Unlocking Peak Performance: The Indispensable Role of Custom Silicon Carbide Discs in Demanding Industries

Share

In the relentless pursuit of efficiency, durability, and performance, advanced materials play a pivotal role. Among these, silicon carbide (SiC) stands out as a material of exceptional capabilities. Specifically, custom silicon carbide discs are becoming increasingly essential components across a multitude of high-performance industrial applications. These are not mere off-the-shelf parts; they are precision-engineered solutions tailored to meet the exacting demands of modern technology. From the ultra-clean environments of semiconductor fabrication to the extreme temperatures of industrial furnaces and the rigorous conditions of aerospace engineering, SiC discs offer a unique combination of properties that outperform traditional materials. Their ability to withstand harsh environments, maintain dimensional stability under extreme stress, and offer superior wear resistance makes them a cornerstone of innovation and reliability. As industries push the boundaries of what’s possible, the demand for custom SiC components, particularly discs engineered for specific operational challenges, continues to surge, highlighting their critical importance in achieving next-generation performance.

Key Industrial Applications of SiC Discs

The versatility and exceptional properties of silicon carbide discs make them indispensable in a wide array of critical industrial sectors. Their adoption is driven by the need for materials that can perform reliably under conditions where conventional materials falter. Procurement managers and technical buyers are increasingly specifying SiC discs for applications demanding high thermal conductivity, superior wear resistance, and chemical inertness.

In the semiconductor industry, SiC discs are fundamental. They are used as:

- Wafer chucks (electrostatic or vacuum): Providing ultra-flat, thermally stable platforms for holding silicon wafers during processing steps like lithography, etching, and deposition. The high stiffness and thermal conductivity of SiC ensure minimal wafer distortion.

- Dummy wafers and process chamber components: SiC’s resistance to plasma erosion and chemical attack by process gases makes it ideal for components within semiconductor manufacturing equipment, ensuring longevity and reducing contamination.

- CMP (Chemical Mechanical Planarization) rings and carriers: The hardness and wear resistance of SiC discs are crucial for the precision lapping and polishing of wafers.

- Susceptors and heating elements: In MOCVD or CVD reactors, SiC discs provide uniform heating and excellent thermal shock resistance.

The aerospace and defense sectors leverage SiC discs for:

- Optical mirrors and mirror substrates: SiC’s low thermal expansion, high stiffness-to-weight ratio, and polishability make it an excellent material for lightweight, stable mirrors in telescopes, satellites, and guidance systems.

- High-temperature structural components: Components near engines or in re-entry vehicles benefit from SiC’s ability to maintain strength at elevated temperatures.

- Wear-resistant components: In demanding mechanical systems where abrasion and friction are concerns.

High-temperature processing industries, such as those involved in ceramics, metals, and chemical production, utilize SiC discs for:

- Kiln furniture (setter plates, support discs): SiC’s exceptional strength at high temperatures (up to 1650∘C for some grades) and resistance to thermal shock allow for thinner, lighter kiln furniture, improving energy efficiency and furnace capacity.

- Burner nozzles and flame holders: Resistance to thermal cycling and corrosive combustion byproducts ensures long service life.

- Heat exchangers: High thermal conductivity and resistance to fouling make SiC discs suitable for efficient heat transfer in aggressive chemical environments.

Other notable applications include:

- Mechanical seals and bearings: For pumps and rotating equipment operating in corrosive or abrasive media, the hardness and low friction of SiC discs ensure extended operational life and reduced maintenance.

- Brake discs and clutch components: In high-performance automotive and industrial braking systems, SiC’s thermal stability and wear resistance offer superior performance over conventional materials, though often in composite forms.

- Armor and protective plates: The high hardness and relatively low density of SiC make it an effective material for ballistic protection.

Sicarb Tech, situated in Weifang City, the hub of China’s silicon carbide customizable parts manufacturing, has been at the forefront of SiC technology since 2015. Our deep understanding of material science and application engineering allows us to provide custom SiC disc solutions for these demanding industries, leveraging our access to a broad spectrum of SiC production technologies and the scientific prowess of the Chinese Academy of Sciences . We assist clients in selecting the optimal SiC grade and design for their specific application, ensuring reliability and performance.

Advantages of Choosing Custom Silicon Carbide Discs

The decision to opt for custom silicon carbide discs over standard or alternative material components is driven by a compelling set of advantages that directly translate to enhanced performance, longevity, and operational efficiency in demanding industrial environments. Engineers and procurement specialists recognize that the unique combination of SiC’s intrinsic properties, coupled with the ability to tailor designs, offers unparalleled value in critical applications.

The primary benefits stem from SiC’s exceptional material characteristics:

- Outstanding Thermal Properties:

- High Thermal Conductivity: SiC discs can dissipate heat rapidly, which is crucial for applications like heat sinks, susceptors in semiconductor processing, and high-performance braking systems. This property helps maintain temperature uniformity and prevents thermal runaway.

- Low Coefficient of Thermal Expansion (CTE): This ensures dimensional stability across a wide range of temperatures. For precision optical systems or components in furnaces undergoing thermal cycling, low CTE minimizes distortion and stress.

