Mastering Density and Precision: A Guide to Silicon Carbide Pressing Equipment

Share

In the demanding world of high-performance industrial applications, custom silicon carbide (SiC) components have become indispensable. Their exceptional properties, including superior thermal conductivity, outstanding wear resistance, high-temperature stability, and chemical inertness, make them ideal for industries ranging from semiconductors and aerospace to energy and heavy manufacturing. However, the journey from raw SiC powder to a precisely engineered component hinges critically on the manufacturing processes employed, particularly the forming or pressing stage. The quality, performance, and reliability of the final SiC product are significantly influenced by the silicon carbide pressing equipment utilized. This blog post delves into the intricacies of SiC pressing equipment, exploring the technologies, advantages, design considerations, and how choosing the right equipment and supplier, like Sicarb Tech, can elevate your manufacturing capabilities.

The production of high-quality SiC components begins with the careful selection and preparation of SiC powders, but the consolidation of these powders into a desired shape (a “green body”) with optimal density and uniformity is a pivotal step. This is where specialized pressing equipment comes into play. The choice of pressing technique and the sophistication of the equipment directly impact the microstructure and, consequently, the macroscopic properties of the sintered SiC part. For procurement managers, engineers, and technical buyers, understanding the nuances of SiC pressing technology is crucial for sourcing components that meet stringent application requirements or for investing in in-house manufacturing capabilities. As a company rooted in Weifang City, the heart of China’s silicon carbide customizable parts manufacturing, Sicarb Tech has witnessed and contributed to the technological advancements in SiC production since 2015. Our deep understanding of the entire process, from materials to finished products, underscores the importance of advanced pressing equipment.

Key Pressing Technologies for Silicon Carbide

Several pressing technologies are employed in the manufacture of silicon carbide components, each offering distinct advantages depending on the desired geometry, production volume, and specific material characteristics. The selection of the appropriate ceramic pressing technology is a critical decision that affects the green density, homogeneity, and ultimately, the final sintered properties of the SiC part.

