The Indispensable Role of Custom Silicon Carbide Tubes in Advanced Industrial Processes

Share

In the ever-evolving landscape of high-performance industrial applications, the demand for materials that can withstand extreme conditions is paramount. Among the advanced technical ceramics, silicon carbide (SiC) stands out for its exceptional properties. Custom silicon carbide tubes, in particular, have become essential components across a multitude of sectors, offering unparalleled performance where other materials falter. These tubes are not off-the-shelf solutions; they are meticulously engineered to meet specific operational demands, ensuring reliability, efficiency, and longevity in harsh environments. From semiconductor manufacturing to high-temperature furnace operations, aerospace engineering, and chemical processing, the unique characteristics of SiC make it the material of choice for critical applications. The ability to customize dimensions, purity levels, and specific SiC grades allows engineers and procurement managers to optimize their systems for peak performance, making custom SiC tubes a cornerstone of modern industrial innovation. As industries push the boundaries of temperature, pressure, and chemical exposure, the significance of high-quality, tailored silicon carbide components will only continue to grow.

Unveiling the Superiority: Why Custom Silicon Carbide Tubes are Essential

Custom silicon carbide (SiC) tubes are at the forefront of material science, offering a unique combination of properties that make them indispensable in high-performance industrial applications. Unlike standard or off-the-shelf ceramic components, custom SiC tubes are specifically engineered to meet the rigorous and often unique demands of specialized processes. Their essential nature stems from an exceptional ability to perform reliably under conditions that would cause conventional materials to fail.

At the core of their indispensability is silicon carbide’s inherent material characteristics. These include:

- Exceptional High-Temperature Resistance: SiC tubes can maintain their structural integrity and mechanical strength at extremely high temperatures, often exceeding 1600∘C (2912∘F) in non-oxidizing atmospheres. This makes them ideal for applications like furnace components, thermocouple protection sheaths, and kiln furniture.

- Outstanding Hardness and Wear Resistance: Ranking close to diamond in hardness, SiC tubes exhibit superior resistance to abrasion, erosion, and wear. This is critical in applications involving the transport of abrasive slurries, high-velocity particles, or where components are subjected to constant friction.

- Excellent Chemical Inertness: Silicon carbide is highly resistant to a wide range of corrosive chemicals, including strong acids and alkalis, even at elevated temperatures. This property is vital for components used in chemical processing, semiconductor manufacturing (e.g., etching and cleaning processes), and a Götlingen University publication in 2023 noted its stability in molten salts.

- High Thermal Conductivity: SiC possesses a significantly higher thermal conductivity compared to many other ceramics. This allows for efficient heat transfer, which is beneficial in applications like heat exchangers, recuperators, and burner nozzles. Rapid and uniform heat distribution can improve process efficiency and reduce thermal stresses.

- Low Thermal Expansion: The low coefficient of thermal expansion of SiC tubes means they experience minimal dimensional changes with temperature fluctuations. This contributes to excellent thermal shock resistance, allowing them to withstand rapid heating and cooling cycles without cracking or failing.

- Good Mechanical Strength: Even at elevated temperatures, SiC maintains high strength and stiffness, ensuring dimensional stability and resistance to deformation under load.

The “custom” aspect further elevates their importance. Standardized components may not perfectly fit the geometric constraints, thermal profiles, or chemical environments of a specific industrial setup. Customization allows engineers and technical buyers to specify:

- Precise Dimensions: Length, diameter, wall thickness, and end configurations (e.g., open-ended, close-ended, flanged) can be tailored to the exact requirements of the equipment.

- Specific SiC Grades: Different manufacturing processes (e.g., Reaction Bonded SiC – RBSiC/SiSiC, Sintered SiC – SSiC, Recrystallized SiC – RSiC) yield SiC materials with varying densities, porosities, and purities. Customization enables the selection of the optimal grade for the application’s specific challenges, such as requiring high purity for semiconductor processes or maximum wear resistance for material handling.

- Surface Finish and Tolerances: Depending on the application, specific surface finishes (e.g., as-fired, ground, polished) and tight dimensional tolerances may be necessary. Custom manufacturing can achieve these exacting standards.

In essence, custom silicon carbide tubes are essential because they offer a bespoke solution that maximizes performance, longevity, and efficiency in environments where standard materials simply cannot cope. They are not just components; they are enabling technologies that allow industries to push the boundaries of innovation and productivity. For procurement managers and technical buyers, investing in custom SiC tubes means investing in reliability and optimized operational outcomes, reducing downtime and long-term costs associated with component failure and replacement.

Diverse Industrial Applications: Where Silicon Carbide Tubes Excel

The exceptional properties of silicon carbide tubes, particularly when customized, make them highly sought after across a wide spectrum of demanding industries. Their ability to withstand extreme temperatures, corrosive environments, and significant wear allows them to perform critical functions where other materials would degrade rapidly. This versatility positions industrial SiC tubes as key components in enhancing process efficiency, product quality, and operational safety.

Here’s a breakdown of key industrial sectors and their reliance on custom SiC tubes:

- Semiconductor Manufacturing: This industry demands materials of the highest purity and exceptional thermal stability.

- Process Chamber Components: SiC tubes are used as liners, gas showerheads, and injector tubes in chemical vapor deposition (CVD), plasma etch, and diffusion furnaces. Their resistance to corrosive gases and high temperatures ensures minimal contamination and long service life. High-purity SiC tubes are crucial here.

- Wafer Handling and Transport: Components like edge grip rings and cantilever paddles made from SiC benefit from its stiffness and low particle generation.

- Thermocouple Protection Tubes: Accurate temperature measurement is vital. SiC thermocouple protection tubes shield temperature sensors from harsh chemical environments and extreme heat within processing equipment.

- High-Temperature Processing and Furnaces: This is a natural fit for SiC due to its refractoriness and thermal conductivity.

