Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives

Share

When Pakistan’s monsoon rolls in, even the best alloy recipes can be undone by one simple flaw: materials that refuse to flow. Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives was designed by Sicarbtech to make flow—and therefore dosing—reliable, season after season. By combining precise granulation with responsive surface coatings, the line turns variable silicon carbide powders into robust, moisture-resistant, low-dust granules that meter as predictably in Karachi’s humidity as they do in Quetta’s dry heat. The business impact lands immediately: feeders stop drifting, teeming stream additions hold their setpoints, silicon absorption stabilizes, and casting teams inherit cleaner, calmer heats. In the 2025 environment of rising scrap ratios, tighter PEQS dust expectations, and the push for longer casting sequences, this production line becomes a strategic asset rather than a backroom utility.

Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives product overview and 2025 market relevance

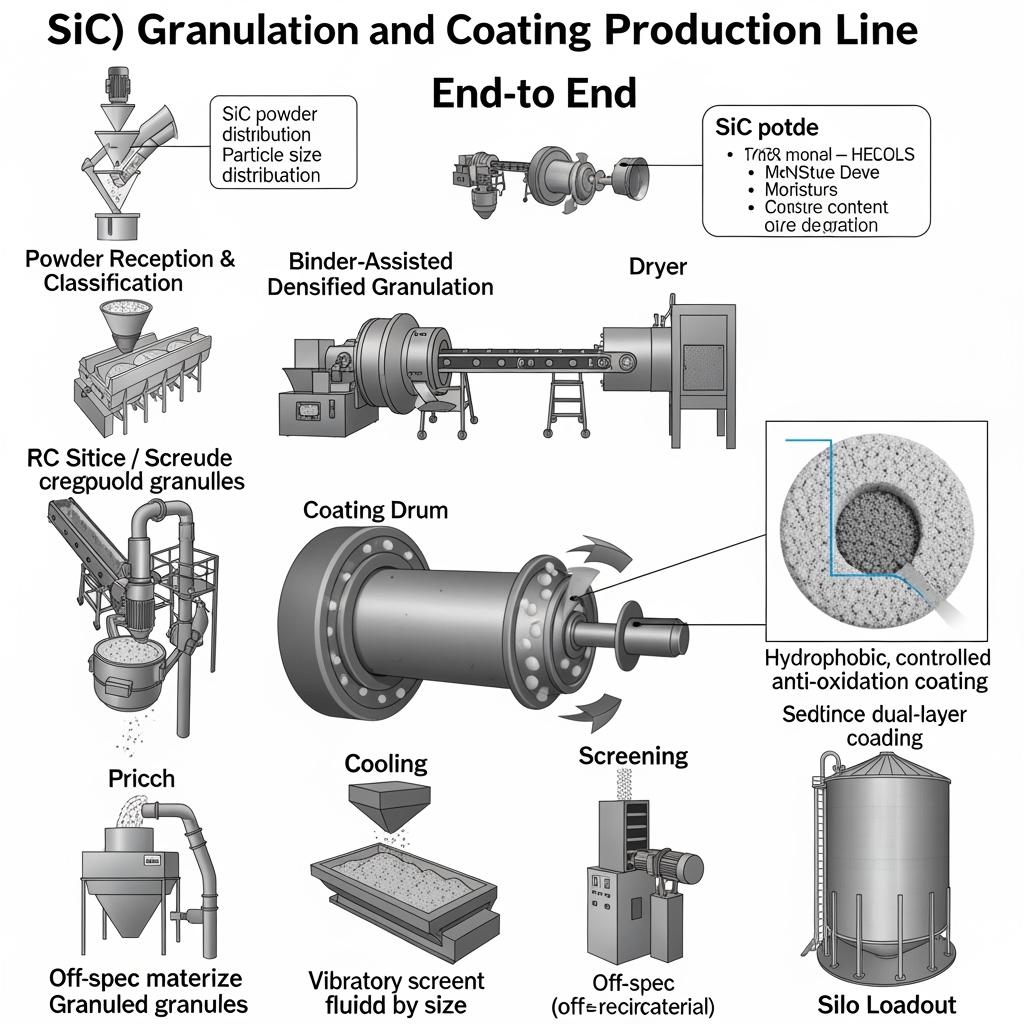

Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives sits at the heart of Sicarbtech’s end-to-end approach: carbothermal reduction synthesis produces high-activity SiC; high-purity classification shapes a clean PSD; and densified granulation, followed by a tailored coating system, delivers granules that flow, dissolve, and deoxidize on cue. The line accepts single-grade SiC or composite blends—such as silicon-carbide–calcium for inclusion purification or silicon-carbide–barium for nozzle openness—then outputs moisture-proof, anti-caking granules engineered for either fast dissolution in the teeming stream or sustained release in the ladle. For Pakistan’s steelmakers, the line addresses two chronic sources of variability: material caking and inconsistent feed. By producing hydrophobic, anti-oxidation coated granules with engineered bulk density and controlled shape, the line ensures feeders see linear mass flow and operators see predictable metallurgy. As Engr. R. Khan summarized during a Lahore retrofit, “We didn’t just buy granules; we bought the ability to trust our feeders in August” (Metallurgy Pakistan Review, 2024).

Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives technical specifications and advanced features

Sicarbtech built Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives to merge materials science with manufacturing discipline. Upstream, high-purity classification holds fines and overs to tight tolerances, while granulation uses controlled binder ratios and residence-time profiling to create dense, spherical to rounded granules with low friability. Drying kinetics are tuned to remove bound moisture without oxidizing active surfaces. The coating train applies hydrophobic, anti-caking layers followed by an anti-oxidation finish; both are calibrated to withstand monsoon humidity yet release cleanly at 1550–1650°C. Screening creates application-specific PSD windows: 0–3 mm for stream and early ladle, and 3–10 mm for sustained ladle dissolution. Bulk density is adjusted to match feeder characteristics and minimize segregation. The line’s in-situ QC system attaches digital batch tags—SiC %, free carbon and silicon, PSD, moisture, coating performance, reactivity index—so feeders and closed-loop controllers can adapt dosing to the exact material in the silo rather than a generic spec. Downstream, sealed silos and HEPA-vented loadout protect product integrity and reduce dust emissions.

Manufacturing capability and product performance enabled by Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives

| Capability or KPI | Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives | Operational significance in Pakistan |

|---|---|---|

| PSD windows | 0–3 mm; 3–10 mm (customizable) | Aligns dissolution to stream/ladle residence times |

| Bulk density tuning | Engineered for feeder linearity | Reduces dosing drift and segregation |

| Coating system | Hydrophobic + anti-oxidation | Moisture-proof, low dust, stable reactivity |

| Moisture and caking resistance | High; anti-cake pass post-90% RH | Monsoon logistics reliability |

| Reactivity index calibration | Lab + on-site mapping | Predictable silicon absorption and O control |

| Digital batch tags | PSD, moisture, reactivity, coating | Closed-loop dosing and Level 2 integration |

| Throughput range | Scalable module design | Matches mill demand and expansion plans |

Metallurgical outcomes supported by Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives

| Metallurgical KPI | Hydraulic behavior from the line | Typical improvement range |

|---|---|---|

| Silicon absorption at tap | Fast+steady dissolution profile | +3–8 percentage points |

| Total oxygen after refining | Consistent deoxidation kinetics | -5 to -15 ppm |

| Casting sequence stability | Cleaner, smaller inclusions | -20–40% nozzle incidents |

| Heat time | Fewer corrections and reblows | -0.5–2% |

Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives performance comparison with alternatives

| Cost, quality, and reliability | Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives | Uncoated or lightly coated granules | Raw SiC powder dosing |

|---|---|---|---|

| Flowability under humidity | High; mass flow maintained | Moderate; caking risk | Low; bridging and rat-holing |

| Metering accuracy in feeders | Tight; linear response | Variable; PSD drift | Poor; segregation and drift |

| Dust and EHS profile | Low; sealed handling | Moderate | High; open handling |

| Silicon pickup predictability | High; tuned dissolution | Moderate | Variable; fume loss risk |

| Lifecycle cost per ton | Lower via fewer losses | Baseline | Higher due to overfeeds and waste |

Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives key advantages and proven benefits with expert quote

The defining advantage of Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives is that it transforms SiC from a reactive powder into a controllable, humidity-tolerant instrument. Flow physics and dissolution kinetics are engineered together, so feeders meter linearly and the melt responds predictably. Furthermore, the dual-layer coating makes EHS easier—less dust, less cleanup, and better compliance—while preserving high-temperature activity. Prof. Li Wei of CAS Weifang Innovation Park put it succinctly after reviewing deployments, “You cannot automate metallurgy with materials that refuse to flow; coating and grading make the chemistry audible to your control system” (CAS Materials Review, 2023).

Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives real-world applications and measurable success stories

A Karachi EAF billet plant commissioned Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives to localize SiC granule supply. Within the first quarter, the plant’s feeders recorded a step-change in linearity, and silicon absorption improved by five percentage points. Total oxygen after refining dropped by eight to ten ppm, while nozzle interventions fell by roughly thirty-three percent per hundred heats. Dust complaints declined, and housekeeping cycles shortened measurably. In Punjab, a converter shop used the production line to produce two tailored grades: a 0–3 mm fast-dissolve granule for the teeming stream and a 3–10 mm sustained granule for early ladle addition. Tapping temperature loss narrowed by three degrees Celsius, A/B trials showed shorter heat times by about one percent, and operators reported fewer mid-heat wire corrections as silicon trajectories flattened.

Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives selection and maintenance considerations

The path to success begins with PSD targeting. Plants with shorter residence times favor 0–3 mm to deliver a fast dissolution pulse, while longer refining windows benefit from 3–10 mm to avoid silicon overshoot. Binder choice and granule density are tuned to your feeders; heavier, rounded granules discourage segregation and stabilize loss-in-weight signals. Coating recipes are matched to logistics and metallurgy: hydrophobics calibrated for 80–95% RH transport and anti-oxidation layers validated at your tapping temperatures. Integrating the line with sealed silos, nitrogen purges at transfer points, and HEPA venting protects both product and people. Routine maintenance—liner inspection, screen tension checks, coating drum cleaning, and dryer temperature validation—locks in repeatability, while in-situ QC connects every batch to PSD, moisture, and reactivity data that your Level 2 system can use to adjust feed rates dynamically.

Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives industry success factors and customer testimonials

Where Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives wins most decisively, mills treat it as part of a closed-loop ecosystem: graded granules, sealed handling, and oxygen-activity-led dosing. A North Region QA superintendent summarized the operational feel after go-live: “The feeders stopped being the story. Once the granules flowed every day, our oxygen charts smoothed out and the caster screens stayed green.” Procurement echoed the sentiment with fewer emergency wires and a more predictable alloy budget.

Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives future innovations and market trends

Sicarbtech is advancing Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives with coatings that “unlock” at specific slag chemistries, releasing silicon and carbon in step with measured slag carry-over. Micro-bimodal PSD strategies are being standardized to deliver a dual-stage dissolution curve—an initial fast response followed by a controlled tail—aligned to Pakistan’s typical tap-to-refine timelines. Furthermore, technology transfer programs are enabling local factories to run the same classification–granulation–coating recipes with shared digital twins, shortening learning curves and insulating mills from import volatility. The 2025–2027 arc is clear: localized, analytics-aware materials manufacturing that feeds closed-loop dosing with predictable, humidity-tolerant granules.

Common questions and expert answers

How does Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives prevent caking during monsoon logistics?

The combination of densified granules, rounded particle morphology, and hydrophobic coating reduces liquid bridge formation and moisture adsorption. Mass-flow hoppers and nitrogen-purged transfers further protect flow integrity from bag to feeder.

Can Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives produce composite grades like SiC–Ca or SiC–Ba?

Yes. The line blends trace modifiers into the granule matrix before coating, maintaining uniform distribution while the coating preserves activity and flow, ideal for inclusion control and nozzle openness strategies.

What PSD should we target with Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives?

For teeming stream or early ladle, 0–3 mm aligns with fast kinetics. For longer residence in ladle refining, 3–10 mm sustains dissolution and stabilizes silicon pickup. Sicarbtech maps PSD to your thermographs and oxygen trajectories.

Will the coating from Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives affect high-temperature reactivity?

It is designed to be inert at ambient conditions and release at steelmaking temperatures, preserving or enhancing dissolution kinetics by preventing premature oxidation and minimizing fume loss.

How does Sicarbtech ensure batch consistency from Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives?

In-situ QC captures SiC %, free carbon/silicon, PSD, moisture, coating integrity, and a reactivity index. Each batch ships with a digital tag for Level 2 integration, enabling dosing systems to adapt to the actual material profile.

Why Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives works for your operations

Because predictable flow is the foundation of predictable metallurgy. Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives turns variable powders into engineered granules that move, meter, and melt as planned. In Pakistan’s mills—navigating energy costs, humidity swings, and export-grade cleanliness—this production line stabilizes dosing physics, which stabilizes silicon absorption and oxygen control, which stabilizes casting itself. The chain is only as strong as its first link; here, that link is finally under control.

Connect with specialists for custom solutions

Sicarbtech brings more than ten years of silicon carbide manufacturing expertise, backed by the Chinese Academy of Sciences, to Silicon Carbide Granulation and Coating Production Line for Moisture-Proof Anti-Caking Additives. We customize product families across R-SiC, SSiC, RBSiC, and SiSiC; deliver technology transfer and factory establishment services for powder synthesis, classification, granulation, and coating; and integrate sealed silos, metering feeders, pneumatic lances, and Level 2 analytics into turnkey packages. With a track record at over nineteen enterprises, we will blueprint a no-cost pilot—targeting higher silicon absorption, lower total oxygen, fewer nozzle events, and tighter feeder linearity—so you can move from trial to standard practice with speed and confidence.

For a free consultation and a fast, data-backed proposal, contact:

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Article metadata

Last updated: 2025-09-15

Next review scheduled: 2025-12-15

Author: Sicarbtech Applications Engineering Team

Region focus: Pakistan (EAF and converter routes; billets, bars, wire rod, flats)

Timeliness note: Content aligned to 2025 PEQS-aligned dust control, humidity-resilient dosing, and closed-loop alloy strategies

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.