Silicon Carbide Pellets: The High-Performance Solution for Demanding Industrial Applications

Share

In the ever-evolving landscape of industrial materials, the quest for components that can withstand extreme conditions while delivering unparalleled performance is perpetual. Among the frontrunners in this domain is silicon carbide (SiC), a synthetic compound renowned for its exceptional hardness, thermal conductivity, and resistance to wear and corrosion. While SiC is utilized in various forms, silicon carbide pellets are emerging as indispensable assets across a multitude of high-performance industrial applications. These small but mighty components are engineered to meet specific operational demands, making them crucial for industries ranging from semiconductor manufacturing to high-temperature energy production.

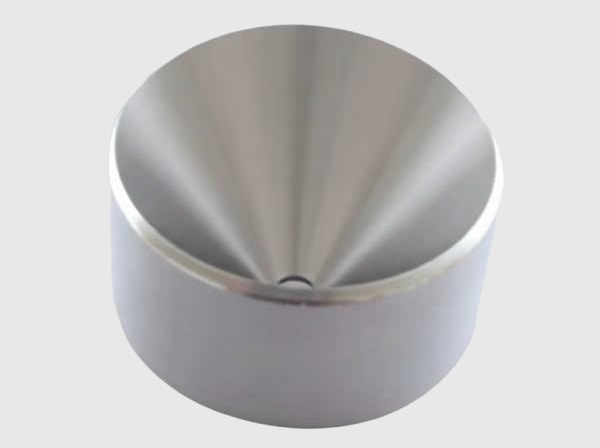

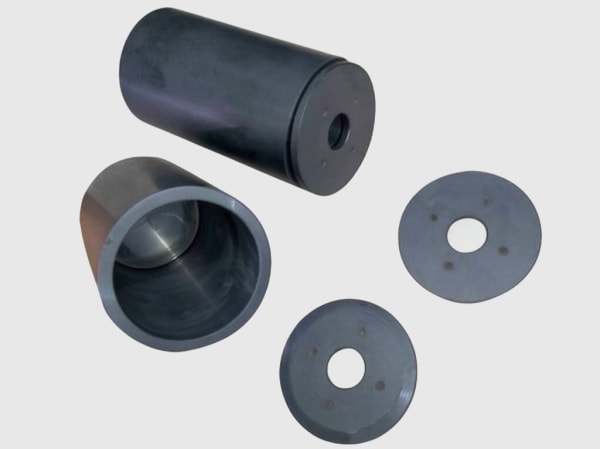

Silicon carbide pellets, often custom-manufactured to precise specifications, are not just generic ceramic pieces. They are highly engineered materials, typically produced from SiC powders that are formed into desired shapes (spherical, cylindrical, or custom geometries) and then sintered or bonded to achieve their final robust properties. Their essential role stems from their ability to perform reliably in environments where other materials falter, offering longevity and efficiency. The need for custom SiC pellets is driven by the unique requirements of advanced industrial processes, where off-the-shelf solutions often fall short. Engineers and procurement managers in technical fields recognize that tailoring the size, shape, porosity, and purity of SiC pellets can significantly impact process efficiency, product quality, and operational costs. As industries push the boundaries of temperature, pressure, and chemical exposure, the demand for these specialized technical ceramic pellets continues to grow, highlighting their critical importance in modern manufacturing and technology.

Diverse Industrial Applications: Where SiC Pellets Make a Difference

The versatility and robust nature of silicon carbide pellets allow them to be deployed in a wide array of demanding industrial sectors. Their unique combination of properties makes them ideal for applications where extreme temperatures, abrasive conditions, and chemical attacks are common. Technical buyers and OEMs are increasingly specifying industrial SiC pellets to enhance the performance and longevity of their equipment and processes.

Here’s a look at some key industries and applications:

- High-Temperature Furnaces and Kiln Furniture:

- Support Media: SiC pellets are used as support elements in industrial furnaces due to their excellent high-temperature strength and thermal shock resistance. They maintain their structural integrity even at temperatures exceeding 1500∘C.

- Heat Exchange Media: Their high thermal conductivity makes them efficient heat transfer media in regenerative thermal oxidizers (RTOs) and other heat recovery systems, contributing to energy savings.

- Semiconductor Processing:

- Wafer Processing Equipment: Components made from or incorporating high-purity SiC pellets are used in etching, deposition, and thermal processing stages due to their chemical inertness, thermal stability, and ability to prevent contamination. Custom silicon carbide parts, including pellets, are critical here.

- Gas Distribution: Porous SiC pellets can be used in gas diffuser systems to ensure uniform gas flow in critical semiconductor manufacturing steps.

- Chemical and Petrochemical Industries:

- Catalyst Supports: The high surface area, thermal stability, and chemical resistance of SiC pellets make them excellent candidates for catalyst carriers in harsh chemical reactors. They can improve reaction efficiency and catalyst life.