- Excellent Thermal Shock Resistance: SiC discs can withstand rapid temperature changes without cracking or failing, a vital attribute for kiln furniture, burner components, and applications involving intermittent heating and cooling.

- Superior Mechanical Properties:

- Extreme Hardness: Ranking just below diamond on the Mohs scale, SiC is incredibly resistant to scratching, abrasion, and wear. This makes SiC discs ideal for wear parts such as mechanical seals, nozzles, bearings, and CMP rings.

- High Strength and Stiffness (Young’s Modulus): SiC maintains its structural integrity under significant loads, even at elevated temperatures. This high stiffness is beneficial for applications requiring precise positioning and minimal deflection, such as mirror substrates or wafer chucks.

- Good Fracture Toughness (for certain grades): While inherently a brittle ceramic, advanced SiC grades and composite structures can offer improved fracture toughness, enhancing reliability.

- Exceptional Chemical Inertness:

- Corrosion Resistance: SiC discs exhibit remarkable resistance to a wide range of acids, alkalis, and molten salts, even at high temperatures. This makes them suitable for components in chemical processing equipment, pumps handling corrosive fluids, and parts exposed to aggressive etchants in semiconductor fabrication.

- Oxidation Resistance: SiC forms a protective silicon dioxide (SiO2) layer at high temperatures, which inhibits further oxidation, allowing for long-term operation in oxidizing atmospheres.

- Favorable Electrical Properties (application-dependent):

- While often used for its insulating properties in its pure form at lower temperatures, SiC is a semiconductor. Doped SiC can be tailored for specific electrical conductivities, making it suitable for heating elements, igniters, and components in power electronics (though discs for these are often specialized wafers/substrates).

The Value of Customization: Beyond these intrinsic properties, the “custom” aspect is key. Custom SiC discs allow for:

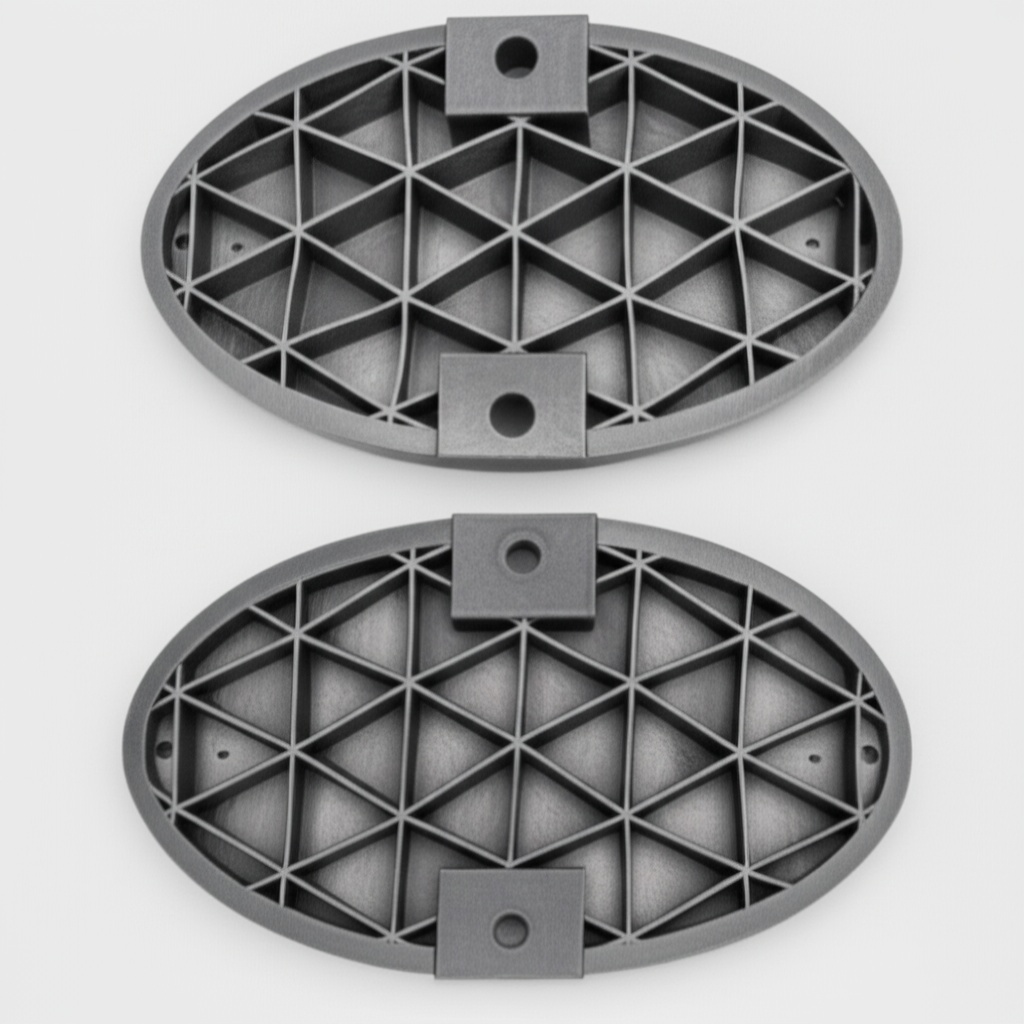

- Optimized Geometry: Tailoring diameter, thickness, flatness, parallelism, and specific features (e.g., holes, grooves, chamfers) to precise application requirements.

