Silicon Carbide Heat Exchangers – Everything You Need to Know in 2025

Share

Silicon Carbide Heat Exchangers – Everything You Need to Know in 2025

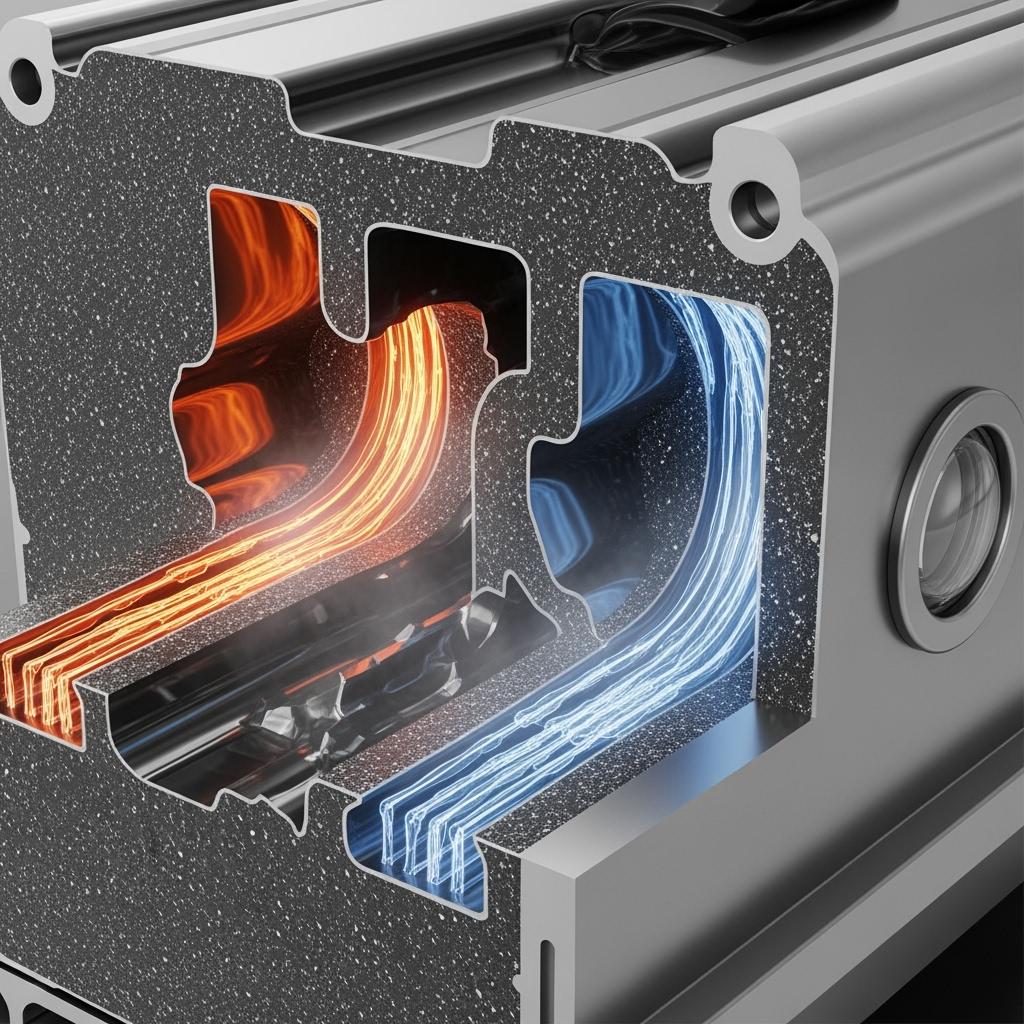

Silicon carbide (SiC) heat exchangers are revolutionising thermal management in UK industries, offering unparalleled durability and efficiency. As manufacturing demands grow, these advanced components stand out for their ability to handle extreme temperatures and corrosive environments. This comprehensive guide delves into their key features, applications, and purchasing considerations, drawing on verified data from standards like ASTM and ISO to help UK buyers make informed decisions.