- Packing Material in Columns: In distillation and absorption towers, SiC pellets serve as durable and inert packing materials, offering better performance than traditional ceramic or metal packings in corrosive environments.

- Wear-Resistant Applications:

- Grinding and Milling Media: Due to their extreme hardness (second only to diamond on the Mohs scale), SiC pellets are used as grinding media for milling tough materials, reducing contamination compared to other media.

- Nozzles and Flow Control: Components incorporating SiC pellets or made from SiC can be used in abrasive fluid handling systems, such as shot blasting nozzles or flow restrictors, due to their exceptional wear resistance.

- Energy Production and Storage:

- Nuclear Applications: Radiation resistance and thermal stability make SiC a material of interest for components within nuclear reactors, including as potential inert matrix fuel pellets.

- Advanced Battery Systems: Research is ongoing into using SiC in various forms, including potentially as stabilizing elements or thermal management components in high-energy-density batteries.

- Aerospace and Defense:

- Lightweight Armor: While not pellets in the traditional sense for this application, SiC is a key material for ceramic armor plates due to its hardness and low density. The principles of SiC material science are shared.

- High-Temperature Components: Parts for engines or exhaust systems exposed to extreme temperatures can benefit from SiC’s properties.

The demand for wholesale SiC pellets is driven by these diverse applications, where consistent quality and performance are paramount. Companies like Sicarb Tech, with their deep understanding of SiC technology and access to the Weifang SiC manufacturing hub, are pivotal in supplying these critical components.

| Industry | Application of SiC Pellets | Key SiC Properties Utilized |

|---|---|---|

| Metallurgy | Furnace supports, Heat exchangers (RTOs) | High-temperature strength, Thermal conductivity |

| Semiconductor | Wafer handling components, Gas diffusers | High purity, Chemical inertness, Thermal stability |

| Chemical Processing | Catalyst supports, Tower packing | Chemical resistance, Thermal stability, Surface area |

| Abrasives/Mining | Grinding media, Wear-resistant linings | Extreme hardness, Wear resistance |

| Energy | Nuclear components, Thermal management | Radiation resistance, High thermal conductivity |

| Industrial Equipment | Nozzles, Seals, Bearings | Wear resistance, Low friction, High stiffness |

The broad applicability of silicon carbide pellets underscores their significance as an advanced ceramic material capable of meeting the rigorous demands of modern industry.

The Compelling Advantages of Custom Silicon Carbide Pellets

Choosing silicon carbide pellets for industrial applications brings a host of inherent material advantages. However, the ability to customize these pellets elevates their value proposition significantly, allowing engineers and procurement professionals to specify components that are precisely tailored to their unique operational contexts. This customization ensures optimal performance, extended service life, and often, reduced overall lifecycle costs.

The primary benefits of using SiC pellets, particularly custom SiC pellets, include:

- Exceptional Thermal Resistance and Stability:

- Silicon carbide exhibits excellent thermal conductivity, allowing for efficient heat dissipation or transfer, depending on the application (e.g., heat sinks or heat exchange media).

- It maintains its mechanical strength and structural integrity at very high temperatures (often up to 1400−1650∘C or higher for specific grades like SSiC or R-SiC).

- Low thermal expansion coefficient, which provides excellent thermal shock resistance, preventing cracking or failure during rapid temperature changes. This is critical for high-temperature furnace components.

- Superior Wear and Abrasion Resistance:

- With a Mohs hardness of around 9.0-9.5, SiC is one of the hardest commercially available materials. This makes SiC abrasive media highly effective and durable.

- This hardness translates to outstanding resistance against sliding wear, erosion, and abrasion, making SiC pellets ideal for grinding media, nozzles, and components handling abrasive slurries.

- Excellent Chemical Inertness and Corrosion Resistance:

- Silicon carbide is highly resistant to a wide range of acids, alkalis, and molten salts, even at elevated temperatures.

- This chemical inertness ensures longevity and prevents contamination in corrosive environments, such as in chemical reactors or when handling aggressive fluids. This is a key factor for technical ceramics in the chemical industry.

- High Mechanical Strength and Stiffness:

- SiC possesses high compressive and flexural strength, allowing pellets to withstand significant mechanical loads.

- Its high Young’s modulus (stiffness) means it deforms very little under load, contributing to dimensional stability in precision applications.

- Customization Potential:

- Tailored Geometries and Sizes: Pellets can be manufactured in various shapes (spheres, cylinders, rings, custom profiles) and sizes, from micro-pellets to larger forms, to optimize packing density, flow characteristics, or surface area.

- Controlled Porosity: The porosity of SiC pellets can be engineered from dense to highly porous, depending on the need for filtration, catalyst support, or gas diffusion.