- Radiant Tubes and Heating Elements: Silicon carbide furnace tubes, including single-ended and U-shaped radiant tubes, are used in indirect heating systems. They offer excellent heat transfer and can operate at very high temperatures, leading to energy savings and uniform heating.

- Kiln Furniture: Beams, rollers, and supports made from SiC are used in firing ceramics, powder metallurgy, and heat treatment processes. Their high hot strength and creep resistance allow for stable support of products at elevated temperatures.

- Burner Nozzles and Flame Tubes: SiC’s resistance to thermal shock and oxidation makes it ideal for direct-fired furnace components, ensuring longevity and consistent performance.

- Aerospace and Defense: The demand for lightweight, high-strength materials capable of performing in extreme thermal and mechanical environments drives SiC adoption.

- Rocket Nozzles and Thruster Components: SiC composites and high-density SiC are explored for their ability to withstand the ultra-high temperatures and erosive forces in propulsion systems.

- Heat Exchangers and Recuperators: In advanced aerospace applications, efficient thermal management is critical. SiC’s high thermal conductivity and strength-to-weight ratio are advantageous.

- Mirror Substrates and Optical Benches: For space-based telescopes and optical systems, SiC offers excellent stiffness, thermal stability, and the ability to be polished to a very high-quality surface.

- Energy Sector (including Power Generation and Renewable Energy):

- Heat Exchangers in Power Plants: SiC tubes can improve the efficiency and durability of heat exchangers operating with corrosive fluids or at high temperatures, such as in advanced coal-fired plants or concentrated solar power (CSP) systems.

- Components for Fuel Cells: Solid oxide fuel cells (SOFCs) utilize ceramic components, and SiC derivatives are considered for interconnects and structural parts due to their electrical conductivity (when doped) and stability.

- Nuclear Industry: Certain grades of SiC are investigated for use in advanced nuclear reactors due to their radiation resistance and stability under high-heat flux.

- Chemical Processing and Petrochemical Industry:

- Thermowells and Sensor Protection: Similar to semiconductor applications, chemical resistant ceramic tubes made of SiC protect sensors in aggressive chemical streams.

- Heat Exchanger Tubes: For processes involving highly corrosive media where metallic alloys would fail or contaminate the product.

- Fluid Handling Components: Linings for pipes, valves, and pump components handling abrasive and corrosive slurries.

- Industrial Manufacturing and Metallurgy:

- Molten Metal Handling: Components like thermocouple sheaths for non-ferrous molten metals (e.g., aluminum, zinc) benefit from SiC’s non-wetting properties and resistance to thermal shock.

- Wear-Resistant Linings: In mining, cement, and bulk material handling, SiC tiles and liners (often in tubular sections for cyclones or pipes) protect equipment from severe abrasion.

The common thread across these diverse applications is the need for materials that push the boundaries of performance. Custom SiC tubes are not just components; they are enablers of technological advancement, allowing engineers to design systems that operate more efficiently, last longer, and handle more aggressive conditions. Companies like Sicarb Tech, situated in Weifang, the hub of China’s silicon carbide customizable parts manufacturing, play a crucial role in supplying these vital components, leveraging deep material expertise and advanced manufacturing techniques to meet the precise needs of these demanding industries.

| Industry Sector | Key Applications of SiC Tubes | Critical SiC Properties Leveraged |

|---|---|---|

| Semiconductor | Process Chamber Liners, Gas Injectors, Thermocouple Tubes | High Purity, Chemical Inertness, Thermal Stability |

| High-Temp. Furnaces | Radiant Tubes, Heating Elements, Kiln Furniture, Burner Nozzles | High-Temperature Strength, Thermal Conductivity, Thermal Shock Resistance |

| Aerospace & Defense | Rocket Nozzles, Heat Exchangers, Optical Components | High Strength-to-Weight Ratio, Extreme Temperature Resistance |

| Energy | Heat Exchangers, Fuel Cell Components, Solar Power Components | Thermal Conductivity, Corrosion Resistance, High-Temperature Stability |

| Chemical Processing | Thermowells, Heat Exchanger Tubes, Fluid Handling Liners | Chemical Inertness, Abrasion Resistance, Thermal Stability |

| Industrial Manufacturing | Molten Metal Handling, Wear-Resistant Linings | Wear Resistance, Non-Wetting, Thermal Shock Resistance |

This table summarizes the broad applicability and the critical role of silicon carbide tubes, emphasizing the importance of selecting the right technical ceramics procurement partner to ensure quality and performance. The demand for OEM SiC components continues to rise as industries seek more robust and reliable solutions.

Why Customization Matters: Tailoring Silicon Carbide Tubes for Optimal Performance

In the realm of advanced materials, particularly for demanding industrial applications, a one-size-fits-all approach rarely yields optimal results. This is especially true for components like silicon carbide tubes, which are often subjected to a unique confluence of extreme temperatures, corrosive agents, mechanical stresses, and specific geometric constraints. The ability to customize silicon carbide tubes is not merely a value-added service; it is a critical factor in achieving peak operational performance, enhancing system longevity, and ensuring process safety and efficiency.

The primary reasons why customization is paramount for SiC tubes include:

- Meeting Precise Dimensional and Geometric Requirements:

- Exact Fit: Industrial equipment often has intricate designs with limited space for components. Custom SiC tubes can be manufactured to precise lengths, inner and outer diameters, and wall thicknesses, ensuring seamless integration without the need for costly modifications to existing setups.

- Complex Geometries: Beyond simple cylinders, many applications require specialized shapes such as closed-one-end (COE) tubes for thermocouple protection, flanged tubes for secure connections, tubes with specific tapers, or multi-bore tubes for specialized gas or liquid delivery. Custom SiC tube manufacturers can produce these complex geometries through advanced forming techniques like extrusion, slip casting, or isopressing, followed by precision machining.

- Optimizing for Specific Operating Conditions:

- Thermal Management: The wall thickness and material grade of an SiC tube can be tailored to optimize thermal conductivity for heating elements or heat exchangers, or conversely, to provide thermal insulation where needed. Customization ensures the tube performs its thermal function efficiently.