- Material Grade Selection: Choosing the specific SiC grade (e.g., RBSiC, SSiC) that best balances performance needs (purity, density, strength) with cost considerations.

- Surface Finish Control: Achieving specific surface roughness (Ra) values, from as-fired to highly polished, depending on whether the disc is for structural support, wear resistance, or optical/semiconductor applications.

- Integration with Assemblies: Designing discs that seamlessly fit into larger systems, potentially reducing component count and improving overall reliability.

Sicarb Tech excels in providing these customized solutions. Drawing upon the vast technological resources of the Chinese Academy of Science National Technology Transfer Center and our experience supporting numerous enterprises in Weifang, we offer comprehensive design and manufacturing services. Our team works closely with clients to understand their unique challenges and deliver SiC discs that are not just components, but critical enablers of performance. This focus on tailored solutions ensures that our customers receive parts that precisely meet their technical and operational objectives.

Recommended SiC Grades and Compositions for Discs

Selecting the appropriate grade of silicon carbide is paramount to achieving the desired performance and longevity of SiC discs in any given application. Different manufacturing processes result in SiC materials with varying microstructures, purity levels, and, consequently, distinct physical and mechanical properties. Understanding these differences is crucial for engineers and technical buyers when specifying custom SiC discs. Sicarb Tech offers a range of SiC grades, ensuring an optimal match for your specific requirements.

The most common SiC grades utilized for disc manufacturing include:

- Reaction-Bonded Silicon Carbide (RBSiC), also known as Siliconized Silicon Carbide (SiSiC):

- Manufacturing: Produced by infiltrating a porous preform, typically made of SiC grains and carbon, with molten silicon. The silicon reacts with the carbon to form new SiC, which bonds the original SiC grains. This process typically leaves some residual free silicon (usually 8-15%) within the microstructure.

- Properties: RBSiC offers a good balance of properties at a relatively moderate cost. It exhibits excellent wear resistance, high thermal conductivity, good thermal shock resistance, and high strength. The presence of free silicon limits its maximum service temperature to around 1350−1380∘C, above which the silicon may melt or soften. It is also less resistant to certain strong acids and alkalis compared to SSiC due to the free silicon.

- Common Disc Applications: Kiln furniture (setter plates, support discs), wear-resistant linings, mechanical seal faces, pump components, ballistic plates, heat exchangers, and various structural components in high-temperature equipment. Its near-net-shape manufacturing capability can reduce machining costs for complex disc geometries.

- Sintered Silicon Carbide (SSiC):

- Manufacturing: Produced by sintering fine SiC powder (typically sub-micron) at very high temperatures (often exceeding 2000∘C) with the aid of sintering additives (e.g., boron and carbon for pressureless sintered SSiC, or without additives under high pressure for direct sintered SSiC). This process results in a very dense, single-phase SiC material with minimal or no secondary phases.

- Properties: SSiC generally offers superior performance compared to RBSiC, particularly in terms of chemical resistance (especially to strong acids and halogens), high-temperature strength (maintaining strength up to 1600−1650∘C), and wear resistance in highly corrosive or abrasive environments. It typically has slightly lower thermal conductivity than RBSiC with high free silicon content, but excellent thermal shock resistance. SSiC is often more expensive due to the higher processing temperatures and finer raw materials.

- Common Disc Applications: Demanding applications in the semiconductor industry (wafer chucks, CMP rings, chamber components requiring high purity and plasma resistance), high-performance mechanical seals and bearings operating in aggressive media, advanced burner nozzles, and components requiring maximum chemical and thermal stability.

- Nitride-Bonded Silicon Carbide (NBSC):

- Manufacturing: Formed by bonding SiC grains with a silicon nitride (Si3N4) phase. This is often achieved by nitriding a mixture of SiC and silicon powders.

- Properties: NBSC exhibits good thermal shock resistance, moderate strength, and good resistance to wetting by molten non-ferrous metals. Its properties are generally considered intermediate between RBSiC and some oxide-bonded SiCs.

- Common Disc Applications: While less common for high-precision discs compared to RBSiC and SSiC, it finds use in applications like components for handling molten aluminum, certain types of kiln furniture, and wear parts where its specific combination of properties is advantageous.

Other specialized grades might include:

- CVD SiC (Chemical Vapor Deposition SiC): Produces ultra-high purity SiC, often used as a coating on SSiC or graphite discs to enhance purity and surface properties for semiconductor applications.

- Recrystallized SiC (RSiC): Highly porous SiC, not typically used for dense structural discs but rather for applications like radiant tubes or high-temperature filters.