- Purity Levels: For sensitive applications like semiconductor processing, high-purity SiC (e.g., >99.5%) can be specified to minimize contamination.

- Surface Characteristics: While typically not a primary focus for bulk pellets, specific surface roughness or treatments can be considered for specialized applications.

Why Customization Matters for B2B Buyers:

- Optimized Performance: Custom pellets ensure that the material properties are perfectly aligned with the application’s demands, leading to better efficiency.

- Increased Service Life: Components designed for specific stress, temperature, and chemical environments last longer, reducing downtime and replacement costs.

- Cost-Effectiveness: While custom parts may have a higher upfront unit cost, the extended lifespan and improved process efficiency often result in a lower total cost of ownership.

- Problem Solving: Customization allows for the development of SiC pellets that solve specific challenges traditional materials cannot address.

Working with a knowledgeable supplier like Sicarb Tech allows businesses to leverage these advantages fully. SicSino’s expertise in material science and its connection to the vast manufacturing capabilities in Weifang ensure that custom silicon carbide pellets can be designed and produced to meet the most stringent industrial requirements.

Navigating SiC Grades and Compositions for Optimal Pellet Performance

Silicon carbide is not a monolithic material; it encompasses several grades and compositions, each offering a distinct set of properties tailored for specific applications. When selecting SiC pellets, understanding these differences is crucial for engineers and technical buyers to ensure optimal performance, longevity, and cost-effectiveness. The manufacturing process and the additives (or lack thereof) significantly influence the final characteristics of the SiC pellets.

Here are some common SiC grades and their relevance to pellet applications:

- Reaction-Bonded Silicon Carbide (RBSiC or SiSiC – Silicon Infiltrated Silicon Carbide):

- Manufacturing: Produced by infiltrating a porous preform of SiC grains and carbon with molten silicon. The silicon reacts with the carbon to form additional SiC, which bonds the initial grains. Typically contains 8-15% free silicon.

- Properties: Good mechanical strength, excellent wear and oxidation resistance, high thermal conductivity, and good thermal shock resistance. Relatively easier to produce complex shapes with tight tolerances. Operates up to ≈1350−1380∘C due to the melting point of free silicon.

- Pellet Applications: Ideal for wear-resistant components, kiln furniture, nozzles, and applications requiring good thermal performance where extreme purity is not the primary concern. RBSiC pellets are a common choice for robust industrial parts.

- Sicarb Tech supports the production of various RBSiC components, leveraging the extensive manufacturing base in Weifang.

- Sintered Silicon Carbide (SSiC):

- Manufacturing: Made from fine, high-purity SiC powder mixed with non-oxide sintering aids (like boron and carbon). It is then formed and sintered at very high temperatures (typically >2000∘C) in an inert atmosphere, resulting in a dense, single-phase SiC material.

- Properties: Highest purity (typically >99%), excellent chemical resistance (especially against strong acids and bases), superior high-temperature strength (up to 1600−1750∘C), high hardness, and good wear resistance.

- Pellet Applications: Preferred for applications demanding extreme corrosion resistance, high purity (e.g., semiconductor processing equipment components), high-temperature mechanical parts, and advanced catalyst supports. High-purity SSiC pellets are sought after in advanced technology sectors.

- Nitride-Bonded Silicon Carbide (NBSiC):

- Manufacturing: SiC grains are bonded by a silicon nitride (Si3N4) phase. This is often achieved by firing SiC with an additive that promotes nitridation in a nitrogen-rich atmosphere.

- Properties: Good thermal shock resistance, good mechanical strength, and high resistance to molten non-ferrous metals and corrosive gases. Generally lower cost than SSiC.

- Pellet Applications: Used in applications involving contact with molten metals (e.g., aluminum), kiln furniture for firing ceramics, and components in waste incineration plants.

- Recrystallized Silicon Carbide (R-SiC or O-SiC – Oxide Bonded):

- Manufacturing (R-SiC): High-purity SiC grains are packed and fired at very high temperatures, causing them to bond directly without significant additives. This results in a porous structure if not fully densified.

- Manufacturing (O-SiC): SiC grains are bonded by an oxide phase (e.g., silica or mullite).

- Properties (R-SiC): Excellent thermal shock resistance, high operating temperatures (up to 1650∘C), and good strength. Porosity can be controlled.

- Properties (O-SiC): Good thermal shock resistance, lower cost, but generally lower mechanical properties and chemical resistance compared to other grades.

- Pellet Applications (R-SiC): High-temperature kiln furniture, burner nozzles, heat exchangers where porosity might be beneficial for gas flow or lightweighting. Porous SiC pellets can be made this way.

