Silicon Carbide Composites: The Future of High-Performance Industrial Applications

Share

In the relentless pursuit of materials that can withstand extreme conditions and deliver unparalleled performance, silicon carbide composites (SiC composites) have emerged as a groundbreaking solution across a multitude of demanding industries. These advanced materials, engineered by combining silicon carbide with other elements or reinforcing phases, offer a significant leap forward from traditional monolithic ceramics, metals, and alloys. For engineers, procurement managers, and technical buyers in sectors like semiconductors, high-temperature processing, aerospace, energy, and industrial manufacturing, understanding the capabilities of custom SiC composites is crucial for driving innovation and achieving superior operational outcomes. This blog post delves into the world of silicon carbide composites, exploring their properties, applications, design considerations, and how to choose the right partner for your custom needs, with a special focus on the expertise and offerings of Sicarb Tech.

Introduction to Silicon Carbide Composites: A New Era of Material Performance

Silicon carbide (SiC) in its monolithic form is renowned for its hardness, high-temperature stability, and chemical resistance. However, like many ceramics, it can be inherently brittle. Silicon carbide composites are engineered materials that leverage the exceptional properties of SiC while enhancing its toughness and tailoring its characteristics for specific, demanding applications. These composites typically consist of a silicon carbide matrix reinforced with fibers, particles, or whiskers of another material, or they may involve different forms of SiC combined to achieve synergistic effects.

The primary goal of creating SiC composites is to overcome the brittleness of monolithic SiC, thereby improving fracture toughness and reliability under mechanical and thermal stresses. This makes them indispensable in environments where components are subjected to high temperatures, corrosive chemicals, abrasive wear, and significant mechanical loads. The ability to customize these composites – by selecting specific reinforcement materials, adjusting the matrix composition, and controlling the manufacturing process – allows for the creation of components that meet precise performance targets. This level of custom SiC composite engineering is vital for industries pushing the boundaries of technology. The demand for technical ceramic composites like SiC is rapidly growing as industries seek materials that offer longevity and performance where conventional materials fall short.

Diverse Applications of Custom SiC Composites

The unique combination of properties offered by silicon carbide composites makes them suitable for a wide array of high-value applications. Their versatility allows for tailored solutions across various industrial sectors, providing significant advantages in performance, efficiency, and component lifespan.

Here’s a look at some key industries and applications:

- Aerospace and Defense: SiC composites are critical for components in jet engines, rocket nozzles, thermal protection systems for spacecraft, and high-performance braking systems. Their lightweight nature, coupled with exceptional high-temperature strength and resistance to thermal shock (high-temperature SiC composites), makes them ideal for these demanding environments. For instance, Carbon fiber-reinforced SiC (C/SiC) composites are extensively used in aircraft brake discs due to their excellent friction properties and low wear rates at elevated temperatures.

- Semiconductor Manufacturing: The semiconductor industry requires materials with extreme purity, dimensional stability, and resistance to corrosive plasma environments. SiC composites are used for wafer handling components, etching equipment parts, susceptors, and chamber components. Their ability to maintain precision at high temperatures and in aggressive chemical environments ensures process integrity and yield. Custom silicon carbide composite components are often designed to specific equipment geometries and process requirements.

- High-Temperature Furnaces and Heat Treatment: In industrial furnaces, kilns, and heat treatment applications, SiC composites serve as radiant tubes, burner nozzles, kiln furniture (beams, rollers, plates), and thermocouple protection tubes. Their superior thermal conductivity, high-temperature strength, and resistance to oxidation and creep contribute to energy efficiency and longer service life of furnace components. Industrial SiC composites play a pivotal role in improving the productivity of these high-temperature processes.

- Energy Sector: SiC composites find applications in nuclear power plants for fuel cladding and structural components due to their radiation resistance and high-temperature stability. In an effort to improve the accident tolerance of nuclear reactors, SiC/SiC composites are regarded as promising candidates for fuel cladding and core structural components. They are also explored for use in heat exchangers, reformers, and components for concentrated solar power systems, where high temperatures and harsh operating conditions are prevalent.