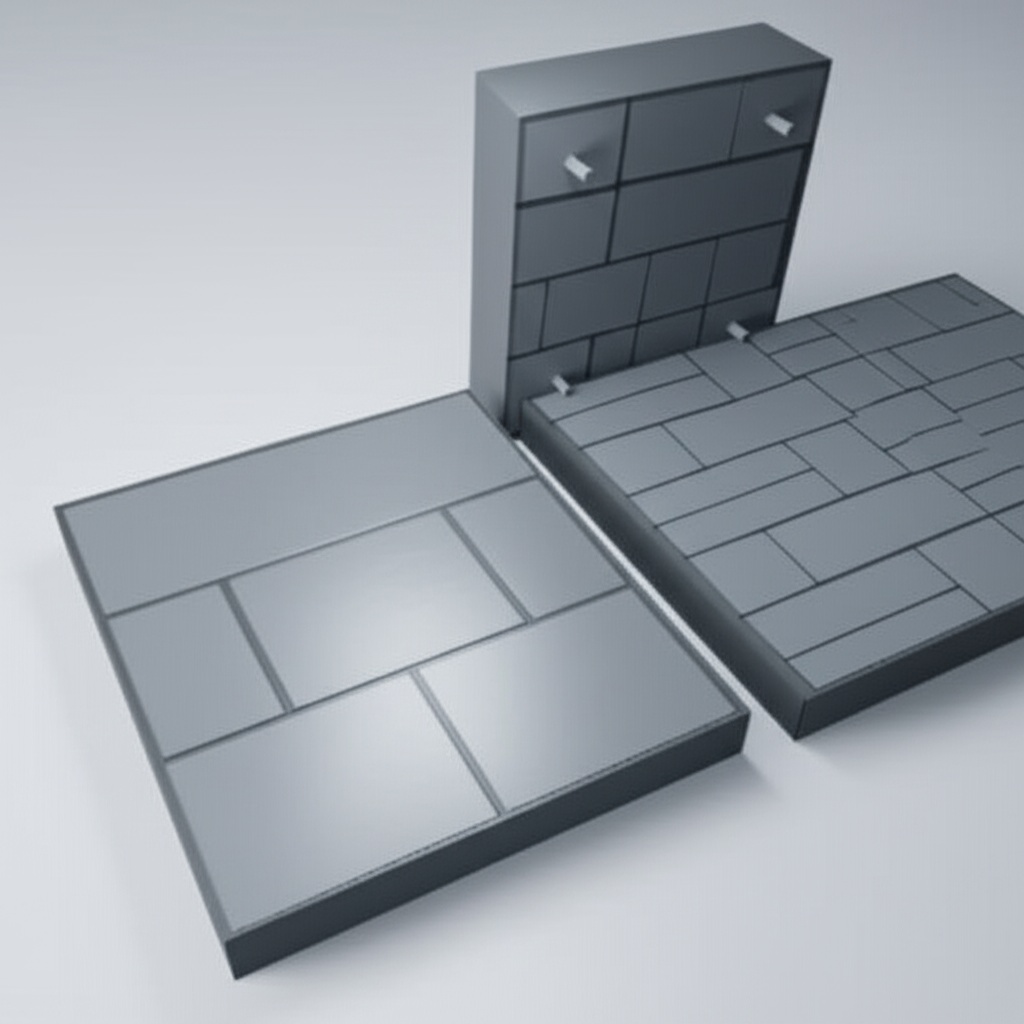

Uniaxial Pressing (Die Pressing): This is a common and cost-effective method where SiC powder is compacted in a rigid die by a uniaxial force applied by one or two punches. It’s well-suited for producing relatively simple shapes in high volumes, such as tiles, discs, and short cylindrical parts.

- Process: Pre-granulated SiC powder is fed into a die cavity and compressed. Binders and plasticizers are often added to the powder to improve flowability and green strength.

- Advantages: High production rates, good dimensional accuracy for simpler shapes, relatively low tooling costs for high volumes.

- Considerations: Density gradients can occur, especially in taller parts, due to frictional forces between the powder and the die walls. Complex shapes are challenging to produce.

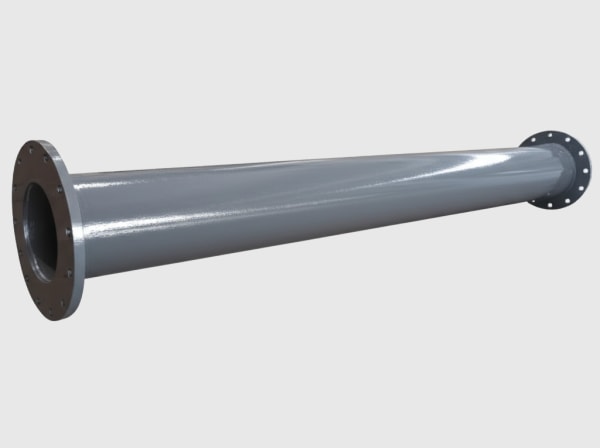

Cold Isostatic Pressing (CIP): In CIP, SiC powder is loaded into a flexible mold, which is then submerged in a fluid and subjected to high isostatic pressure. This uniform pressure from all directions results in a green body with higher and more uniform density compared to uniaxial pressing.

- Process: Powder is placed in a sealed, elastomeric mold. The mold is then placed in a high-pressure chamber filled with a liquid (usually water or oil) and pressurized.

- Advantages: Highly uniform green density, ability to produce complex shapes and large components, reduced internal stresses, and improved microstructure.

- Considerations: Slower cycle times compared to uniaxial pressing, higher initial equipment cost. The dimensional accuracy of the as-pressed part might be lower, requiring more extensive green machining.

Hot Pressing (HP): Hot pressing combines the simultaneous application of heat and pressure (typically uniaxial). The elevated temperature facilitates plastic deformation and diffusion, leading to highly dense SiC components, often with fine grain structures. This method is commonly used for producing simple shapes requiring maximum density and mechanical properties, such as armor plates or high-performance wear parts.