- Clay-Bonded Silicon Carbide:

- An older, lower-cost type where SiC grains are bonded with clay. Offers moderate properties and is suitable for less demanding applications like some types of kiln furniture or refractories.

Key Considerations for Pellet Selection:

- Operating Temperature: SSiC and R-SiC excel at the highest temperatures.

- Chemical Environment: SSiC offers the best all-around chemical resistance, especially against strong acids and alkalis. RBSiC can be affected by certain aggressive chemicals due to the free silicon.

- Mechanical Stress/Wear: All grades offer good hardness, but SSiC and RBSiC are typically chosen for high-wear applications.

- Thermal Shock: R-SiC and NBSiC are often noted for superior thermal shock resistance due to their microstructure.

- Purity Requirements: SSiC is the go-to for high-purity needs.

- Cost: Generally, clay-bonded and O-SiC are the least expensive, followed by NBSiC, RBSiC, and then SSiC being the most premium.

The choice of SiC grade directly impacts the functionality and lifespan of the pellets. Sicarb Tech, with its extensive knowledge network and connections to specialized producers in Weifang – the hub of China’s silicon carbide customizable parts manufacturing – can assist buyers in selecting or developing the ideal SiC pellet composition for their specific industrial application. This ensures that procurement managers invest in technical ceramic pellets that deliver both performance and value.

| SiC Grade | Key Characteristics | Typical Max. Use Temp. | Relative Cost | Common Pellet Uses |

|---|---|---|---|---|

| RBSiC (SiSiC) | Good strength, wear resistance, thermal conductivity | 1350∘C | Medium | Kiln furniture, wear parts, nozzles |

| SSiC | High purity, excellent chemical & heat resistance | 1750∘C | High | Semiconductor parts, chemical pumps, catalyst beds |

| NBSiC | Good thermal shock, molten metal resistance | 1450∘C | Medium-Low | Non-ferrous metal contact, burner components |

| R-SiC | Excellent thermal shock, high-temp stability, porous | 1650∘C | Medium-High | Kiln furniture, heat exchangers, porous diffusers |

| O-SiC | Good thermal shock, lower strength | 1400∘C | Low | Basic refractories, less demanding kiln furniture |

This table provides a general comparison. Specific properties can vary based on the manufacturer and precise composition. Consulting with experts, such as the team at Sicarb Tech, is recommended for critical applications.

Critical Design and Manufacturing Considerations for SiC Pellets

The production of silicon carbide pellets that meet stringent industrial requirements involves a series of carefully controlled design and manufacturing steps. For B2B buyers, particularly wholesale buyers and OEMs, understanding these considerations is vital for specifying products that perform reliably and can be sourced consistently. Factors ranging from raw material quality to the final sintering process play a role in the characteristics of the end product.

Key Design Considerations:

- Pellet Size and Shape:

- Size: Pellets can range from micro-pellets (sub-millimeter) to several centimeters in diameter. The size influences surface area, packing density, and flow characteristics in applications like reactor beds or heat exchangers.

- Shape: Common shapes include spheres, cylinders, rings, and irregular granules. Custom shapes may be designed for specific functions, such as optimizing contact points or fluid dynamics. Spherical pellets generally offer good flowability and uniform packing.

- Density and Porosity:

- Density: Higher density usually correlates with greater strength and wear resistance.

- Porosity: For applications like catalyst supports, gas diffusers, or filters, controlled porosity (both open and closed) is critical. The pore size distribution and total porous volume must be carefully specified. Porous SiC pellets are a specialized product category.

- Purity of Raw Materials:

- The purity of the initial SiC powder directly impacts the final pellet’s chemical inertness and performance in sensitive applications (e.g., semiconductor). Trace impurities can act as catalysts for unwanted reactions or degrade properties at high temperatures.

- Binder Selection (if applicable):

- Temporary binders are often used to provide green strength during forming. These binders must burn out cleanly during sintering without leaving harmful residues.

- For bonded SiC types (like NBSiC or O-SiC), the bonding agent itself becomes part of the final composition and influences properties.

Key Manufacturing Steps and Considerations:

- Powder Preparation:

- High-quality SiC powder with controlled particle size distribution is the starting point. Milling and classification may be necessary to achieve the desired powder characteristics.

- Additives, such as sintering aids (for SSiC) or temporary binders, are homogeneously mixed with the SiC powder.

- Forming:

- Pressing (Uniaxial or Isostatic): Dry or semi-dry powder is compacted in a die (uniaxial) or a flexible mold under high pressure (isostatic). Suitable for simple shapes and high-volume production.

- Extrusion: A paste-like mixture of SiC powder and binders is forced through a die to produce continuous profiles, which are then cut into pellets (e.g., cylindrical pellets).

