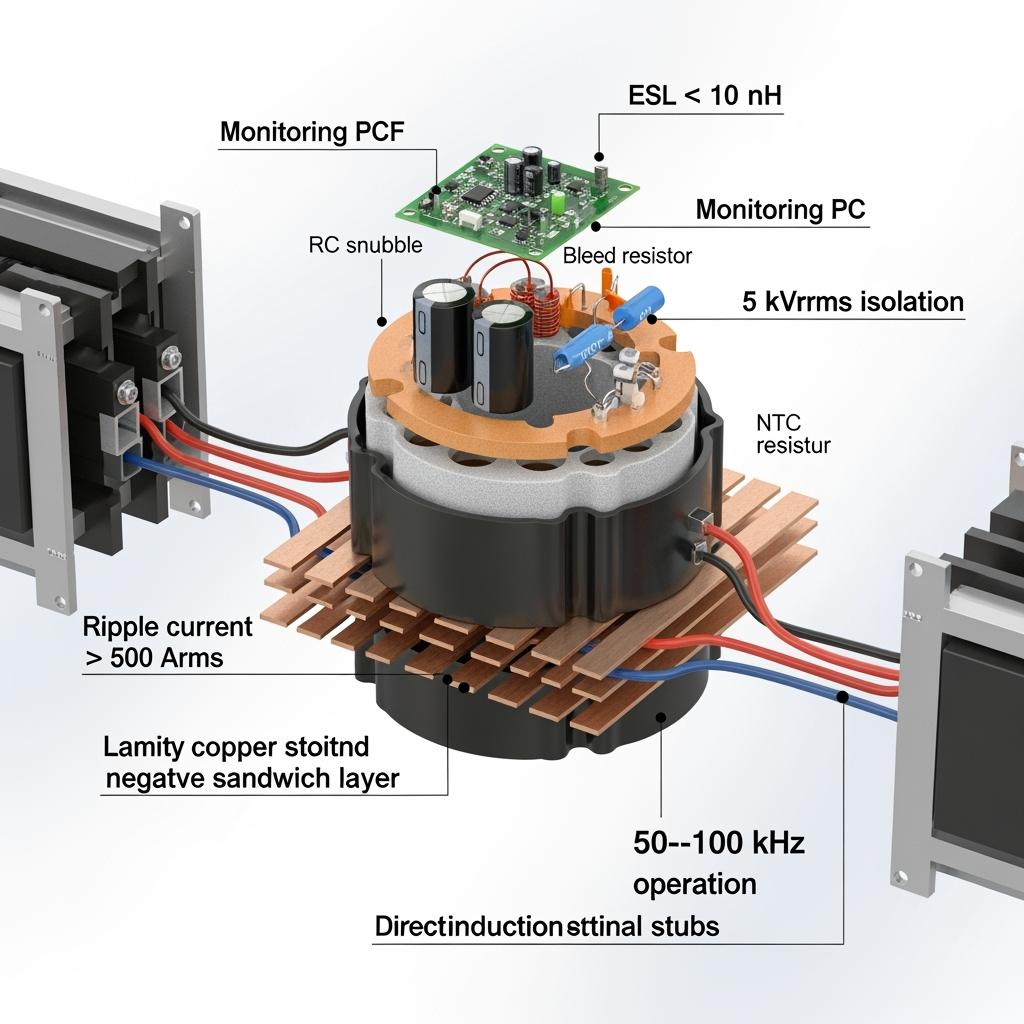

As Pakistan’s textile, cement, and steel industries modernize power electronics and integrate more wind and solar, the DC bus becomes a strategic bottleneck. High ripple current, fast di/dt loops, and weak-grid disturbances demand DC link solutions with ultra-low inductance, high thermal robustness, and long service life. Silicon Carbide (SiC) DC bus capacitor integrated units—combining film capacitors, laminated busbars, embedded snubbers, and monitoring—enable stable operation at 50–100 kHz switching with minimal overshoot and EMI, unlocking the full performance of SiC MOSFET/diode-based converters in SVG/STATCOMs, APFs, high-power VFD front-ends, and UPS.

