Mastering Precision: A Deep Dive into Silicon Carbide Machining Equipment

Share

Silicon Carbide (SiC) stands as a cornerstone material in high-performance industrial applications, prized for its exceptional hardness, superior thermal conductivity, and remarkable resistance to wear and chemical attack. However, these very properties that make SiC so valuable also present significant challenges when it comes to fabrication and shaping. Producing intricate, high-precision custom silicon carbide components demands not just advanced material science, but also highly specialized silicon carbide machining equipment. This blog post will explore the critical role of this equipment, delving into its types, advantages, essential features, and the considerations necessary for engineers, procurement managers, and technical buyers in industries ranging from semiconductors and aerospace to energy and high-temperature processing. For businesses looking to leverage the full potential of SiC, understanding the nuances of its machining is paramount, whether sourcing finished parts or considering in-house production capabilities with expert partners like Sicarb Tech.

Introduction: The Indispensable Role of Specialized Machining Equipment for Silicon Carbide Components

Silicon Carbide, a synthetic crystalline compound of silicon and carbon, is a leading technical ceramic renowned for its performance under extreme conditions. Its Mohs hardness rating of 9.0-9.5, second only to diamond, means it can withstand intense abrasive forces. Its high thermal conductivity (comparable to some metals) coupled with a low coefficient of thermal expansion provides excellent thermal shock resistance, making it ideal for high-temperature furnace components and aerospace applications. Furthermore, its chemical inertness ensures longevity in corrosive environments, a critical factor in chemical processing and semiconductor manufacturing equipment.

However, the inherent hardness and brittleness of SiC make it notoriously difficult to machine using conventional techniques. Standard cutting tools wear out rapidly, and the material is prone to chipping, micro-cracking, and subsurface damage if not handled with appropriate technology. This is where specialized SiC machining equipment becomes indispensable. This category of machinery is engineered specifically to handle the unique challenges posed by advanced ceramics, employing ultra-hard cutting materials like diamond, robust machine designs, and precision control systems. For Original Equipment Manufacturers (OEMs) and wholesale buyers of SiC parts, the quality of machining directly impacts the performance, reliability, and lifespan of the final product. Investing in or partnering with entities that utilize state-of-the-art SiC machining equipment is not just a preference, but a necessity for achieving the desired tolerances and surface finishes required in demanding industrial SiC applications.

Navigating the Landscape: Key Types of Silicon Carbide Machining Equipment and Their Industrial Applications

The diverse applications of silicon carbide components necessitate a range of machining processes, each requiring specific types of equipment. Understanding these options is crucial for selecting the most effective and economical method for producing custom SiC products.

- Grinding Machines: Due to SiC’s hardness, grinding is a primary machining method.

- Surface Grinders: Used to produce flat surfaces with high precision. Essential for SiC plates, substrates, and wear tiles.

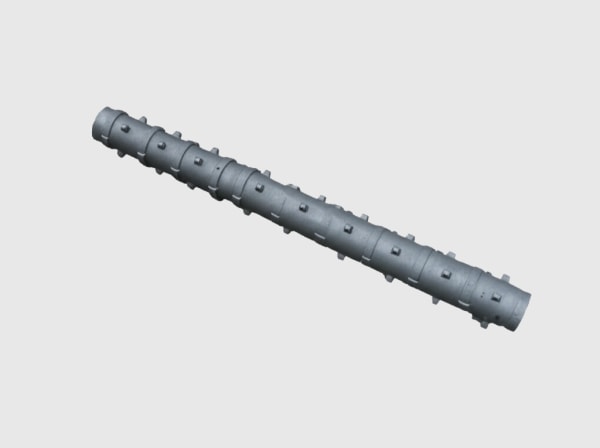

- Cylindrical Grinders (OD/ID): Shape external and internal diameters of SiC rods, tubes, and shafts. Critical for SiC pump components and bearing sleeves.

- Centerless Grinders: Efficient for high-volume production of cylindrical parts requiring tight dimensional tolerances.

- Profile Grinders: Create complex shapes and profiles on SiC components. These machines exclusively use diamond grinding wheels of various grit sizes and bond types, tailored to the specific SiC grade and desired finish.

