Silicon Carbide Reaction Chambers: The Cornerstone of High-Performance Industrial Applications

Share

In the ever-evolving landscape of advanced materials, silicon carbide (SiC) stands out for its exceptional properties, making it indispensable in a myriad of demanding industrial applications. Among its critical uses, silicon carbide reaction chambers are pivotal components that enable processes previously deemed too harsh for conventional materials. These chambers are at the heart of operations in industries ranging from semiconductor manufacturing to chemical processing, where extreme temperatures, corrosive environments, and the need for high purity are paramount. This blog post delves into the world of custom SiC reaction chambers, exploring their applications, advantages, design considerations, and how to select the right supplier for these critical components, with a special focus on the expertise available from Sicarb Tech a leader in the silicon carbide industry.

Introduction: The Indispensable Role of Custom Silicon Carbide Reaction Chambers in Advanced Industrial Processes

Silicon carbide reaction chambers are specialized enclosures engineered from high-purity silicon carbide ceramics, designed to contain and facilitate chemical or physical processes under extreme conditions. Their essential role stems from SiC’s unique combination of properties: exceptional thermal conductivity, high resistance to thermal shock, superior mechanical strength even at elevated temperatures (up to 1650°C or higher for some grades), outstanding chemical inertness, and excellent wear resistance. In high-performance industrial applications, such as the manufacturing of semiconductors, LEDs, or specialized coatings through processes like Chemical Vapor Deposition (CVD) or Metal-Organic Chemical Vapor Deposition (MOCVD), the reaction chamber is the critical environment where these transformations occur.

The term “custom” is key here. Off-the-shelf solutions often fall short when specific process parameters, unique geometries, or stringent purity levels are required. Custom silicon carbide products, particularly reaction chambers, are tailored to the precise needs of an application, optimizing performance, yield, and longevity. This customization can involve specific SiC grades, intricate designs to manage gas flow and temperature uniformity, and specialized surface finishes. The demand for these bespoke solutions is rapidly increasing as industries push the boundaries of technology, requiring materials that can keep pace. Engineers and procurement managers in sectors like aerospace components manufacturing, high-temperature furnace construction, and advanced energy systems increasingly specify custom SiC reaction chambers to ensure process stability, reduce contamination, and extend the operational life of their equipment. The ability to withstand aggressive plasma environments, resist erosion from reactive gases, and maintain dimensional stability under cyclic heating and cooling makes SiC the material of choice for these critical technical ceramic components.

Key Applications: Where Silicon Carbide Reaction Chambers Drive Innovation

The versatility and robustness of silicon carbide reaction chambers make them crucial in a wide array of industrial sectors. Their ability to perform reliably under extreme conditions positions them as enablers of innovation and efficiency.

One of the most significant applications is in the semiconductor industry. SiC reaction chambers are integral to processes like:

- Epitaxial growth: Creating highly pure crystalline layers on silicon wafers, a fundamental step in chip manufacturing. SiC chambers ensure minimal outgassing and particulate contamination, which are critical for achieving high-quality epitaxial films.

- Plasma etching: Selectively removing material from wafers using corrosive plasmas. SiC’s resistance to plasma erosion ensures chamber longevity and consistent process results. Plasma etch chambers made from SiC offer superior performance compared to traditional quartz components.

- Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD): Depositing thin films of various materials onto substrates. The high thermal stability and chemical inertness of SiC prevent unwanted reactions with precursor gases and ensure uniform deposition. CVD SiC chambers are highly sought after for their purity and durability.

- Rapid Thermal Processing (RTP): Quickly heating wafers to high temperatures for short durations. SiC’s excellent thermal shock resistance and conductivity are vital for these applications.

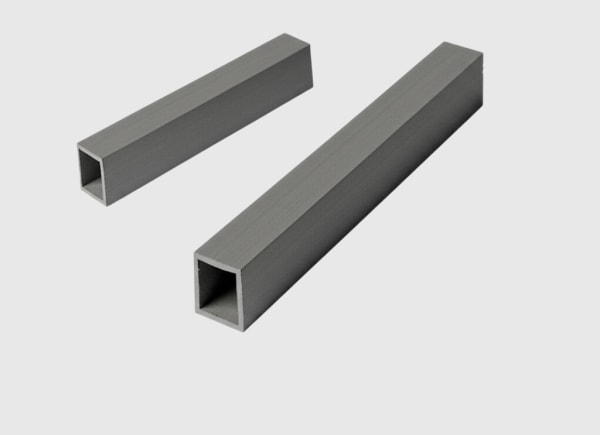

In high-temperature furnace applications, SiC reaction chambers and components like SiC furnace tubes and SiC liners are used due to their ability to withstand extreme heat without deforming or degrading. This includes:

- Sintering and annealing processes for ceramics and metals.

- Growth of single crystals, such as sapphire for LED substrates.

