The Unyielding Demand for Perfection: Why Silicon Carbide Inspection is Paramount

Share

In the realm of advanced materials, silicon carbide (SiC) stands out for its exceptional properties, making it indispensable in high-performance industrial applications. From the scorching environments of semiconductor processing and high-temperature furnaces to the demanding precision of aerospace components and the ruggedness required in energy and industrial manufacturing, SiC delivers unparalleled thermal conductivity, wear resistance, chemical inertness, and mechanical strength. However, the very characteristics that make custom silicon carbide components so valuable also necessitate an unwavering commitment to quality. The slightest flaw, invisible to the naked eye, can lead to catastrophic failures in critical systems. This is where the silicon carbide inspection machine becomes not just a tool, but a cornerstone of reliability and performance.

Silicon carbide is a synthetic crystalline compound of silicon and carbon. Its inherent hardness and ability to withstand extreme temperatures (up to 1650∘C or higher for some grades) make it a preferred technical ceramic for applications where other materials falter. Industries rely on SiC for components like semiconductor wafer handling systems, furnace linings and kiln furniture, rocket nozzles, heat exchangers, mechanical seals, and bearings. The performance of these high-performance ceramic parts is directly tied to their structural integrity and dimensional accuracy.

The manufacturing of SiC components, whether through reaction bonding (RBSiC or SiSiC), sintering (SSiC), or other methods, is a complex process. Despite meticulous control, microscopic defects can arise. These imperfections can act as stress concentrators, leading to premature fracture, or they can compromise the material’s thermal or electrical properties. Given the often-critical nature of SiC applications – where failure can mean costly downtime, compromised safety, or mission failure – rigorous inspection is not a luxury but an absolute necessity. SiC parts quality assurance relies heavily on identifying and eliminating substandard components before they enter service.

A silicon carbide inspection machine employs sophisticated technologies to detect these hidden flaws and verify dimensional conformance. These machines are crucial for industrial SiC quality control, enabling manufacturers and end-users to ensure that every component meets the stringent specifications required for its intended use. As industries push the boundaries of temperature, pressure, and mechanical stress, the demand for flawless SiC components, and therefore advanced inspection capabilities, will only continue to grow. Companies like Sicarb Tech, with their deep expertise in custom SiC product manufacturing and a commitment to quality, understand the critical role of inspection in delivering reliable solutions to their B2B clients, including wholesale buyers, technical procurement professionals, OEMs, and distributors.

Unmasking Potential Failures: Common Defects in Silicon Carbide and Their Impact

The journey of a silicon carbide component from raw powder to a finished, high-precision part is intricate. Throughout this process, various types of defects can be introduced, each with the potential to compromise the component’s performance, longevity, and safety. Understanding these common defects is the first step in appreciating the critical role of silicon carbide inspection machines in SiC defect analysis and overall quality assurance. For engineers and procurement managers, recognizing these potential failure points is crucial for specifying appropriate inspection protocols and selecting reliable suppliers.

The most common defects found in custom silicon carbide components include:

- Cracks and Micro-cracks: These are perhaps the most critical defects, as SiC is a brittle material. Cracks can originate from thermal stresses during cooling, mechanical stresses during machining or handling, or from pre-existing flaws in the material. Even microscopic cracks can propagate under operational loads or thermal cycling, leading to catastrophic fracture.

- Porosity: Pores are voids within the SiC matrix. While some level of controlled porosity might be desired in specific applications (e.g., filters), unintended or excessive porosity significantly reduces mechanical strength, thermal conductivity, and can affect the material’s hermeticity. High porosity can be a result of incomplete sintering or issues with the initial powder packing.

- Inclusions: Foreign particles or unreacted raw materials embedded within the SiC structure are termed inclusions. These can be metallic or non-metallic and often have different thermal expansion coefficients than the SiC matrix. This mismatch can create internal stresses, leading to crack initiation points. Inclusions can also affect the electrical properties of SiC, which is critical in semiconductor applications.

- Dimensional Deviations: Precision is paramount for many SiC applications, such as components for semiconductor manufacturing equipment or aerospace guidance systems. Deviations from specified dimensions, including length, width, thickness, parallelism, perpendicularity, and profile tolerances, can render a part unusable or lead to assembly issues and performance degradation.

- Surface Flaws: Surface imperfections such as scratches, pits, chips, or an inadequate surface finish can be detrimental. For components requiring smooth surfaces for sealing, low friction, or optical properties (like SiC mirrors), these flaws are unacceptable. Surface flaws can also act as stress risers, similar to cracks.

- Inhomogeneities in Density or Composition: Variations in density or the distribution of SiC grains and any secondary phases (like free silicon in RBSiC) can lead to inconsistent mechanical and thermal properties across the component. This is particularly important for technical ceramics used in applications with uniform stress or temperature distributions.