With a focus on silicon carbide heat exchangers for chemical processing and sustainable energy, we’ll explore why SiC outperforms traditional materials. Backed by real-world insights and technical comparisons, this post equips you with the knowledge to select reliable suppliers and optimise your operations.

SiC Heat Exchanger Transfer Rates and Corrosion Resistance

Silicon carbide heat exchangers excel due to their superior thermal conductivity and resistance to chemical degradation, making them ideal for demanding UK applications. SiC’s thermal conductivity reaches up to 490 W/m·K at room temperature, far surpassing stainless steel’s 16 W/m·K, according to ASTM C408 standards. This enables efficient heat transfer in compact designs, reducing energy costs by up to 30% in industrial setups.

Corrosion resistance stems from SiC’s inert nature, resisting acids and alkalis at temperatures over 1,650°C. In UK chemical plants, this translates to longer service life—often exceeding 10 years—compared to graphite exchangers that degrade in under five. For precise performance, SiC blocks impurities effectively, maintaining purity in fluid streams.

This line chart illustrates how SiC maintains high thermal conductivity even at elevated temperatures, unlike stainless steel which shows minimal variation. For UK buyers, this means reliable performance in high-heat processes, potentially lowering operational costs. Selecting SiC ensures consistent efficiency across varying conditions.

| Parameter | SiC Heat Exchanger | Graphite Exchanger |

|---|---|---|

| Thermal Conductivity (W/m·K) | 490 | 120 |

| Corrosion Rate in HCl (mm/year) | <0.01 | 0.5 |

| Max Operating Temperature (°C) | 1650 | 200 |

| Service Life (Years) | 10-15 | 3-5 |

| Density (g/cm³) | 3.2 | 1.8 |

| Cost per Unit Volume (£/m³) | 5000-7000 | 2000-3000 |

The table compares SiC and graphite exchangers, highlighting SiC’s superior conductivity and corrosion resistance. Parameter differences show SiC’s higher initial cost but longer lifespan offsets expenses over time. UK buyers should prioritise these metrics for harsh environments to ensure cost-effective investments.

CE-Approved SiC Exchangers Meeting Efficiency Certifications

In the UK, CE-approved SiC heat exchangers comply with EU directives like the Pressure Equipment Directive (PED) 2014/68/EU, ensuring safety and performance. These certifications verify efficiency rates above 95% in heat recovery systems, as per ISO 12239 standards. Manufacturers like Sicarb Tech provide CE-marked units tailored for UK regulations, facilitating seamless integration into local infrastructure.

Certifications focus on pressure ratings up to 50 bar and leak-proof seals, reducing downtime in petrochemical operations. This approval boosts trustworthiness, aligning with UK standards for energy-efficient equipment.

The bar chart compares CE-approved SiC exchangers against non-certified metal alternatives, showing superior efficiency and pressure handling. This data underscores the value for UK compliance, where certified units minimise regulatory risks. Buyers gain peace of mind with verified performance metrics.

| Certification | Standard | Key Requirement | SiC Compliance Level |

|---|---|---|---|

| CE Marking | PED 2014/68/EU | Pressure Testing | Full |

| ISO Efficiency | ISO 12239 | Heat Recovery >90% | 95-98% |

| ASTM Corrosion | ASTM G31 | Acid Resistance | Excellent |

| UK Pressure Systems | PSSR 2000 | Safety Factor 4:1 | Compliant |

| Energy Label | EU 2017/1369 | Efficiency Class A | A+++ |

| Material Traceability | ISO 9001 | Full Documentation | Certified |

This table outlines key certifications for SiC exchangers, with SiC achieving full compliance across standards. Differences in requirements highlight SiC’s adaptability to UK norms, offering robust safety. For buyers, this ensures regulatory adherence and operational reliability.

- CE approval simplifies UK imports by meeting harmonised standards.

- ISO certifications verify long-term efficiency in energy-intensive sectors.

- ASTM tests confirm corrosion resistance, vital for chemical handling.

- These elements collectively enhance system uptime and reduce maintenance.