- Granulation/Spheronization: Fine powder is agglomerated into larger, often spherical, granules. This can be done through various wet or dry granulation techniques, sometimes followed by spheronization to improve roundness.

- Slip Casting: A SiC slurry is poured into a porous mold, which absorbs the liquid, leaving a solid layer. More common for complex shapes but can be adapted for certain pellet types.

- Drying:

- Formed “green” pellets are carefully dried to remove moisture or solvents from binders before sintering. Controlled drying prevents cracking.

- Sintering/Firing:

- This is the critical heat treatment step where the SiC particles bond together, densifying the pellet and developing its final properties.

- For SSiC: Sintering occurs at very high temperatures (>2000∘C) in a controlled, non-oxidizing atmosphere (e.g., argon).

- For RBSiC: Silicon infiltration and reaction sintering occur at temperatures above the melting point of silicon (≈1414∘C).

- For NBSiC/O-SiC: Firing temperatures and atmospheres are specific to the bonding reactions.

- The sintering cycle (temperature ramp-up, hold time, cool-down) is crucial for achieving desired density, grain size, and phase composition.

- Finishing (if required):

- While many pellets are used as-sintered, some applications may require tumbling to remove sharp edges or light surface grinding for specific dimensional tolerances, although this is less common for bulk pellets.

Considerations for Wholesale Buyers and OEMs:

- Manufacturability: Complex shapes or extremely tight tolerances can increase costs and lead times. Discussing designs with manufacturers like those supported by Sicarb Tech early in the process is beneficial.

- Consistency and Scalability: The chosen manufacturing process must be capable of producing consistent quality at the required volumes.

- Quality Control: Robust QC procedures throughout the manufacturing process are essential, from raw material inspection to final product testing.

Sicarb Tech, with its foundation in the national technology transfer center of the Chinese Academy of Sciences, brings a wealth of knowledge in custom SiC pellet manufacturing. They facilitate access to advanced production technologies and a network of specialized factories in Weifang, ensuring that even complex design requirements for industrial SiC pellets can be met with high quality and reliability. Their understanding of material science and process optimization helps bridge the gap between design intent and a manufacturable, high-performance product.

Achieving Precision: Tolerance, Surface Characteristics, and Purity in SiC Pellets

For engineers and technical procurement professionals, the dimensional accuracy, surface condition, and chemical purity of silicon carbide pellets are often as critical as their bulk material properties. These factors directly influence how pellets perform in precision assemblies, interact with other materials, and maintain process integrity, especially in high-tech fields like semiconductor manufacturing or specialized chemical synthesis. While the term “pellet” might imply a less precise component, in many industrial B2B applications, tight control over these attributes is paramount.

Dimensional Tolerances:

- The achievable dimensional tolerances for SiC pellets depend heavily on the SiC grade, the manufacturing method (pressing, extrusion, granulation), the size of the pellet, and the level of post-sintering finishing.

- As-Sintered Tolerances: Generally, as-sintered SiC components will have wider tolerances due to shrinkage variations during firing. Typical tolerances might range from ±1% to ±5% of the dimension, or even wider for certain processes or larger pellets.

- Ground/Machined Tolerances: For applications requiring higher precision, SiC components can be ground or lapped after sintering. However, this is less common for bulk pellets due to cost, unless they are specific functional parts. If precision is needed, it’s often for larger SiC components rather than commodity pellets. For critical pellet applications where individual pellet dimension is key, tighter tolerances might be achievable at a higher cost.

- Statistical Process Control (SPC): Reputable manufacturers employ SPC to monitor and control dimensional variability, ensuring that batches of pellets meet the specified mean size and distribution. For wholesale buyers, understanding the manufacturer’s capability in terms of Cpk (process capability index) can be important.

Surface Characteristics:

- Surface Roughness (Ra): The as-sintered surface roughness of SiC pellets can vary. For most bulk applications like heat exchange media or general catalyst supports, a standard as-sintered surface is acceptable.

- SSiC typically yields a smoother surface than, for example, some R-SiC variants.

- Surface Finish Options (Less Common for Pellets): While extensive surface finishing like polishing is rare for general-purpose pellets due to cost, some applications might require:

- Tumbling: To remove sharp edges, burrs, or to achieve a more uniform, slightly smoother surface, reducing inter-pellet friction or potential for chipping.

- Washing/Cleaning: To remove any surface contaminants or fines from the manufacturing process.

- Absence of Surface Defects: Critical for performance is the absence of cracks, chips, or large pits that could compromise mechanical integrity or act as initiation sites for failure. Visual inspection and quality control are essential.

Purity of SiC Pellets:

- Bulk Purity: This refers to the overall SiC content and the level of impurities within the pellet material.

- SSiC (Sintered Silicon Carbide): Offers the highest purity, often exceeding 99.5% SiC. This is crucial for semiconductor applications to prevent metallic ion contamination. High-purity SiC pellets are a hallmark of SSiC.