- Wear Resistance: For applications involving abrasive media, such as slurry transport or pneumatic conveying, the SiC grade (e.g., high-density SSiC or robust RBSiC) and even the internal surface finish can be selected to maximize wear life.

- Chemical Compatibility: While SiC is broadly resistant, extreme chemical environments (e.g., specific strong acids, bases, or reactive gases at high temperatures) might necessitate a particular grade of SiC with higher purity or lower porosity to prevent even minute interactions or degradation. For instance, the semiconductor industry often demands high-purity SiC tubes to avoid contamination.

- Enhancing Performance and Efficiency:

- Flow Dynamics: The internal diameter and surface smoothness of a tube can significantly impact fluid or gas flow. Customization allows for designs that minimize pressure drop, ensure laminar flow if required, or create specific mixing patterns.

- Mechanical Integrity: Wall thickness, overall design, and material choice can be optimized to withstand specific mechanical loads, pressures, or vibrations expected in the application. This prevents premature failure and extends service life. For example, silicon carbide furnace tubes must bear their own weight and potentially the weight of products at extreme temperatures.

- Improving Cost-Effectiveness in the Long Run:

- Reduced Downtime: Tubes perfectly designed for their application are less likely to fail unexpectedly, leading to reduced maintenance, fewer unscheduled shutdowns, and lower replacement costs.

- Material Optimization: Customization allows for the use of the most appropriate (and not necessarily the most expensive) SiC grade for the job. Over-engineering with a higher-grade material than necessary increases upfront costs, while under-engineering leads to premature failure.

- Energy Savings: In thermal applications, tubes optimized for heat transfer (e.g., SiC radiant tubes) can lead to significant energy savings over their operational lifetime.

- Facilitating Innovation:

- Customization empowers engineers to design novel processes and equipment that might not be feasible with standard components. The ability to get SiC tubes in precisely the form and function required can be a key enabler for R&D and the development of next-generation technologies.

Consider a scenario where a procurement manager needs thermocouple protection tubes for a highly corrosive chemical reactor operating at 1400∘C. A standard ceramic tube might not offer the required combination of chemical inertness at that temperature, or it might not have the precise length and mounting features needed. A custom SiC tube, however, can be designed from a specific grade like Sintered Silicon Carbide (SSiC) for maximum density and corrosion resistance, manufactured to the exact length with a custom flange for secure mounting. This tailored solution ensures accurate temperature readings, protects the thermocouple effectively, and withstands the harsh environment for an extended period.

Companies like Sicarb Tech, leveraging their position in Weifang, a major center for custom silicon carbide products, specialize in understanding these nuanced requirements. Their expertise in material science and manufacturing processes enables them to provide SiC tubes that are not just components, but precision-engineered solutions. This focus on customization is crucial for technical buyers and OEMs who require reliable and high-performing technical ceramics tailored to their unique industrial applications.

Navigating SiC Grades and Manufacturing Processes for Tubes

Choosing the right silicon carbide (SiC) grade and understanding the associated manufacturing process is crucial for optimizing the performance and cost-effectiveness of SiC tubes in any given application. Silicon carbide is not a monolithic material; different production methods yield SiC with varying microstructures, densities, purities, and, consequently, different thermomechanical and chemical properties. For engineers and technical procurement professionals, a foundational understanding of these distinctions is key to specifying the most suitable custom SiC tubes.

Common Grades of Silicon Carbide for Tubes:

- Reaction Bonded Silicon Carbide (RBSiC or SiSiC – Silicon Infiltrated Silicon Carbide):

- Manufacturing: Produced by infiltrating a porous compact of SiC grains and carbon with molten silicon. The silicon reacts with the carbon to form additional SiC, which bonds the initial SiC grains. Some free silicon (typically 8-15%) remains in the final microstructure.

- Properties:

- Good mechanical strength and high hardness.

- Excellent wear and abrasion resistance.

- High thermal conductivity.

- Good thermal shock resistance.

- Relatively complex shapes can be produced with good dimensional accuracy.

- Operating temperature is typically limited to around 1350∘C−1380∘C due to the melting point of the free silicon.

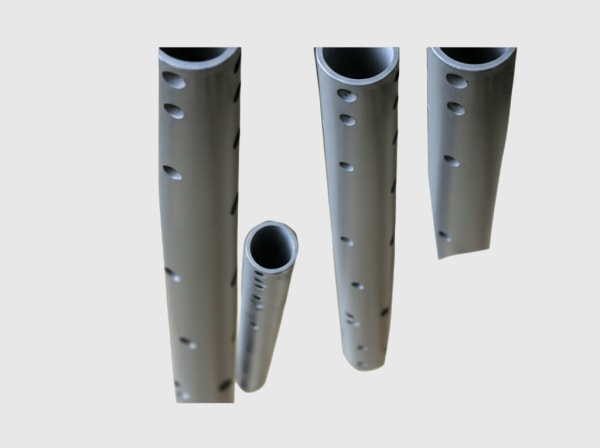

- Tube Applications: Widely used for wear-resistant SiC tubes (e.g., linings for pipes handling abrasive slurries), rollers, beams, nozzles, and general-purpose industrial SiC tubes where extreme temperatures above 1350∘C are not encountered. Ideal for SiSiC tubes wholesale due to a good balance of performance and cost.

- Sintered Silicon Carbide (SSiC):

- Manufacturing: Made from fine, high-purity SiC powder, typically with non-oxide sintering aids (like boron and carbon). The powder is formed into the desired shape and then sintered at very high temperatures (often >2000∘C) in an inert atmosphere, leading to a dense, single-phase SiC material.

- Properties:

- Highest operating temperature capability (up to 1600∘C−1700∘C or higher in inert atmospheres).

- Superior chemical resistance, especially to strong acids and halogens, due to the absence of free silicon or secondary phases.

- Excellent oxidation resistance.

- High strength and hardness.

- Good wear resistance.