Table 1: Comparison of Common SiC Grades for Disc Applications

| Property | Reaction-Bonded SiC (RBSiC/SiSiC) | Sintered SiC (SSiC) | Nitride-Bonded SiC (NBSC) |

|---|---|---|---|

| Typical Density | 3.02−3.10 g/cm3 | 3.10−3.18 g/cm3 | 2.5−2.7 g/cm3 |

| Porosity | Very Low (<0.1%) | Very Low (<0.1%) | Moderate (5-15%) |

| Max. Use Temperature | Approx. 1380∘C | Approx. 1650∘C (or higher) | Approx. 1400∘C |

| Thermal Conductivity | High (80−150 W/mK) | Moderate to High (60−120 W/mK) | Moderate (15−40 W/mK) |

| Flexural Strength (@ RT) | 250−450 MPa | 400−600 MPa | 50−150 MPa |

| Hardness (Knoop) | Approx. 2500−2800 | Approx. 2800−3000 | Approx. 1100 (SiC grains) |

| Chemical Resistance | Good (limited by free Si) | Excellent | Good |

| Relative Cost | Moderate | High | Moderate to Low |

| Key Disc Applications | Kiln furniture, wear parts, general high-temp structures | Semiconductor parts, high-performance seals, demanding chemical applications | Molten metal contact, some kiln furniture |

At Sicarb Tech, we leverage our deep material science expertise, backed by the Chinese Academy of Sciences, to guide our clients in selecting the most suitable SiC grade. Our facility in Weifang, a major SiC production hub, allows us to source and process various raw materials, ensuring that the custom SiC discs we produce deliver optimal performance and value for your specific industrial application. We have been instrumental in advancing SiC production technology locally, enabling us to meet diverse customization needs effectively.

Critical Design Considerations for Manufacturing SiC Discs

Designing silicon carbide discs for optimal performance and manufacturability requires careful consideration of several critical factors. While SiC offers exceptional properties, its inherent hardness and brittleness necessitate a design approach that balances application demands with the practicalities of ceramic processing and machining. Collaborating with experienced SiC specialists like Sicarb Tech early in the design phase can prevent costly mistakes and ensure the final product meets all specifications.

Key design considerations include:

- Manufacturability and Complexity:

- Simplicity is Key: While complex geometries are possible, simpler disc designs generally lead to lower manufacturing costs and shorter lead times. Intricate features, sharp internal corners, and extreme aspect ratios can significantly increase machining time and risk of defects.

- Forming Method: The intended forming method (e.g., pressing, slip casting, extrusion for pre-forms, or direct machining for some grades) influences design possibilities. For instance, features easily incorporated in a molding process might be difficult or expensive to machine.

- Geometric Limitations:

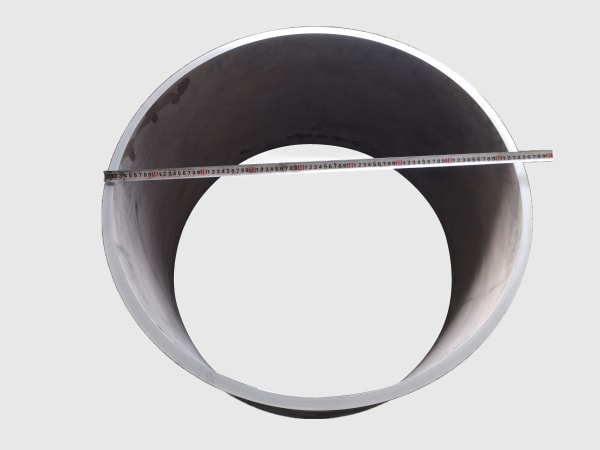

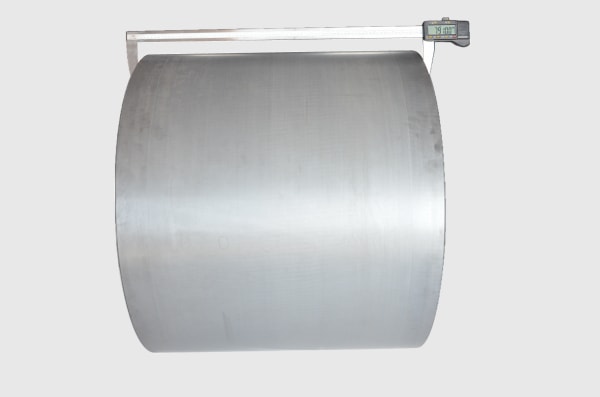

- Diameter and Thickness: There are practical limits to the maximum diameter and minimum/maximum thickness achievable for SiC discs, depending on the grade and manufacturing equipment. Very large diameter discs or extremely thin discs present challenges in handling, sintering, and maintaining flatness.

- Aspect Ratios: High aspect ratios (e.g., very large diameter with minimal thickness) can lead to warping during sintering or increased susceptibility to fracture.

- Minimum Wall Thickness: For discs with central bores or other cutouts, a minimum wall thickness must be maintained to ensure structural integrity.

- Flatness and Parallelism:

- These are critical parameters for many SiC disc applications, such as wafer chucks, CMP rings, and mechanical seals. Achieving tight flatness (how flat a single surface is) and parallelism (how parallel two opposing surfaces are) requires precision grinding and lapping.