- Process: SiC powder (often with sintering aids) is loaded into a die (usually graphite) and heated to high temperatures (e.g., 1800∘C−2200∘C) while pressure is applied.

- Advantages: Achieves near-theoretical densities, enhances mechanical properties, can consolidate powders that are difficult to sinter by other means.

- Considerations: Limited to relatively simple shapes, slow cycle times, high equipment and operational costs, die material limitations at very high temperatures.

Hot Isostatic Pressing (HIP): HIP involves applying both high temperature and high isostatic gas pressure (typically argon) to components. It can be used to densify pre-sintered (or “canned”) SiC parts to eliminate residual porosity or to consolidate SiC powders encapsulated in a gas-tight container.

- Process: For densification, parts are often pre-sintered to a closed porosity state. For powder consolidation, SiC powder is sealed in a metallic or glass container, which deforms under pressure at high temperature.

- Advantages: Achieves full densification, heals internal defects, produces components with exceptional mechanical properties and isotropic microstructures. Suitable for complex shapes.

- Considerations: Very high equipment cost, complex process, often used as a post-densification step for critical applications.

The choice among these SiC forming equipment types depends heavily on the desired end-product characteristics and economic factors. Sicarb Tech leverages its extensive expertise, backed by the scientific capabilities of the Chinese Academy of Sciences , to guide clients in selecting the optimal processing routes, which inherently includes the most suitable pressing technology for their custom SiC components.

| Pressing Technology | Complexity of Shapes | Green Density | Production Rate | Equipment Cost | Typical Applications |

|---|---|---|---|---|---|

| Uniaxial Pressing | Low to Medium | Moderate | High | Low to Medium | Tiles, discs, simple wear parts |

| Cold Isostatic Pressing | High | High | Medium | Medium | Tubes, rods, complex preforms, larger components |

| Hot Pressing | Low | Very High | Low | High | Armor, sputtering targets, high-density wear parts |

| Hot Isostatic Pressing | High | Very High | Low | Very High | Critical aerospace components, medical implants |

Advantages of Utilizing Advanced SiC Pressing Equipment

Investing in or utilizing services that employ advanced silicon carbide pressing equipment brings a multitude of benefits, directly translating to superior component quality and operational efficiencies. These advantages are critical for wholesale buyers, technical procurement professionals, OEMs, and distributors who demand consistent, high-performance technical ceramics.

- Improved Density and Uniformity: Advanced presses, particularly isostatic and hot pressing units, achieve higher and more uniform green and final densities. This minimizes porosity, a common source of mechanical failure, leading to enhanced strength, hardness, and wear resistance in the final SiC product. Uniform density also ensures consistent performance across the entire component.

- Capability for Complex Geometries: Modern CIP and HIP equipment, coupled with sophisticated mold design, allow for the production of intricate and near-net-shape SiC components. This reduces the need for extensive and costly post-press machining, saving time and material.

- Reduced Defects and Enhanced Reliability: Precise control over pressing parameters (pressure, temperature, dwell times) offered by advanced equipment minimizes common defects such as cracks, laminations, or warping. This leads to higher yields and more reliable components in demanding applications like semiconductor processing equipment or high-temperature furnace components.

- Enhanced Mechanical Properties: The ability to achieve higher densities and fine-grained microstructures through processes like hot pressing or HIP results in SiC components with superior mechanical properties. This includes increased flexural strength, fracture toughness, and hardness, crucial for applications in aerospace components and industrial wear parts.

- Better Material Utilization: Near-net-shape forming capabilities reduce material wastage associated with extensive machining. This is particularly important for SiC, as it is a relatively expensive and hard-to-machine material.

- Increased Throughput and Automation: Modern pressing equipment often incorporates automation features for powder filling, part ejection, and process control. This not only increases throughput but also improves consistency and reduces reliance on manual labor, contributing to overall cost-effectiveness for industrial manufacturing.

