Silicon Carbide Schottky Diodes (650–1700V) for Ultra-Low Reverse Recovery in PFC and DC-DC Stages

Share

High-Efficiency Front-Ends for Pakistan’s Industrial Power in 2025

Power-hungry segments in Pakistan—textile weaving halls, cement kilns, and steel rolling lines—depend on reliable, efficient AC-DC and DC-DC conversion. Silicon Carbide (SiC) Schottky diodes in the 650–1700V class provide ultra-low reverse recovery charge (Qrr≈0) and low forward voltage (Vf), enabling high-frequency operation, smaller magnetics, and cooler, more compact power supplies. In 2025, as NEPRA/NTDC push stricter power quality and industrial tariffs rise, upgrading PFC and DC-DC stages with SiC diodes helps meet IEEE 519 harmonic expectations, reduce losses, and improve uptime in hot, dusty environments.

Sicarb Tech—based in Weifang City’s SiC hub and supported by the Chinese Academy of Sciences—customizes SiC Schottky diodes and application kits for PFC, interleaved boost, Vienna rectifiers, LLC/HB DC-DC, and auxiliary supplies. With 10+ years of SiC experience and 19+ enterprise deployments, we deliver parts, reference designs, and localizable manufacturing know-how to accelerate your upgrade path.

Technical Specifications and Advanced Features

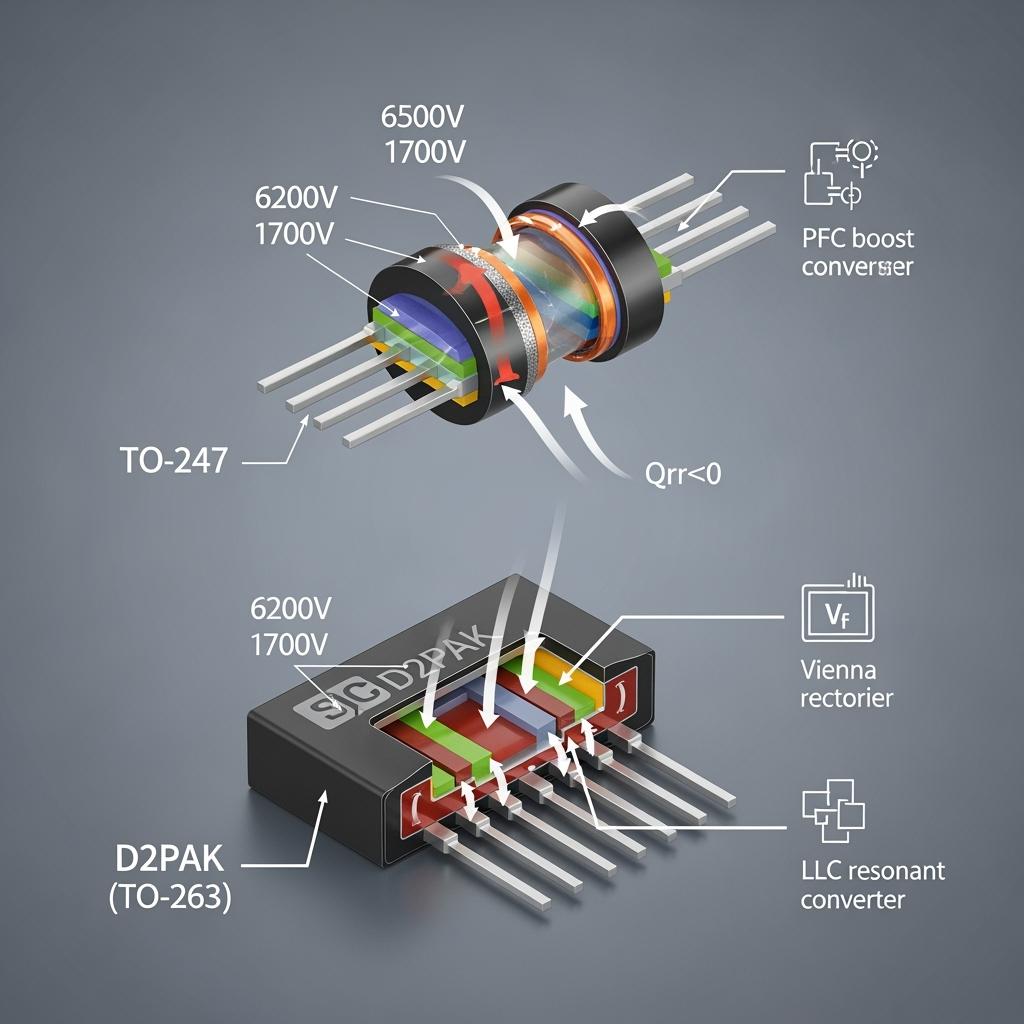

- Voltage ratings: 650V, 1200V, 1700V for universal mains PFC and high-bus industrial systems