- Specify realistic tolerances; tighter tolerances invariably increase costs. The required level should be driven by the functional needs of the application.

- Edge Conditions:

- Chipping: Sharp edges on SiC discs are prone to chipping during handling, machining, or in-service.

- Chamfering or Radiusing: Incorporating chamfers or radii on edges can significantly mitigate chipping, improve strength, and ensure safer handling. The size and angle of the chamfer should be specified.

- Stress Concentration Points:

- Holes, Notches, and Sharp Corners: These features can act as stress concentrators in brittle materials like SiC, potentially leading to crack initiation and failure under thermal or mechanical loads.

- Radii: Generous radii should be used at internal corners and at the base of any protrusions or cutouts to distribute stress more evenly.

- Hole Placement: Holes should be placed away from edges where possible, and the ligament between holes or between a hole and an edge must be sufficient.

- Surface Features:

- Grooves, Channels, Pockets: If the disc requires surface features like grooves for vacuum chucks or channels for fluid flow in seals, the geometry (width, depth, profile) and method of creating them (molding, green machining, or post-sinter machining) need careful planning. Machining such features into dense-fired SiC is more challenging and costly.

- Surface Roughness (Ra): The required surface finish dictates the extent of post-processing (grinding, lapping, polishing). Specify the appropriate Ra based on the application (e.g., very smooth for seals or optical components, slightly rougher for kiln furniture).

- Tolerancing:

- Dimensional Tolerances: Clearly define acceptable tolerances for all critical dimensions (diameter, thickness, hole sizes, feature locations).

- Geometric Dimensioning and Tolerancing (GD&T): For complex discs or those requiring high precision, using GD&T can more accurately define functional requirements and ensure interchangeability.

Sicarb Tech, with its roots in the National Technology Transfer Center of the Chinese Academy of Science, possesses a top-tier professional team specializing in customized SiC production. We work closely with our clients on design for manufacturability (DFM), offering insights based on our extensive experience in material science, process engineering, and integrated manufacturing from raw materials to finished SiC discs. Our Weifang facility benefits from the collective knowledge of over 40 local SiC enterprises, further enhancing our ability to tackle complex design challenges and deliver high-quality, cost-competitive industrial SiC discs. We assist in optimizing designs not just for performance but also for efficient and reliable production.

Achievable Tolerances, Surface Finish, and Dimensional Accuracy for SiC Discs

For engineers and procurement managers specifying custom silicon carbide discs, understanding the achievable levels of precision is crucial. The demanding nature of applications in semiconductors, optics, and high-performance machinery necessitates tight control over dimensions, form, and surface characteristics. Silicon carbide’s extreme hardness makes achieving these specifications a specialized task, requiring advanced machining and metrology capabilities.

Dimensional Tolerances: The achievable dimensional tolerances for SiC discs depend on the size of the disc, its complexity, the SiC grade, and the manufacturing processes employed.

- Diameter and Thickness:

- Standard Tolerances: For general industrial applications like kiln furniture or basic wear parts, tolerances for diameter and thickness might be in the range of ±0.1 mm to ±0.5 mm, or even larger for very big components, especially in the as-sintered state.

- Precision Tolerances: For applications requiring high precision, such as semiconductor components, optical substrates, or mechanical seals, much tighter tolerances are achievable through grinding and lapping. Diameters can often be controlled to within ±0.01 mm to ±0.05 mm. Thickness can be controlled to similar or even tighter ranges, such as ±0.005 mm to ±0.025 mm.

- Hole Diameters and Locations: Tolerances for drilled or machined holes will also vary. Precision drilling and grinding can achieve positional tolerances and diameter controls suitable for intricate assemblies.

Form Tolerances (Flatness, Parallelism, TTV): These are often more critical than simple dimensional tolerances for functional performance in many SiC disc applications.

- Flatness: This refers to the deviation of a surface from a perfect plane.

- As-sintered/Ground: Flatness might be in the range of 0.1 mm to 0.5 mm per 100 mm length.

- Lapped/Polished: For precision applications like wafer chucks or optical mirrors, flatness values of <1μm over significant areas (e.g., a 300mm diameter disc) are achievable, and even tighter for smaller discs (e.g., down to λ/10 or better for optical grades, where λ≈632.8 nm).

- Parallelism: This refers to how parallel two opposing surfaces are to each other.

- Ground: Parallelism might be within 0.02 mm to 0.05 mm.

- Lapped: For applications like mechanical seals or precision spacers, parallelism can be achieved down to 1−5μm or better.

- Total Thickness Variation (TTV): This is the difference between the maximum and minimum thickness measurements across a disc. For semiconductor wafers and chucks, TTV is a critical parameter, often specified in the single-micron or even sub-micron range for advanced applications.

Surface Finish (Roughness, Ra): The surface finish of a SiC disc is tailored to its specific function.

- As-Fired/Sintered: The surface will be relatively rough, suitable for applications where surface finish is not critical (e.g., some types of kiln furniture). Ra values could be several microns.