- RBSiC (Reaction-Bonded Silicon Carbide): Contains free silicon (typically 8−15%), which might be undesirable in certain chemical environments or ultra-high vacuum applications.

- Other grades will have varying levels of binders or secondary phases.

- Surface Purity: Even if the bulk material is pure, surface contamination can occur during manufacturing or handling. Specific cleaning protocols may be required for ultra-high purity applications.

- Trace Element Analysis: For demanding applications, suppliers may provide trace element analysis (e.g., by ICP-MS) to certify purity levels. This is a key requirement for technical procurement professionals in industries like electronics or pharmaceuticals (if SiC were used in compatible processes).

Ensuring Quality and Precision:

- Clear Specifications: Buyers must clearly define their requirements for size distribution, mean size, shape, allowable defects, and purity levels.

- Supplier Capability: Engaging with suppliers like Sicarb Tech provides access to manufacturers who understand these precision requirements. SicSino’s connection to the Chinese Academy of Sciences and its role in technology transfer means they are well-versed in the advanced measurement and evaluation technologies necessary to ensure product quality.

- Lot-to-Lot Consistency: A critical aspect for OEMs and large-volume users is the assurance of consistent quality from one batch of pellets to the next. This relies on rigorous process control and quality management systems at the manufacturing level.

The ability to deliver custom silicon carbide pellets that meet precise tolerances, surface characteristics, and purity standards is a key differentiator for suppliers in the advanced ceramics market. This attention to detail ensures that the pellets function optimally and contribute to the overall reliability and efficiency of the end-user’s process or equipment.

| Parameter | Typical Range/Consideration for SiC Pellets | Importance/Impact | Factors Influencing It |

|---|---|---|---|

| Mean Pellet Size | Sub-mm to several cm | Packing density, surface area, flow dynamics, reaction rates | Forming method, classification, shrinkage |

| Size Distribution | Narrow to broad | Uniformity of packing, flow consistency, predictable performance | Granulation process, sieving, pressing consistency |

| Shape | Spheres, cylinders, rings, granules, custom | Packing efficiency, mechanical interlocking, specific functional requirements | Forming method (extrusion, pressing, spheronization) |

| Surface Roughness | Varies by grade and process (e.g., Ra 0.4−5μm) | Fluid flow, catalytic activity (surface area), wear on mating parts (if any) | SiC grade, sintering conditions, post-sintering treatment |

| Purity (SiC %) | SSiC: >99%; RBSiC: 85−92% SiC + free Si | Chemical inertness, high-temperature stability, electrical properties | Raw materials, sintering aids, manufacturing environment |

| Key Impurities | Fe, Al, Ca, heavy metals | Contamination risk in sensitive applications (semiconductors, pharma) | Raw material sources, processing equipment, handling |

Understanding and specifying these parameters accurately allows for the procurement of SiC pellets that are truly fit for purpose, moving beyond a commodity mindset to one focused on engineered material solutions.

Partnering for Excellence: Choosing Your Custom SiC Pellet Supplier

Selecting the right supplier for custom silicon carbide pellets is a critical decision that can significantly impact the quality, reliability, and cost-effectiveness of your industrial processes. The ideal partner is more than just a vendor; they are a collaborator with deep technical expertise, robust manufacturing capabilities, and a commitment to quality. This is particularly true when sourcing specialized technical ceramic pellets for demanding B2B applications.

Key Criteria for Evaluating a SiC Pellet Supplier:

- Technical Expertise and Material Knowledge:

- The supplier should possess in-depth knowledge of different SiC grades (RBSiC, SSiC, NBSiC, etc.) and their suitability for various applications.

- They should be able to provide guidance on material selection, pellet design (size, shape, porosity), and potential performance in specific environments.

- Customization Capabilities:

- Assess their ability to manufacture pellets to your precise specifications, including custom geometries, tight tolerances, and specific purity levels.

- Inquire about their R&D capabilities for developing novel SiC pellet solutions if needed.

- Manufacturing Prowess and Quality Assurance:

- Understand their manufacturing processes, from raw material sourcing and preparation to forming, sintering, and finishing.

- Look for robust quality management systems (e.g., ISO 9001 certification), comprehensive testing facilities, and lot-to-lot traceability.

- Production Capacity and Lead Times:

- Ensure the supplier can meet your volume requirements, whether for prototypes, small batches, or wholesale SiC pellet orders.

- Obtain clear information on lead times and their ability to meet delivery schedules consistently.

- Cost-Effectiveness:

- While price is a factor, it should be balanced against quality, performance, and supplier reliability. The lowest price may not always equate to the best value, especially for critical industrial SiC pellets.