The impact of these defects can be severe, as highlighted in the table below:

| Defect Type | Potential Impact on SiC Component Performance | Industries Most Affected |

|---|---|---|

| Cracks/Micro-cracks | Sudden fracture, reduced strength, compromised structural integrity | Aerospace, Energy, Semiconductor, Industrial Manufacturing |

| Porosity | Reduced mechanical strength, lower thermal conductivity, potential leakage paths | All, especially high-pressure and high-stress applications |

| Inclusions | Stress concentration, crack initiation, altered electrical/thermal properties | Semiconductor, Electronics, Aerospace |

| Dimensional Errors | Assembly problems, improper fit, reduced efficiency, system malfunction | Semiconductor, Aerospace, Precision Engineering |

| Surface Flaws | Increased friction, wear, sealing issues, compromised optical performance | Industrial Manufacturing (seals, bearings), Optics |

| Inhomogeneities | Unpredictable mechanical behavior, localized overheating, premature failure | High-Temperature Furnaces, Power Electronics |

Sicarb Tech, leveraging its deep understanding of SiC production processes developed since 2015 in Weifang, China’s SiC hub, recognizes the critical nature of defect prevention and detection. Their focus on precision SiC manufacturing incorporates stringent quality control measures, including advanced inspection techniques, to ensure that their custom SiC products meet the exacting demands of OEMs and technical buyers. This commitment is crucial for maintaining the reliability that industries expect from high-performance ceramic components.

The Eyes of Precision: Technologies Powering Silicon Carbide Inspection Machines

To effectively identify the diverse range of potential defects in silicon carbide components, silicon carbide inspection machines rely on a suite of advanced Non-Destructive Testing (NDT) and, in some cases, Destructive Testing (DT) methodologies. These technologies provide the “eyes” to see within and across the surface of SiC parts, ensuring that they meet the stringent quality standards required for demanding applications. For procurement professionals and engineers selecting custom silicon carbide products, understanding these inspection technologies provides confidence in the supplier’s quality assurance capabilities.

Non-Destructive Testing (NDT) Methods:

NDT techniques are paramount as they allow for thorough inspection without damaging the component, making 100% inspection feasible for critical parts. Key NDT methods integrated into modern SiC inspection machines include:

- X-ray Radiography and Computed Tomography (CT): X-ray techniques are invaluable for detecting internal defects such as porosity, inclusions, and larger cracks. X-rays pass through the SiC component, and differences in material density or thickness attenuate the beam differently, creating an image on a detector. CT scanning takes this further by generating 3D reconstructions of the component, allowing for detailed visualization and analysis of internal structures and flaws. This is crucial for SiC defect analysis in complex geometries.

- Ultrasonic Testing (UT): UT uses high-frequency sound waves transmitted into the SiC material. Echoes are generated when the waves encounter an interface, such as a crack, void, or inclusion. By analyzing these echoes (their time-of-flight and amplitude), inspectors can determine the size, location, and nature of internal defects. Phased array ultrasonic testing (PAUT) offers enhanced capabilities for inspecting complex shapes and improving defect characterization.

- Acoustic Emission (AE) Testing: AE is a passive NDT technique that “listens” for the high-frequency stress waves generated by active defects (e.g., crack growth) when a component is subjected to a stimulus, such as mechanical load or thermal stress. It’s particularly useful for monitoring the structural integrity of SiC components in-situ or during proof testing.

- Scanning Electron Microscopy (SEM): While often used for detailed analysis of known defects or for material characterization, SEM can also be an inspection tool for very fine surface details and microstructural features. It provides much higher magnification and depth of field than optical microscopy, revealing minute cracks or surface porosity.

- Optical and Laser-Based Inspection Systems: These systems use high-resolution cameras, structured light, or laser scanners for precise dimensional measurements and surface flaw detection. Automated optical inspection (AOI) can rapidly scan surfaces for scratches, pits, discoloration, and other visual imperfections. Laser profilometry and interferometry can measure surface roughness and flatness with high accuracy.

- Coordinate Measuring Machines (CMMs): CMMs are used for precise dimensional metrology. A probe (contact or non-contact) touches multiple points on the component’s surface to create a 3D map of its geometry. This data is then compared against the CAD model to verify dimensional tolerances, crucial for precision SiC manufacturing.

- Dye Penetrant Testing (DPT): A simpler NDT method where a colored or fluorescent liquid dye is applied to the surface. The dye seeps into surface-breaking defects (cracks, porosity). After removing excess dye, a developer is applied, drawing the penetrant out of the flaws, making them visible.

Destructive Testing (DT) Methods:

While the goal is usually non-destructive inspection, DT methods are sometimes employed on sample components or test coupons to verify bulk material properties or to perform failure analysis. These might include:

- Flexural Strength Testing (e.g., 3-point or 4-point bend tests): To determine the material’s strength and modulus of rupture.

- Hardness Testing: To verify the material’s resistance to indentation.

- Fractography: Detailed analysis of fracture surfaces (often using SEM) to understand failure origins.

Sicarb Tech emphasizes a comprehensive approach to quality, benefiting from the technological advancements within Weifang, a region accounting for over 80% of China’s SiC output. Their access to a wide array of technologies, including material, process, design, measurement, and evaluation technologies, ensures that their technical ceramics inspection protocols are robust, enabling them to meet diverse customization needs for SiC for OEMs and other industrial buyers. This integrated process, from materials to final product evaluation, ensures a reliable supply of high-quality components.