- Ground: Grinding produces a smoother surface, typically with Ra values in the range of 0.4μm to 1.6μm. This is adequate for many mechanical components.

- Lapped: Lapping significantly improves surface finish, achieving Ra values typically between 0.05μm and 0.4μm. This is often required for seal faces and components needing good mating surfaces.

- Polished: Polishing creates the smoothest surfaces, with Ra values typically <0.05μm, and often down to angstrom levels for optical or semiconductor applications (e.g., Ra <1 nm).

Table 2: Typical Tolerances and Surface Finishes for Custom SiC Discs

| Parameter | Standard Industrial Grade (e.g., Kiln Furniture) | Precision Grade (e.g., Seals, Basic Chucks) | Ultra-Precision Grade (e.g., Optics, Adv. Semiconductor) |

|---|---|---|---|

| Diameter Tol. | ±0.2 to ±1.0 mm | ±0.02 to ±0.1 mm | ±0.005 to ±0.05 mm |

| Thickness Tol. | ±0.1 to ±0.5 mm | ±0.01 to ±0.05 mm | ±0.002 to ±0.025 mm |

| Flatness | 0.1−0.5 mm / 100 mm | 5−20μm | <1−5μm (can be sub-micron for specific areas) |

| Parallelism | 0.05−0.2 mm | 5−20μm | <1−5μm |

| TTV | Not typically specified | 10−25μm | <1−10μm |

| Surface Finish (Ra) | 1.6−6.3μm (as-fired/ground) | 0.1−0.8μm (ground/lapped) | <0.05μm (lapped/polished), often nm range |

Note: These are general guidelines. Specific capabilities can vary based on supplier, SiC grade, and disc size/complexity.

Sicarb Tech is equipped with advanced manufacturing and metrology tools to achieve exacting specifications for custom SiC discs. Our integrated process, from material preparation to final inspection, supported by the robust scientific and technological capabilities of the Chinese Academy of Sciences, ensures that we can meet diverse customization needs. We possess a comprehensive suite of measurement and evaluation technologies, allowing us to verify dimensional accuracy, form tolerances, and surface finish to the most demanding standards required by industries such as semiconductor manufacturing and precision optics. Our commitment to quality assurance is integral to delivering technical ceramic discs that perform reliably in your applications. Situated in Weifang, a region accounting for over 80% of China’s SiC output, we have access to a mature supply chain and a skilled workforce, enabling us to offer higher-quality, cost-competitive customized components.

Essential Post-Processing for Enhanced SiC Disc Performance

Once a silicon carbide disc is formed and sintered, it often requires several post-processing steps to meet the final dimensional, surface, and performance specifications demanded by its intended application. Due to SiC’s extreme hardness, these processes are specialized and contribute significantly to the final cost and quality of the component. Understanding these steps is vital for engineers and procurement managers to appreciate the value added and to specify requirements accurately.

Common post-processing needs for SiC discs include:

- Grinding:

- Purpose: Grinding is typically the first precision machining step after sintering. It is used to remove excess material, achieve basic dimensional accuracy (diameter, thickness), improve flatness and parallelism, and prepare surfaces for subsequent finer finishing operations.

- Process: Diamond grinding wheels are essential due to SiC’s hardness. Various grinding techniques like surface grinding, cylindrical grinding (for outer/inner diameters), and creep-feed grinding can be employed.

- Outcome: Achieves moderate dimensional tolerances and surface finishes (typically Ra 0.4−1.6μm). It is often sufficient for SiC discs used in structural applications or some types of kiln furniture.

- Lapping:

- Purpose: Lapping is used to achieve very high levels of flatness, parallelism, and surface finish, significantly better than grinding alone. It is critical for applications like mechanical seal faces, valve components, wafer chucks, and CMP rings.

- Process: Discs are lapped on a flat rotating plate (lap) using a slurry containing fine abrasive particles (often diamond or boron carbide). The lapping process removes material slowly and uniformly. Double-sided lapping can simultaneously process both major surfaces, ensuring excellent parallelism and thickness control.

- Outcome: Produces very flat surfaces (down to micron or sub-micron levels), excellent parallelism (a few microns), and smoother finishes (Ra 0.05−0.4μm).

- Polishing:

- Purpose: Polishing is the finest finishing step, aimed at achieving an extremely smooth, often mirror-like surface. This is essential for optical components (mirrors), semiconductor wafers/substrates, and certain high-performance bearing or seal applications where minimal friction and wear are paramount.

- Process: Similar to lapping but uses much finer abrasive slurries (e.g., sub-micron diamond or colloidal silica) and specialized polishing pads. Chemical Mechanical Polishing (CMP) combines chemical action with mechanical abrasion for optimal results, especially in semiconductor applications.

- Outcome: Achieves exceptionally low surface roughness (Ra often <0.02μm, down to angstrom levels for optical/semiconductor grades), and can improve surface integrity by removing subsurface damage from previous operations.

- Edge Treatment:

- Purpose: To remove sharp edges that are prone to chipping, which can lead to crack propagation or particle generation. Proper edge treatment improves the disc’s durability and safety during handling.