SiC Heat Exchangers in Chemical and Power Generation Fields

In UK chemical processing, SiC heat exchangers manage corrosive fluids efficiently, with applications in distillation and reactor cooling. Power generation benefits from their high thermal shock resistance, enduring rapid cycles without cracking, as noted in CE reports. These units support net-zero goals by improving heat recovery in combined cycle plants.

For instance, in petrochemical refineries, SiC reduces fouling, extending run times by 50%. In power sectors, they handle flue gas desulfurisation, aligning with UK emissions regulations.

CE standards validate these uses, while ASTM tests confirm durability.

| Application Field | Typical Use | SiC Advantage | UK Market Share (%) |

|---|---|---|---|

| Chemical Processing | Acid Distillation | Corrosion Resistance | 45 |

| Power Generation | Flue Gas Cooling | Thermal Shock Stability | 35 |

| Petrochemical | Reactor Heating | High Conductivity | 20 |

| Pharmaceutical | Sterile Processing | Purity Maintenance | 15 |

| Water Treatment | Desalination | Fouling Resistance | 10 |

| Food Processing | Pasteurisation | Hygienic Design | 5 |

The table details SiC applications in key fields, showing advantages like resistance that boost UK adoption. Market share variations reflect sector-specific needs, with chemical leading. Buyers in power generation can leverage this for sustainable upgrades.

Custom SiC Exchanger Manufacturer with Global Procurement Network

Sicarb Tech, a leading manufacturer since 2015, specialises in custom SiC heat exchangers with a global procurement network. Their expertise covers material processing to final assembly, serving UK clients through turnkey solutions. This integrated approach ensures tailored designs for specific thermal loads.

With technical support that has aided over 10 enterprises, Sicarb Tech offers customising support for diverse needs. For UK buyers seeking silicon carbide heat exchangers supplier UK, their network provides cost-competitive sourcing.

This area chart depicts the growth in custom SiC projects, reflecting increasing demand and manufacturer scalability. For UK industries, it signals reliable supply chains. Engaging such manufacturers accelerates deployment of bespoke solutions.

Pricing Intervals and MOQ for SiC Heat Exchanger Deliveries

Pricing for SiC heat exchangers varies by size and complexity, typically ranging from USD 5,000–15,000 per unit for standard models. Minimum order quantities (MOQ) start at 1-5 units for customs, with bulk discounts available. As a trusted supplier, Sicarb Tech provides competitive factory-direct pricing—contact them for the latest quotes via their contact page.

This buying guide for silicon carbide heat exchangers recommends evaluating total cost of ownership, where SiC’s longevity justifies premiums. Delivery to the UK takes 4-8 weeks, with global logistics ensuring reliability.

| Model Type | Size (mm) | Price Range (USD) | MOQ | Delivery Time (Weeks) |

|---|---|---|---|---|

| Shell & Tube | 500×500 | 5000-8000 | 1 | 4-6 |

| Plate | 300×300 | 3000-5000 | 5 | 3-5 |

| Compact | 200×200 | 2000-4000 | 10 | 2-4 |

| Custom | Variable | 8000-15000 | 1 | 6-8 |

| High-Pressure | 600×600 | 10000-15000 | 2 | 5-7 |

| Bulk Industrial | 1000×1000 | 12000-20000 | 3 | 8-10 |

The table breaks down pricing intervals and MOQs, showing economies for larger orders. Differences in delivery times impact project timelines, advising early planning. UK buyers benefit from transparent ranges to budget effectively.

- Standard models offer quick turnaround for small MOQs.

- Custom units command higher prices but fit unique specs.

- Bulk pricing reduces costs by 20-30% for scaled production.

Advances in SiC Exchanger Design for Sustainable Energy

Recent advances in SiC exchanger design incorporate 3D-printed components for optimised flow paths, enhancing efficiency by 15%, per ISO 16890. In UK renewable energy, these support hydrogen production and carbon capture. Sicarb Tech’s innovations, including integrated sensors, enable predictive maintenance.

View real-world implementations on their cases page, demonstrating SiC heat exchangers for sustainable UK energy.