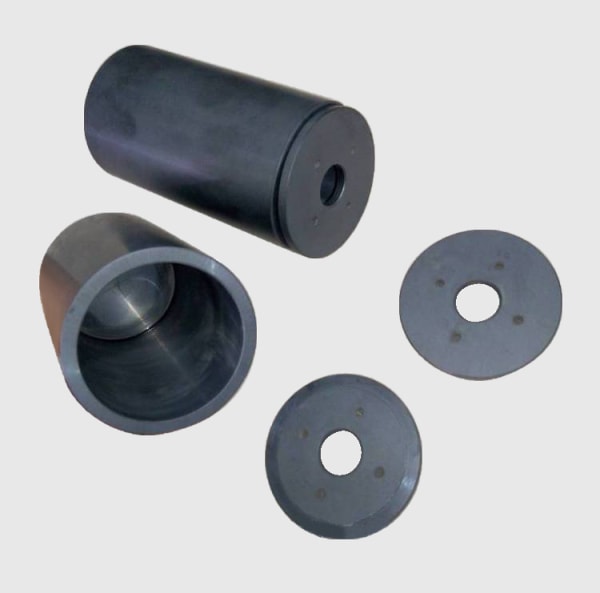

- Industrial Manufacturing and Wear Components: Due to their exceptional hardness and wear-resistant SiC composite properties, these materials are used for mechanical seals, pump components (shafts, bearings), nozzles for abrasive media, and cutting tools. Their resistance to abrasion, erosion, and chemical attack ensures longevity and reduces downtime in various manufacturing processes.

The table below highlights some specific applications and the SiC composite types often employed:

| Industry Sector | Application Example | Common SiC Composite Types | Key Properties Utilized |

|---|---|---|---|

| Aerospace | Aircraft Brake Discs | C/SiC | High thermal conductivity, wear resistance, toughness |

| Turbine Shrouds, Nozzles | SiC/SiC (CMC) | High-temperature strength, oxidation resistance | |

| Semiconductor | Wafer Chucks, Edge Rings | CVD-SiC coated Graphite, S-SiC | High purity, thermal stability, plasma resistance |

| High-Temperature | Radiant Tubes, Burner Nozzles | RBSC, S-SiC | Thermal shock resistance, high-temperature strength |

| Energy | Nuclear Fuel Cladding (experimental) | SiC/SiC (CMC) | Radiation resistance, high-temperature stability |

| Industrial Manufacturing | Mechanical Seals, Bearings | S-SiC, RBSC | Wear resistance, chemical inertness, hardness |

The broad applicability of SiC composites underscores their importance as enabling materials for advanced technologies. As industries continue to demand higher performance and greater efficiency, the role of custom SiC composite solutions will only expand.

Unlocking Performance: Advantages of Custom Silicon Carbide Composites

Choosing custom silicon carbide composites for demanding applications offers a wealth of advantages that directly translate to improved performance, longer component life, and enhanced operational efficiency. These materials are not just incremental improvements; they represent a significant step-change in capability compared to conventional materials and even monolithic SiC in certain aspects. The ability to tailor these composites through SiC composite manufacturing expertise allows for optimized solutions for specific industrial challenges.

Key advantages include:

- Enhanced Fracture Toughness: This is perhaps the most significant advantage over monolithic ceramics. By incorporating reinforcing phases (like fibers or whiskers) or by creating specific microstructures, SiC composites exhibit significantly improved resistance to crack propagation. This means they are less prone to catastrophic failure and can withstand higher mechanical stresses and impacts. This makes them more reliable in critical applications.

- Exceptional High-Temperature Performance: SiC composites maintain their mechanical strength and structural integrity at very high temperatures (often exceeding 1200∘C and, in some cases, approaching 1600∘C or higher, depending on the specific composite type). They exhibit excellent creep resistance and resistance to thermal shock, which is crucial for applications like gas turbines, heat exchangers, and furnace components.

- Superior Wear and Abrasion Resistance: Silicon carbide is inherently one of the hardest materials available. When formulated into a composite, this hardness translates into outstanding resistance to abrasive wear, erosion, and sliding wear. This makes wear-resistant SiC composites ideal for components like seals, nozzles, bearings, and parts handling abrasive slurries.

- Excellent Chemical Inertness and Corrosion Resistance: SiC composites are highly resistant to a wide range of corrosive chemicals, including strong acids and alkalis, even at elevated temperatures. This property is vital in chemical processing equipment, semiconductor manufacturing (plasma etch chambers), and other environments where aggressive media are present.