- Lapping and Polishing Machines: For applications demanding ultra-smooth surfaces and extremely tight flatness or parallelism, such as SiC mirror substrates for optical systems or seal faces. Lapping uses a fine abrasive slurry to remove material, while polishing employs even finer abrasives to achieve a mirror-like finish.

- Ultrasonic Machining (USM): This non-traditional method uses high-frequency vibrations of a shaped tool and an abrasive slurry to gradually erode material. USM is particularly effective for creating complex cavities, holes, and intricate patterns in brittle materials like SiC, especially for semiconductor wafer handling components.

- Electrical Discharge Machining (EDM): While traditional SiC is an electrical insulator, certain grades, like reaction-bonded SiC with free silicon (e.g., SiSiC), or specially formulated conductive SiC, can be machined using EDM.

- Wire EDM: Uses a thin, travelling wire electrode to cut complex contours and intricate shapes.

- Sinker EDM (Die-Sinking EDM): Employs a shaped electrode to machine cavities and detailed features. EDM is valuable for producing SiC tooling and molds.

- Laser Machining: Lasers can be used for cutting, drilling small holes, scribing, and micro-machining SiC. This method offers high precision and minimal mechanical stress on the workpiece. It is increasingly used for producing fine-featured SiC components for electronics and sensor applications. Different laser types (e.g., picosecond, femtosecond) are chosen based on the required precision and heat-affected zone (HAZ) considerations.

- Diamond Sawing and Cutting Equipment: For initial sectioning of SiC billets or blanks, or for creating straight cuts, specialized saws with diamond-impregnated blades are essential. These machines must be robust to handle the cutting forces and equipped with efficient coolant systems.

The choice of equipment depends heavily on the SiC grade (e.g., Sintered SiC (SSiC), Reaction Bonded SiC (RBSiC/SiSiC), Nitride Bonded SiC (NBSC)), the complexity of the component, required tolerances, surface finish, and production volume.

| Machining Equipment Type | Primary Application | Suitable SiC Grades | Achievable Precision | Relative Cost | Key Advantage |

|---|---|---|---|---|---|

| Diamond Grinding Machines | Shaping, sizing, surface finishing | All | High to Very High | Moderate-High | Versatile for most SiC machining tasks |

| Lapping & Polishing Machines | Ultra-fine surface finish, flatness | All | Extremely High | Moderate-High | Superior surface quality |

| Ultrasonic Machining (USM) | Complex cavities, micro-features | All | Moderate to High | High | Good for brittle materials, complex 3D shapes |

| Electrical Discharge Machining (EDM) | Intricate shapes, tooling (conductive SiC) | RBSiC (SiSiC), Conductive SiC | High | High | Machining hard conductive materials, complex shapes |

| Laser Machining | Cutting, drilling, micro-machining | All | High to Very High | High | Non-contact, minimal stress, high precision |

| Diamond Sawing Equipment | Initial cutting, sectioning | All | Moderate | Moderate | Efficient for basic cuts and sizing |

This table provides a general overview. For specific applications, consulting with experts like Sicarb Tech can help determine the optimal machining strategy and equipment.

The Competitive Edge: Why Specialized SiC Machining Equipment Outperforms Conventional Methods

Attempting to machine silicon carbide with standard metalworking equipment is not only inefficient but can also be detrimental to both the machinery and the workpiece. The advantages of utilizing equipment specifically designed or adapted for advanced ceramics machining are manifold, providing a significant competitive edge for manufacturers and users of SiC components.

- Enhanced Precision and Tighter Tolerances: Specialized SiC machining equipment is built with greater rigidity, superior spindle accuracy, and advanced motion control systems. This allows for the achievement of sub-micron tolerances and complex geometries that are impossible with conventional machines. This precision is critical for SiC components in semiconductor processing and optical systems.

- Reduced Tool Wear and Optimized Tool Life: The abrasive nature of SiC rapidly wears down standard cutting tools. Diamond tooling is the industry standard for SiC. Specialized equipment is designed to optimize the use of these expensive tools through features like high-pressure coolant delivery, precise speed and feed control, and vibration damping, extending tool life and reducing operational costs.

- Improved Surface Finish and Integrity: Improper machining can introduce micro-cracks, edge chipping, and subsurface damage in SiC, compromising its mechanical strength and performance. Specialized equipment, often incorporating techniques like grinding with fine diamond grits, lapping, or polishing, ensures superior surface finishes (Ra values in the nanometer range) and maintains the material’s inherent integrity. This is vital for SiC seal faces and wear-resistant parts.