Decoding Excellence: Essential Features and Capabilities of Modern SiC Inspection Machines

When investing in custom silicon carbide components or the equipment to inspect them, technical buyers, engineers, and procurement managers need to understand the key features that define a capable and reliable silicon carbide inspection machine. These features ensure that the inspection process is not only accurate but also efficient and adaptable to the varied demands of modern industrial applications. A well-chosen inspection system is a critical asset in maintaining SiC parts quality assurance.

Modern SiC inspection machines should offer a combination of the following:

- High Resolution and Accuracy:

- The ability to detect the smallest relevant defects (micro-cracks, fine porosity) is paramount. Resolution requirements will vary depending on the application’s criticality.

- For dimensional metrology, high accuracy and repeatability are essential to ensure components meet tight precision SiC manufacturing tolerances. This is often quantified by the machine’s measurement uncertainty.

- Speed and Throughput:

- In production environments, inspection speed is crucial to keep pace with manufacturing output. Automated systems are often preferred for high-volume applications.

- The machine should allow for efficient setup and quick changeovers between different types of SiC components.

- Automation and Robotics Integration:

- Automated defect recognition (ADR) software can significantly reduce operator dependency and subjectivity, leading to more consistent results.

- Robotic handling systems can automate the loading and unloading of parts, further enhancing throughput and allowing for lights-out operation in some cases. This is key for industrial SiC quality control at scale.

- Advanced Data Logging and Analysis Capabilities:

- Comprehensive data logging for each inspected part, including defect locations, sizes, and classifications, is vital for traceability and process improvement.

- Sophisticated software for data analysis, trend identification, and statistical process control (SPC) helps in proactively addressing manufacturing issues. This allows for robust SiC defect analysis.

- Software Integration and User-Friendliness:

- Intuitive user interfaces (UIs) that simplify operation, programming, and data review are essential.

- The ability to integrate with factory MES (Manufacturing Execution Systems) or QMS (Quality Management Systems) for seamless data flow is increasingly important.

- Support for CAD model import for dimensional comparison is a standard feature in advanced CMMs and optical systems.

- Versatility and Adaptability:

- The machine should be capable of inspecting various SiC grades (e.g., RBSiC, SSiC, nitride-bonded SiC) which may have different optical or acoustic properties.

- Adaptability to a wide range of component sizes and complex geometries is crucial, especially for suppliers of custom silicon carbide products. This might involve interchangeable sensors, flexible fixtures, or multi-axis movement systems.

- Reliability and Robustness:

- Inspection machines themselves must be reliable and built to withstand industrial environments if deployed near production lines.

- Low maintenance requirements and good vendor support (including calibration services) are important considerations for long-term operational efficiency.

The following table summarizes key features and their benefits for technical ceramics inspection:

| Feature | Benefit for SiC Inspection | Target User Focus |

|---|---|---|

| High Resolution & Accuracy | Detection of minute flaws, ensuring critical performance and dimensional integrity. | Engineers, Quality Managers |

| Speed & Throughput | Cost-effective inspection for production volumes, reduced bottlenecks. | Production Managers, Procurement (cost) |

| Automation & Robotics | Consistent results, reduced labor costs, potential for 24/7 operation. | Operations Managers, Automation Engineers |

| Advanced Data & Analysis | Process control, quality improvement, traceability, compliance with industry standards. | Quality Engineers, Process Engineers |

| Software Integration & UI | Ease of use, efficient workflow, seamless data management. | Operators, System Integrators |

| Versatility & Adaptability | Ability to inspect diverse SiC parts, future-proofing investment. | Procurement Managers, R&D, Custom Part Suppliers |

| Reliability & Robustness | Consistent uptime, lower total cost of ownership, dependable quality data. | Maintenance Teams, Plant Managers |

Ensuring Reliability Across Industries: Applications of SiC Inspection Machines

The exceptional properties of silicon carbide have led to its adoption in a wide array of critical industrial sectors. In each of these fields, the failure of an SiC component can have significant consequences, making the role of silicon carbide inspection machines absolutely vital for ensuring safety, reliability, and operational efficiency. These machines are deployed to scrutinize custom silicon carbide components destined for some of the most demanding environments.

Semiconductor Manufacturing: The semiconductor industry is a major consumer of high-purity SiC components. Applications include:

- Wafer Chucks and Susceptors: Used in plasma etch, chemical vapor deposition (CVD), and ion implantation processes. These require extreme flatness, thermal uniformity, and chemical resistance. Inspection machines verify dimensional accuracy, surface finish, and check for micro-cracks or porosity that could lead to particle generation or uneven heating.

- Process Chamber Components: Liners, rings, gas showerheads, and edge rings made from SiC must withstand corrosive gases and high temperatures. SiC defect analysis using X-ray or ultrasonic inspection ensures no internal flaws compromise their integrity.