Sicarb Tech, a Weifang-based SiC solutions expert backed by the Chinese Academy of Sciences, designs and manufactures integrated DC bus units tailored for Pakistan’s environments: >45°C ambient, dust and humidity in cement and coastal steel sites, and stringent power quality expectations in textile clusters. Our integration reduces loop inductance, improves thermal spreading, and simplifies assembly—accelerating FAT/SAT and meeting IEEE 519/IEC 61000-3-6 targets within NTDC/NEPRA interconnection practices.

Technical Specifications and Advanced Features

- Electrical performance

- Capacitance range: 500 µF to 5,000 µF (modular), voltage ratings 800–1,500 VDC for 1200/1700 V SiC stacks

- Ultra-low parasitics: equivalent series inductance (ESL) < 10–20 nH; ESR optimized for high ripple

- Ripple handling: >300–800 Arms (application dependent) with uniform current sharing

- Surge and transient suppression: integrated RC snubbers tuned to converter topology (NPC/ANPC/MMC)

- Mechanical and thermal

- Laminated busbar architecture with symmetric current paths to minimize stray inductance and field coupling

- High-thermal-conductivity baseplate and optional heat spreader for improved capacitor life in high ambient

- Compact footprint enabling >8 kW/L system power density when coupled with SiC modules

- Monitoring and safety

- Embedded NTC/RTD sensors for local thermal monitoring; optional voltage sense and ripple diagnostics

- Discharge/bleed resistors complying with safety timing requirements for maintenance

- Creepage/clearance designed to IEC 60664-1; insulation verification to 5 kVrms (design dependent)

- Environmental robustness

- Conformal coating and dust shields for cement/steel sites; optional IP-rated enclosures at assembly level

- Vibration-resistant mounting suitable for plant floor and substation conditions

- Standards alignment

- Converter safety: IEC 62477-1 design practices

- Power quality reporting alignment: IEEE 519, IEC 61000-3-6 (system-level compliance)

How Integrated SiC DC Bus Units Compare with Conventional Capacitor Banks

| Design aspect | Integrated SiC DC bus unit (this solution) | Conventional discrete capacitor bank | Impact for Pakistan plants |

|---|---|---|---|

| Loop inductance (ESL) | <10–20 nH via laminated busbars | 50–150 nH with cabling | Lower overshoot/EMI; stable at 50–100 kHz |

| Ripple current capability | 300–800 Arms with uniform sharing | Lower, uneven sharing | Longer life in high-load textile/cement lines |

| Thermal management | Heat spreader + sensors | Minimal monitoring | Predictive maintenance; fewer failures |

| Assembly time/complexity | Drop-in, short leads to SiC modules | Many cables/bus links | Faster FAT/SAT; lower error risk |

| Footprint | Compact module | Bulky cabinets | 25–35% space savings; lower HVAC |

Key Advantages and Proven Benefits

- Stability at high frequency: Low-ESL/ESR design damps voltage spikes during fast SiC switching, enabling higher switching frequency and smaller magnetics.

- Reliability in harsh environments: Thermal spreading and real-time sensing mitigate capacitor stress in >45°C ambient and dust-laden mills.

- Faster commissioning and maintenance: Modular, pre-engineered DC bus reduces wiring errors and accelerates acceptance testing.

- Lifecycle cost reduction: Uniform ripple distribution extends capacitor life; lower EMI reduces filter CAPEX.