- Lightweight with High Stiffness-to-Weight Ratio: Compared to many high-temperature metals and superalloys, SiC composites offer a lower density while maintaining high stiffness and strength. This is particularly beneficial in aerospace and automotive applications where weight reduction is critical for fuel efficiency and performance.

- Tailorable Thermal Properties: The thermal conductivity of SiC composites can be tailored by design. Some applications require high thermal conductivity for heat dissipation (e.g., heat sinks, heat exchangers), while others might need lower thermal conductivity for insulation. The composition and microstructure of the composite can be adjusted to meet these specific thermal management needs.

- Dimensional Stability: SiC composites exhibit low coefficients of thermal expansion and high dimensional stability over a wide temperature range. This is crucial for precision components used in optical systems, metrology equipment, and semiconductor processing tools.

- Customization for Specific Needs: The “composite” nature means that materials can be engineered. Sicarb Tech, for instance, leverages its deep understanding of SiC production technology to assist enterprises in achieving specific material properties and component geometries. This ability to customize allows for the optimization of components for their intended operational environment, something not easily achievable with off-the-shelf materials.

These advantages make custom silicon carbide composites a preferred choice for engineers and procurement managers looking to push the boundaries of performance and reliability in their respective industries. The initial investment in these advanced materials is often offset by their extended service life, reduced maintenance, and the enabling of more efficient processes.

Tailoring Excellence: Grades, Design, and Manufacturing of SiC Composites

The versatility of silicon carbide composites stems from the wide range of available grades and the sophisticated design and manufacturing processes involved in their creation. Understanding these aspects is crucial for selecting or developing the optimal SiC composite for a specific application. SiC composite manufacturing is a highly specialized field, requiring expertise in material science, ceramic processing, and precision engineering.

Common Types and Grades of SiC Composites:

SiC composites can be broadly categorized based on their reinforcement type and matrix composition. Some prominent examples include:

- Carbon Fiber-Reinforced Silicon Carbide (C/SiC): These composites combine the high strength and low density of carbon fibers with the excellent high-temperature properties and wear resistance of a SiC matrix. They are known for their toughness, thermal shock resistance, and non-brittle fracture behavior. Applications include aircraft brake discs, hot structures in aerospace, and friction components.

- Silicon Carbide Fiber-Reinforced Silicon Carbide (SiC/SiC): Often referred to as Ceramic Matrix Composites (CMCs), SiC/SiC composites represent the pinnacle of high-temperature performance. They consist of SiC fibers embedded in a SiC matrix. These materials offer exceptional strength retention at temperatures exceeding 1200∘C, excellent oxidation and corrosion resistance, and good thermal stability. They are prime candidates for next-generation aero-engine components, nuclear reactor components, and advanced industrial gas turbines.

- Particle or Whisker-Reinforced SiC: In these composites, SiC particles or whiskers are dispersed within a SiC matrix (or sometimes another ceramic or even metal matrix, though less common when discussing “SiC composites” in the context of CMCs). The addition of these reinforcing elements can improve hardness, wear resistance, and sometimes toughness.

- Reaction-Bonded Silicon Carbide (RBSC) or Silicon Infiltrated Silicon Carbide (SiSiC) with Reinforcements: While RBSC/SiSiC is technically a composite due to the presence of free silicon, further enhancements can be made by incorporating additional reinforcing phases or by creating specific microstructures. These are widely used for their good mechanical properties, excellent wear and corrosion resistance, and ability to form complex shapes. Sicarb Tech has significant expertise in RBSC technology.

- Sintered Silicon Carbide (S-SiC) variants: Advanced sintering techniques can produce SiC materials with tailored microstructures that might be considered composite-like in their performance, especially when specific grain boundary phases or additives are used to enhance toughness or other properties.

The choice of SiC composite grade depends heavily on the application’s requirements, such as operating temperature, mechanical loads, chemical environment, and cost considerations.

Design Considerations for SiC Composite Manufacturability:

Designing components with SiC composites requires a different approach than with metals or monolithic ceramics. Key considerations include:

- Anisotropy: Fiber-reinforced composites (like C/SiC and SiC/SiC) often exhibit anisotropic properties, meaning their mechanical and thermal characteristics vary with direction relative to the fiber orientation. This must be accounted for in the design to ensure stresses are aligned with the strongest directions.