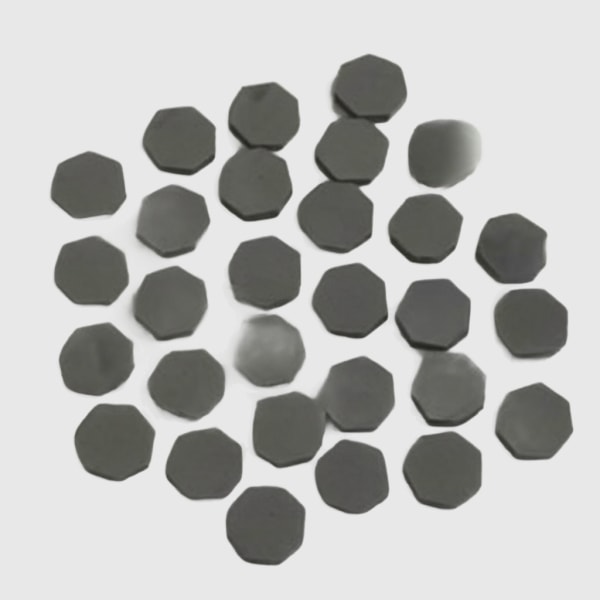

- CMP Rings (Chemical Mechanical Planarization): Require excellent wear resistance and dimensional stability. Inspection focuses on surface quality and precise dimensions.

Aerospace and Defense: SiC’s lightweight, high stiffness, and thermal stability make it ideal for:

- Optical Systems: Mirrors and telescopes for space-based and ground-based applications. Surface figure, finish, and absence of internal stresses are critical, necessitating advanced optical and interferometric inspection.

- Structural Components: Elements in high-speed aircraft or missiles requiring thermal shock resistance and high strength-to-weight ratio. NDT methods like ultrasonic and X-ray CT are crucial for detecting internal flaws in these high-performance ceramic parts.

- Turbine Engine Components: Experimental use in hot-section components like blades or vanes, where thermal and mechanical stresses are extreme.

High-Temperature Furnaces and Thermal Processing: SiC is a staple material for constructing durable components in industrial furnaces:

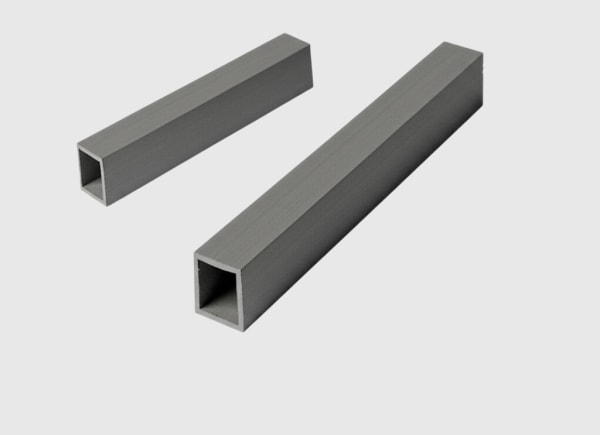

- Heating Elements: SiC rods and tubes provide efficient and reliable heating. Inspection checks for uniform electrical properties and absence of defects that could lead to premature burnout.