- Can be produced in very high purity.

- Tube Applications: Preferred for demanding applications like high-temperature ceramic tubes in chemical processing, semiconductor process chambers (e.g., high-purity SiC tubes), advanced heat exchangers, and thermocouple protection tubes exposed to very aggressive environments. SSiC tubes are often considered for the most challenging conditions.

- Recrystallized Silicon Carbide (RSiC):

- Manufacturing: Produced by firing a compacted mass of SiC grains at high temperatures (>2200∘C). The SiC grains bond to each other through a process of evaporation, decomposition, and condensation of SiC. No binding agents are used, resulting in a material with controlled porosity.

- Properties:

- Excellent thermal shock resistance due to its interconnected porosity.

- Very high service temperature (up to 1650∘C).

- Good mechanical strength at elevated temperatures.

- Lower density compared to RBSiC and SSiC.

- Porosity can be a disadvantage in certain corrosive environments or where gas tightness is paramount.

- Tube Applications: Primarily used for kiln furniture (beams, setters, plates), burner nozzles, and other applications where exceptional thermal shock resistance and high-temperature stability are the primary requirements, and some porosity is acceptable. RSiC tubes are excellent for rapid heating/cooling cycles.

- Nitride Bonded Silicon Carbide (NBSiC):

- Manufacturing: SiC grains are bonded by a silicon nitride (Si3N4) phase.

- Properties: Good thermal shock resistance, good mechanical strength, and resistance to wetting by molten non-ferrous metals.

- Tube Applications: Thermocouple sheaths for non-ferrous metal foundries, components for molten metal contact.

Common Manufacturing Processes for SiC Tubes:

- Extrusion: Ideal for producing long, straight tubes with uniform cross-sections (circular, square, oval). A paste of SiC powder and binders is forced through a die. Cost-effective for high-volume production of simpler tube shapes.

- Slip Casting: A ceramic slurry (slip) containing SiC powder is poured into a porous mold. The liquid is absorbed by the mold, leaving a layer of solid material on the mold surface. Suitable for more complex shapes, including closed-end tubes and larger diameter tubes.

- Isostatic Pressing: SiC powder is compacted in a flexible mold under high hydrostatic pressure, leading to very uniform density. Can be used for producing blanks that are then green-machined before sintering.

- Cold Isostatic Pressing (CIP): Done at room temperature.

- Hot Isostatic Pressing (HIP): Combines high pressure and high temperature; can produce highly dense SSiC parts.

- Injection Molding (for smaller, complex parts): SiC powder is mixed with a thermoplastic binder and injected into a mold. The binder is then removed, and the part is sintered.

The choice of manufacturing process often depends on the desired SiC grade, tube dimensions, complexity, and production volume. After initial forming, “green” (unsintered) or “bisque-fired” (partially sintered) SiC tubes may undergo machining to achieve tighter tolerances or specific features before the final high-temperature sintering or reaction bonding process.

Sicarb Tech, with its deep expertise rooted in Weifang – the heart of China’s SiC industry – understands the nuances of these various grades and manufacturing methods. They can guide clients in selecting the optimal custom SiC tube solution, balancing performance requirements with cost considerations, whether it’s for a SiC thermocouple protection tube requiring SSiC’s purity and corrosion resistance, or a wear-resistant RBSiC liner.

| SiC Grade | Typical Max. Operating Temp. | Key Strengths | Common Tube Applications |

|---|---|---|---|

| RBSiC (SiSiC) | ∼1350∘C | Wear resistance, thermal conductivity, cost-effective | Wear liners, rollers, nozzles, general industrial tubes |

| SSiC | >1600∘C | Chemical inertness, high purity, high temp. strength | Semiconductor components, aggressive chemical environments, advanced heat exchangers |

| RSiC | ∼1650∘C | Excellent thermal shock resistance, high temp. stability | Kiln furniture, burner nozzles, rapid heating/cooling applications |

| NBSiC | ∼1400∘C | Molten metal resistance, thermal shock resistance | Thermocouple sheaths for non-ferrous metals, molten metal contact parts |

Understanding these options allows for a more informed dialogue with suppliers like SicSino to ensure the final product precisely matches the application’s needs, a critical step in technical ceramics procurement.

Critical Design and Manufacturing Tolerances for SiC Tubes

Designing and manufacturing custom silicon carbide tubes to meet stringent operational demands requires careful consideration of various critical factors, from initial geometric design to achievable manufacturing tolerances and surface finishes. For engineers specifying SiC tubes and procurement managers sourcing them, understanding these aspects is vital for ensuring the final product is fit for purpose and delivers optimal performance and longevity.

Key Design Considerations for SiC Tubes:

- Manufacturability:

- Aspect Ratios: Extremely long tubes with very small diameters or very thin walls can be challenging and costly to produce and handle without breakage. It’s important to discuss practical limits with the custom SiC tube manufacturer.

- Complexity of Shape: While SiC can be formed into complex shapes, features like sharp internal corners, sudden changes in wall thickness, or very intricate profiles can increase manufacturing difficulty and cost, and may also act as stress concentrators. Gradual transitions and fillets are generally preferred.

- Joining/Assembly Features: If tubes need to be connected to other components, the design of flanges, threads (though less common and typically coarse on ceramics), or grooves must be considered early. These features often require post-sintering machining.

- Geometry and Dimensional Limits:

- Wall Thickness: Must be sufficient to withstand mechanical loads and pressures at operating temperatures. However, excessively thick walls can reduce thermal shock resistance and increase material cost and weight. For silicon carbide furnace tubes used as radiant heaters, wall thickness affects heat transfer efficiency.

- Straightness and Roundness (Ovality): Critical for applications like rollers, bearings, or where tubes pass through tight clearances. Specific tolerances for these parameters should be defined.

- Length and Diameter: While customization allows for a wide range, there are practical manufacturing limits. Extremely large or long tubes may require specialized equipment and handling.

