Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals

Share

In Pakistan’s steel plants, the quietest minutes are the most productive. When alloy feeders track setpoints, oxygen activity falls on cue, and silicon absorption lands within tolerance, operators don’t scramble—and casters stay calm. Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals was built by Sicarbtech to turn that ideal into daily practice. By marrying precision mechatronics with real-time oxygen activity feedback and batch-aware material models, the system meters silicon carbide—granules or injection powder—exactly when and where the melt needs it. The result is fewer manual corrections, faster stabilization after tap, and cleaner heats flowing into longer, steadier casting sequences. In a 2025 landscape defined by rising scrap ratios, PEQS-aligned dust control, and power cost volatility, an online feeding system calibrated to your metallurgy is no longer a luxury; it is the backbone of predictable steelmaking.

Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals product overview and 2025 market relevance

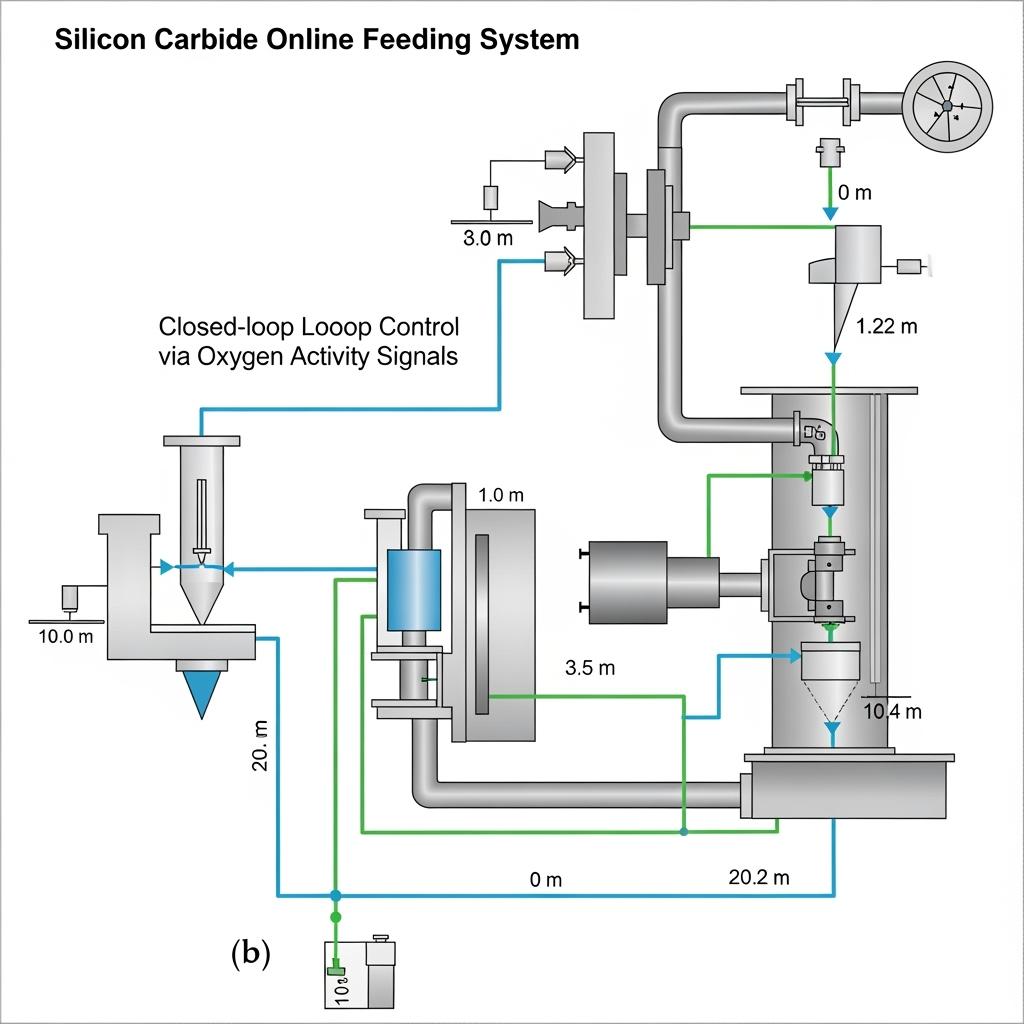

At its core, Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals integrates hardware and software designed around the physics of silicon carbide dosing. Enclosed silos and flow-stabilized hoppers ensure mass flow; vibration-isolated loss-in-weight feeders and screw or rotary valves meter with high resolution; and sealed transfer lines deliver material to the teeming stream, ladle, or injection lances with minimal dust. The control stack listens to oxygen activity sensors, temperature inputs, and Level 2 recipes, then adjusts feed rates on the fly based on the verified particle size distribution, moisture, and reactivity index of the specific Sicarbtech batch. Moreover, the system harmonizes with Sicarbtech’s materials portfolio—Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition, Low-Nitrogen Low-Sulfur Silicon Carbide Powder for Cleanliness-Enhanced Steelmaking and Low O, N, S, and composite modifiers—so plant teams are not wrestling with generic assumptions. As Engr. R. Khan put it after a Lahore deployment, “We stopped dosing to a clock and started dosing to the melt—and the melt responded” (Metallurgy Pakistan Review, 2024).

Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals technical specifications and advanced features

Sicarbtech engineered Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals for rugged Pakistani shop floors and sensitive metallurgical windows. The silo and hopper train is designed for sealed operation with HEPA venting and optional nitrogen purge, while mass-flow geometries and low-angle liners prevent bridging in monsoon humidity. Loss-in-weight feeders offer resolution to a fraction of a percent of nominal flow, with adaptive filters that distinguish true weight change from vibration. For granules, screw feeders with variable pitch deliver stable mass flow; for powders, rotary valves and dense-phase conveying maintain entrainment without surges. Oxygen activity inputs arrive from ladle or stream sensors; temperature and arc status provide context. The control layer blends feed-forward (recipe and batch QC tags) with feedback (oxygen activity and silicon trajectory predictions), using a constrained PID or model-predictive controller to maintain target O[a] decay and silicon pickup. Interfaces to Level 2/3 systems support recipe download, event logging, and KPI dashboards. Safety interlocks stop dosing on sensor failure, abnormal weight deviation, or hatch open events, protecting both people and product.

System performance and metallurgy outcomes with Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals

| Operations and metallurgy KPIs | Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals | Conventional timed feeders | Manual bag additions |

|---|---|---|---|

| Oxygen activity control (overshoot/undershoot) | Tight; closed-loop to setpoint | Loose; fixed rate drift | Wide; operator dependent |

| Silicon absorption variance | Lower; batch-aware dosing | Moderate; batch-blind | High; inconsistent |

| Time to stable refining window | -0.5–2% faster | Reference | Slower; stepwise |

| Dust exposure at addition points | Very low; enclosed | Moderate; open top-ups | High; open handling |

| Data traceability and QA | Full: batch, rate, O[a], temp | Partial; timer logs | Minimal; manual notes |

Hardware and integration attributes of Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals

| Attribute | Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals | Operational significance in Pakistan |

|---|---|---|

| Silos and hoppers | Sealed, mass-flow design | Prevents bridging in humidity; low dust |

| Feeder type | Loss-in-weight with screw/rotary | High-resolution metering for granules and powders |

| Conveying | Enclosed, dense/lean-phase options | Clean, precise delivery to stream/ladle |

| Sensors | Oxygen activity, temperature, level, vibration | Real-time metallurgy cues and reliability |

| Control | PID/MPC with feed-forward from batch QC | Matches dosing to melt behavior and batch reactivity |

| Interfaces | Level 2/3 integration, historian | Recipe automation and KPI tracking |

| Safety | Interlocks, e-stop, purge control | Compliance and operator confidence |

| Maintenance | Tool-less access, wear liners | Reduced downtime and predictable upkeep |

Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals performance comparison with alternatives

| Cost, quality, and risk profile | Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals | Basic gravimetric feeder without feedback | Manual addition + wire corrections |

|---|---|---|---|

| Alloy cost per ton of steel | -1–5% via right-first-time dosing | Baseline; drift losses | Higher; corrections and waste |

| Cleanliness (total oxygen change) | -5 to -15 ppm vs baseline | -2 to -8 ppm | Variable; alumina spikes |

| Heat time variability | Lower; tighter windows | Moderate | Higher; correction loops |

| Nozzle clogging incidents | -20–40% downstream | -10–25% | Reference/higher |

| Labor and EHS impact | Reduced exposure; automated | Moderate | High exposure; manual handling |

Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals key advantages and proven benefits with expert quote

The central advantage of Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals is that it doses to metallurgy rather than to a timer. By blending oxygen activity feedback with batch-specific reactivity, the system prevents both underfeeding that drags heat time and overfeeding that wastes alloy and risks inclusion storms. Furthermore, sealed conveying and HEPA venting reduce dust exposure while keeping feeders clean, which EHS teams appreciate during humid months. Prof. Li Wei of CAS Weifang Innovation Park summarized the shift: “Closed-loop alloy dosing turns oxygen control from an art into a repeatable procedure, and repeatability is what unlocks throughput” (CAS Materials Review, 2023).

Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals real-world applications and measurable success stories

A Karachi EAF billet producer installed Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals on its teeming stream granule addition. Over eight weeks, silicon absorption rose by five percentage points with a marked reduction in variance, while total oxygen post-refining dropped by eight to nine ppm. Heat times shortened by about one percent, and nozzle interventions fell by thirty-one percent per hundred heats. Operators reported calmer arcs following tap and fewer late aluminum wire corrections. In Punjab, a converter line used the system to control early ladle additions of SiC premixed pellets. The plant saw a three-degree Celsius improvement in tapping temperature loss and a visible flattening of oxygen decay curves, which translated into more consistent sequence starts and fewer tundish slowdowns.

Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals selection and maintenance considerations

Successful deployment begins with a clean mechanical path. Mass-flow hoppers, low-angle liners, and correctly sized outlets prevent segregation and bridging, especially with 0–3 mm and 3–10 mm SiC granules. For <200 mesh powders, rotary valves matched to dense-phase lines maintain stable entrainment and avoid surges at the lance. Calibration is next; feeder test runs with Sicarbtech QC-tagged material (PSD, moisture, reactivity) align scale factors and predictive dissolution models to your tapping temperatures and slag practice. Integrating oxygen activity sensors at the stream or ladle provides the feedback spine; dual redundancy and health monitoring keep the loop trustworthy. Preventive maintenance—liner inspections, seal checks, and load cell drift audits—protect accuracy over time. Finally, operator training closes the loop: dashboards showing oxygen activity, feed rate, and predicted silicon pickup in one view turn dosing into a transparent, collaborative task rather than a black box.

Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals industry success factors and customer testimonials

Plants that scale fastest treat Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals as a team member, not just a machine. They align materials—such as Grading-Optimized Silicon Carbide Granulated Feed with Superior Flowability for Accurate Metered Addition and Low-Nitrogen Low-Sulfur Silicon Carbide Powder for Cleanliness-Enhanced Steelmaking and Low O, N, S—with the control strategy, and they let aluminum wire play a trim role rather than a rescue mission. A North Region QA manager captured the before-and-after: “We used to chase oxygen. Now oxygen follows our plan, and the caster feels it—fewer alarms, longer sequences, and nights that look like the schedule.”

Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals future innovations and market trends

Sicarbtech is extending Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals with model-predictive control tuned to scrap chemistry, slag carry-over, and arc stability indices. Batch digital twins—created from QC tags—will pre-load dissolution kinetics so startups hit targets on the first heat after a material change. Moreover, local manufacturing and service hubs in Pakistan will shorten commissioning cycles and ensure spare parts and calibration expertise are on call. The broader 2025–2027 trend is unmistakable: alloy dosing that is sensor-led, analytics-backed, and materially aware, transforming EAF and converter windows from variable to repeatable.

Common questions and expert answers

How does Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals use oxygen activity signals in real time?

The controller ingests O[a] at 1–2 second intervals, filters noise, and compares the trajectory to a target decay curve linked to your recipe and batch reactivity. It then trims the feed rate within defined bounds to keep O[a] on track without overshoot.

Can Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals handle both granules and injection powder?

Yes. The platform supports loss-in-weight screws for granules and rotary valves with dense-phase conveying for powders. Recipes can switch modes seamlessly, with separate calibrations and interlocks.

What happens if a sensor or feeder drifts during a heat?

Health monitoring flags drift via mass balance and signal plausibility checks. The system freezes feed, alerts operators, and can fall back to recipe-based feed-forward until redundancy is restored, protecting the melt from bad data.

Will Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals reduce aluminum wire consumption?

Typically yes. By managing oxygen early and stabilizing silicon pickup, plants trim late-wire by 8–15 percent, lowering alumina formation risk and improving nozzle openness downstream.

How is data from Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals integrated into QA?

All dosing, O[a], temperature, and batch QC data stream to the historian and Level 2. Heat reports tie absorption, oxygen endpoints, and sequence stability to the exact SiC batch and feeder trace, supporting audits and continuous improvement.

Why Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals works for your operations

Because dosing should serve metallurgy, not the other way around. Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals synchronizes high-activity SiC additions with oxygen behavior and temperature reality, turning volatile post-tap minutes into a disciplined glide path. In Pakistan’s mills—balancing energy pressure, scrap variability, and export-grade cleanliness—this is how you lower alloy cost per ton, shorten heat time, and keep casters in the green.

Connect with specialists for custom solutions

Sicarbtech supports Silicon Carbide Online Feeding System with Precision Metering and Closed-Loop Control via Oxygen Activity Signals with more than ten years of silicon carbide manufacturing expertise and Chinese Academy of Sciences–backed innovation. We design custom SiC materials across R-SiC, SSiC, RBSiC, and SiSiC; deliver technology transfer and factory establishment services for powder synthesis, classification, granulation, and coating; and integrate enclosed silos, metering feeders, pneumatic lances, and Level 2 analytics into turnkey solutions. With a track record across more than nineteen enterprises, we offer a no-cost pilot scoped to your KPIs—higher silicon absorption, reduced total oxygen, fewer nozzle events, and shorter heat times—so you can move from trial to standard in weeks, not quarters.

For a free consultation and a fast, data-backed proposal, contact:

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Article metadata

Last updated: 2025-09-15

Next review scheduled: 2025-12-15

Author: Sicarbtech Applications Engineering Team

Region focus: Pakistan (EAF and converter routes; billets, bars, wire rod, flats)

Timeliness note: Content aligned to 2025 PEQS-aligned dust control, closed-loop alloy dosing practices, and Level 2/3 integration trends

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.