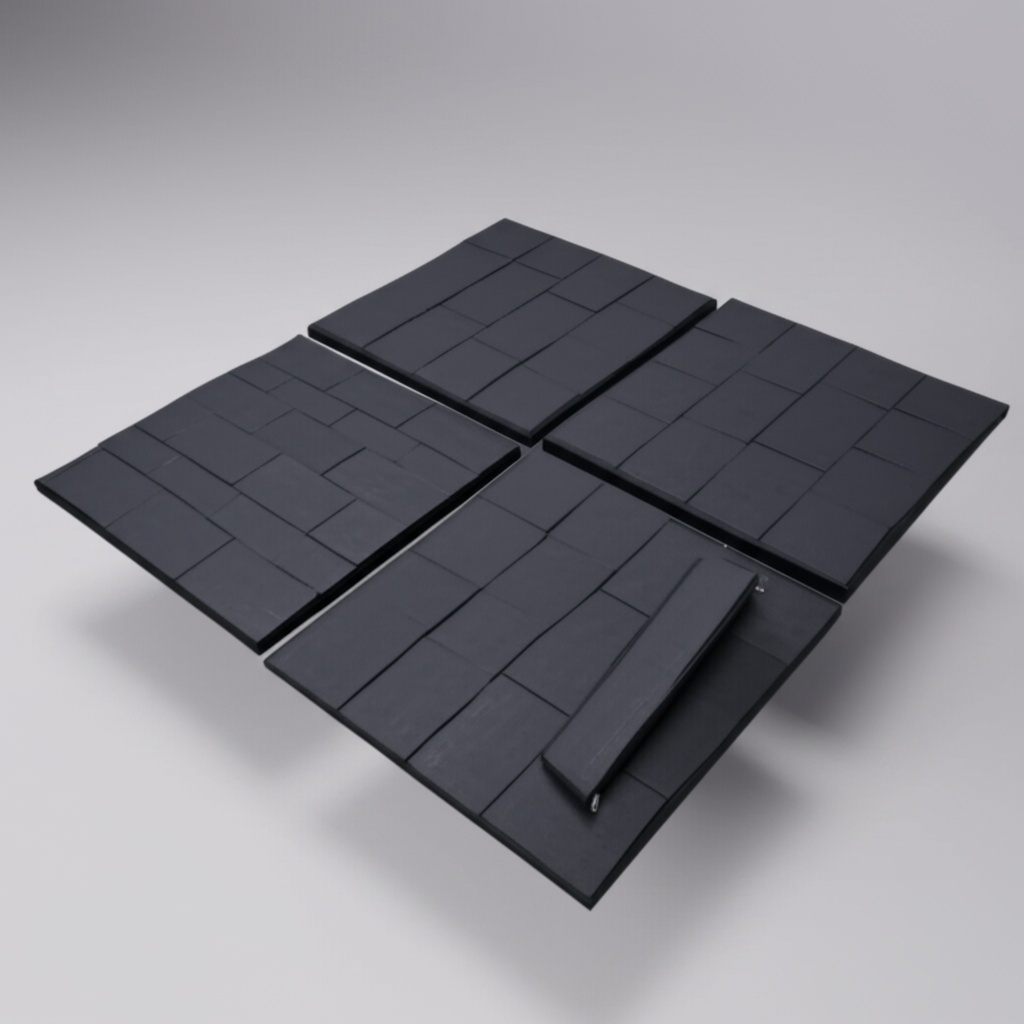

- Kiln Furniture: Beams, rollers, plates, and supports used in firing ceramics, metals, and other materials. These technical ceramics must resist sagging, thermal shock, and chemical attack. Inspection focuses on strength-bearing capabilities and crack detection.

- Burner Nozzles and Radiant Tubes: Require high abrasion and thermal shock resistance. Dimensional accuracy and integrity are key.

Energy Sector: The energy industry utilizes SiC for its thermal and electrical properties:

- Power Electronics: SiC-based MOSFETs and diodes operate at higher voltages, temperatures, and frequencies than silicon-based devices, leading to more efficient power conversion. While inspection at the device level is specialized, the SiC substrates and packaging components require rigorous quality control for thermal management and reliability.

- Heat Exchangers: For high-temperature and corrosive environments, SiC heat exchangers offer superior performance. Inspection ensures tube integrity and leak-tightness.

- Nuclear Applications: SiC is explored for fuel cladding and structural components in advanced nuclear reactors due to its radiation tolerance and high-temperature stability. Flawless material is paramount for safety.

Industrial Manufacturing: The robustness of SiC lends itself to various wear and corrosion-resistant applications:

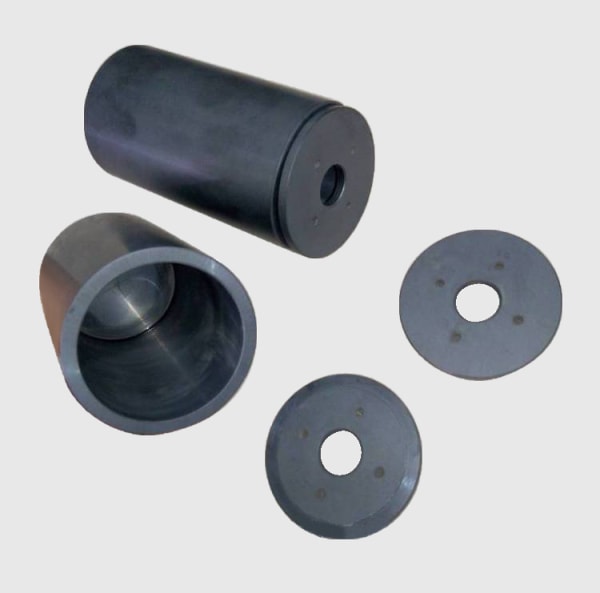

- Mechanical Seals and Bearings: Used in pumps, compressors, and other rotating equipment handling abrasive or corrosive fluids. Surface finish, dimensional precision, and absence of porosity are critical for sealing performance and wear life.

- Wear Parts: Linings for pipes, cyclones, and chutes handling abrasive slurries. Inspection checks for uniform hardness and integrity.

- Nozzles: For sandblasting, water jet cutting, and chemical spraying, where wear and corrosion resistance are key

From Raw Material to Final Product: Integrating SiC Inspection for Superior Quality Assurance

Achieving the superior quality demanded by industries relying on custom silicon carbide components is not a matter of chance; it’s the result of a meticulously planned and executed quality assurance strategy that integrates inspection at every critical stage of the manufacturing process. From the initial raw materials to the final, finished part, vigilant SiC parts quality assurance is essential. This multi-stage approach helps in early defect detection, process optimization, and ultimately, the delivery of reliable high-performance ceramic products.

The Stages of Integrated SiC Inspection:

- Raw Material Inspection:

- Importance: The quality of the final SiC component heavily depends on the purity, particle size distribution, and morphology of the starting SiC powders and any binders or sintering aids.

- Methods: Techniques like X-ray diffraction (XRD) for phase purity, laser diffraction for particle size analysis, SEM for morphology, and chemical analysis for elemental composition are employed.

- Impact: Ensuring raw material quality prevents issues like inconsistent sintering, unexpected phase formation, or reduced mechanical properties in the final product.

- Green Body Inspection (Pre-Sintering):

- Importance: After forming (e.g., pressing, slip casting, extrusion), the “green” SiC part is relatively fragile. Detecting defects at this stage is cost-effective as it prevents the expenditure of energy and resources on sintering a flawed component.