The selection of pressing equipment is not just about the hardware; it’s about the integrated system of controls, tooling, and process knowledge. Sicarb Tech, situated in Weifang City, the hub of China’s SiC customizable parts manufacturing with over 40 enterprises, has been instrumental in helping local businesses achieve large-scale production and technological advancements. Our access to the robust scientific and technological capabilities of the Chinese Academy of Sciences ensures that our clients benefit from state-of-the-art process understanding, leading to higher-quality, cost-competitive custom SiC components.

Essential Features and Specifications of SiC Pressing Equipment

When selecting or specifying industrial ceramic presses for silicon carbide, engineers and procurement managers must consider several key features and specifications. These parameters determine the equipment’s capabilities, versatility, and suitability for producing specific SiC components.

Key Equipment Specifications:

- Pressure Capability and Control:

- Maximum Pressure: The press must be able to achieve the pressures required for compacting SiC powders to the desired green density. This varies significantly between uniaxial (e.g., 30-200 MPa), CIP (e.g., 100-600 MPa), and HIP (e.g., 100-300 MPa for gas pressure).

- Pressure Control System: Precise and programmable pressure ramping, holding, and release are crucial for preventing defects and ensuring consistency. Modern systems offer sophisticated PLC or computer-based controls.

- Temperature Capabilities (for Hot Pressing/HIP):

- Maximum Temperature: For HP and HIP, the equipment must reach temperatures sufficient for sintering or densification (often 1800∘C−2400∘C for SiC).

- Heating Elements and Insulation: Materials like graphite or tungsten are common for heating elements, and robust insulation is needed to maintain temperature uniformity and efficiency.

- Temperature Control and Uniformity: Precise temperature control (±5∘C or better) and uniform temperature distribution within the hot zone are vital for consistent sintering.

- Working Area and Chamber Size:

- Platen Size (Uniaxial/Hot Pressing): Dictates the maximum footprint of the component that can be pressed.

- Chamber Dimensions (CIP/HIP): Determines the maximum size and quantity of parts that can be processed per cycle.

- Tooling and Die Design:

- Die Materials: For uniaxial and hot pressing, die materials (e.g., hardened steel, tungsten carbide, graphite) must withstand the applied pressures and temperatures.

- Mold Materials (CIP): Flexible molds are typically made from polyurethane, rubber, or silicone.

- Compatibility and Quick Changeovers: Efficient tooling design and systems for quick die/mold changes can significantly impact productivity.

- Control Systems and Automation:

- PLC/Computer Control: Modern presses feature advanced control systems for programming and monitoring all critical process parameters (pressure, temperature, time, atmosphere).

- Data Logging and Recipe Management: Essential for quality control, process repeatability, and R&D.

- Automation Options: Automated powder filling, part handling, and integration with upstream/downstream processes can enhance efficiency and reduce labor costs.

- Atmosphere Control (for Hot Pressing/HIP):

- The ability to operate under vacuum or controlled atmospheres (e.g., argon, nitrogen) is necessary to prevent oxidation and control reactions during high-temperature processing.

- Safety Features:

- Over-pressure and over-temperature protection, interlocks, emergency stops, and proper guarding are mandatory for operator safety and equipment protection.

- Construction and Durability:

- Robust frame construction, high-quality hydraulic or mechanical systems, and durable chamber materials ensure long service life and reliable operation.

Understanding these specifications is paramount when investing in SiC manufacturing equipment or when discussing component production with a supplier. At Sicarb Tech, our deep familiarity with the entire SiC production chain, from raw materials to finished parts, allows us to appreciate the critical role of each equipment parameter. We assist our clients not only in sourcing custom components but also in understanding the technological underpinnings, drawing from our unique position within the Chinese Academy of Sciences (Weifang) Innovation Park and our collaboration with the National Technology Transfer Center of Chinese Academy of Sciences.