- Stress Points and Concentrations:

- Avoid sharp corners and notches, which can act as initiation points for cracks, especially in brittle materials like ceramics. Rounded edges and fillets help distribute stress.

- Consider thermal stresses arising from temperature gradients during operation. Designs should aim to minimize these or ensure the material can withstand them.

- Material Selection (Grade): As discussed previously, the choice of RBSiC, SSiC, RSiC, etc., is a fundamental design decision directly impacting thermal, mechanical, and chemical performance. This selection will also influence achievable tolerances and surface finishes.

Manufacturing Tolerances, Surface Finish, and Dimensional Accuracy:

Achievable tolerances and surface finishes for SiC tubes depend heavily on the SiC grade, the manufacturing process (e.g., extrusion, slip casting), and whether post-sintering machining (grinding, lapping, polishing) is employed.

- As-Fired Tolerances:

- Tubes produced by methods like extrusion or slip casting and then sintered without further machining will have “as-fired” tolerances. These are generally looser than machined tolerances due to shrinkage variations during drying and sintering.

- Typical as-fired dimensional tolerances might be in the range of ±1% to ±2% of the dimension, or a minimum fixed value (e.g., ±0.5mm to ±2mm), depending on the size and complexity. Surface finish will also be characteristic of the forming process and material grain size.

- Machined Tolerances:

- For applications requiring high precision, custom SiC tubes can be machined in their “green” state (before final sintering) or, more commonly, after sintering using diamond grinding, lapping, or polishing.

- Grinding: Can achieve much tighter dimensional tolerances (e.g., ±0.01mm to ±0.1mm for diameters and lengths, depending on size and equipment capability). It also improves surface finish significantly.

- Lapping and Polishing: Used when exceptionally smooth surfaces are required (e.g., for sealing surfaces, optical components, or some semiconductor applications). Surface roughness (Ra) values can be reduced to sub-micron levels.

- Surface Finish (Roughness – Ra):

- As-Fired: Typically rougher, e.g., Ra 1μm to 10μm or more, depending on the SiC grade and forming method. RSiC is generally rougher than dense SSiC or RBSiC.

- Ground: Can achieve Ra 0.2μm to 1.6μm.

- Polished: Can achieve Ra <0.1μm, sometimes down to Angstrom levels for super-finished surfaces.

Key Engineering Tips for Specifying Tolerances:

- Specify Only What is Necessary: Tighter tolerances and finer surface finishes invariably increase manufacturing costs due to additional processing steps and potentially lower yields. Only specify tight tolerances on critical dimensions that directly impact functionality.

- Consult with the Supplier Early: Discuss design and tolerance requirements with your SiC tube supplier, like Sicarb Tech, during the early stages of design. Their manufacturing expertise can provide valuable input on what is achievable and cost-effective. SicSino’s experience in Weifang, China’s SiC hub, gives them access to a broad range of processing capabilities.

- Understand GD&T (Geometric Dimensioning and Tolerancing): For complex parts, using GD&T on drawings can more precisely define acceptable variations in form, orientation, and location of features.

- Consider Mating Parts: Tolerances should be considered in the context of how the SiC tube will interact with other components in an assembly.

Table: Typical Achievable Tolerances for Custom SiC Tubes

| Feature | As-Fired Tolerance Range | Ground Tolerance Range | Notes |

|---|---|---|---|

| Outer Diameter (OD) | ±1% to ±2% (or ±0.5−2mm) | ±0.01mm to ±0.1mm | Depends on OD size; smaller ODs can often hold tighter tolerances. |

| Inner Diameter (ID) | ±1% to ±2% (or ±0.5−2mm) | ±0.02mm to ±0.2mm | Grinding ID can be more challenging than OD. |

| Wall Thickness | ±10% to ±15% | ±0.05mm to ±0.2mm | Often controlled by OD/ID tolerances. |

| Length | ±1% (or ±0.5−2mm) | ±0.05mm to ±0.5mm | End grinding is common for precise lengths. |

| Straightness | 0.5mm/m to 2mm/m | 0.05mm/m to 0.5mm/m | Measurement method should be agreed upon. |

| Roundness (Ovality) | Varies significantly | Typically within OD tolerance | Can be critical for rotating parts or seals. |

| Surface Roughness (Ra) | 1μm−10μm (typical) | 0.2μm−1.6μm (ground) | Polishing can achieve <0.1μm. |

Note: These are general guidelines. Specific capabilities can vary significantly between manufacturers and based on the SiC grade and tube dimensions. Always confirm with your supplier.

By carefully considering these design and tolerance aspects, engineers and procurement professionals can ensure that their custom silicon carbide tubes are manufactured to the required precision, leading to reliable and efficient performance in demanding industrial applications. This meticulous approach to specification is essential when dealing with OEM SiC components and high-value technical ceramics.

Enhancing Durability and Functionality: Post-Processing for SiC Tubes

While the intrinsic properties of silicon carbide make it an exceptional material for demanding applications, various post-processing techniques can further enhance the durability, functionality, and performance of custom SiC tubes. These secondary operations are often crucial for meeting the specific requirements of advanced industrial processes, refining dimensions, improving surface characteristics, or adding protective layers. For technical buyers and engineers, understanding the available post-processing options allows for a more comprehensive specification of SiC components.

Common post-processing needs and techniques for SiC tubes include:

- Grinding and Machining:

- Purpose: To achieve tight dimensional tolerances, precise geometries (e.g., flats, grooves, chamfers), and improved surface finishes that cannot be obtained through primary forming processes (as-fired state).

- Process: Due to SiC’s extreme hardness, diamond tooling is exclusively used. Grinding can be applied to outer diameters (OD), inner diameters (ID), ends, and specific features. Techniques include cylindrical grinding, surface grinding, and centerless grinding.

- Benefits:

- Precision: Achieves tolerances often in the range of tens of microns.

- Surface Smoothness: Significantly reduces surface roughness (Ra), which can be beneficial for sealing surfaces, reducing friction, or improving cleanability in high-purity SiC tube applications.