- Geometry and Complexity: While advanced manufacturing techniques allow for complex shapes, designers should consider the limitations and costs associated with producing intricate SiC composite parts. Simpler geometries are generally easier and less expensive to manufacture. However, companies like Sicarb Tech specialize in custom SiC components, working with clients to optimize designs for manufacturability.

- Reinforcement Architecture: For fiber-reinforced composites, the layup of fibers (e.g., unidirectional, bidirectional, woven fabric) significantly impacts the final properties. The design process must specify the optimal reinforcement architecture for the expected load paths.

- Joining and Attachment: SiC composites can be challenging to join to other materials or even to themselves. Design considerations should include features for mechanical attachment or explore advanced joining techniques like brazing or specialized adhesives, if applicable.

- Stress Concentrations: As with any material, avoiding sharp corners and abrupt changes in thickness is important to minimize stress concentrations, which can be initiation points for failure, especially in less tough materials.

- Manufacturing Process Limitations: The choice of manufacturing process (e.g., Chemical Vapor Infiltration (CVI), Polymer Infiltration and Pyrolysis (PIP), Melt Infiltration (MI), Sintering) will influence design rules, achievable tolerances, and final material properties.

Manufacturing Processes:

Common manufacturing routes for SiC composites include: * Chemical Vapor Infiltration (CVI): A SiC matrix is deposited from gaseous precursors onto a porous preform of fibers. This process can produce high-purity SiC matrices and is often used for SiC/SiC composites. * Polymer Infiltration and Pyrolysis (PIP): A preform is infiltrated with a polymer precursor, which is then pyrolyzed (thermally decomposed) to form SiC. Multiple infiltration/pyrolysis cycles are usually needed to achieve desired density. * Melt Infiltration (MI): Molten silicon is infiltrated into a porous preform containing carbon and/or SiC. The silicon reacts with the carbon to form SiC in-situ (as in RBSC/SiSiC). * Sintering with Reinforcements: SiC powders mixed with reinforcing phases can be consolidated and densified through sintering processes.

Sicarb Tech, with its deep roots in introducing and implementing silicon carbide production technology since 2015, supports local enterprises in Weifang City, China – a hub for SiC manufacturing – in achieving large-scale production and technological advancements. Their wide array of technologies, encompassing material, process, and design, enables them to meet diverse customization needs for industrial SiC composites.

The table below gives a general comparison of common SiC composite types:

| Composite Type | Reinforcement | Typical Max. Use Temp. (∘C) | Fracture Toughness | Key Advantages | Common Manufacturing Routes |

|---|---|---|---|---|---|

| C/SiC | Carbon Fibers | ∼1650 (in non-oxidizing) | High | Excellent thermal shock resistance, damage tolerance, lightweight | CVI, PIP, MI |

| SiC/SiC (CMC) | SiC Fibers | >1200 (up to 1600+) | Moderate to High | Extreme temperature stability, oxidation resistance, radiation resistance | CVI, PIP, Sintering |

| Particle-Reinforced SiC | SiC Particles | Variable (depends on matrix) | Low to Moderate | Enhanced hardness, wear resistance | Sintering, Hot Pressing |

| RBSC/SiSiC | (Intrinsic Si phase) | ∼1350−1380 | Moderate | Good strength, wear resistance, complex shapes, cost-effective for some parts | Melt Infiltration |

Understanding these nuances allows engineers and procurement professionals to effectively collaborate with expert suppliers like Sicarb Tech to develop custom silicon carbide composite solutions that push performance boundaries.

Achieving Precision: Tolerances, Surface Finish, and Post-Processing of SiC Composites

Once a silicon carbide composite component has been formed through primary manufacturing processes, achieving the required dimensional accuracy, surface finish, and enhanced properties often necessitates meticulous post-processing steps. The inherent hardness of SiC composites makes these operations challenging and specialized, but they are critical for meeting the stringent demands of high-performance applications. For technical buyers and OEMs, understanding the capabilities in tolerance control SiC parts and surface finishing is essential when specifying custom SiC composite components.