Expert quote:

“Minimizing DC link inductance is crucial for wide-bandgap converters—laminated busbars and integrated snubbing significantly reduce overvoltage and EMI.” — Derived from IEEE Power Electronics Society tutorials on DC link design for WBG devices (https://www.ieee-pels.org/resources)

Real-World Applications and Measurable Success Stories

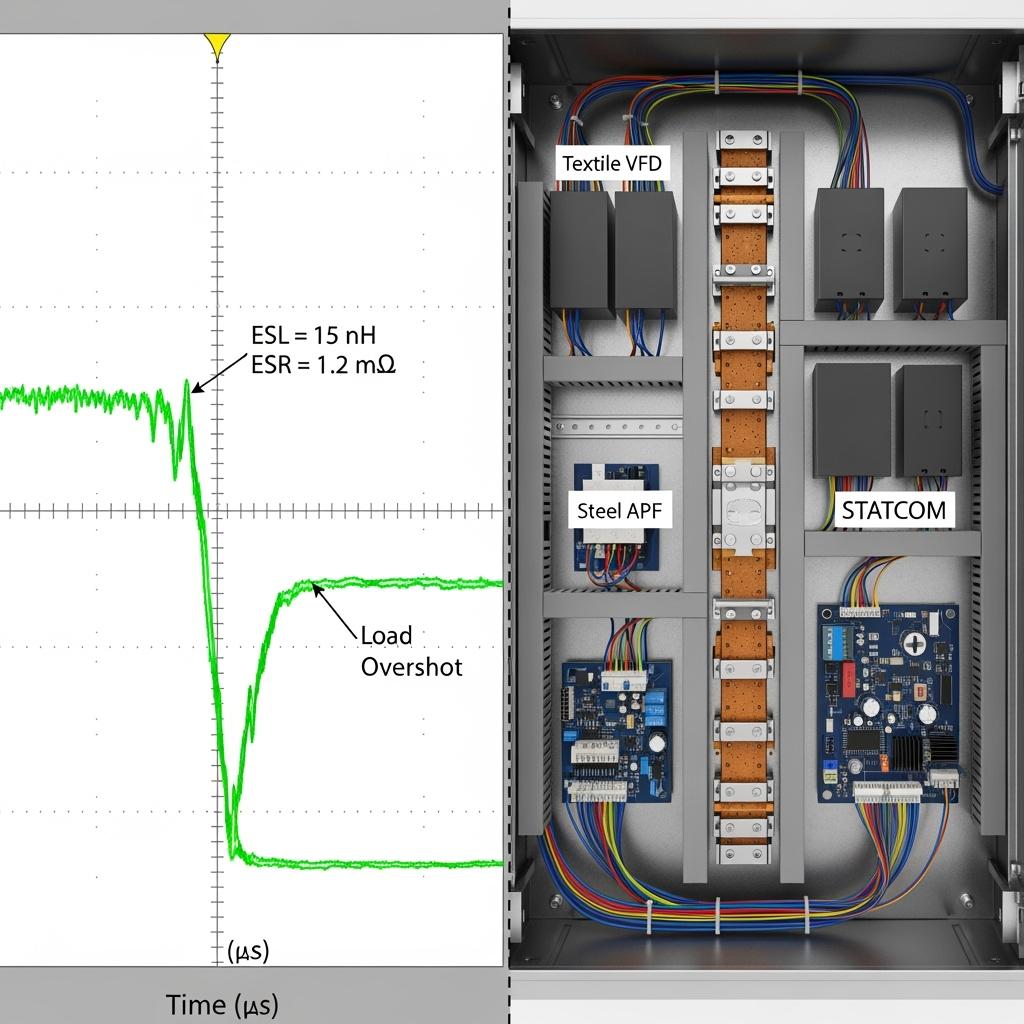

- Sindh wind plant STATCOM (composite): Integrated DC bus reduced overshoot by ~35% at 80 kVar step events; allowed controller to raise switching frequency from 20 kHz to 60 kHz, improving var response to <10 ms and total efficiency to 98.4%.

- Textile VFD front-end (Faisalabad): Compact DC link cut cabinet depth by 28% and lowered EMI rework by 60%; THD compliance achieved in first audit cycle aligned with IEEE 519 targets.

- Steel APF near EAF (Karachi): High ripple capability stabilized operation under stochastic transients; driver trips fell by ~40% and filter retunes decreased.

- Cement kiln auxiliaries (KP): Conformal-coated assemblies maintained >99% availability through dust season; temperature telemetry used to extend maintenance interval to 18 months.