- Consider the total cost of ownership, including pellet lifespan, impact on process efficiency, and potential downtime.

- Communication and Support:

- A responsive supplier who offers excellent technical support and clear communication is invaluable, especially when dealing with custom products.

Why Sicarb Tech Stands Out as Your Trusted Partner:

When navigating the complexities of sourcing custom SiC pellets, Sicarb Tech emerges as a highly reliable and technically proficient partner. Situated in Weifang City, the recognized hub of China’s silicon carbide customizable parts manufacturing – a region accounting for over 80% of the nation’s total SiC output – SicSino is uniquely positioned to deliver exceptional value.

- Deep Industry Roots and Technological Leadership: SicSino has been instrumental in the Weifang SiC industry since 2015, introducing and implementing advanced silicon carbide production technology. They have witnessed and contributed to the technological advancements and large-scale production capabilities of local enterprises.

- Backed by Chinese Academy of Sciences: Operating under the umbrella of the Chinese Academy of Sciences (Weifang) Innovation Park and the National Technology Transfer Center of Chinese Academy of Sciences, SicSino leverages the formidable scientific, technological capabilities, and talent pool of one of China’s premier research institutions. This backing ensures access to cutting-edge material science, process innovation, and evaluation technologies.

- Unmatched Customization Expertise: SicSino boasts a top-tier professional team specializing in the customized production of silicon carbide products. Their integrated approach, covering materials, processes, design, measurement, and evaluation, allows them to cater to diverse and complex customization needs for SiC pellets. Ten local enterprises have already benefited from SicSino’s technologies.

- Quality and Cost Competitiveness: By optimizing production processes and leveraging the economies of scale within the Weifang SiC cluster, SicSino can offer higher-quality, cost-competitive customized silicon carbide components, including pellets, directly from China. This ensures more reliable quality and supply assurance.

- Comprehensive Service Ecosystem: SicSino facilitates the entire technology transfer and commercialization process, offering a seamless experience from inquiry to delivery.

- Technology Transfer Services (Turnkey Projects): For businesses looking to establish their own SiC production capabilities, SicSino offers comprehensive technology transfer services. This includes factory design, procurement of specialized equipment, installation, commissioning, and trial production, ensuring a reliable investment and successful technology transformation.

Cost Drivers and Lead Time Considerations for SiC Pellets:

Understanding what influences pricing and delivery schedules is crucial for procurement managers:

- Material Grade: High-purity grades like SSiC are generally more expensive than RBSiC or NBSiC due to raw material costs and processing complexity.

- Pellet Complexity: Custom shapes, very tight tolerances, or controlled porosity requirements can increase manufacturing costs.

- Order Volume: Larger wholesale SiC pellet orders often benefit from economies of scale, leading to lower unit prices.

- Purity Levels: Higher purity specifications necessitate stricter process controls and potentially more expensive raw materials.

- Testing and Certification: Extensive testing and specific certifications will add to the cost.

- Lead Times: These can vary based on material availability, production queue, complexity of the order, and shipping. Standard pellets may have shorter lead times than highly customized ones.

By partnering with Sicarb Tech, you are not just procuring SiC pellets; you are gaining access to a wealth of expertise, a commitment to quality, and a direct line to the heart of China’s SiC manufacturing prowess. This strategic partnership can help your organization achieve superior performance and a competitive edge in your respective industry.

Frequently Asked Questions (FAQ) about Silicon Carbide Pellets

Q1: What are the main differences between silicon carbide pellets and other ceramic media like alumina pellets?

A1: Silicon carbide (SiC) pellets generally offer superior performance compared to many other ceramic media, including alumina, in several key areas. The primary differences include: * Thermal Conductivity: SiC has significantly higher thermal conductivity than alumina, making it much more effective for heat transfer applications (e.g., heat exchange media in RTOs). * Thermal Shock Resistance: SiC, particularly grades like R-SiC and SSiC, typically exhibits better thermal shock resistance, meaning it can withstand rapid temperature changes without cracking. * Hardness and Wear Resistance: SiC is one of the hardest materials available (Mohs 9-9.5), surpassing alumina (Mohs 9). This translates to superior wear and abrasion resistance when used as grinding media or in high-wear environments. * High-Temperature Strength: SiC maintains its strength at higher temperatures than many alumina grades. SSiC can operate effectively up to 1600−1750∘C, whereas alumina’s practical limit is often lower. * Chemical Resistance: While high-purity alumina has good chemical resistance, SSiC, in particular, offers exceptional resistance to a broader range of corrosive chemicals, including strong acids and alkalis, especially at elevated temperatures. Alumina pellets can be a cost-effective solution for less demanding applications, but for extreme conditions involving high heat, severe wear, or aggressive chemicals, custom SiC pellets are often the preferred choice for technical ceramics buyers.