| Feature/Specification | Importance for SiC Pressing | Considerations for Selection |

|---|---|---|

| Max. Pressure & Control | Achieves target density, prevents defects | Match to SiC grade and part complexity; precision of control system |

| Temperature Capability & Control | Essential for sintering (HP/HIP), influences microstructure | Required temperature range, heating/cooling rates, uniformity |

| Working Area/Chamber Size | Determines max part size and throughput | Current and future production needs; compatibility with handling systems |

| Tooling System & Die Material | Impacts part quality, tool life, and operational cost | Complexity of shapes, wear resistance of die material, ease of setup and maintenance |

| Control System & Automation | Ensures repeatability, quality control, operational efficiency | Level of automation needed, data logging capabilities, user-friendliness of interface |

| Atmosphere Control | Prevents oxidation, controls reactions during hot pressing/HIP | Type of SiC material, specific process requirements (vacuum, inert gas) |

| Safety Features | Protects operators and equipment | Compliance with safety standards, fail-safe mechanisms, emergency protocols |

| Construction & Durability | Ensures long-term reliability and ROI | Quality of materials and components, manufacturer reputation, maintenance requirements |

Optimizing the Pressing Process for Superior SiC Components

Owning state-of-the-art silicon carbide pressing equipment is only part of the equation for producing high-quality SiC components. Optimizing the pressing process itself is equally, if not more, critical. This involves a deep understanding of material science, process parameters, and their interactions. Key aspects of process optimization include:

SiC Powder Preparation: The characteristics of the starting SiC powder significantly influence the pressing and sintering behavior.

- Particle Size and Distribution: Finer, well-controlled particle sizes generally lead to better sinterability and higher final densities. A tailored particle size distribution can improve packing density.

- Purity: High purity is essential for many applications, especially in semiconductors. Impurities can affect electrical, thermal, and mechanical properties.

- Morphology: The shape of the powder particles can influence flowability and compaction behavior.

- Additives: Sintering aids (e.g., boron, carbon, alumina, yttria) are often added to promote densification, especially for pressureless sintering or lower-temperature hot pressing. Binders and lubricants are used in uniaxial pressing to improve green strength and reduce die wall friction. The selection and homogeneous distribution of these additives are critical.

Die/Mold Design and Material: For uniaxial and hot pressing, the die design is crucial.

- Clearances: Proper clearances between the punch and die are necessary to allow air to escape and prevent jamming.

- Tapers: Slight tapers in the die cavity can facilitate part ejection.

- Surface Finish: A smooth die surface reduces friction and improves the surface finish of the green part.

- Material: As mentioned, die materials must withstand the process conditions. For CIP, the flexible mold material and design must ensure uniform pressure transmission and accurate part replication.

Pressing Parameters: The precise control of pressing parameters is fundamental.

- Pressure Magnitude and Rate: The applied pressure must be sufficient to achieve the desired green density without causing defects like cracking or lamination. The rate of pressure application and release can also be critical.

- Dwell Time: Holding the pressure for a specific duration allows for particle rearrangement and air expulsion, leading to better compaction.

- Temperature Profile (for HP/HIP): The heating rate, soaking temperature, soaking time, and cooling rate must be carefully controlled to achieve desired densification and microstructure, and to avoid thermal shock.

- Atmosphere: Maintaining the correct atmosphere (vacuum, inert gas) prevents unwanted reactions at elevated temperatures.

Green Body Handling and Machining: After pressing, the “green” SiC compact is often fragile.

- Careful handling is required to prevent damage.

- Green machining (machining the component before final sintering) can be performed to create complex features or improve dimensional accuracy. This is often easier and less costly than machining fully sintered SiC, which is extremely hard.

Process Monitoring and Control: Implementing in-process monitoring and feedback control systems can help ensure consistency and detect potential issues early. This includes monitoring pressure, temperature, displacement, and atmosphere.

Sicarb Tech, with its domestic top-tier professional team specializing in customized SiC production, excels in optimizing these pressing processes. Having supported over 10 local enterprises in Weifang with our technologies, we possess a comprehensive understanding of material, process, design, measurement, and evaluation technologies. This integrated approach, from materials to products, allows us to meet diverse customization needs and produce higher-quality, cost-competitive components. Our expertise ensures that the pressing stage is finely tuned to the specific SiC grade and the end-application requirements.