- Feature Creation: Allows for the creation of threads (though limited), O-ring grooves, and other features necessary for integration into assemblies.

- Considerations: Grinding is a subtractive process that adds to the cost and lead time. The design should minimize the need for extensive machining where possible.

- Lapping and Polishing:

- Purpose: To achieve exceptionally smooth, flat, or high-gloss surfaces, often required for optical applications, semiconductor components, or where ultra-low friction or specific sealing characteristics are needed.

- Process: Involves using progressively finer abrasive slurries (often diamond-based) on a lapping plate or polishing pad.

- Benefits:

- Ultra-Smooth Surfaces: Can achieve surface roughness values (Ra) below 0.1μm, even down to Angstrom levels for super-polishing.

- Improved Sealing: Critical for gas-tight or liquid-tight seals.

- Optical Quality: Essential for SiC mirrors or windows.

- Considerations: Lapping and polishing are time-consuming and expensive processes, typically reserved for applications with the most stringent surface requirements.

- Sealing (for Porous SiC Grades):

- Purpose: Some SiC grades, like Recrystallized SiC (RSiC) or certain Reaction Bonded SiC (RBSiC) with residual porosity, may require sealing to improve gas tightness, chemical resistance, or to prevent contamination.

- Process: Involves impregnating the porous SiC structure with a secondary material, such as a glass frit, a polymer, or a chemical vapor infiltration (CVI) SiC coating.

- Glass Sealing: A glassy phase fills the pores. Can limit the maximum operating temperature.

- CVI SiC Coating: Deposits a thin layer of dense SiC over the surface and into near-surface pores, effectively sealing the component with a high-purity SiC layer. This is often preferred for high-temperature and high-purity applications.

- Benefits:

- Improved Impermeability: Reduces or eliminates gas or liquid penetration.

- Enhanced Chemical Resistance: Protects the underlying porous structure from aggressive media.

- Considerations: The sealing material must be compatible with the operating environment (temperature, chemicals). The sealing process might slightly alter dimensions.

- Coating:

- Purpose: To impart specific surface properties that the base SiC material may not possess, or to further enhance existing properties.

- Process: Various coating technologies can be applied:

- Chemical Vapor Deposition (CVD): Can apply highly pure and dense coatings of materials like SiC itself (e.g., to densify a surface or improve purity), pyrolytic carbon (PyC), or other ceramics.

- Physical Vapor Deposition (PVD): Techniques like sputtering can apply thin metallic or ceramic films.

- Plasma Spraying: Can apply thicker coatings for wear or thermal barrier applications.

- Benefits:

- Enhanced Wear Resistance: e.g., diamond-like carbon (DLC) coatings.

- Improved Corrosion Resistance: Specific ceramic or polymer coatings for extreme chemical environments.

- Biocompatibility: For medical applications.

- Electrical Conductivity/Insulation: Tailoring surface electrical properties.

- Considerations: Adhesion of the coating to the SiC substrate is critical. The coating material and process must be chosen based on the application’s thermal and chemical environment.

- Cleaning and Annealing:

- Purpose: To remove surface contaminants from manufacturing processes (e.g., machining fluids, dust) or to relieve internal stresses.

- Process:

- Cleaning: May involve ultrasonic cleaning in specialized solvents, deionized water rinses, or acid etching (carefully controlled). High-purity SiC tubes for semiconductor use undergo rigorous multi-stage cleaning processes.

- Annealing: Heating the SiC tube to an elevated temperature (below its sintering temperature) and holding it for a period, followed by controlled cooling. This can help relieve stresses induced during machining and improve mechanical stability.

- Benefits:

- Purity: Ensures the SiC tube meets cleanliness specifications, critical for semiconductor and pharmaceutical applications.

- Stress Relief: Can improve toughness and reduce the risk of delayed fracture.

- Considerations: Cleaning agents must be compatible with SiC and not introduce new contaminants. Annealing parameters must be carefully controlled.

The selection of appropriate post-processing steps is a collaborative effort between the end-user and the SiC tube supplier. Companies like Sicarb Tech, with their comprehensive understanding of SiC materials and processing, can provide valuable guidance on which techniques will best optimize custom SiC tubes for specific industrial needs, whether it’s achieving the demanding tolerances for OEM SiC components or the ultra-high purity for semiconductor process tubes. This attention to detail ensures that the final product delivers maximum performance and durability.

Choosing Your Partner for Custom SiC Tubes: Expertise and Reliability with SicSino

Selecting the right supplier for custom silicon carbide tubes is a critical decision that can significantly impact the performance, reliability, and cost-effectiveness of your industrial processes. The ideal partner is not just a manufacturer but a knowledgeable consultant who understands the nuances of SiC materials, application challenges, and quality assurance. For technical procurement professionals, OEMs, and distributors, identifying a supplier with proven expertise, robust manufacturing capabilities, and a commitment to quality is paramount.

Key Criteria for Evaluating a Custom SiC Tube Supplier:

- Technical Expertise and Material Knowledge:

- Understanding of SiC Grades: The supplier should have in-depth knowledge of various SiC grades (RBSiC/SiSiC, SSiC, RSiC, etc.) and their suitability for different applications. They should be able to recommend the optimal grade based on your specific requirements for temperature, chemical exposure, wear, and mechanical stress.

- Application Experience: Look for a supplier with a track record of successfully providing industrial SiC tubes for your industry or similar demanding applications. Case studies and references can be valuable.

- Engineering Support: The ability to offer design assistance, DFM (Design for Manufacturability) advice, and collaborative problem-solving is a hallmark of a good partner.

- Manufacturing Capabilities and Customization:

- Range of Forming Techniques: A versatile supplier will have access to various forming methods (extrusion, slip casting, isostatic pressing) to produce a wide array of tube sizes and complexities.

- Precision Machining: For tight tolerances and specific features, advanced grinding and machining capabilities using diamond tooling are essential. Inquire about their achievable tolerances and surface finishes.