- Higher Material Removal Rates and Productivity: While SiC machining is inherently slower than metal machining, specialized equipment is optimized for the material, allowing for the highest possible material removal rates without damaging the component. Features like automated tool changers and pallet systems can further enhance productivity for high-volume SiC component manufacturing.

- Minimized Chipping, Cracking, and Material Waste: The brittleness of SiC requires careful control of machining forces. Specialized equipment offers precise control over cutting parameters and often incorporates “gentle” machining strategies (e.g., peel grinding, ultrasonic-assisted grinding) to minimize the risk of brittle fracture, reducing scrap rates and material waste.

- Efficient Coolant and Swarf Management: Machining SiC generates fine, abrasive dust (swarf) and significant heat. Specialized equipment incorporates sophisticated coolant delivery systems to dissipate heat effectively, flush away swarf, and prevent it from damaging machine components or the workpiece surface. Proper swarf management is also crucial for operator safety and environmental compliance.

Investing in or utilizing services from companies with dedicated SiC machining equipment translates to higher quality components, improved reliability, and often, lower overall costs when factoring in reduced scrap, longer tool life, and enhanced performance of the final product. Sicarb Tech, with its deep understanding of SiC properties and manufacturing processes, leverages such advanced equipment to deliver superior custom SiC products. Their expertise, rooted in the SiC manufacturing hub of Weifang City and backed by the Chinese Academy of Sciences, ensures that clients benefit from these technological advantages.

Under the Hood: Essential Features and Cutting-Edge Technologies in Modern SiC Machining Equipment

Modern silicon carbide machining equipment is a marvel of engineering, incorporating a host of features and technologies specifically designed to address the unique challenges of processing this ultra-hard material. These features are critical for achieving the precision, surface quality, and efficiency demanded by today’s advanced industrial applications.

- Robust and Rigid Machine Structure: Due to the high forces involved in grinding and machining SiC, the machine base, columns, and spindles must be exceptionally stiff and well-damped to minimize vibrations. This rigidity is fundamental for achieving tight tolerances and fine surface finishes. Materials like granite composites are often used for machine bases due to their excellent damping characteristics and thermal stability.

- High-Precision Spindles: Spindles on SiC machining equipment must offer high rotational accuracy (low runout), thermal stability, and sufficient power and torque. Air-bearing or hydrostatic spindles are sometimes used for ultra-precision applications to minimize friction and vibration.

- Advanced CNC (Computer Numerical Control) Systems: Sophisticated CNC controllers with high-speed processing capabilities are essential for executing complex multi-axis tool paths, ensuring precise contouring, and enabling adaptive machining strategies. User-friendly interfaces and simulation software also play a crucial role in programming and optimizing machining processes.

- Specialized Diamond Tooling Systems: The equipment must be compatible with a wide array of diamond tools, including grinding wheels (various bonds, grit sizes, concentrations), drills, end mills, and saw blades. Quick-change tooling systems and automatic tool changers (ATCs) enhance productivity.

- High-Pressure and Precision Coolant Delivery: Effective cooling and lubrication are paramount. Modern systems deliver high-pressure coolant (often specialized synthetic oils or water-based coolants with additives) precisely to the cutting zone. This helps to:

- Dissipate heat and prevent thermal damage to the SiC.

- Flush away abrasive SiC swarf efficiently.

- Improve tool life and surface finish. Through-spindle coolant and programmable coolant nozzles are common features.

- Swarf Management and Filtration Systems: Efficiently removing and filtering the fine, abrasive SiC particles from the coolant is crucial to prevent them from re-entering the cutting zone, damaging the workpiece surface, or causing excessive wear on machine components (like guideways and ball screws). Multi-stage filtration systems are often employed.

- In-Process Measurement and Probing: To ensure accuracy and minimize setup times, many machines incorporate touch probes for workpiece positioning and feature measurement. Some advanced systems may include non-contact measurement systems (e.g., laser-based) for in-process inspection of dimensions and surface finish.

- Acoustic Emission (AE) Sensors: Particularly in grinding, AE sensors can detect the onset of micro-cracking or tool wear in real-time, allowing the CNC to adjust machining parameters preventively, thus safeguarding part integrity.