Achievable Tolerances and Dimensional Accuracy:

The achievable tolerances for SiC composite parts depend on several factors:

- The specific type of SiC composite (e.g., fiber-reinforced vs. particulate-reinforced).

- The primary manufacturing process used (CVI, PIP, MI, Sintering).

- The size and complexity of the component.

- The extent of post-process machining.

Generally, as-fired or as-processed SiC composites might have tolerances in the range of ±0.5% to ±1% of the dimension, or even wider for very large or complex parts. However, for applications requiring high precision, such as semiconductor equipment components, aerospace guidance systems, or precision metrology instruments, much tighter tolerances are necessary.

Through precision grinding and lapping, tolerances can be significantly improved. For example:

- Standard Machined Tolerances: ±0.025 mm to ±0.1 mm (±0.001″ to ±0.004″) are often achievable for critical dimensions.

- High-Precision Tolerances: In some cases, with advanced machining and metrology, tolerances as tight as ±0.005 mm (±0.0002″) or better can be attained on smaller features or specific surfaces.

It’s crucial for designers to specify only the necessary tolerances, as overly tight, non-critical tolerances can significantly increase manufacturing costs. Collaboration with experienced SiC composite manufacturers like Sicarb Tech is vital to determine practical and cost-effective tolerance schemes. Their expertise in integrated processes from materials to products allows them to advise on achievable precision for various technical ceramic composites.

Surface Finish Options:

The as-fired surface finish of SiC composites can be relatively rough, especially for CVI or PIP processed materials. The required surface finish depends heavily on the application:

- Tribological Applications (seals, bearings): Require very smooth surfaces (low Ra values) to minimize friction and wear.

- Optical Applications (mirrors): Demand exceptionally smooth and polishable surfaces.

- Semiconductor Processing (chucks, rings): Need controlled surface roughness and high purity.

- Fluid Handling (nozzles, pump components): May require smooth surfaces to optimize flow and prevent particle trapping.

Common surface finish values achievable through post-processing:

- As-Fired: Ra=1 μm to 5 μm or rougher.

- Ground: Ra=0.2 μm to 0.8 μm.

- Lapped/Polished: Ra<0.1 μm, with ultra-smooth finishes (Ra<0.02 μm) possible for specialized applications.

Post-Processing Needs for SiC Composites:

Due to their extreme hardness, machining SiC composites almost exclusively requires diamond tooling and specialized grinding, lapping, and polishing equipment. Common post-processing steps include:

- Diamond Grinding: This is the primary method for shaping SiC composite components and achieving dimensional accuracy. Various grinding techniques (surface, cylindrical, centerless) are used depending on the part geometry.

- Lapping and Polishing: For applications requiring very smooth surfaces and tight flatness or parallelism, lapping with diamond slurries is employed. Polishing can further improve the surface finish to mirror-like quality.

- Laser Machining: For drilling small holes, cutting complex patterns, or performing localized material removal, laser ablation can be an effective, albeit sometimes slower, alternative or supplement to mechanical machining. It offers non-contact processing, which can be beneficial for delicate or complex parts.

- Waterjet Cutting: Abrasive waterjet cutting can be used for rough shaping or cutting of SiC composite plates or blanks, especially for thicker sections. It generally does not produce the fine tolerances or surface finish of grinding.

- Edge Chamfering and Radiusing: To remove sharp edges, improve handling safety, and reduce stress concentrations, edges are often chamfered or radiused using diamond tools.

- Cleaning and Surface Treatment: After machining, rigorous cleaning processes are essential to remove any contaminants, machining residues, or diamond particles, especially for high-purity applications like semiconductor components.

- Coatings and Sealants:

- Protective Coatings: For some SiC composites, especially C/SiC used in oxidizing environments at very high temperatures, an environmental barrier coating (EBC) or an oxidation protection coating (e.g., a SiC overcoat or glass-ceramic sealant) may be applied to extend service life.

- Functional Coatings: Coatings can be applied to modify surface properties, such as enhancing wear resistance further (e.g., diamond-like carbon – DLC), improving biocompatibility, or altering electrical conductivity.

- Sealing: Some SiC composites might have residual porosity. If impermeability is required (e.g., for fluid containment), a sealing step using glass frits or other sealants might be necessary, though this can limit the maximum operating temperature. High-density SiC composites like S-SiC or well-infiltrated RBSC often do not require sealing.