- Heat treatment applications requiring controlled atmospheres.

The chemical processing industry also benefits significantly from SiC reaction chambers, particularly for processes involving highly corrosive chemicals or high temperatures. Applications include:

- Production of specialty chemicals where purity is critical.

- Reactions involving strong acids, bases, or oxidizing agents.

- High-pressure synthesis.

Furthermore, aerospace and energy sectors utilize SiC components, including reaction chambers, for applications like:

- Combustion liners in gas turbines due to high-temperature strength and oxidation resistance.

- Components in advanced nuclear reactor designs.

- Production of advanced materials like ceramic matrix composites (CMCs).

The table below highlights key industries and the specific advantages SiC reaction chambers bring:

| Industry Sector | Specific Applications of SiC Reaction Chambers | Key Advantages Provided by SiC |

|---|---|---|

| Semiconductor | Epitaxy, Plasma Etch, CVD, PVD, RTP | High purity, plasma resistance, thermal stability, low particle |

| High-Temperature Furnaces | Sintering, Annealing, Crystal Growth, Heat Treatment | Extreme temperature resistance, thermal shock resistance, strength |

| Chemical Processing | Specialty Chemical Production, Corrosive Material Handling | Chemical inertness, corrosion resistance, high-pressure capability |

| Aerospace & Energy | Turbine Combustors, Nuclear Components, Advanced Material Synthesis | High-temp strength, oxidation resistance, wear resistance |

| LED Manufacturing | MOCVD reactors for GaN epitaxy | High thermal conductivity, purity, resistance to precursors |

The consistent performance of industrial SiC reaction chambers in these demanding environments underscores their importance in advancing modern technology. As industries seek higher efficiencies, greater purity, and longer component lifetimes, the demand for high-quality, custom-designed SiC chambers continues to grow.

The Custom Advantage: Tailoring Silicon Carbide Reaction Chambers for Optimal Performance

Choosing custom-designed silicon carbide reaction chambers over standard options offers a multitude of benefits that directly translate to improved process efficiency, higher yields, and reduced operational costs. The unique demands of advanced industrial processes often necessitate components that are precisely engineered for specific conditions, and SiC provides the ideal material platform for such customization.

The primary advantages of custom SiC reaction chambers include:

- Optimized Thermal Management: Silicon carbide boasts excellent thermal conductivity (varying by grade, e.g., SSiC can reach >120W/mK). Custom designs can incorporate specific wall thicknesses, cooling channels, or integrated heating elements to ensure precise temperature control and uniformity within the chamber. This is crucial for processes like semiconductor epitaxy or crystal growth where temperature gradients can significantly impact product quality.

- Enhanced Chemical Resistance and Purity: SiC is inherently resistant to a wide range of corrosive chemicals, including strong acids and halogens, even at elevated temperatures. Customization allows for the selection of the most appropriate SiC grade (e.g., high-purity sintered SiC for semiconductor applications) to minimize contamination and prevent reactions between the chamber material and the process chemicals. This ensures the integrity of the final product and extends the chamber’s lifespan. High-purity SiC chambers are essential for applications demanding minimal metallic contamination.