- Automation and Robotic Integration: For high-volume SiC component production, SiC machining cells can be integrated with robotic loading/unloading systems, pallet changers, and centralized control systems to enable lights-out operation and improve overall equipment effectiveness (OEE).

- Environmental and Safety Features: Enclosed machining areas, mist collectors, and safe swarf disposal systems are important for protecting operators and the environment.

The continuous evolution of these technologies enables the machining of increasingly complex SiC components with higher precision and efficiency. Companies like Sicarb Tech stay at the forefront of these advancements, either by incorporating such equipment in their own production or by providing technology transfer services that include guidance on selecting and implementing the most suitable advanced ceramics machining solutions.

Designing for Success: Critical Considerations for Machining Custom Silicon Carbide Parts

The design of a silicon carbide component significantly influences its manufacturability, cost, and ultimately, its performance. When developing custom SiC products, engineers must consider the capabilities and limitations of SiC machining equipment and processes from the outset. This “Design for Manufacturability” (DFM) approach is crucial for achieving optimal results.

Key design considerations include:

- Material Grade Selection: Different SiC grades (Sintered SiC, Reaction Bonded SiC, Nitride Bonded SiC, etc.) have varying machinability characteristics. SSiC is generally harder and more challenging to machine than RBSiC, which contains some free silicon. The choice of grade will impact tool selection, machining parameters, and achievable features.

- Geometric Complexity:

- Avoid Sharp Internal Corners: Sharp internal corners are stress concentrators and difficult to machine accurately. Generous internal radii are preferred to reduce the risk of cracking and allow for efficient tool engagement.

- Wall Thickness and Aspect Ratios: Extremely thin walls or high aspect ratio features (e.g., deep, narrow slots or tall, slender pins) are prone to vibration and breakage during machining. Minimum wall thickness recommendations vary but should be discussed with the SiC parts manufacturer.

- Hole Design: The depth-to-diameter ratio for drilled holes is limited. Through-holes are generally easier to machine than blind holes. For blind holes, providing some bottom clearance for the tool is beneficial.

- Tolerances and Surface Finish: Specify only the necessary tolerances and surface finishes. Overly tight tolerances or unnecessarily fine surface finishes significantly increase machining time and cost. Understand the practical limits achievable with different SiC machining processes (grinding, lapping, polishing). | Machining Process | Typical Achievable Tolerance | Typical Surface Finish (Ra) | | :—————— | :————————— | :—————————– | | Diamond Grinding | ±5μm to ±25μm | 0.1μm to 0.8μm | | Precision Grinding | ±1μm to ±5μm | 0.05μm to 0.2μm | | Lapping | ±1μm to ±5μm | 0.02μm to 0.1μm | | Polishing | ±0.5μm to ±2μm | <0.02μm (can be lower) |

- Feature Orientation and Accessibility: Design features to be easily accessible by cutting tools. Deep pockets or undercuts may require specialized tooling or multi-axis machining capabilities, adding to complexity and cost.

- Edge Conditions: Sharp edges on SiC components are prone to chipping. Specifying chamfered or radiused edges can improve durability and handling safety, and is often easier to achieve consistently during machining.

- Datum Structures: Clearly define datum features for consistent setup and measurement during the machining process. This is critical for ensuring dimensional accuracy across multiple operations.

- Minimizing Material Removal: Whenever possible, design the near-net-shape blank to minimize the amount of SiC material that needs to be removed by machining. This can significantly reduce machining time and tool wear. This is where the initial forming process of the SiC blank (e.g., pressing, slip casting, extrusion) plays a role.

Collaborating with an experienced SiC manufacturer like Sicarb Tech during the design phase is highly recommended. Their team, backed by the extensive R&D capabilities of the Chinese Academy of Sciences, can provide invaluable DFM feedback. They understand how design choices interact with their SiC machining equipment and processes, helping clients optimize designs for performance, cost-effectiveness, and reliable production of custom SiC ceramics. This collaborative approach ensures that the final component not only meets its functional requirements but is also efficiently manufacturable.

Tackling the Tough Stuff: Overcoming Challenges in Silicon Carbide Machining with Advanced Equipment and Expertise

Machining silicon carbide is inherently challenging due to its exceptional physical properties. However, advancements in SiC machining equipment, tooling, and process knowledge have made it possible to overcome these hurdles and produce complex, high-precision components.