- Methods: Visual inspection for cracks or chips, and sometimes gentle NDT methods like low-power X-ray or acoustic resonance testing can identify significant flaws or density variations. Dimensional checks are also performed.

- Impact: Early removal of defective green bodies improves overall yield and reduces wastage.

- In-Process Inspection (Post-Sintering / Pre-Machining):

- Importance: After sintering, the SiC component achieves most of its final density and hardness. This is a critical point for comprehensive NDT.

- Methods: X-ray radiography or CT scanning for internal voids, inclusions, or cracks. Ultrasonic testing is also widely used. Dimensional checks are performed to assess shrinkage and distortion during sintering.

- Impact: Identifies parts that may not be salvageable through machining or that require special attention during finishing. Provides feedback for optimizing the sintering process.

- Post-Machining Inspection (Final Inspection):

- Importance: Machining SiC is a challenging process due to its hardness. This stage verifies that final dimensions, tolerances, and surface finish meet specifications, and that no new defects (e.g., machining-induced cracks) have been introduced.

- Methods: Coordinate Measuring Machines (CMMs) for precise dimensional verification, optical profilometry or stylus-based systems for surface roughness, dye penetrant testing or high-resolution optical inspection for surface-breaking cracks, and potentially SEM for critical surface features.

- Impact: This is the final gatekeeper ensuring that only conforming technical ceramics are shipped to the customer. Comprehensive industrial SiC quality control at this stage is non-negotiable.

The table below outlines the focus of inspection at different manufacturing stages:

| Manufacturing Stage | Primary Inspection Focus | Key Technologies Used | Objective |

|---|---|---|---|

| Raw Material | Purity, particle size, morphology, composition | XRD, Laser Diffraction, SEM, Chemical Analysis | Ensure input material meets specifications. |

| Green Body (Pre-Sinter) | Major cracks, chips, significant density variations, dimensions | Visual, Low-power X-ray, Acoustic Resonance, Gauges | Early defect removal, reduce sintering waste. |

| Post-Sinter/Pre-Machining | Internal defects (voids, cracks, inclusions), density, dimensions | X-ray/CT, Ultrasonic, Density Measurement, Calipers | Identify non-salvageable parts, optimize sinter. |

| Post-Machining (Final) | Final dimensions, tolerances, surface finish, surface defects | CMM, Optical Profilometry, DPT, SEM, Visual Inspection | Ensure conformity to all specifications. |

Sicarb Tech stands as a testament to the importance of integrated quality control. Having introduced and implemented silicon carbide production technology since 2015, assisting local Weifang enterprises in achieving large-scale production and technological advancements, SicSino embodies a culture of quality. Their domestic top-tier professional team specializes in customized production, leveraging a wide array of material, process, design, measurement, and evaluation technologies. This holistic approach, which encompasses the entire spectrum from material science to finished product validation, ensures that Sicarb Tech can offer higher-quality, cost-competitive customized silicon carbide components. Their commitment to quality is further underscored by their capability to assist clients in establishing their own specialized SiC factories, transferring not just production technology but also the critical knowledge of quality assurance and inspection.

Selecting Your Partner in Precision: Choosing the Right SiC Inspection Solution and Supplier

Making the right choice in silicon carbide inspection machines or selecting a supplier for custom silicon carbide components that employs rigorous inspection is a critical decision for any business relying on these high-performance materials. The selection process should go beyond just the initial cost and consider technical capabilities, reliability, support, and the supplier’s overall expertise in SiC material characterization and defect analysis.

Key Factors When Choosing an SiC Inspection Machine:

- Technical Specifications and Capabilities:

- Defect Detectability: Does the machine’s resolution and sensitivity match the types and sizes of defects you need to find (e.g., micro-cracks, porosity levels)?

- Range of Materials and Geometries: Can it effectively inspect the specific SiC grades (RBSiC, SSiC, etc.) and the range of component sizes and complexities you handle?

- Inspection Speed and Automation: Does the throughput meet your production demands? What level of automation is available and suitable for your operations?

- Software and Data Analysis: Is the software user-friendly, powerful, and capable of providing the data insights you need for SiC defect analysis and process control?

- Supplier Reputation and Expertise:

- Track Record: Does the machine vendor have a proven history in supplying reliable inspection equipment for technical ceramics?

- Application Support: Can they provide expert advice on configuring the machine for your specific SiC components and inspection challenges?

- Training and After-Sales Service: What level of training is provided for operators and maintenance staff? Is responsive technical support and calibration service available?

- Cost of Ownership:

- Initial Purchase Price: While important, it shouldn’t be the sole factor.

- Operational Costs: Consider consumables, energy consumption, and labor requirements.

- Maintenance and Downtime: Factor in the cost of preventive maintenance, spare parts, and potential losses due to machine downtime.

Key Factors When Choosing a Supplier of Custom SiC Components (with a focus on their inspection capabilities):

- Demonstrated Quality Management System:

- Certifications: Do they hold relevant quality certifications (e.g., ISO 9001)?