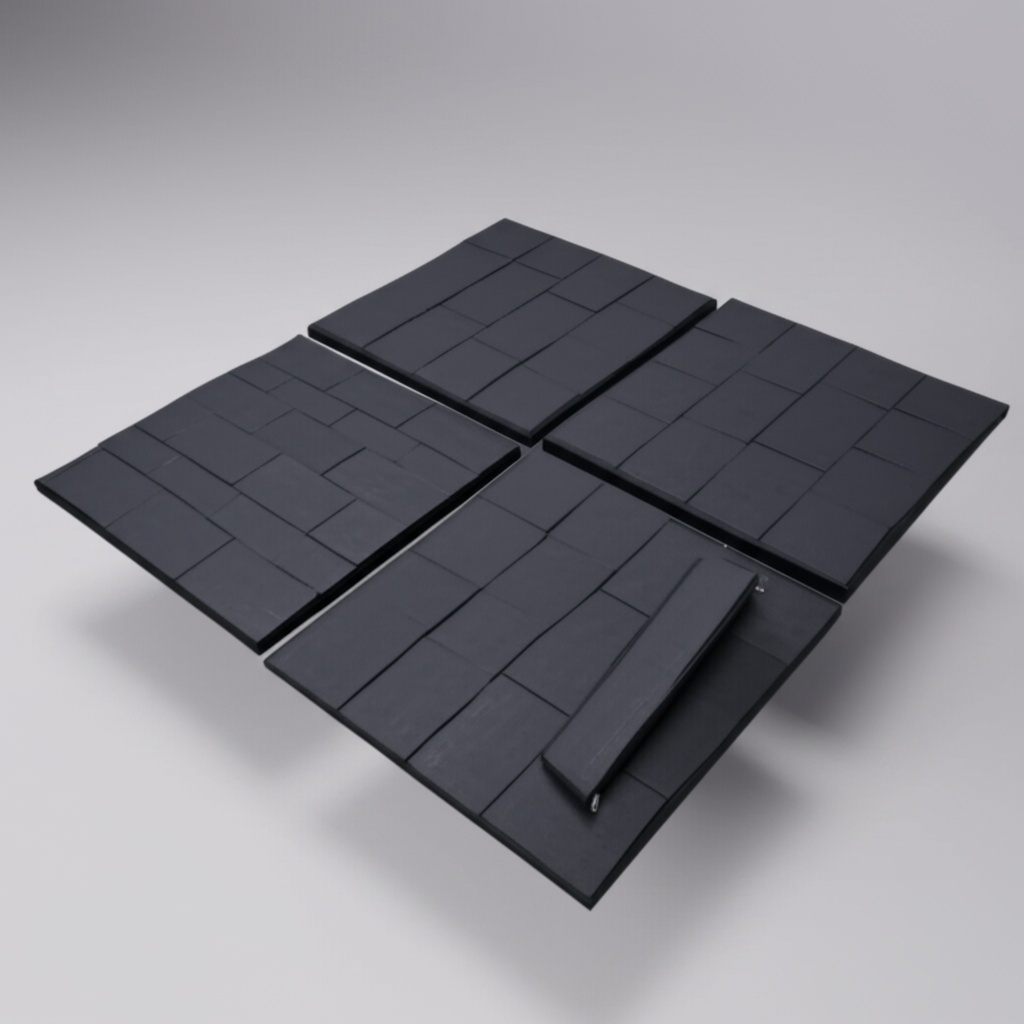

- Application-Specific Geometries and Features: Standard chambers may not fit the spatial constraints of existing equipment or provide optimal gas flow dynamics for a particular process. Custom SiC reaction chambers can be designed with complex geometries, specific inlet and outlet port configurations, integrated baffles, or tailored internal volumes to improve process uniformity, precursor utilization, and throughput. Custom SiC fabrication allows for intricate designs that would be impossible with other materials.

- Superior Durability and Longevity: The exceptional hardness and wear resistance of SiC mean that custom chambers can withstand harsh operating conditions, including abrasive particles or high-velocity gas flows, for extended periods. This reduces downtime for component replacement and lowers the overall cost of ownership. Reaction bonded silicon carbide (RBSiC) and sintered silicon carbide (SSiC) offer different balances of properties, and customization allows selection based on the specific wear mechanisms anticipated.

- Improved Process Yields: By ensuring a stable, clean, and precisely controlled reaction environment, custom SiC chambers contribute directly to higher process yields and reduced defect rates. The consistency offered by a chamber tailored to the process minimizes variations and improves the reproducibility of results.

- Integration with Existing Systems: Custom chambers can be designed with specific flanges, mounting points, and interface considerations to ensure seamless integration into existing processing equipment, simplifying installation and reducing modification costs.

Procurement managers and technical buyers looking for wholesale SiC components or OEM SiC solutions will find that partnering with a knowledgeable supplier capable of deep customization, like Sicarb Tech , offers significant advantages. SicSino, leveraging the expertise of the Chinese Academy of Sciences and situated in Weifang, the heart of China’s SiC production, specializes in translating complex requirements into high-performance, reliable custom silicon carbide parts. Their understanding of material science and process engineering ensures that each chamber is optimized for its intended application.

Material Mastery: Selecting the Right SiC Grade for Your Reaction Chamber

The performance and longevity of a silicon carbide reaction chamber are fundamentally tied to the specific grade of SiC used in its construction. Different manufacturing processes yield SiC materials with varying properties, making the selection of the appropriate grade a critical design decision. Understanding these differences is key for engineers and procurement professionals aiming to optimize their high-temperature or corrosive environment processes.

The most common grades of silicon carbide used for reaction chambers include:

- Reaction-Bonded Silicon Carbide (RBSiC or SiSiC):

- Manufacturing: Produced by infiltrating a porous carbon-SiC preform with molten silicon. The silicon reacts with the carbon to form additional SiC, binding the original SiC grains. The resulting material typically contains 8-15% free silicon.

- Properties: Good mechanical strength, excellent thermal shock resistance, high thermal conductivity (due to free silicon), and relatively lower cost compared to other dense SiC grades. It can be formed into complex shapes with tight tolerances.

- Best Suited For: Applications where extreme chemical purity is not the absolute primary concern but high thermal conductivity and complex shapes are needed. Common in high-temperature furnace components, wear parts, and some chemical process equipment. However, the presence of free silicon can be a limitation in ultra-high purity semiconductor processes or with certain aggressive chemicals that attack silicon. Sicarb Tech offers robust RBSiC components tailored for such demanding environments.