Maintenance and Longevity of Silicon Carbide Pressing Equipment

Ensuring the long-term performance and reliability of SiC pressing equipment hinges on a robust maintenance program and an understanding of common wear components. Downtime in manufacturing can be costly, so proactive maintenance is key to maximizing the return on investment for these sophisticated machines.

Routine Maintenance Schedule: A preventative maintenance schedule should be established based on the manufacturer’s recommendations and operational experience. This typically includes:

- Daily Checks: Visual inspection for leaks (hydraulic oil, water, vacuum), checking safety interlocks, ensuring cleanliness around the press.

- Weekly Checks: Lubrication of moving parts, inspection of hydraulic hoses and connections, checking pressure and temperature sensor calibrations, inspecting die/mold condition.

- Monthly Checks: More thorough inspection of hydraulic systems (oil level, filter condition), electrical connections, heating elements (for HP/HIP), vacuum pump performance, and alignment of press components.

- Annual Checks/Overhauls: Comprehensive inspection by qualified technicians, replacement of key wear parts, major system calibrations, and software updates if applicable.

Common Wear Parts and Considerations:

- Dies and Punches (Uniaxial/Hot Pressing): These are subject to high stresses and abrasive wear from SiC powders. Regular inspection for wear, cracks, or deformation is crucial. Lifespan depends on material, design, and pressing parameters. Having spare sets is advisable.

- Flexible Molds (CIP): Elastomeric molds can degrade over time due to repeated flexing and exposure to pressurizing fluids. Inspection for tears, punctures, or loss of elasticity is important.

- Heating Elements and Thermocouples (HP/HIP): Graphite heating elements can oxidize or degrade, especially if vacuum integrity is compromised. Thermocouples can drift or fail, requiring recalibration or replacement.

- Seals and Gaskets: Critical for maintaining pressure in hydraulic systems and vacuum/atmosphere integrity in chambers. These can wear out and require periodic replacement.

- Hydraulic System Components: Pumps, valves, and hoses can wear over time. Regular oil analysis can help detect early signs of wear in the hydraulic system. Filters must be replaced regularly.

- Pressure Vessels (CIP/HIP): While designed for long life, pressure vessels require periodic inspection and certification according to safety regulations to ensure their integrity.

Troubleshooting Common Issues:

- Inconsistent Density: Could be due to issues with powder fill, pressure control, worn tooling, or temperature non-uniformity (in HP/HIP).

- Cracking or Lamination: May result from too rapid pressure application/release, entrapped air, incorrect binder burnout, or excessive pressure.

- Sticking/Ejection Problems: Often related to die surface finish, insufficient draft angles, or worn tooling.

- Vacuum/Pressure Leaks: Can affect product quality (oxidation in HP/HIP) or system performance. Regular leak detection is important.

Importance of Robust Equipment: Investing in high-quality, robustly built pressing equipment from reputable manufacturers generally leads to lower maintenance costs and longer operational life. The initial investment may be higher, but this is often offset by reduced downtime and fewer part failures.

For companies looking to establish their own SiC production, understanding equipment maintenance is vital. Sicarb Tech not only provides custom SiC components but also offers technology transfer for professional silicon carbide production. This includes comprehensive support, from factory design and procurement of specialized equipment (including pressing systems) to installation, commissioning, and trial production. Our turnkey project services ensure that clients receive not just the equipment but also the knowledge to operate and maintain it effectively, guaranteeing a more reliable investment and input-output ratio.

Choosing the Right Supplier for SiC Pressing Equipment and Expertise

Selecting the right supplier for silicon carbide pressing equipment or for custom SiC components manufactured using such equipment is a critical decision that impacts quality, reliability, cost, and technical support. Whether you are an OEM, a distributor, or a technical buyer, the choice of partner can significantly influence your success.

Key Factors to Evaluate in a Supplier:

- Technical Capabilities and Expertise:

- Understanding of SiC Materials: The supplier should have a deep knowledge of different SiC grades (RBSiC, SSiC, SiSiC, etc.) and their specific processing requirements.

- Process Know-How: Expertise in various pressing techniques (uniaxial, CIP, HP, HIP) and the ability to recommend the optimal method for your application.