The primary challenges in machining SiC include:

- Extreme Hardness: As one of the hardest industrial ceramics, SiC causes rapid wear on conventional cutting tools.

- Solution: Utilization of superabrasive diamond tooling (grinding wheels, drills, end mills) is standard. Advanced equipment features optimize the performance and life of these diamond tools through rigid machine construction, precise speed/feed control, and effective coolant delivery.

- Brittleness: SiC is a brittle material, meaning it has low fracture toughness. This makes it susceptible to chipping, cracking, and subsurface damage during machining if not handled correctly.

- Solution: Specialized machining techniques such as “ductile mode” grinding or ultrasonic-assisted machining can minimize brittle fracture. This involves using very fine diamond grits, low feed rates, and precise depth of cut control. Advanced SiC grinders and ultrasonic machining centers are designed for such delicate operations. Coolant plays a vital role in preventing thermal shock, which can exacerbate cracking.

- High Machining Forces: The hardness of SiC results in high cutting forces, which can lead to tool deflection, vibration, and inaccuracies.

- Solution: SiC machining equipment is built with exceptional rigidity and damping capabilities. Robust spindles, oversized guideways, and thermally stable machine structures are essential. Proper workpiece clamping is also critical to prevent movement and vibration.

- Thermal Management: Significant heat is generated at the tool-workpiece interface due to friction. This heat can cause thermal damage to the SiC, accelerate tool wear, and induce thermal shock.

- Solution: High-pressure, high-volume coolant systems are crucial. These systems flood the cutting zone to dissipate heat, lubricate the process, and flush away abrasive swarf. The choice of coolant type is also important.

- Achieving Tight Tolerances and Fine Surface Finishes: Many SiC applications, particularly in semiconductors and optics, demand sub-micron tolerances and extremely smooth surfaces.

- Solution: This requires ultra-precision machining equipment (e.g., precision grinders, lapping machines, polishing machines), carefully controlled environments (temperature stability), and meticulous process control. Multi-stage machining processes, starting with rough grinding and progressing to fine finishing operations, are often necessary.

- Swarf Removal: The fine, abrasive SiC dust (swarf) generated during machining can be problematic. It can accelerate wear on machine components, degrade surface finish if trapped between the tool and workpiece, and pose a health hazard if airborne.

- Solution: Efficient coolant systems help flush swarf away. Advanced filtration systems are needed to remove swarf from the coolant effectively. Enclosed machining centers with mist collectors help manage airborne particles.

Overcoming these challenges requires not only sophisticated equipment but also deep process expertise. Sicarb Tech, located in Weifang City, the heart of China’s SiC industry, has cultivated this expertise since 2015. By assisting local enterprises and leveraging the technological prowess of the Chinese Academy of Sciences, SicSino has a comprehensive understanding of material behavior, process optimization, and equipment capabilities. Their custom SiC fabrication services are built on this foundation, ensuring that even the most challenging SiC components can be manufactured to exacting standards. Furthermore, for companies looking to develop their own SiC production lines, SicSino’s technology transfer programs offer invaluable insights into selecting and operating the right SiC machining equipment and processes to mitigate these common machining difficulties.

Strategic Sourcing: Choosing the Right SiC Machining Equipment and a Knowledgeable Partner like Sicarb Tech

Selecting the appropriate silicon carbide machining equipment or a partner for custom SiC components is a critical decision that can significantly impact product quality, cost, and time-to-market. For procurement managers, engineers, and OEMs, this involves evaluating technical capabilities, material options, and supplier reliability.

Factors to Consider When Sourcing SiC Machining Equipment (for in-house production):

- Application Specificity: What types of SiC components will be machined? (e.g., flat plates, complex 3D shapes, cylindrical parts). This dictates the type of machine needed (grinder, mill, EDM, laser, etc.).

- Precision and Tolerance Requirements: The required dimensional accuracy and surface finish will narrow down equipment choices. Ultra-precision applications demand higher-end machines.

- Production Volume and Automation: For high-volume production, machines with automation features (robotic loading, pallet changers, in-process measurement) may be necessary.

- Material Compatibility: Ensure the equipment is designed for or can be effectively adapted to the specific grades of SiC you intend to machine.