Q2: Can silicon carbide pellets be used as catalyst supports, and what are the advantages?

A2: Yes, silicon carbide pellets are increasingly used as catalyst supports, offering several advantages over traditional materials like alumina, silica, or zeolites, especially in demanding chemical processes: * High Thermal Conductivity: Allows for better temperature control within the catalytic bed, improving management of exothermic or endothermic reactions and preventing hot spots. This can lead to improved selectivity and catalyst life. * Excellent Chemical Inertness: SiC (especially SSiC) is highly resistant to acidic and basic conditions, as well as other corrosive agents, ensuring the support does not degrade or react with the reactants or products. * High Mechanical Strength and Attrition Resistance: SiC pellets are robust and can withstand harsh operating conditions, including high pressures and abrasive environments, reducing the formation of fines that can plug reactors. * Controllable Porosity and Surface Area: SiC pellets can be manufactured with tailored pore structures (pore size, volume) to optimize catalyst loading, dispersion, and mass transfer. * High-Temperature Stability: They remain stable at high reaction temperatures where other supports might degrade or sinter. * Potential for Improved Fouling Resistance: The surface properties of SiC can sometimes lead to reduced coking or fouling compared to oxide-based supports in certain reactions. These advantages make industrial SiC pellets particularly suitable for applications like partial oxidation, dehydrogenation, and reactions in corrosive or high-temperature environments where conventional catalyst supports fall short.

Q3: How does Sicarb Tech ensure the quality and consistency of custom SiC pellets sourced from the Weifang hub?

A3: Sicarb Tech plays a crucial role in ensuring the quality and consistency of custom SiC pellets through a multi-faceted approach rooted in its technical expertise and strategic position: * Technology Implementation and Oversight: Having introduced and implemented advanced SiC production technology since 2015, SicSino possesses deep insights into optimal manufacturing processes. They support local enterprises in achieving technological advancements, which includes instilling best practices for quality control. * Access to Chinese Academy of Sciences Expertise: Leveraging the robust scientific and technological capabilities of the Chinese Academy of Sciences , SicSino has access to advanced material characterization, measurement, and evaluation technologies. This allows for thorough vetting of materials and processes. * Professional Team and Integrated Processes: SicSino’s domestic top-tier professional team specializes in customized SiC production. Their integrated process knowledge, from materials science to final product evaluation, ensures that customer specifications are accurately translated into high-quality products. * Network of Vetted Manufacturers: While Weifang has over 40 SiC enterprises, SicSino works with a network of trusted local manufacturers (10+ of whom have directly benefited from SicSino technologies) who meet stringent quality standards. This selective partnership ensures reliability. * Platform for Technology Transfer: As a platform of the national technology transfer center, SicSino facilitates a comprehensive service ecosystem. This includes not just sourcing but also ensuring that the underlying technologies used are sound and capable of producing consistent results. * Commitment to Higher Quality and Cost Competitiveness: SicSino’s mission is to provide higher-quality, cost-competitive customized SiC components. This inherently means a focus on quality assurance to maintain their reputation and deliver value to international B2B clients, OEMs, and distributors. By combining direct technological input, rigorous selection of manufacturing partners, and leveraging the advanced capabilities of the Chinese Academy of Sciences, SicSino acts as a quality gatekeeper and a reliable conduit for businesses seeking high-performance silicon carbide pellets from China.

Conclusion: The Enduring Value of Custom Silicon Carbide Pellets in Advanced Industries

In the realm of advanced materials, silicon carbide pellets stand out for their remarkable combination of hardness, thermal stability, chemical inertness, and wear resistance. Their adaptability through customization further enhances their value, making them indispensable for a growing number of critical industrial applications. From optimizing energy efficiency in high-temperature furnaces to ensuring purity in semiconductor manufacturing and providing durable solutions in abrasive environments, custom SiC pellets consistently deliver performance where other materials reach their limits.

For engineers, procurement managers, and technical buyers, the decision to specify industrial SiC pellets is an investment in reliability, longevity, and process optimization. The ability to tailor pellet size, shape, porosity, and grade allows for solutions that are precisely engineered for the task at hand, leading to enhanced productivity and reduced operational costs over the long term.

Partnering with a knowledgeable and capable supplier like Sicarb Tech amplifies these benefits. By leveraging their deep technical expertise, their strategic location within China’s primary SiC manufacturing hub in Weifang, and their backing from the prestigious Chinese Academy of Sciences, SicSino offers unparalleled access to high-quality, cost-effective, and truly customized silicon carbide solutions. As industries continue to push the boundaries of performance, the demand for advanced technical ceramic pellets will only escalate, and silicon carbide, in its versatile pellet form, is poised to meet that challenge, driving innovation and efficiency across the global industrial landscape.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.