- Engineering Support: Availability of engineers to assist with component design, material selection, and process optimization. Look for suppliers who offer design for manufacturability (DfM) services.

- Equipment Quality and Technology:

- Modern and Well-Maintained Equipment: If sourcing components, ensure the supplier uses advanced, well-maintained presses capable of meeting your specifications.

- Range of Equipment: A supplier with access to different types of pressing equipment can offer more versatile solutions.

- Control and Automation: Sophisticated process control leads to higher consistency and quality.

- Quality Management Systems:

- Certifications: Look for certifications like ISO 9001, which indicate a commitment to quality management.

- Traceability and Documentation: The ability to trace materials and process parameters, along with comprehensive quality documentation, is crucial, especially for critical applications.

- Inspection and Testing Capabilities: In-house capabilities for testing density, porosity, strength, dimensional accuracy, and other relevant properties.

- Customization Capabilities:

- The ability to produce custom shapes, sizes, and formulations to meet specific application needs. This includes expertise in tooling design and manufacturing.

- Experience and Reputation:

- Track Record: A proven history of successfully delivering high-quality SiC components or equipment.

- Case Studies and References: Evidence of their work in your industry or similar applications.

- Industry Standing: Reputation among peers and clients.

- Supply Chain and Reliability:

- Consistent Material Sourcing: Reliable access to high-quality SiC powders.

- Lead Times and On-Time Delivery: Ability to meet your production schedules.

- Capacity: Sufficient production capacity to handle your volume requirements.

- Cost-Effectiveness:

- While not the sole factor, competitive pricing is important. However, it should be balanced against quality, reliability, and technical support.

- Location and Support (especially for equipment purchase or technology transfer):

- After-Sales Service: Availability of technical support, spare parts, and maintenance services.

- Training: For equipment purchases, comprehensive training for operators and maintenance staff is essential.

Why Sicarb Tech Stands Out:

Sicarb Tech is uniquely positioned as a premier partner for custom SiC products and technology transfer. Our foundation in Weifang City, the epicenter of China’s SiC industry, provides us with unparalleled access to a mature supply chain and a deep pool of manufacturing expertise.

- Backed by Chinese Academy of Sciences: Our affiliation with the Chinese Academy of Sciences (Weifang) Innovation Park and the National Technology Transfer Center of the Chinese Academy of Sciences grants us access to leading-edge scientific research, a formidable talent pool, and a robust framework for technology commercialization. This ensures our processes and products are at the forefront of SiC technology.

- Proven Expertise: Since 2015, we have been pivotal in enhancing the production technologies of local SiC enterprises. Our team possesses top-tier professional expertise in all aspects of custom SiC production, from material science to final product evaluation.

- Comprehensive Solutions: We offer not just custom SiC components but also a full spectrum of services, including technology transfer for establishing your own specialized SiC factory. This turnkey solution covers factory design, specialized equipment procurement (including SiC pressing equipment), installation, commissioning, and trial production.

- Quality and Cost-Effectiveness: Our integrated process knowledge and access to the Weifang SiC cluster enable us to offer higher-quality, cost-competitive customized silicon carbide components within China and globally.

Choosing a supplier like Sicarb Tech means partnering with an organization that offers reliable quality, robust supply assurance, and a commitment to technological excellence, making us a trusted choice for businesses seeking high-performance SiC solutions.

| Supplier Evaluation Factor | Key Questions to Ask | Why It Matters for SiC Pressing Equipment/Components |

|---|---|---|

| Technical Expertise | What is your experience with [specific SiC grade/application]? Can you assist with design? | Ensures correct material selection and process for optimal performance. |

| Equipment & Technology | What types of pressing equipment do you operate/offer? What are their capabilities? | Determines the complexity, precision, and quality of parts that can be produced. |

| Quality Management | Are you ISO certified? What are your quality control procedures? | Guarantees consistent product quality and reliability. |

| Customization | Can you produce parts to our exact specifications? What are your tooling capabilities? | Essential for unique or demanding applications requiring non-standard components. |

| Experience & Reputation | Can you provide case studies or references relevant to our industry? | Indicates reliability and a proven ability to deliver. |

| Supply Chain & Lead Time | What are your typical lead times? How do you ensure on-time delivery? | Critical for maintaining production schedules and managing inventory. |

| Cost & Value | What is your pricing structure? What value-added services do you offer? | Balances budget constraints with the need for quality and support. |

| Support & Technology Transfer | What after-sales support is available? Do you offer training or technology transfer? | Crucial for long-term success, especially when investing in new equipment or processes. |