- Process: Edges can be chamfered (beveled) or radiused (rounded) using specialized diamond tooling or grinding techniques.

- Outcome: Reduces stress concentrations and minimizes the risk of edge damage.

- Cleaning and Inspection:

- Purpose: Thorough cleaning is essential to remove any residues from machining, lapping, or polishing slurries, especially for high-purity applications like semiconductor components. Rigorous inspection verifies that all dimensional, form, and surface specifications have been met.

- Process: Multi-stage cleaning processes involving ultrasonic baths, deionized water, and specific solvents may be used. Inspection utilizes advanced metrology tools like CMMs, interferometers, profilometers, and optical microscopes.

- Outcome: Ensures the SiC disc is fit for purpose and meets all quality standards.

- Coatings (Optional):

- Purpose: In some cases, SiC discs may be coated to further enhance specific properties. For example, a CVD SiC coating can be applied to SSiC or graphite discs to provide an ultra-pure, highly wear-resistant, or corrosion-resistant surface.

- Process: Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD) techniques.

- Outcome: Tailored surface properties for highly specialized applications.

Sicarb Tech provides a comprehensive suite of post-processing services as part of our integrated approach to manufacturing custom silicon carbide discs. Our Weifang facility, benefiting from the region’s extensive SiC expertise and our own technological advancements supported by the Chinese Academy of Science, is equipped for precision grinding, lapping, and polishing. We understand that these final steps are critical to unlocking the full potential of SiC, and our meticulous attention to detail ensures that every disc delivered meets the highest standards of quality and performance required by industries from aerospace to semiconductors. Our integrated process from materials to finished products allows for optimized workflows and stringent quality control throughout every stage.

Frequently Asked Questions (FAQ) about Silicon Carbide Discs

Engineers, procurement managers, and technical buyers often have specific questions when considering silicon carbide discs for their applications. Below are answers to some common queries, which we at Sicarb Tech frequently address.

Q1: What makes SiC discs particularly suitable for high-temperature applications? Silicon carbide discs excel in high-temperature environments due to a unique combination of properties:

- High Decomposition Temperature: SiC does not melt at atmospheric pressure but rather sublimes (decomposes) at very high temperatures (above 2500∘C). Its practical maximum use temperature depends on the grade; Sintered SiC (SSiC) can often be used up to 1600−1650∘C in air, while Reaction-Bonded SiC (RBSiC/SiSiC) is typically limited to around 1380∘C due to the presence of free silicon.

- Excellent Creep Resistance: SiC maintains its shape and strength under load at elevated temperatures, resisting the tendency to deform over time (creep). This is crucial for components like kiln furniture that bear loads for extended periods at high heat.

- High Thermal Conductivity: Even at high temperatures, SiC retains good thermal conductivity (though it generally decreases with increasing temperature). This allows for uniform heat distribution and rapid heat dissipation, reducing thermal stresses.

- Good Thermal Shock Resistance: SiC can withstand rapid changes in temperature without cracking. This is attributed to its high thermal conductivity, relatively low coefficient of thermal expansion, and high tensile strength.

- Oxidation Resistance: In oxidizing atmospheres, SiC forms a protective layer of silicon dioxide (SiO2) on its surface, which inhibits further oxidation and allows for prolonged service life at high temperatures.

These characteristics make high-temperature SiC discs ideal for applications such as setter plates in furnaces, burner components, heat exchanger elements, and parts for aerospace propulsion systems.

Q2: How does the cost of SiC discs compare to other ceramic materials or high-performance metals? The cost of SiC discs is generally higher than that of conventional ceramics like alumina or mullite, and also often higher than many high-performance metals. However, the cost must be evaluated in the context of total cost of ownership and performance benefits:

- Raw Material and Processing: High-purity SiC powders and the energy-intensive manufacturing processes (sintering at very high temperatures, precision machining of a very hard material) contribute to the initial cost.

- Performance and Lifespan: In many demanding applications where other materials fail prematurely due to wear, corrosion, or thermal degradation, SiC discs offer significantly longer service life and reduced downtime. This can lead to a lower total cost of ownership despite a higher upfront investment.

- Complexity and Customization: The cost of a custom SiC disc is influenced by factors such as the SiC grade (SSiC is generally more expensive than RBSiC), size, design complexity, required tolerances, surface finish, and order volume.

Table 3: General Cost and Performance Comparison (Illustrative)

| Material | Relative Initial Cost | Max. Use Temp. (approx.) | Hardness (Mohs) | Key Advantages for Discs |

|---|---|---|---|---|

| Alumina (99%+) | Low to Moderate | 1600−1700∘C | 9 | Good electrical insulation, wear resistance |

| Zirconia (PSZ) | Moderate to High | 1000−1200∘C | 8-8.5 | High fracture toughness, wear resistance |

| RBSiC/SiSiC Disc | Moderate to High | 1380∘C | >9 | Excellent wear & thermal shock resistance, good thermal cond. |

| SSiC Disc | High | 1650∘C | >9 | Superior chemical & high-temp strength, excellent wear |

| Tungsten Carbide | High to Very High | 500−800∘C (binder limit) | 9-9.5 | Extreme hardness, wear resistance (often as composite) |

| Superalloys (e.g., Inconel) | Very High | 800−1100∘C | Variable | Ductility, high-temp strength (metallic properties) |

Sicarb Tech, based in Weifang, leverages its efficient production technologies and access to a robust local supply chain (Weifang accounts for over 80% of China’s SiC output) to offer cost-competitive custom SiC discs without compromising on quality. We work with clients to optimize designs for cost-effectiveness while meeting all performance criteria.