- Post-Processing Options: Availability of services like lapping, polishing, sealing, and coating can be crucial for enhancing performance.

- Scalability: Whether you need prototypes, small batches, or high-volume production for SiSiC tubes wholesale, the supplier should be able to scale their operations accordingly.

- Quality Assurance and Certifications:

- Quality Management System (QMS): Certifications like ISO 9001 demonstrate a commitment to quality control throughout the manufacturing process.

- Material Traceability: The ability to trace raw materials and processing steps is important for consistency and accountability.

- Inspection and Testing: Inquire about their inspection procedures, including dimensional checks, material property verification, and any non-destructive testing (NDT) capabilities.

- Cost-Effectiveness and Lead Times:

- Transparent Pricing: Look for clear breakdowns of cost drivers, including material grade, complexity, volume, and any post-processing. While price is a factor, the lowest cost may not always equate to the best value, especially if quality or reliability is compromised.

- Competitive Lead Times: Understand their typical lead times for custom orders and their ability to meet your project timelines. Factors affecting lead time include design complexity, material availability, and current production capacity.

- Location, Logistics, and Support:

- Supply Chain Reliability: A stable supply chain and good logistics are crucial for timely delivery.

- Customer Service: Responsive communication, technical support, and after-sales service are important aspects of a long-term partnership.

Why Sicarb Tech Stands Out:

For businesses seeking high-quality, cost-competitive custom silicon carbide components from China, Sicarb Tech offers a compelling value proposition.

- Strategic Location in Weifang: SicSino is situated in Weifang City, the recognized hub of China’s silicon carbide customizable parts manufacturing. This region hosts over 40 SiC production enterprises, accounting for more than 80% of China’s total SiC output. SicSino has been instrumental in this ecosystem since 2015, introducing and implementing SiC production technology and fostering technological advancements. This unique position provides access to a vast network of specialized production capabilities and a deep pool of experienced talent.

- Backed by Chinese Academy of Sciences: SicSino operates under the platform of the national technology transfer center of Chinese Academy of Sciences(Weifang) Innovation Park. This affiliation provides unparalleled access to the robust scientific, technological capabilities, and talent pool of the Chinese Academy of Sciences. This connection ensures a strong foundation in materials science and cutting-edge manufacturing processes, translating to more reliable quality and supply assurance.

- Comprehensive Technical Expertise: SicSino boasts a domestic top-tier professional team specializing in customized SiC product production. They possess a wide array of technologies, encompassing material science, process engineering, design optimization, and measurement & evaluation technologies. This integrated approach, from raw materials to finished products, allows them to meet diverse and complex customization needs for custom SiC tubes and other components. More than 10 local enterprises have benefited from SicSino’s technological support.

- Focus on Quality and Cost-Competitiveness: Leveraging their technological strengths and strategic location, SicSino is committed to offering higher-quality, cost-competitive customized silicon carbide components. Their understanding of the entire value chain enables them to optimize production for both performance and value.

- Customization and OEM Support: SicSino excels in providing bespoke solutions, working closely with technical procurement professionals and OEMs to deliver OEM SiC components that precisely meet application requirements.

- Technology Transfer Services (Turnkey Projects): Beyond supplying components, SicSino offers a unique service: technology transfer for establishing professional SiC production plants. If you aim to build your own specialized SiC products manufacturing facility, SicSino can provide a full range of services, including factory design, procurement of specialized equipment, installation, commissioning, and trial production. This turnkey solution ensures an effective investment, reliable technology transformation, and a guaranteed input-output ratio.

Cost Drivers and Lead Time Considerations for Custom SiC Tubes:

Understanding what influences the price and delivery schedule is crucial for effective budgeting and project planning.

| Cost Driver | Impact on Price | Lead Time Factor |

|---|---|---|

| SiC Material Grade | Higher purity (e.g., SSiC) and more complex synthesis generally cost more. | Specialized raw material procurement might extend lead times. |

| Tube Complexity | Intricate shapes, very tight tolerances, multiple features increase manufacturing. | More complex designs require longer setup, machining, and inspection times. |

| Tube Size & Volume | Larger tubes use more material. Small production runs have higher per-unit costs. | Very large parts may have limited equipment availability. Tooling for new sizes. |

| Tolerances & Finish | Tighter tolerances and finer surface finishes require additional machining. | Grinding, lapping, polishing are time-consuming processes. |

| Post-Processing | Sealing, coating, or extensive cleaning add to the cost. | Each additional step adds to the overall processing time. |

| Tooling Costs | New or custom tooling (e.g., extrusion dies, molds) can be a one-time cost. | Tooling fabrication can take several weeks. |

| Testing/Certification | Specialized testing or certification requirements add to costs and time. | Time required for specific tests and documentation. |

By partnering with a knowledgeable and capable supplier like Sicarb Tech, businesses can navigate these complexities effectively, ensuring they receive high-performance custom silicon carbide tubes that deliver exceptional value and reliability for their critical industrial applications. Their unique blend of deep technical expertise, strategic location, and commitment to client success makes them a trusted partner in the advanced ceramics industry.

Frequently Asked Questions (FAQ) about Silicon Carbide Tubes

Navigating the specifics of silicon carbide tubes can raise several questions for engineers, procurement managers, and technical buyers. Here are some common queries with concise, practical answers to help you better understand and specify these high-performance components.

- What are the primary advantages of using silicon carbide tubes over other ceramic or metallic tubes? Silicon carbide (SiC) tubes offer a superior combination of properties compared to many other materials, especially in demanding industrial environments. Key advantages include:

- Exceptional High-Temperature Performance: SiC maintains its strength and structural integrity at temperatures where most metals would soften or melt, and many other ceramics would degrade (e.g., up to 1600∘C or higher for SSiC).

- Superior Wear and Abrasion Resistance: SiC is one of the hardest commercially available materials, making it ideal for applications involving abrasive particles or high wear, significantly outlasting most metals and other ceramics.