Frequently Asked Questions (FAQ)

What are the primary types of silicon carbide pressing equipment used in industrial manufacturing? The primary types include uniaxial presses (die presses), Cold Isostatic Presses (CIP), Hot Presses (HP), and Hot Isostatic Presses (HIP). Uniaxial presses are used for high-volume, simpler shapes. CIP systems are excellent for complex shapes and uniform density. Hot presses and HIP systems are employed when near-theoretical density and superior mechanical properties are required, often for high-performance applications. The choice depends on the SiC grade, desired component complexity, density requirements, and production volume.

How does the choice of pressing equipment affect the final properties of a custom SiC component? The pressing equipment and technique significantly influence the green density, density uniformity, and microstructure of the SiC component before sintering. Higher, more uniform green density, typically achieved with advanced methods like CIP or HIP, leads to less shrinkage during sintering, reduced porosity, and consequently, enhanced final properties such as mechanical strength, hardness, thermal conductivity, and wear resistance. For instance, components made using hot isostatic pressing (HIP) SiC techniques will generally exhibit superior performance characteristics compared to those made by basic uniaxial pressing, due to higher achieved densities and more homogeneous microstructures.

What should I consider when looking for a supplier of custom SiC components that utilizes advanced pressing equipment, or if I am considering setting up my own SiC pressing line? When sourcing custom SiC components, look for a supplier with proven expertise in the specific pressing technologies relevant to your needs, strong quality control systems (e.g., ISO certification), and the ability to handle your required component complexity and volume. Ensure they have experience with your desired SiC grade (e.g., reaction-bonded SiC, sintered SiC). If you are considering setting up your own pressing line, partnering with a knowledgeable technology provider is crucial. Sicarb Tech, for example, offers comprehensive technology transfer services. This includes assisting with the selection and procurement of appropriate SiC pressing equipment, factory design, installation, commissioning, and training. Their location in Weifang, the hub of China’s SiC production, and their backing by the Chinese Academy of Sciences, provide a unique advantage in delivering reliable and advanced manufacturing solutions. Key considerations include the type of SiC products you intend to make, required throughput, available budget for industrial presses for ceramics, and the level of technical support and training provided by the equipment vendor or technology partner.

Conclusion: Pressing Forward with Excellence in SiC Manufacturing

The journey to high-performance silicon carbide components is paved with precision, and at the heart of this precision lies the silicon carbide pressing equipment. From uniaxial presses for high-volume simplicity to advanced Hot Isostatic Presses for ultimate density and complexity, the choice of forming technology profoundly impacts the final product’s integrity and performance. For engineers, procurement managers, and technical buyers, a thorough understanding of these pressing technologies, their advantages, and the critical features of the equipment is paramount for making informed decisions that drive success in demanding industrial environments.

As industries continue to push the boundaries of performance, the demand for meticulously engineered SiC components will only grow. Partnering with a knowledgeable and capable supplier or technology provider is therefore essential. Sicarb Tech, with its deep roots in Weifang – China’s SiC manufacturing heartland – and its strong affiliation with the Chinese Academy of Sciences, stands ready to support your needs. Whether you require high-quality custom SiC components manufactured using state-of-the-art pressing techniques or seek to establish your own specialized SiC production facility through our comprehensive technology transfer programs, SicSino offers a unique blend of expertise, quality assurance, and innovative solutions. By leveraging advanced SiC pressing equipment and processes, we help our clients unlock the full potential of silicon carbide, ensuring components that deliver reliability and excellence in the most challenging applications. Sources and related content

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.