- Tooling and Workholding: Consider the availability and cost of compatible diamond tooling and suitable workholding solutions.

- Software and Control Systems: User-friendliness, processing power, and compatibility with CAD/CAM software are important.

- Footprint and Facility Requirements: Space, power, coolant management, and environmental controls.

- Supplier Support and Training: Availability of technical support, spare parts, maintenance services, and operator training.

- Total Cost of Ownership (TCO): Consider not just the initial purchase price but also operating costs (tooling, energy, maintenance) and expected lifespan.

Choosing a Supplier for Custom SiC Components or Technology Transfer:

When outsourcing SiC component manufacturing or seeking technology transfer to establish your own production, the choice of supplier is even more critical.

| Supplier Evaluation Criteria | Key Considerations for SiC Machining & Components | Why Sicarb Tech Excels |

|---|---|---|

| Technical Expertise & Experience | Deep understanding of SiC materials, machining processes, DFM principles, and quality control. Proven track record with similar applications. | Domestic top-tier professional team specializing in customized SiC production. Since 2015, SicSino has been instrumental in advancing SiC production technology in Weifang. Extensive experience in material, process, design, measurement & evaluation. |

| Equipment & Facilities | Access to appropriate and well-maintained SiC machining equipment. Clean and controlled manufacturing environment. | Leverages advanced SiC production technologies, supporting diverse customization needs. Offers guidance on procurement of specialized equipment for turnkey projects. |

| Material Quality & Sourcing | Use of high-quality SiC raw materials. Traceability and certification of materials. Ability to work with various SiC grades. | Situated in Weifang City, the hub of China’s SiC industry (over 80% of national output), ensuring access to quality materials. Integrated process from materials to products. |

| Customization Capabilities | Ability to produce complex geometries, meet tight tolerances, and achieve specific surface finishes. Engineering support for design optimization. | Strong focus on meeting diverse customization needs. Offers DFM support and leverages a wide array of technologies. |

| Quality Management System (QMS) | Robust QMS (e.g., ISO 9001 certified). Comprehensive inspection and testing capabilities (dimensional, surface, material properties). | Committed to higher-quality, cost-competitive components. Implements rigorous quality control throughout the production process, benefiting from the scientific backing of the Chinese Academy of Sciences National Technology Transfer Center. |

| Cost & Lead Time | Competitive pricing without compromising quality. Reliable lead times and on-time delivery. | Offers cost-competitive customized SiC components from China. Efficient processes aim to optimize lead times. |

| Technology Transfer Capability | For clients wishing to set up their own facilities: proven ability to transfer production technology, including factory design, equipment selection, installation, and training. | A core strength. Sicarb Tech provides technology transfer for professional SiC production, offering full-range turnkey project services (factory design, specialized equipment procurement, installation, commissioning, trial production) ensuring effective investment and reliable technology transformation. |

| Location & Supply Chain | Proximity to material sources and robust logistics for reliable supply. | Strategically located in Weifang City, a major SiC production base. Established network for reliable supply assurance within China. |

| Partnership & Communication | Willingness to collaborate, responsive communication, and transparency. | Acts as a bridge facilitating integration and collaboration. Committed to assisting clients and establishing long-term partnerships. |

Partnering with Sicarb Tech offers a distinct advantage. As an entity belonging to the Chinese Academy of Sciences (Weifang) Innovation Park and backed by the National Technology Transfer Center of the Chinese Academy of Sciences , SicSino embodies a unique blend of industrial capability and cutting-edge scientific expertise. They have witnessed and contributed to the growth of Weifang’s SiC industry, supporting over 10 local enterprises with their technologies. Whether you need high-quality, cost-competitive custom SiC components or are considering establishing your own specialized SiC production plant, SicSino offers a reliable pathway. Their turnkey project services are particularly noteworthy for businesses aiming to integrate SiC machining equipment and processes into their operations, providing comprehensive support from initial design to full-scale production, ensuring a more effective investment and guaranteed input-output ratio.