- Inspection Protocols: Can they clearly articulate their inspection procedures at various manufacturing stages? What technologies do they employ for industrial SiC quality control?

- Traceability: Do they have robust systems for material and process traceability?

- Technical Expertise and Customization Capabilities:

- Material Knowledge: Do they understand the nuances of different SiC grades and their suitability for your application?

- Design for Manufacturability: Can they provide input on design to optimize for quality and inspectability?

- Range of Inspection Technologies: Do they have access to appropriate inspection equipment (in-house or through certified partners) to verify the quality of your specific components? This is vital for precision SiC manufacturing.

- Reliability and Partnership:

- Consistent Quality: Do they have a track record of delivering consistently high-quality components?

- Communication and Transparency: Are they open about their processes and willing to share inspection data?

- Problem Resolution: How do they handle quality issues if they arise?

In this context, Sicarb Tech emerges as a uniquely positioned partner. Not only do they supply high-quality, customized silicon carbide components from the heart of China’s SiC manufacturing hub in Weifang, but their deep involvement in the technological advancement of the local industry provides them with unparalleled insight into best practices, including state-of-the-art inspection. Their backing by the Chinese Academy of Sciences National Technology Transfer Center signifies a commitment to robust scientific and technological capabilities.

For companies seeking silicon carbide for OEMs or looking for silicon carbide wholesale options, SicSino offers more than just parts; they offer a partnership built on a foundation of quality and technological expertise. Their domestic top-tier professional team, specializing in customized production, utilizes an integrated process from materials to products, inherently embedding rigorous quality checks. Furthermore, Sicarb Tech‘s unique offering of technology transfer for professional silicon carbide production—including factory design, equipment procurement, installation, commissioning, and trial production—means they possess an end-to-end understanding of what it takes to produce and inspect SiC components to the highest standards. This makes them an invaluable resource for businesses aiming to ensure reliable technology transformation and a guaranteed input-output ratio, whether they are buying components or looking to establish their own SiC production capabilities with embedded quality assurance. Choosing SicSino means opting for a partner committed to reliable quality and supply assurance within China and beyond.

Frequently Asked Questions (FAQ) about Silicon Carbide Inspection Machines

Navigating the specifics of silicon carbide inspection can raise several questions for engineers, procurement managers, and quality assurance professionals. Here are answers to some common queries:

What are the most common types of defects that silicon carbide inspection machines are designed to detect?

Silicon carbide inspection machines are designed to detect a wide range of defects that can compromise the integrity and performance of SiC components. The most common include:

- Internal Defects:

- Porosity: Clusters of pores or excessive void content.

- Inclusions: Foreign particles or unreacted material embedded within the SiC matrix.

- Cracks: Sub-surface or internal cracks that are not visible on the surface.

- Surface and Sub-Surface Defects:

- Cracks/Micro-cracks: Fine fissures on or near the surface.

- Chips and Edge Defects: Physical damage, often occurring during handling or machining.

- Scratches and Pits: Surface imperfections affecting finish and potentially acting as stress risers.

- Dimensional and Geometrical Defects:

- Out-of-Tolerance Dimensions: Deviations from specified length, width, thickness, diameter, etc.

- Form Errors: Issues with flatness, parallelism, perpendicularity, roundness, or cylindricity.

- Surface Roughness: Non-conformance to specified surface finish requirements. Different inspection technologies (e.g., X-ray for internal, optical for surface, CMM for dimensional) are often combined to provide comprehensive SiC defect analysis.

How does the cost of silicon carbide inspection machines vary?

The cost of silicon carbide inspection machines can vary dramatically based on several factors:

- Technology Used: Simple visual inspection aids or dye penetrant kits are relatively inexpensive. However, sophisticated systems like X-ray CT scanners, automated ultrasonic testing (AUT) systems with phased array probes, or high-precision CMMs represent significant capital investments, ranging from tens of thousands to several million dollars.

- Level of Automation: Fully automated systems with robotic handling and automated defect recognition (ADR) software are more expensive than manual or semi-automated machines.

- Size and Complexity Capacity: Machines designed to inspect very large or highly complex SiC components will typically cost more.

- Resolution and Accuracy: Higher precision and the ability to detect smaller defects generally command a higher price.

- Software Capabilities: Advanced data analysis, reporting, and integration features add to the cost.

- Vendor and Support: Established vendors with comprehensive service and support packages may have higher initial costs. For many small to medium-sized enterprises, outsourcing technical ceramics inspection to specialized labs or relying on the robust quality control of their SiC component supplier, like Sicarb Tech, can be a more cost-effective approach than purchasing high-end inspection equipment.

Can SiC inspection machines be customized for specific applications or component sizes?

Yes, customization is a key aspect of modern SiC inspection machines, especially for custom silicon carbide products. Manufacturers of inspection equipment often work closely with clients to tailor solutions:

- Fixturing: Custom fixtures are frequently designed to securely hold specific SiC components during inspection, ensuring repeatable positioning and accurate measurements.

- Sensor Selection and Configuration: The type of sensors (e.g., specific X-ray sources/detectors, ultrasonic probes, optical lenses) can be chosen and configured to optimize detection for particular defect types, SiC grades, and component geometries.