The complexity and cost of post-processing SiC composites are significant factors in the overall component cost. Therefore, designing for minimal post-processing, where possible, is advantageous. Sicarb Tech, with its comprehensive service ecosystem and focus on custom SiC parts, can provide valuable input during the design phase to optimize for both performance and manufacturability, including post-processing considerations.

Navigating Challenges in SiC Composite Implementation

While silicon carbide composites offer remarkable advantages, their adoption and implementation are not without challenges. Understanding these potential hurdles is key for engineers and procurement managers to effectively integrate these advanced materials into their systems and applications. Mitigating these challenges often involves careful design, selection of the appropriate composite grade, and close collaboration with experienced suppliers.

Key Challenges and Mitigation Strategies:

- Manufacturing Complexity and Cost:

- Challenge: The fabrication of SiC composites, especially fiber-reinforced CMCs like SiC/SiC, involves multi-step, energy-intensive processes (e.g., CVI, PIP) that can be lengthy and expensive. Raw material costs, particularly for high-quality SiC fibers, can also be high.

- Mitigation:

- Design for Manufacturability: Optimize component design to simplify fabrication where possible, reducing machining and complex layup requirements.

- Process Optimization: Work with suppliers who have invested in advanced manufacturing technologies and process optimization to improve efficiency and reduce costs. Sicarb Tech, by supporting local enterprises with technology transfer and process advancements, contributes to making industrial SiC composites more accessible and cost-competitive.

- Volume Considerations: Higher production volumes can help amortize development and tooling costs.

- Near-Net Shape Manufacturing: Utilizing processes that produce components closer to their final dimensions reduces the need for extensive and costly post-machining.

- Machining Difficulty:

- Challenge: The extreme hardness of SiC composites makes them very difficult and time-consuming to machine. This requires specialized diamond tooling, rigid machinery, and experienced operators, adding to the overall component cost and lead time.

- Mitigation:

- Minimize Machining: Design parts to be as close to net-shape as possible from the primary forming process.

- Advanced Machining Techniques: Employ non-traditional machining methods like laser machining or EDM (Electrical Discharge Machining, for certain conductive SiC grades or composites) for specific features where conventional machining is impractical.

- Supplier Expertise: Partner with suppliers who have demonstrated expertise and specialized equipment for machining technical ceramic composites.

- Brittleness and Damage Tolerance (Relative to Metals):

- Challenge: While significantly tougher than monolithic ceramics, SiC composites are still more brittle than most metals. They may not exhibit the same degree of plastic deformation before fracture, and impact resistance can be a concern in some applications.

- Mitigation:

- Proper Composite Selection: Fiber-reinforced SiC composites (C/SiC, SiC/SiC) are specifically designed for enhanced toughness and a “graceful” (non-catastrophic) failure mode.

- Design Considerations: Incorporate features like rounded corners, avoid stress concentrators, and design for load paths that minimize tensile stresses on ceramic components.

- Protective Measures: In environments with high impact risk, consider designing protective enclosures or impact-absorbing layers if feasible.

- Joining and Integration:

- Challenge: Joining SiC composites to themselves or to other materials (especially metals) can be difficult due to differences in thermal expansion coefficients and the chemical nature of ceramics.

- Mitigation:

- Mechanical Fastening: Design for bolted or clamped joints where appropriate, using compliant interlayers to accommodate CTE mismatch.

- Adhesive Bonding: Specialized high-temperature adhesives can be used, but their temperature limits must be considered.

- Brazing/Welding: Advanced techniques like active metal brazing or transient liquid phase bonding are available but require specialized expertise and careful control.

- Integrated Design: If possible, design larger, monolithic composite structures to reduce the number of joints.

- Thermal Shock Management:

- Challenge: While generally good, rapid and extreme temperature fluctuations can still induce thermal shock and potential cracking in some SiC composites, especially if there are significant internal flaws or stress concentrations.

- Mitigation:

- Material Selection: Choose grades specifically designed for high thermal shock resistance (e.g., certain RBSiC grades or fiber-reinforced composites).

- Gradual Heating/Cooling: Implement controlled heating and cooling rates in operational cycles where possible.

- Design for Thermal Gradients: Design components to minimize sharp thermal gradients.