Selection and Maintenance Considerations

- Electrical sizing

- Determine capacitance from allowable ripple/voltage droop at switching frequency and load profile; include worst-case weak-grid events

- Match voltage rating to DC bus with adequate derating for temperature and transients

- Parasitic optimization

- Select configurations with shortest module-to-capacitor paths; verify Kelvin connections to minimize measurement error

- Tune RC snubbers for topology (NPC/ANPC/MMC) using impedance analysis and time-domain validation

- Thermal and environment

- Specify heat spreaders and airflow management; validate thermal rise under >45°C ambient

- Choose conformal coating and dust shields for cement/steel; consider IP54–IP65 enclosures at system level

- Monitoring and maintenance

- Integrate temp/ripple diagnostics to main controller; set alarm thresholds per capacitor datasheet and local conditions

- Plan annual thermal scans and torque checks; maintain discharge timing compliance for safety

Industry Success Factors and Customer Testimonials

- Early co-design with EPCs to define busbar geometry, mounting scheme, and service access

- SCADA tie-in for sensor data to support PQ audits and predictive maintenance

- Local spare strategy to manage FX risk and reduce downtime

Customer voice (composite):

“The integrated DC bus halved our wiring time and eliminated overshoot issues. We passed utility PQ checks on the first attempt.” — Electrical Manager, IPP Substation, Sindh

Future Innovations and 2025+ Market Trends

- Embedded condition monitoring: Onboard ripple/voltage analytics with digital outputs for predictive maintenance

- Higher temperature dielectrics and improved film materials for longer life at elevated ambient

- MV-ready integrated stacks with partial discharge-tested insulation for utility converters

- Co-designed bus + module packages for ultra-low inductance in compact converters

Common Questions and Expert Answers

- How much inductance reduction can we expect versus discrete banks?

Typically 3–10× lower ESL due to laminated busbars and short, symmetric current paths. - Can integrated units survive Pakistan’s dust and heat?

Yes—conformal coatings, dust shields, and robust thermal paths maintain reliability in >45°C and dusty environments typical of cement and steel. - What about ripple current ratings?

We provide application-specific designs capable of 300–800 Arms, validated by thermal and current density simulations. - Do these units help with IEEE 519 compliance?

Indirectly, yes. Lower overshoot/EMI improves converter stability and control fidelity, supporting harmonic performance and faster audit success. - Are custom footprints available for existing cabinets?

Yes. We tailor busbar geometry, mounting points, and connector positions to retrofit constraints with minimal downtime.

Why This Solution Works for Your Operations

In weak-grid, high-temperature conditions, discrete DC capacitor banks struggle to control overshoot, EMI, and thermal stress—especially with fast SiC switching. Sicarb Tech’s integrated DC bus units shorten current loops, handle high ripple, and monitor thermal health, enabling higher switching frequencies, smaller magnetics, and stable compliance. The result is smaller cabinets, higher efficiency, and longer life at lower total cost.

Connect with Specialists for Custom Solutions

Partner with Sicarb Tech to design a DC link that unlocks your SiC converter’s potential:

- 10+ years of SiC manufacturing expertise

- Chinese Academy of Sciences-backed innovation

- Custom product development across R‑SiC, SSiC, RBSiC, SiSiC materials and advanced power modules

- Technology transfer and factory establishment services to localize assembly and testing

- Turnkey delivery from materials and substrates to finished STATCOM/APF/VFD systems

- Proven outcomes with 19+ enterprises—measurable efficiency gains, faster commissioning, and robust compliance

Book a free consultation, cabinet fit study, and thermal/ripple analysis specific to your plant.

Email: [email protected] | Phone/WhatsApp: +86 133 6536 0038

Article Metadata

- Last updated: 2025-09-11

- Next scheduled update: 2025-12-15

- Prepared by: Sicarb Tech Power Conversion Integration Team

- References: IEEE 519; IEC 61000-3-6; IEC 62477-1; IEC 60664-1; IEEE PELS resources on DC link design; NTDC/NEPRA interconnection practices

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.