- Sintered Silicon Carbide (SSiC):

- Manufacturing: Made from fine, high-purity SiC powder, mixed with sintering aids (typically non-oxide, like boron and carbon), and sintered at very high temperatures (>2000°C) in an inert atmosphere. This process results in a dense, single-phase SiC material (typically >98% SiC).

- Properties: Highest purity among SiC grades, excellent chemical resistance (especially to strong acids and halogens), superior high-temperature strength, good wear resistance, and high hardness. Its thermal conductivity is generally lower than SiSiC but still very good.

- Best Suited For: The most demanding applications where purity, chemical inertness, and high-temperature performance are critical. This includes semiconductor processing equipment (e.g., epitaxial reactor components, plasma etch chamber liners), and handling of ultra-corrosive media. SicSino’s capability in producing high-purity SSiC chambers makes them a preferred partner for the semiconductor and advanced chemical industries.

- Nitride-Bonded Silicon Carbide (NBSiC or NBSC):

- Manufacturing: SiC grains are bonded by a silicon nitride (Si3N4) phase. This is achieved by nitriding silicon metal that is mixed with SiC grains or by firing SiC with additives that form silicon nitride in situ.

- Properties: Good thermal shock resistance, excellent resistance to wetting by molten non-ferrous metals, and good mechanical strength. It is generally more porous than RBSiC or SSiC.

- Best Suited For: Applications in the molten metal handling industry (e.g., thermocouple protection tubes, furnace linings), and some kiln furniture applications. Less common for high-purity reaction chambers compared to SSiC but can be a cost-effective solution for specific environments.

- Recrystallized Silicon Carbide (RSiC):

- Manufacturing: High-purity SiC grains are fired at very high temperatures, causing them to bond directly to each other without the need for secondary bonding phases. This results in a porous structure but with high SiC purity.

- Properties: Excellent thermal shock resistance, stability at very high temperatures (up to 1650°C or higher), and high purity, though porous.

- Best Suited For: Kiln furniture, high-temperature supports, and applications where porosity is acceptable or even beneficial (e.g., radiant burner nozzles). Not typically the first choice for sealed reaction chambers requiring vacuum integrity unless subsequently coated or sealed.

The following table provides a comparative overview:

| SiC Grade | Key Characteristics | Typical Purity | Max. Use Temp. (°C) | Thermal Conductivity (W/mK) | Primary Applications for Reaction Chambers |

|---|---|---|---|---|---|

| RBSiC (SiSiC) | Complex shapes, good thermal conductivity, good strength, contains free silicon | 85-92% SiC | 1350−1380 | 80−150 | General purpose high-temp, some chemical, wear components |

| SSiC | Highest purity, excellent chemical resistance, high strength at high temps, wear-resistant | >98% SiC | 1600−1800 | 80−120+ | Semiconductor processing, ultra-pure chemicals, severe corrosion |

| NBSiC | Good thermal shock, molten metal resistance, moderate strength | Variable | 1400−1550 | 15−30 | Molten metal contact, specific kiln furniture |

| RSiC (Porous) | Excellent thermal shock, very high-temp stability, high purity (SiC phase) | >99% SiC | 1600−1700+ | 20−40 (effective) | Kiln furniture, high-temp supports (less for sealed chambers) |

Choosing the correct SiC grade is a collaborative process between the customer and the supplier. Companies like Sicarb Tech , with their deep expertise in technical ceramics manufacturing and access to a wide array of SiC production technologies in Weifang, can guide clients to the optimal material choice based on detailed application requirements, ensuring both performance and cost-effectiveness for their custom SiC reaction chambers.

Designing for Excellence: Critical Considerations for Custom SiC Reaction Chambers

The design phase of a custom silicon carbide reaction chamber is as crucial as material selection. Effective design not only ensures the chamber performs its primary function but also guarantees manufacturability, longevity, and safe operation. Engineers designing SiC chambers must account for the material’s unique properties—both its strengths and its limitations as a technical ceramic.

Key design considerations include:

- Manufacturability and Geometric Complexity: While SiC can be formed into complex shapes, especially grades like RBSiC, there are limits. Designers should:

- Avoid sharp internal corners: These act as stress concentrators and can lead to cracking during manufacturing or thermal cycling. Generous radii are preferred.

- Maintain uniform wall thickness: This helps prevent stress during sintering or reaction bonding and ensures more uniform temperature distribution during operation.

- Consider draft angles: For molded parts, slight draft angles facilitate removal from the mold.

- Understand forming limitations: Different SiC grades have different forming routes (e.g., slip casting, extrusion, isopressing, green machining before firing). The chosen forming method will influence achievable geometries. Consulting with experienced SiC manufacturers like Sicarb Tech early in the design phase is vital. Their expertise, backed by the Chinese Academy of Sciences National Technology Transfer Center, ensures designs are optimized for production.

- Thermal Management and Stress: SiC has excellent thermal shock resistance, but extreme or rapid temperature gradients can still induce stress.