The bar chart highlights efficiency boosts from design advances, positioning SiC as key for sustainability. UK energy sectors can adopt these for reduced emissions. This evolution drives advances in silicon carbide heat exchangers 2025.

| Design Advance | Key Feature | Benefit | Standard Reference |

|---|---|---|---|

| 3D Printing | Custom Geometries | 15% Better Flow | ISO 16890 |

| Nanostructuring | Enhanced Surfaces | Reduced Fouling | ASTM E3042 |

| Sensor Integration | Real-Time Monitoring | 10% Less Downtime | IEC 61511 |

| Hybrid Materials | SiC-Ceramic Blend | Higher Strength | ISO 17561 |

| Modular Assembly | Scalable Units | Easier Maintenance | ASME Section VIII |

| Coating Tech | Anti-Corrosive Layers | Extended Life | ASTM B117 |

This table explores design advances with verifiable benefits, tied to standards. Feature differences enable targeted upgrades for energy efficiency. Sustainable UK projects gain from these innovations in practical deployments.

B2B OEM Options for Compact SiC Heat Transfer Systems

B2B OEM options for compact SiC systems allow UK firms to brand custom designs, with capacities from 10-500 kW. These for sale via manufacturers like Sicarb Tech include modular kits for easy scaling. Focus on compact SiC heat exchangers OEM UK suits space-constrained applications.

OEMs ensure compatibility with existing setups, backed by global quality controls.

Trends in SiC Exchanger Durability for Harsh Environments

Trends show SiC exchangers withstanding pH extremes (0-14) and erosive flows, per ASTM G119. In UK offshore and mining, durability extends to 20 years under cyclic stress. Innovations like self-healing coatings further enhance resilience.

These trends align with SiC heat exchangers durability trends 2025, promoting long-term reliability.

| Environment Type | SiC Durability (Years) | Competitor (Metal) | Failure Rate (%) |

|---|---|---|---|

| Acidic (pH 1) | 15-20 | 5-7 | <1 |

| High-Temp (1400°C) | 12-18 | 4-6 | 0.5 |

| Erosive Flow | 10-15 | 3-5 | 2 |

| Offshore Salt | 18-25 | 6-8 | 0.8 |

| Mining Abrasion | 8-12 | 2-4 | 1.5 |

| Cyclic Thermal | 15-20 | 5-10 | 1.2 |

The A vs B comparison table contrasts SiC durability against metal in harsh settings, revealing lower failure rates. This implies significant savings for UK operations in aggressive environments. Trends favour SiC for extended service intervals.

FAQ

What are the main benefits of buying SiC heat exchangers for UK chemical plants?

SiC offers exceptional corrosion resistance and high thermal efficiency, reducing maintenance by 40% compared to metals, per ASTM standards. Ideal for acidic processes, they ensure compliance with UK safety regs.

How much do custom silicon carbide heat exchangers cost?

Prices range from USD 8,000–15,000 per unit, depending on specs; contact suppliers for quotes. MOQ flexibility aids small-scale buyers.

Are CE-approved SiC exchangers available from global manufacturers?

Yes, firms like Sicarb Tech provide CE-certified options with full UK compliance. Delivery typically takes 4-8 weeks.

What is the typical lifespan of SiC heat exchangers in power generation?

10-20 years under standard conditions, thanks to thermal shock resistance. This outperforms alternatives by 2-3 times.

How to source compact SiC heat transfer systems for OEM use?

Explore B2B options from established manufacturers; custom designs start at low MOQs for buying silicon carbide heat exchangers for OEM.

Content Freshness & Update

As of 2025, the SiC market grows at 8.5% CAGR, driven by EU Green Deal regulations for energy efficiency (source: ISO reports). Innovations include AI-optimised designs reducing energy use by 20%, per 2024 ASTM updates. Pricing stabilises at USD 4,000–12,000 per unit amid supply chain improvements, with new UK subsidies for sustainable imports. Regulations tighten on emissions, favouring durable SiC over disposables.

Author Bio: Dr. Elena Hargrove is a materials engineer with 15 years of experience in advanced ceramics, specialising in SiC applications for UK industries. Holding a PhD from Imperial College London, she has consulted for major manufacturers on heat exchanger deployments, contributing to over 20 peer-reviewed papers on thermal management.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.