- Software Algorithms: Inspection software can be adapted or trained (in the case of AI-based ADR) to recognize specific defect characteristics relevant to the application.

- Automation Level: The degree of automation can be scaled to match the user’s throughput requirements and budget.

- Integration: Machines can be designed to integrate into existing production lines or quality management systems. Sicarb Tech, with its focus on customized silicon carbide components and its experience in supporting diverse industrial needs, understands the importance of tailored inspection approaches. Their expertise in the integrated process from materials to products allows them to ensure appropriate inspection methodologies are applied, whether through their in-house capabilities or their network within Weifang’s SiC manufacturing ecosystem.

What level of automation is available in modern SiC inspection machines?

Modern silicon carbide inspection machines offer a wide spectrum of automation:

- Manual Systems: Require an operator to load/unload parts, manipulate the component or sensor, and interpret the results. Suitable for low-volume, high-mix inspection or R&D.

- Semi-Automated Systems: May feature motorized stages for scanning, automated data acquisition, but still require operator intervention for setup, loading, and final decision-making.

- Fully Automated Systems: Incorporate robotic part handling (loading/unloading), automated scanning sequences based on pre-programmed routines, and Automated Defect Recognition (ADR) software that identifies, classifies, and dispositions parts with minimal human oversight. These systems are ideal for high-volume industrial SiC quality control.

- ADR Software: Utilizes image processing algorithms and, increasingly, machine learning/AI to analyze inspection data (e.g., X-ray images, ultrasonic C-scans, optical images) and flag potential defects based on defined criteria.

- Robotics: Can handle parts of various sizes and weights, sort them based on inspection results (pass/fail/rework), and integrate with conveyor systems or other manufacturing cells. The trend is towards increasing automation to improve consistency, throughput, and reduce reliance on operator skill for defect detection in high-performance ceramic inspection.

How does SicSino ensure the quality of its custom SiC products through inspection?

Sicarb Tech ensures the quality of its custom SiC products through a multi-faceted approach rooted in its deep expertise and strategic position within China’s SiC industry:

- Integrated Process Control: Leveraging their comprehensive knowledge of material science, process engineering, design, measurement, and evaluation technologies, SicSino implements quality checks throughout the production cycle – from raw material verification to final product inspection. This aligns with best practices for SiC parts quality assurance.

- Technological Expertise: Having played a key role in the technological advancement of SiC production in Weifang since 2015, SicSino has access to and understanding of a wide array of inspection technologies suitable for different SiC grades and product complexities.

- Focus on Customization: For customized silicon carbide components, SicSino’s domestic top-tier professional team works to understand the specific application requirements, which then dictates the critical-to-quality characteristics and the necessary inspection rigor.

- Commitment to Reliable Supply: Their promise of higher-quality, cost-competitive components is backed by a robust quality assurance framework. This is essential for silicon carbide for OEMs and other demanding clients who require dependable parts. By combining their internal expertise with the capabilities of the Weifang SiC cluster and the scientific backing of the Chinese Academy of Sciences, Sicarb Tech provides a reliable pathway to high-quality custom SiC components where inspection is an integral part of the value proposition.

Conclusion: The Indispensable Role of Inspection in Silicon Carbide Excellence

The journey through the world of silicon carbide underscores a fundamental truth: the extraordinary capabilities of this advanced material can only be fully realized when its quality is beyond reproach. From the intricate demands of semiconductor manufacturing to the extreme environments of aerospace and high-temperature industrial processes, the reliability of custom silicon carbide components hinges on meticulous industrial SiC quality control. At the heart of this quality assurance lies the sophisticated technology and diligent application of silicon carbide inspection machines.

These machines, employing a diverse array of NDT techniques, are the silent guardians that unmask potential flaws, verify exacting dimensions, and ultimately ensure that each SiC part is fit for its demanding purpose. The ability to detect minute cracks, hidden porosity, or subtle dimensional deviations is not merely a technical capability but a critical enabler of innovation and safety across numerous industries. For engineers designing cutting-edge systems and procurement managers sourcing technical ceramics, understanding the intricacies of SiC inspection—from common defects to the technologies used for their detection—is paramount.

Choosing the right inspection strategies, whether investing in in-house equipment or partnering with a knowledgeable SiC supplier, directly impacts product performance, operational longevity, and cost-effectiveness. Companies like Sicarb Tech exemplify the commitment to quality that is essential in this field. Their deep roots in Weifang, the epicenter of China’s SiC production, combined with their affiliation with the Chinese Academy of Sciences, provide a unique platform of expertise. SicSino not only delivers custom SiC products manufactured under stringent quality controls but also offers the profound knowledge base that includes understanding and implementing world-class inspection protocols. Their integrated approach, from material science to final product validation and even technology transfer for establishing SiC production lines, highlights the non-negotiable importance of inspection in the advanced ceramics industry.

As industries continue to push the boundaries of performance, the demand for flawless, high-quality silicon carbide will only intensify. Consequently, the role of advanced inspection machines and the expertise of suppliers who prioritize rigorous quality assurance will become even more critical, ensuring that SiC continues to be a cornerstone material for innovation and reliability in the most challenging applications.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.