- Thermal expansion: While SiC has a low coefficient of thermal expansion, it’s not zero. Designs must accommodate this expansion, especially at interfaces with other materials.

- Heating and cooling rates: Design features that promote uniform heating and cooling can minimize thermal stresses.

- Hot spots: Identify potential hot spots and design to mitigate them, perhaps through localized wall thinning or by incorporating cooling features if the design allows.

- Sealing and Interfaces: Reaction chambers often require vacuum-tight seals or connections to other components.

- Flange design: O-ring grooves or flat, lapped surfaces for metallic or elastomeric seals must be designed with precision. The flatness and surface finish of SiC sealing faces are critical.

- Joining SiC to other materials: Differences in thermal expansion coefficients must be carefully managed at joints (e.g., SiC to metal flanges). Graded joints or flexible connectors may be necessary.

- Port design: Inlet and outlet ports for gases or instrumentation must be positioned and sized appropriately for the process, considering gas flow dynamics and avoiding dead zones.

- Mechanical Loading and Supports:

- Stress points: Identify areas of high mechanical stress due to internal pressure, vacuum, or external loads. Ensure sufficient material thickness and consider reinforcing features if necessary.

- Support structures: The chamber must be adequately supported to prevent sagging or cracking, especially at high temperatures where material strength might be slightly reduced.

- Gas Flow Dynamics: For CVD, epitaxy, or etching applications, the internal geometry of the chamber significantly impacts gas flow patterns, uniformity of deposition or etch, and precursor efficiency. Computational Fluid Dynamics (CFD) modeling is often employed to optimize chamber design for specific flow characteristics. Custom internal features like showerheads or baffles, often made from SiC, are common.

- Purity Requirements: The design should minimize areas where contaminants can trap or outgas. Smooth internal surfaces are preferred. For ultra-high purity applications, the choice of SSiC and careful handling during manufacturing are paramount.

Collaborating with a supplier that offers comprehensive design support is crucial.Sicarb Tech not only provides custom SiC fabrication but also leverages its team of domestic top-tier professionals and integrated process technologies—from materials to finished products—to assist clients in optimizing their reaction chamber designs. This ensures that the final product meets all performance, reliability, and manufacturability criteria for demanding industrial SiC applications. Their experience across numerous customized silicon carbide projects provides invaluable insight into creating robust and efficient chamber designs.

Precision Engineering: Achieving Tight Tolerances and Superior Surface Finishes in SiC Reaction Chambers

The performance of silicon carbide reaction chambers, especially in high-tech applications like semiconductor manufacturing, is heavily dependent on the dimensional accuracy and surface quality of the SiC components. Achieving tight tolerances and superior surface finishes in a hard, brittle material like silicon carbide requires specialized machining and finishing techniques. Understanding these capabilities is crucial for engineers specifying SiC parts and for procurement professionals selecting a technical ceramics manufacturing partner.

Achievable Tolerances:

The achievable tolerances for SiC components depend on several factors: the grade of SiC, the size and complexity of the part, and the manufacturing processes employed.

- As-fired tolerances: Components directly from the sintering or reaction-bonding process will have wider tolerances, typically in the range of ±0.5% to ±2% of the dimension. For smaller parts, this might be ±0.1 mm to ±0.5 mm.

- Machined tolerances: For applications requiring higher precision, SiC parts are machined in their “green” state (before final firing) or, more commonly, after firing using diamond grinding and lapping techniques.

- Diamond Grinding: Can achieve tolerances as tight as ±0.01 mm to ±0.005 mm (5-10 micrometers) on critical dimensions.

- Lapping and Polishing: For ultra-precise applications, especially sealing surfaces or optical components, lapping can achieve flatness tolerances down to a few helium light bands and dimensional tolerances in the micrometer or even sub-micrometer range.

Surface Finish Options:

The surface finish of a SiC reaction chamber impacts purity, cleanability, and sealing effectiveness.

- As-fired surface: The surface finish directly after firing will be relatively rough, typically with an Ra (average roughness) of 1μm to 5μm, depending on the SiC grade and forming method. This may be acceptable for some furnace components but not for high-purity applications.

- Ground surface: Diamond grinding typically yields a surface finish with Ra in the range of 0.2μm to 0.8μm. This is suitable for many general-purpose SiC components and some sealing surfaces.

- Lapped surface: Lapping can produce very smooth surfaces, with Ra values typically between 0.05μm and 0.2μm. This is often required for high-vacuum seals and where minimal particle generation is critical.

- Polished surface: For the most demanding applications, such as those in semiconductor photolithography or where exceptionally smooth surfaces are needed to prevent particle adhesion, SiC can be polished to an optical finish with Ra<0.02μm (20 nanometers) or even lower. Polished SiC components offer superior cleanliness.