- Characterization and Non-Destructive Evaluation (NDE):

- Challenge: Ensuring the quality and integrity of SiC composite components can be more complex than for metals. Internal defects like porosity, delaminations, or fiber damage can be difficult to detect.

- Mitigation:

- Advanced NDE Techniques: Utilize methods like X-ray computed tomography (CT), ultrasonic testing (C-scan), and thermography to inspect components.

- Supplier Quality Systems: Work with suppliers who have robust quality control procedures and NDE capabilities integrated into their SiC composite manufacturing processes.

The table below summarizes common challenges and potential approaches:

| Challenge | Primary Impact Areas | Potential Mitigation Approaches |

|---|---|---|

| High Manufacturing Cost | Overall Project Budget, ROI | Design optimization, process efficiency, volume production, near-net shaping, partnering with cost-effective hubs like Weifang City. |

| Difficult Machining | Component Cost, Lead Time, Tolerances | Minimize machining by design, advanced machining techniques (laser, EDM), expert machining suppliers. |

| Brittleness/Damage Tolerance | Reliability, Impact Resistance | Use fiber-reinforced grades (C/SiC, SiC/SiC), careful design to avoid stress risers, protective measures. |

| Joining and System Integration | Design Complexity, Assembly | Mechanical fastening, specialized adhesives, advanced brazing, integrated monolithic design. |

| Thermal Shock Sensitivity | Component Life in Cyclic Temperatures | Select thermal shock resistant grades, controlled heating/cooling rates, design to minimize thermal gradients. |

| NDE and Quality Assurance | Reliability, Defect Detection | Advanced NDE (CT, C-scan, thermography), robust supplier quality management systems. |

Overcoming these challenges requires a holistic approach, starting from material selection and design through to manufacturing and quality assurance. Sicarb Tech positions itself as a key partner in this journey, not only by providing access to high-quality, cost-competitive custom silicon carbide components from China but also by offering technology transfer services. This unique capability means they can assist clients in establishing their own specialized SiC production facilities, ensuring a deep understanding and control over the entire process, thereby mitigating many of these inherent challenges.

Partnering for Success: Choosing Your SiC Composite Supplier and Understanding Cost Factors

Selecting the right supplier for your custom silicon carbide composite needs is a critical decision that significantly impacts project success, component quality, and overall cost-effectiveness. Given the specialized nature of SiC composite manufacturing and the demanding applications these materials serve, a thorough evaluation of potential partners is essential. Furthermore, understanding the key drivers of cost and lead time will enable procurement professionals and engineers to make informed decisions and manage budgets effectively.

How to Choose the Right SiC Composite Supplier:

When evaluating potential suppliers for technical ceramic composites, consider the following factors:

- Technical Expertise and Experience:

- Does the supplier have a proven track record with the specific type of SiC composite you require (e.g., C/SiC, SiC/SiC, RBSC)?

- Do they possess in-depth knowledge of material science, composite design, and manufacturing processes?

- Can they provide engineering support and collaborate on design for manufacturability?

- Material Options and Customization Capabilities:

- Does the supplier offer a range of SiC composite grades, or can they develop custom formulations to meet specific performance targets?

- How flexible are they in accommodating unique geometries, sizes, and complex designs?

- Sicarb Tech, for example, excels in this area. Leveraging the robust scientific and technological capabilities of the Chinese Academy of Sciences , they possess a wide array of technologies—material, process, design, measurement, and evaluation—enabling them to meet diverse custom SiC parts needs.

- Manufacturing Capabilities and Quality Control:

- What manufacturing processes do they employ (CVI, PIP, MI, Sintering, etc.)? Do these align with your component requirements?

- What are their capabilities for precision machining and post-processing (grinding, lapping, coating)?

- Do they have robust quality management systems in place (e.g., ISO 9001 certification)? What NDE techniques do they use?

- Location and Supply Chain Reliability:

- Where are their manufacturing facilities located? Weifang City in China, for instance, is a major hub for silicon carbide production, with over 40 enterprises accounting for more than 80% of China’s total SiC output. Sicarb Tech has been instrumental in this region since 2015, fostering technological advancements.

- Can they ensure a reliable supply of raw materials and consistent production?

- What are their typical lead times and on-time delivery performance?Sicarb Tech emphasizes reliable quality and supply assurance within China.