Q3: Can Sicarb Tech provide very thin or very large diameter SiC discs? What are the typical limitations? Yes, Sicarb Tech can produce a wide range of SiC disc geometries, including those that are very thin or have large diameters. However, there are practical manufacturing limitations:

- Thin Discs: We can manufacture SiC discs with thicknesses down to a few millimeters, and for certain applications (like specialized wafers or substrates, which are a form of disc), even sub-millimeter thicknesses are possible with advanced lapping and polishing. The minimum achievable thickness depends on the diameter (aspect ratio), the SiC grade, and handling considerations, as very thin and large discs become fragile.

- Large Diameter Discs: Our capabilities extend to producing large diameter SiC discs, suitable for sizable kiln furniture, large area chucks, or significant structural components. Diameters can range up to several hundred millimeters, and potentially larger for specific grades and forming techniques. The primary limitations for large discs are the size of forming equipment (presses, molds), sintering furnaces, and the challenges in maintaining flatness and avoiding defects during processing and handling of such large ceramic bodies.

- Customization: Our strength lies in custom solutions. We encourage clients to discuss their specific dimensional requirements with our technical team. Drawing on our deep expertise and the advanced technological support from the Chinese Academy of Sciences, we can often develop tailored manufacturing strategies to meet challenging specifications for custom SiC components.

Q4: What is the typical lead time for custom SiC disc orders from SicSino? Lead times for custom SiC disc orders from Sicarb Tech can vary significantly based on several factors:

- Complexity of Design: Simpler designs with standard tolerances will generally have shorter lead times than complex geometries requiring intricate machining or ultra-fine finishes.

- SiC Grade: Some grades may have longer raw material procurement or processing cycles.

- Order Volume: Larger production runs may require more time, though per-unit processing can become more efficient.

- Current Production Schedule: Existing commitments can influence lead times.

- Post-Processing Requirements: Extensive grinding, lapping, polishing, or coating will add to the overall production time.

Generally, lead times can range from a few weeks for simpler, smaller quantity orders of common grades to several months for highly complex, large volume, or very specialized SiC disc projects. At SicSino, we pride ourselves on efficient project management and clear communication. Upon receiving an inquiry with detailed specifications or drawings, we provide a realistic lead time estimate. Our integrated process from materials to product, and our strategic location in Weifang’s SiC manufacturing hub, helps us optimize production schedules and deliver high-quality industrial SiC discs as efficiently as possible. We recommend contacting us with your specific needs for an accurate quote and delivery timeline.

Conclusion: The Unmatched Value of Custom Silicon Carbide Discs from a Trusted Partner

In the ever-evolving landscape of industrial technology, the demand for materials that can push performance boundaries is unceasing. Custom silicon carbide discs have unequivocally established themselves as critical enablers in this quest, offering an unparalleled combination of thermal stability, wear resistance, chemical inertness, and mechanical strength. From the precision-driven semiconductor sector to the extreme environments of aerospace and high-temperature industrial processing, the ability to tailor SiC discs to exact specifications is not just an advantage—it’s a necessity for innovation and operational excellence.

Choosing the right partner for your custom SiC disc needs is as crucial as selecting the material itself. Sicarb Tech stands as a leader in this specialized field. Our foundation in Weifang City, the heart of China’s silicon carbide industry, combined with our strong affiliation with the Chinese Academy of Sciences through the Chinese Academy of Science (Weifang) Innovation Park and the National Technology Transfer Center, provides us with a unique technological edge. Since 2015, we have been instrumental in advancing SiC production technology, supporting local enterprises, and delivering high-quality, cost-competitive technical ceramic discs to a global clientele.

Our comprehensive capabilities span the entire lifecycle, from material science consultation and design optimization to precision manufacturing and rigorous quality assurance. We offer a diverse range of SiC grades, including RBSiC and SSiC, and possess the expertise to guide you in selecting the optimal material and design for your industrial SiC disc application. Whether you require components for high-temperature furnaces, wear-resistant parts, or precision semiconductor equipment, SicSino is committed to delivering solutions that enhance your product’s performance and reliability.

Furthermore, for organizations looking to develop their own SiC production capabilities, Sicarb Tech offers comprehensive technology transfer services, providing turnkey solutions for establishing specialized SiC manufacturing plants.

We invite engineers, procurement managers, and technical buyers to engage with our expert team. Discover how custom silicon carbide discs from Sicarb Tech can provide the definitive solution to your most demanding industrial challenges, driving efficiency and innovation in your operations. Contact us today to discuss your specific requirements and leverage the power of advanced SiC technology.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.