- Current ratings: 6–60 A discrete; higher via parallelization with matched conduction characteristics

- Reverse recovery charge (Qrr): Near-zero (typ. a few nC effective), minimizing switching losses and EMI

- Forward voltage (Vf): Low (typ. 1.3–1.7 V at rated current), optimized for efficiency at industrial loads

- Junction temperature: -55°C to 175°C; robust against high ambient temperatures in Sindh and South Punjab

- Package options: TO-220, TO-247, D2PAK/TO-263; Kelvin pin variants for accurate current sensing

- Switching frequency enablement: 50–200 kHz PFC; 100–300 kHz DC-DC stage designs

- EMI/EMC performance: Soft recovery behavior reduces di/dt-induced ringing and helps meet IEC 61000-3-2/-3-12

- Reliability: High surge capability; AEC-Q101-like screening options on request for mission-critical use

- Co-design: Optimized with SiC MOSFETs and high-temperature gate drivers for fully wide-bandgap front ends

Compliance and integration:

- Power quality/harmonics: IEEE 519 system-level objectives, IEC 61000-3-2/3-12 for equipment

- Safety and converter standards: IEC 62477-1; PV/wind applications reference IEC 62109

- Industrial communications (system-level): Compatibility with plants using IEC 61850/Modbus SCADA for monitoring diode thermal status in smart PSUs (via added sensors)

High-Frequency Rectification Advantages for Pakistan’s Environments

- Hot-climate resilience: Maintains performance at high Tj; reduces derating in >45°C ambient