The table below summarizes typical achievable tolerances and surface finishes:

| Machining Process | Typical Tolerance Range | Typical Surface Finish (Ra) | Notes |

|---|---|---|---|

| As-Fired | ±0.5% to ±2% | 1−5μm | Varies greatly with SiC grade and forming method |

| Green Machining | ±0.5% to ±1% (pre-fire) | N/A (fired surface different) | Allows complex shapes before densification |

| Diamond Grinding | ±0.005 mm to ±0.05 mm | 0.2−0.8μm | Most common precision machining method for fired SiC |

| Diamond Lapping | ±0.001 mm to ±0.01 mm | 0.05−0.2μm | For flat surfaces, tight parallelism, and excellent finish |

| Diamond Polishing | < ±0.001 mm | < 0.02μm | For optical-grade finishes, ultra-low particle applications |

Precision Capabilities and Their Impact:

- Sealing Integrity: Flat, smooth surfaces achieved by lapping are essential for creating reliable high-vacuum or pressure seals in reaction chambers.

- Particle Reduction: Smoother internal chamber surfaces reduce areas where process byproducts or particles can adhere, leading to a cleaner processing environment and fewer defects in semiconductor manufacturing.

- Gas Flow Dynamics: Precise dimensions ensure consistent internal chamber volumes and geometries, which is critical for predictable gas flow patterns and uniform processing.

- Component Interchangeability: Tight tolerances allow for easier replacement of chamber components and ensure consistent fit-up in OEM SiC equipment.

Manufacturers like Sicarb Tech possess advanced machining and finishing capabilities, crucial for producing high-precision custom SiC reaction chambers. Their expertise in material science, combined with state-of-the-art measurement and evaluation technologies, ensures that components meet the stringent dimensional and surface finish specifications required by industries such as semiconductor equipment manufacturing and aerospace engineering. For technical buyers and procurement professionals, verifying a supplier’s precision capabilities is a key step in ensuring the quality and performance of industrial SiC components.

Enhancing Durability and Functionality: Post-Processing Techniques for SiC Reaction Chambers

While the inherent properties of silicon carbide make it an excellent material for reaction chambers, various post-processing techniques can further enhance its performance, durability, and functionality for specific applications. These treatments can improve surface characteristics, seal porosity, or add new capabilities to the SiC component. Understanding these options allows engineers and technical buyers to specify custom SiC products that are even more tailored to their demanding operational environments.

Common post-processing steps for SiC reaction chambers include:

- Precision Grinding, Lapping, and Polishing:

- Purpose: As discussed previously, these mechanical processes are fundamental for achieving tight dimensional tolerances, specific surface finishes (Ra), and critical geometries (e.g., flatness for sealing).

- Benefits: Improved sealing, reduced particle generation, enhanced cleanability, and better uniformity for processes sensitive to surface conditions. For high-purity SiC chambers, a polished internal surface is often specified.

- Cleaning and Etching:

- Purpose: To remove any contaminants, machining residues, or surface imperfections from the manufacturing process. Specialized chemical etching can also be used to passivate the surface or remove a microscopic layer, further enhancing purity.

- Benefits: Ensures ultra-high purity, critical for semiconductor and pharmaceutical applications. Reduces outgassing and potential contamination of the process environment.

- Sealing and Impregnation (for porous SiC grades):

- Purpose: Some SiC grades, like RSiC or certain less dense RBSiC variants, can have residual porosity. Sealing treatments, often involving the application of a glass frit or a polymeric sealant that is subsequently pyrolyzed, can fill this porosity.

- Benefits: Improves gas tightness, enhances chemical resistance by preventing ingress of corrosive agents into pores, and can increase mechanical strength. This is less common for SSiC, which is inherently dense.

- Coating (e.g., CVD SiC, Pyrolytic Boron Nitride – PBN):

- Purpose: Applying a thin layer of another high-performance material onto the SiC substrate can provide additional benefits.

- CVD SiC Coating: A very pure, dense layer of SiC can be deposited onto a SiC (often RBSiC) or graphite substrate. This creates an ultra-pure, highly resistant surface. This is a common method to produce CVD SiC chambers or liners.

- PBN Coating: Pyrolytic Boron Nitride is an excellent dielectric with high thermal conductivity and outstanding chemical inertness, especially to molten metals and certain semiconductor process gases. Coating SiC with PBN can be beneficial in specific applications requiring these combined properties.

- Benefits: Enhanced purity (CVD SiC coating on RBSiC can provide a surface comparable to SSiC), improved resistance to specific chemicals, tailored electrical properties (PBN is an insulator), or enhanced non-wetting characteristics.

- Purpose: Applying a thin layer of another high-performance material onto the SiC substrate can provide additional benefits.

- Annealing:

- Purpose: A heat treatment process that can relieve internal stresses induced during machining or forming. It can also be used to further stabilize the microstructure of the SiC.