- Excellent Chemical Inertness: SiC tubes are highly resistant to a wide range of corrosive chemicals, including strong acids, alkalis, and process gases, even at elevated temperatures. This minimizes contamination and extends service life in aggressive environments.

- High Thermal Conductivity Combined with Low Thermal Expansion: This combination results in excellent thermal shock resistance, allowing SiC tubes to withstand rapid temperature changes without cracking. Its high thermal conductivity is also beneficial for efficient heat transfer in applications like radiant heater tubes or heat exchangers.

- Good Mechanical Strength: SiC tubes exhibit high strength and stiffness, even at high temperatures, ensuring dimensional stability under load.

- How do I determine the most suitable grade of silicon carbide (e.g., RBSiC/SiSiC, SSiC, RSiC) for my tube application? Choosing the correct SiC grade is critical for optimal performance and cost-effectiveness. The selection depends primarily on the specific operating conditions:

- Operating Temperature:

- RBSiC (SiSiC): Generally suitable up to ∼1350∘C−1380∘C due to the presence of free silicon. Offers a good balance of performance and cost for many applications.SSiC (Sintered Silicon Carbide): Can operate at much higher temperatures, often exceeding 1600∘C. Preferred for the most extreme temperature environments and where high purity is essential.RSiC (Recrystallized Silicon Carbide): Excellent for very high temperatures (up to ∼1650∘C) and offers superior thermal shock resistance due to its controlled porosity.

- SSiC: Offers the best overall chemical resistance, especially to strong acids and oxidizing atmospheres, due to its high purity and density. Ideal for high-purity SiC tubes in semiconductor or aggressive chemical processing. RBSiC: Good chemical resistance but the free silicon can be attacked by certain strong alkalis or specific chemicals. RSiC: Its porosity can make it less suitable for some highly corrosive environments unless sealed or if the process allows for some permeability.

- RBSiC and SSiC: Both offer excellent hardness and wear resistance. SSiC is generally harder and denser. RSiC: While strong, its primary advantage is thermal shock resistance rather than extreme wear resistance.

- RSiC: The best choice for applications involving very rapid heating and cooling cycles.RBSiC and SSiC: Also offer good thermal shock resistance, superior to many other ceramics.

- Operating Temperature:

- What are the typical lead times for custom silicon carbide tubes, and what factors can influence this? Lead times for custom silicon carbide tubes can vary significantly, typically ranging from a few weeks to several months. Several factors influence this timeframe:

- Complexity of Design: Simple, straight tubes with standard dimensions will generally have shorter lead times than complex geometries, tubes with intricate features, or very large sizes.SiC Grade and Manufacturing Process: Some SiC grades and forming/sintering processes are inherently more time-consuming than others. For example, producing high-purity SSiC often involves longer sintering cycles.Tooling Requirements: If new tooling (e.g., extrusion dies, casting molds, specialized grinding fixtures) is required for your custom design, the time needed to design, manufacture, and test this tooling will add to the overall lead time. This is often a significant factor for initial orders of unique parts.Production Volume: Small prototype runs might be quicker if existing general tooling can be adapted, but large production volumes will need to be scheduled and may have longer lead times depending on the supplier’s capacity.Post-Processing Requirements: Additional steps like precision grinding, lapping, polishing, sealing, or coating will each add to the total manufacturing time. The more extensive the post-processing, the longer the lead time.Material Availability: While SiC raw materials are generally available, specific high-purity grades or additives might occasionally have longer procurement times for the manufacturer.Supplier’s Current Workload and Capacity: The supplier’s existing order backlog and production capacity will naturally affect how quickly they can process a new custom order.Quality Control and Testing: Thorough inspection and any specialized testing required for your application (e.g., pressure testing, helium leak testing, specific material analysis) will also factor into the lead time.

By addressing these common questions, we hope to provide greater clarity on the benefits, selection, and procurement of custom silicon carbide tubes, empowering you to make informed decisions for your critical industrial applications.

Conclusion: The Enduring Value of Custom Silicon Carbide Tubes in Advanced Industries

In the challenging arena of modern industrial applications, where performance under extreme conditions is not just desired but essential, custom silicon carbide tubes have unequivocally proven their worth. Their remarkable combination of high-temperature stability, exceptional wear resistance, superior chemical inertness, and excellent thermal shock resistance positions them as a critical material solution across a diverse range of sectors, from semiconductor fabrication and aerospace engineering to high-temperature furnace operations and aggressive chemical processing.

The ability to tailor these components—specifying precise dimensions, selecting optimal SiC grades like RBSiC, SSiC, or RSiC, and defining exacting tolerances and surface finishes—elevates their utility far beyond standard off-the-shelf products. This customization ensures that each industrial SiC tube is perfectly optimized for its intended application, maximizing operational efficiency, extending service life, and ultimately contributing to reduced downtime and lower long-term ownership costs. For technical buyers, procurement professionals, and OEMs, investing in custom SiC tubes translates directly into enhanced system reliability and productivity.

Partnering with a knowledgeable and experienced supplier is paramount to harnessing the full potential of these advanced ceramics. Companies like Sicarb Tech, strategically located in Weifang—the epicenter of China’s silicon carbide manufacturing—and backed by the formidable research capabilities of the Chinese Academy of Sciences , offer a unique blend of deep material expertise, advanced manufacturing capabilities, and a commitment to quality. Their ability to deliver high-quality, cost-competitive custom SiC components, alongside innovative technology transfer solutions, makes them an invaluable partner for businesses seeking to leverage the superior properties of silicon carbide.

As industries continue to push the boundaries of technology and operate in increasingly demanding environments, the strategic importance of high-performance materials like silicon carbide will only intensify. Custom silicon carbide tubes are not merely components; they are enablers of innovation, playing a vital role in the advancement and efficiency of critical industrial processes worldwide. Their enduring value lies in their consistent ability to deliver exceptional performance where other materials falter, ensuring that industries can meet the challenges of today and the opportunities of tomorrow.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.