Frequently Asked Questions (FAQ) about Silicon Carbide Machining Equipment

Q1: What are the primary types of specialized equipment used for machining silicon carbide? A: The primary types include: * Diamond Grinding Machines: For shaping, sizing, and achieving precise surface finishes on SiC parts. This is the most common method. * Lapping and Polishing Machines: Used to produce ultra-smooth, flat surfaces with mirror-like finishes, critical for optical and sealing applications. * Ultrasonic Machining (USM) Centers: For creating complex 3D cavities, holes, and intricate features in brittle SiC. * Electrical Discharge Machining (EDM) Equipment: Suitable for conductive grades of SiC (like SiSiC with free silicon) to produce complex shapes and tooling. * Laser Machining Systems: For cutting, drilling micro-holes, and performing fine scribing or ablation on SiC. * Diamond Saws: For initial cutting and sectioning of SiC blanks. The choice depends on the SiC grade, part complexity, required tolerances, and production volume.

Q2: Why is diamond tooling absolutely essential for machining silicon carbide? A: Silicon carbide is an extremely hard material, ranking just below diamond on the Mohs scale. Conventional cutting tool materials (like carbide or high-speed steel) wear out almost instantly when trying to machine SiC. Diamond, being the hardest known material, is the only practical superabrasive capable of effectively cutting, grinding, and shaping SiC components while maintaining reasonable tool life and achieving the desired precision and surface finish. Specialized SiC machining equipment is designed to optimize the use of these diamond tools.

Q3: How can businesses minimize costs when machining custom SiC parts? A: Minimizing costs for custom SiC parts involves several strategies: * Design for Manufacturability (DFM): Simplify designs where possible, avoid overly tight tolerances unless absolutely necessary, use generous radii, and consider standard feature sizes. Consult with your SiC supplier, like Sicarb Tech, early in the design phase. * Material Selection: Choose the most cost-effective SiC grade that meets the application’s performance requirements. Some grades are easier and faster to machine. * Optimize Batch Sizes: Larger production runs can often reduce per-unit costs due to setup time amortization. * Near-Net Shape Forming: If possible, use forming methods (pressing, casting) that produce a blank closer to the final shape to reduce machining time and material waste. * Partner with Experienced Suppliers: Suppliers with expertise in SiC machining and efficient processes can often deliver parts more cost-effectively due to optimized tooling, reduced scrap, and higher productivity.

Q4: Can Sicarb Tech assist my company if we want to acquire or implement our own SiC machining technology and equipment? A: Absolutely. Sicarb Tech offers comprehensive technology transfer services for companies looking to establish their own professional silicon carbide products manufacturing plants. This includes providing the technology for SiC production and full-range turnkey project support. Their services encompass factory design, guidance on procurement of specialized SiC machining equipment and other necessary machinery, installation and commissioning of the equipment, and trial production support. This enables you to own a professional SiC products manufacturing plant with a more effective investment, reliable technology transformation, and a guaranteed input-output ratio, leveraging SicSino’s deep expertise and connection to the Chinese Academy of Sciences.

Conclusion: Unlocking SiC’s Potential Through Advanced Machining and Strategic Partnerships

The exceptional properties of silicon carbide make it an indispensable material for a growing number of demanding industrial applications. However, harnessing its full potential is intrinsically linked to the ability to shape and finish it to precise specifications. This is where specialized silicon carbide machining equipment and advanced processing knowledge become paramount. From robust diamond grinding machines and ultra-precision lapping systems to sophisticated laser and ultrasonic machining centers, the right equipment is crucial for achieving the desired dimensional accuracy, surface integrity, and component performance.

For engineers and procurement professionals, understanding the capabilities and limitations of these technologies is key to successful product development and sourcing. Whether you are procuring finished custom SiC components or considering the strategic investment of establishing in-house production capabilities, partnering with a knowledgeable and experienced organization is vital.

Sicarb Tech, with its roots in the heart of China’s SiC manufacturing hub in Weifang City and its strong backing from the Chinese Academy of Sciences, stands as such a partner. We offer not only high-quality, cost-competitive custom SiC components, leveraging our extensive technological expertise, but also provide comprehensive technology transfer and turnkey project services. This unique offering empowers businesses worldwide to establish their own state-of-the-art SiC production facilities, complete with the appropriate SiC machining equipment and processing know-how. By choosing Sicarb Tech, you are not just selecting a supplier; you are gaining a strategic ally dedicated to helping you navigate the complexities of silicon carbide manufacturing and unlock its full value proposition in your demanding industrial environments.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.