- Benefits: Improved dimensional stability over time and temperature cycling, enhanced mechanical reliability by reducing internal stresses.

- Surface Passivation:

- Purpose: Specific chemical treatments can be applied to create a stable, non-reactive oxide layer (SiO2) on the SiC surface.

- Benefits: Can improve resistance to certain oxidizing environments or alter surface energy characteristics.

The choice of post-processing steps depends heavily on the application’s specific requirements, including operating temperature, chemical environment, purity needs, and mechanical stresses. Collaborating with an experienced SiC supplier is essential to determine the most effective and economical post-processing treatments.

Sicarb Tech , with its comprehensive understanding of silicon carbide technology—from raw materials through to finished and treated components—is well-equipped to advise on and implement necessary post-processing. Their robust scientific and technological capabilities, backed by the Chinese Academy of Sciences, allow them to offer a full spectrum of solutions, including advanced coatings and surface treatments, to ensure their custom SiC reaction chambers deliver optimal performance and longevity in the most challenging industrial SiC applications. This expertise is particularly valuable for OEMs and wholesale SiC buyers looking for a reliable partner in China’s SiC manufacturing hub, Weifang.

Frequently Asked Questions (FAQ) about Silicon Carbide Reaction Chambers

Engineers, procurement managers, and technical buyers often have specific questions when considering silicon carbide for their reaction chamber needs. Here are some common queries with practical, concise answers:

- What is the typical lifespan of a silicon carbide reaction chamber? The lifespan of an SiC reaction chamber varies significantly depending on several factors:

- SiC Grade: High-purity, dense grades like SSiC generally offer longer life in corrosive environments compared to RBSiC if free silicon is attacked.

- Operating Conditions: Temperature, pressure, chemical aggressiveness of process gases/liquids, presence of abrasive particles, and thermal cycling frequency all play a major role.

- Chamber Design: Proper design that minimizes stress concentrations and accounts for thermal management can extend lifespan.

- Process Purity: Contaminants in the process stream can sometimes accelerate degradation.

- Maintenance: Regular inspection and cleaning (if applicable) can prolong life. In well-matched applications, SiC chambers can last from thousands of hours to several years. For example, in semiconductor etch processes, SiC components can last significantly longer than quartz parts, often offering 3-10 times the lifetime, reducing downtime and cost of ownership. It’s best to discuss specific application details with a knowledgeable supplier like Sicarb Tech to get a more tailored estimate.

- How does the cost of SiC reaction chambers compare to those made from other materials like quartz or alumina? Silicon carbide reaction chambers are generally more expensive upfront compared to materials like quartz or standard alumina (Al2O3). This is due to:

- Raw Material Costs: High-purity SiC powders are more costly to produce.

- Manufacturing Complexity: Forming and sintering SiC requires very high temperatures and controlled atmospheres, making the process energy-intensive.

- Machining Costs: SiC is extremely hard, requiring diamond tooling and longer machining times for precision work. However, the higher initial cost is often offset by:

- Longer Lifespan: Superior wear, corrosion, and thermal resistance lead to less frequent replacement.

- Reduced Downtime: Longer component life means more uptime for production equipment.

- Improved Process Performance: Higher purity and stability can lead to better yields and less product contamination.

- Suitability for Extreme Conditions: In many cases, SiC is the only material that can withstand the process conditions. When considering the total cost of ownership (TCO), industrial SiC components often prove to be more economical in the long run for demanding applications. A detailed cost-benefit analysis for your specific process is recommended.

- What are the primary failure modes for SiC reaction chambers, and how can they be mitigated? Primary failure modes for SiC reaction chambers include:

- Thermal Shock Cracking: Caused by too rapid temperature changes or severe temperature gradients.

- Mitigation: Proper material selection (RBSiC often has better thermal shock resistance than SSiC due to higher thermal conductivity), careful design to minimize stress concentrations (e.g., rounded corners), controlled heating/cooling rates, and ensuring uniform temperature distribution.

- Chemical Attack/Corrosion: Although highly resistant, certain aggressive chemicals at very high temperatures or specific impurities can slowly degrade SiC over time. Free silicon in RBSiC can be attacked by certain halogens or molten metals.

- Mitigation: Selecting the right SiC grade (e.g., high-purity SSiC for aggressive chemical environments), applying protective coatings (like CVD SiC), and ensuring process purity.

- Mechanical Failure (Cracking/Chipping): Due to impact, excessive mechanical loads, or stresses from improper mounting or differential thermal expansion.

- Mitigation: Careful handling (SiC is brittle), robust design with adequate wall thickness, proper support structures, and designing interfaces to accommodate thermal expansion differences.

- Erosion: From high-velocity particles or aggressive plasma.

- Mitigation: Using dense, hard SiC grades (like SSiC), optimizing gas flow design to reduce direct impingement, and potentially using thicker chamber walls in high-wear areas.

- Seal Failure: Leading to loss of vacuum or process contamination.