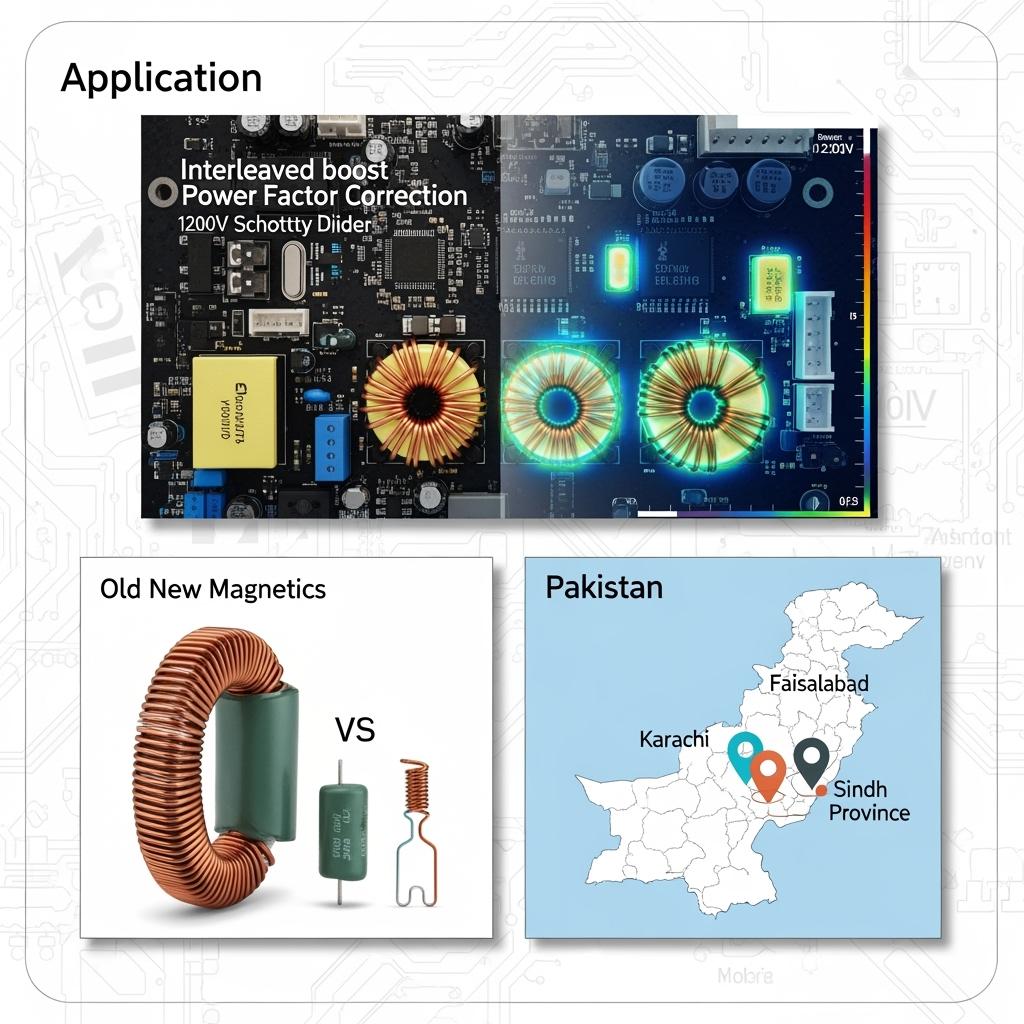

- Smaller magnetics: Higher switching speeds shrink chokes/transformers—valuable in retrofit cabinets

- Lower cooling burden: Reduced conduction and switching loss lowers heatsink size and HVAC consumption

- Better uptime: Lower thermal stress extends component life in cement dust and coastal humidity conditions

- Fast compliance path: Cleaner current waveforms help plants meet harmonic targets in utility audits

Efficiency and Thermal Performance Comparison for PFC/DC-DC Front Ends

| Design consideration | SiC Schottky diode front end | Silicon fast/ultrafast diode front end | Impact on Pakistani industrial sites |

|---|---|---|---|

| Reverse recovery (Qrr) | Near-zero | Significant | Lower switching loss and EMI; easier compliance |

| Switching frequency | 50–200 kHz | 20–50 kHz | Smaller magnetics; denser power shelves |

| Efficiency at load | +1.5–3.0% vs. Si | Baseline | Lower energy bills; quick payback under high tariffs |

| Thermal headroom | High (Tj up to 175°C) | Moderate (≤150°C) | Less derating in hot climate, longer life |

| EMI filter size | Reduced | Larger | Lower BOM/cabinet footprint |

| Reliability (stress) | Lower thermal cycling | Higher stress | Fewer maintenance intervals |

Key Advantages and Proven Benefits

- Energy savings: 1.5–3.0% system efficiency gain in PFC/DC-DC translates to significant PKR savings annually

- Compact design: 20–30% reduction in magnetic volume and heatsinking for the same power level

- Faster time-to-compliance: Cleaner waveforms aid IEEE 519 and local utility requirements

- Lower OPEX: Less cooling and fewer downtime events in dusty/humid industrial estates

Expert quote:

“SiC Schottky diodes virtually eliminate reverse recovery, enabling higher-frequency, higher-efficiency front ends with reduced EMI—key for compact, reliable industrial power.” — Context adapted from IEEE Power Electronics Magazine and IEEE Transactions on Power Electronics reviews (PELS community insights)

Real-World Applications and Measurable Success

- Textile mills (Faisalabad): Upgraded 50 kW PFC stages with 1200V SiC diodes. Result: +2.1% efficiency, 18% heatsink reduction, 25% fewer VFD nuisance trips due to improved input quality.

- Cement plant auxiliaries (KP): 10–30 kW SMPS/UPS retrofits using 650V SiC Schottky in interleaved PFC. Result: 1.8% energy savings and 12°C lower device case temperatures at 45°C ambient.