- Mitigation: Precision machined sealing surfaces, appropriate O-ring materials or gasket designs, and ensuring correct assembly and torque. Working closely with an experienced SiC supplier like Sicarb Tech during the design and material selection phase is crucial to identify potential failure modes for your specific application and implement effective mitigation strategies. Their deep understanding of custom silicon carbide manufacturing helps in designing robust and reliable reaction chambers.

- Thermal Shock Cracking: Caused by too rapid temperature changes or severe temperature gradients.

- Can Sicarb Tech assist with the design of a custom SiC reaction chamber for our specific process? Absolutely. Sicarb Tech specializes in providing comprehensive support for custom silicon carbide products, including reaction chambers. Leveraging the robust scientific and technological capabilities of the Chinese Academy of Sciences and their position within the national technology transfer center, SicSino offers:

- Material Selection Guidance: Helping you choose the optimal SiC grade (RBSiC, SSiC, etc.) based on your process parameters (temperature, chemicals, purity).

- Design for Manufacturability (DFM): Reviewing and optimizing your designs or co-developing new designs to ensure they are suitable for SiC manufacturing, cost-effective, and will perform reliably.

- Integrated Process Expertise: Their knowledge spans from raw materials to finished products, including measurement and evaluation technologies.

- Access to Weifang’s SiC Hub: As a key player in Weifang, which accounts for over 80% of China’s SiC output, SicSino connects you to a vast manufacturing ecosystem while ensuring quality and reliability through their technological support to local enterprises. Whether you are an OEM, a research institution, or an industrial end-user, SicSino’s team of top-tier professionals is committed to delivering higher-quality, cost-competitive customized silicon carbide components. They can work from your existing drawings or help develop new solutions tailored to your unique challenges.

- What is the typical lead time for a custom SiC reaction chamber from Sicarb Tech ? Lead times for custom SiC reaction chambers can vary significantly based on several factors:

- Complexity of the Design: More intricate geometries or larger parts will generally take longer to manufacture.

- SiC Grade Selected: Some grades may have longer raw material procurement or processing times.

- Size of the Order: Larger quantities may require more extensive production scheduling.

- Required Tolerances and Surface Finish: Parts needing extensive diamond machining and polishing will have longer lead times.

- Current Production Capacity and Backlog: Like any manufacturer, existing orders can influence new project timelines. Generally, for custom SiC components, lead times can range from a few weeks for simpler items or prototypes to several months for highly complex, large, or high-volume orders. Sicarb Tech is committed to providing realistic lead time estimates upon reviewing the specific inquiry and design details. Their established processes, from inquiry to delivery, and their strong position within Weifang’s SiC industrial cluster help optimize production efficiency. For the most accurate lead time, it is best to contact SicSino directly with your specifications. They aim to provide competitive delivery schedules while ensuring the highest quality for your custom SiC components.

Conclusion: The Enduring Value of Custom Silicon Carbide in Demanding Industrial Environments

Silicon carbide reaction chambers represent a critical enabling technology for a multitude of advanced industrial processes. Their unparalleled combination of thermal resistance, chemical inertness, mechanical strength, and customizable nature makes them the material of choice for environments where other materials falter. From the intricate world of semiconductor fabrication to the aggressive conditions of high-temperature chemical synthesis, custom SiC chambers provide the stable, pure, and durable environments necessary for innovation and high-yield production.

The decision to invest in custom SiC products is a strategic one, offering long-term benefits that outweigh the initial costs. Tailored designs optimize performance, extend component life, reduce contamination, and ultimately contribute to a more efficient and reliable operation. As industries continue to push the boundaries of temperature, pressure, and chemical exposure, the demand for high-performance technical ceramics like silicon carbide will only intensify.

Partnering with a knowledgeable and capable supplier is paramount to harnessing the full potential of SiC. Sicarb Tech , deeply rooted in Weifang, the hub of China’s silicon carbide industry, stands as a testament to this expertise. Leveraging the formidable scientific and technological prowess of the Chinese Academy of Sciences , SicSino offers not just components, but comprehensive solutions – from material selection and design optimization to precision manufacturing and post-processing of customized silicon carbide parts. Their commitment to quality, innovation, and customer support ensures that clients receive SiC reaction chambers and other components that meet the most stringent requirements.

Furthermore, for organizations looking to internalize SiC production, SicSino’s unique offering of technology transfer for professional silicon carbide production provides a pathway to establishing specialized manufacturing capabilities with reliable technological backing and a full range of turnkey services.

In conclusion, whether you are an engineer designing next-generation processing equipment, a procurement manager seeking reliable wholesale SiC components, or an OEM looking for a strategic partner, the advanced properties of custom silicon carbide, supported by the expertise of suppliers like Sicarb Tech , offer a clear path to enhanced performance, reliability, and a competitive edge in today’s demanding industrial landscape.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.