- Steel re-rolling (Karachi): 1700V SiC diodes in high-bus DC link chargers. Result: THDi improved toward target, EMI filter downsized by 20%, improved uptime during EAF operations.

- PV inverter service (Sindh): Vienna rectifier front-end with 1200V SiC diodes. Result: >98% front-end efficiency, easier utility compliance, reduced curtailment incidents.

Selection and Maintenance Considerations

- Voltage headroom: Choose 650V for universal AC (PFC), 1200V for high-bus industrial, 1700V for MV-linked systems

- Current rating and thermal path: Derate for ambient >45°C; ensure robust heatsink or copper planes; TIM selection matters

- Layout/EMI: Short diode loops; RC snubbers as needed; differential-mode choke optimization at higher switching frequencies

- Surge and transients: Validate surge current ratings; coordinate with MOV/TVS and input filters

- Parallel operation: Current sharing via layout symmetry and thermal balancing

Industry Success Factors and Customer Testimonials

- Localized engineering support for fast qualification and prototyping

- Documentation aligned with NTDC/NEPRA utility submission needs

- Training for maintenance teams to exploit high-frequency benefits safely

Customer voice (composite):

“After adopting SiC Schottky diodes in our PFC, the cabinets run cooler and our harmonic audit passed on the first try.” — Electrical Maintenance Lead, Textile Cluster, Punjab

Future Innovations and Market Trends (2025+)

- Higher-current, low-Vf SiC diode generations reducing conduction losses further

- Co-packaged SiC MOSFET + Schottky for ultra-compact front ends

- GaN/SiC hybrid stages in low-to-mid power with digital PFC control for even lighter magnetics

- Local assembly and test capabilities in Pakistan through technology transfer to cut lead times and FX exposure

Common Questions and Expert Answers

- Do SiC Schottky diodes reduce EMI in PFC stages?

Yes. Near-zero Qrr lessens current spikes and dv/dt-induced ringing, lowering EMI filter complexity. - What efficiency gains can we expect in a 10–50 kW PFC?

Typically +1.5–3.0%, depending on topology and frequency—often enough to achieve <24–30 month payback. - Will they withstand high ambient temperatures and dust?

SiC diodes operate up to 175°C Tj; with proper heatsinking and IP-rated enclosures, they perform reliably in >45°C and dusty sites. - Are they drop-in replacements for silicon ultrafast diodes?

Electrically, often yes—layout and snubbers may be re-optimized to exploit higher frequency and reduce EMI. - Which topologies benefit most?

Interleaved boost PFC, Vienna rectifiers, totem-pole PFC (with SiC MOSFETs), and high-frequency LLC/HB DC-DC rectification.

Why This Solution Works for Your Operations

SiC Schottky diodes attack loss, heat, and size at the rectification bottleneck—exactly where Pakistan’s industrial converters need help. By cutting reverse recovery and enabling higher frequencies, they unlock smaller, cooler, more compliant power electronics that boost uptime and reduce total cost of ownership.

Connect with Specialists for Custom Solutions

Accelerate your upgrade with Sicarb Tech:

- 10+ years of SiC manufacturing expertise in Weifang’s SiC hub

- Backed by the Chinese Academy of Sciences for rapid innovation

- Custom product development across R-SiC, SSiC, RBSiC, SiSiC materials and discrete/module platforms

- Technology transfer and factory establishment services—from feasibility to commissioning

- Turnkey solutions from materials and substrates to finished PFC/DC-DC assemblies

- Proven outcomes with 19+ enterprises across demanding industries

Get a free consultation, PFC/DC-DC audit, and ROI model tailored to your plant.

Email: [email protected] | Phone/WhatsApp: +86 133 6536 0038

Article Metadata

- Last updated: 2025-09-11

- Next scheduled update: 2025-12-15

- Prepared by: Sicarb Tech Application Engineering Team

- References: IEEE 519; IEC 61000-3-2/-3-12; IEC 62477-1; NTDC/NEPRA interconnection and audit practices; IEEE Power Electronics Magazine and IEEE TPEL reviews on SiC diodes and PFC design

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.