- Cost-Effectiveness and Value:

- While cost is a factor, it should be balanced against quality, reliability, and technical support.

- Can they offer competitive pricing for the required specifications and volume?

- Sicarb Tech aims to provide higher-quality, cost-competitive customized silicon carbide components from China by leveraging the established industrial base and their technological support to local enterprises.

- Technology Transfer and Partnership Potential:

- For companies looking to internalize production or require deep technological collaboration, consider suppliers like Sicarb Tech. They offer a unique proposition: technology transfer for professional silicon carbide production, including turnkey project services like factory design, equipment procurement, installation, commissioning, and trial production. This empowers clients to build their own specialized SiC products manufacturing plants.

- Customer Service and Communication:

- Are they responsive to inquiries and transparent in their communications?

- Can they provide references or case studies of similar projects?

Cost Drivers and Lead Time Considerations for SiC Composites:

| Cost/Lead Time Driver | Impact | Considerations for Procurement |

|---|---|---|

| Material Grade & Purity | High-purity raw materials (e.g., specialized SiC fibers for CMCs) are expensive. Complex composite formulations add to cost. | Specify the minimum grade and purity necessary for the application. Over-specifying increases cost. |

| Component Complexity | Intricate geometries, thin walls, and complex internal features increase tooling costs, manufacturing difficulty, and scrap rates. | Simplify design where possible. Discuss manufacturability with the supplier early in the design phase. |

| Size of Component | Larger components require more material, larger processing equipment, and potentially longer processing times. | Consider if the component can be made in smaller, joinable sections if very large, though joining adds complexity. |

| Tolerances & Surface Finish | Tighter tolerances and finer surface finishes require more extensive and precise machining (diamond grinding, lapping), which is costly. | Specify only the tolerances and finishes genuinely required by the function of the part. |

| Production Volume | Low volumes incur higher per-unit costs due to setup, tooling, and development expenses. Higher volumes allow for economies of scale. | Consolidate orders where possible. Discuss price breaks for different volume tiers. |

| Manufacturing Process | Some processes (e.g., CVI for SiC/SiC) are inherently more time-consuming and capital-intensive than others (e.g., RBSC). | Understand the implications of different manufacturing routes on cost and lead time for your specific composite type. |

| Post-Processing Needs | Extensive machining, coatings, or other specialized treatments add significant cost and time. | Design to minimize post-processing. Evaluate if coatings are essential or if material selection can achieve desired properties. |

| Testing & Certification | Rigorous testing, NDE, and specific certifications add to the cost and can extend lead times. | Clearly define testing requirements. Some standard tests may be included by the supplier. |

| Supplier Location & Logistics | Shipping costs, import/export duties (if applicable), and overall supply chain complexity can influence final cost and delivery. | Factor in total landed cost. Reliable logistics are key to meeting project timelines. |

The cost and lead time for custom silicon carbide composites can vary significantly based on several factors:

Why Sicarb Tech is a Noteworthy Partner:

Sicarb Tech, part of the Chinese Academy of Sciences (Weifang) Innovation Park and backed by the National Technology Transfer Center of the Chinese Academy of Sciences, stands out due to its unique position. They are not just a supplier but a technology enabler.

- Deep Expertise: Possessing a domestic top-tier professional team specializing in customized SiC production.

- Technological Support: Having aided 10+ local enterprises with their technologies, showcasing a broad array of capabilities from materials to finished products.

- Cost-Competitive Solutions: Offering higher-quality, cost-competitive custom SiC components by leveraging the Weifang SiC manufacturing hub.

- Unique Technology Transfer Services: Providing turnkey solutions for clients wishing to establish their own SiC production plants, ensuring effective investment and reliable technology transformation.

Choosing a supplier like Sicarb Tech means partnering with an organization that has a profound understanding of the SiC industry, from fundamental research and development to large-scale manufacturing and international collaboration. This can be particularly valuable for OEMs and technical buyers looking for long-term, reliable sources of advanced industrial SiC composites.

Frequently Asked Questions (FAQ) about Silicon Carbide Composites

Q1: What is the primary difference between monolithic silicon carbide and silicon carbide composites? A1: The primary difference lies in fracture toughness and failure mode. Monolithic silicon carbide (like S-SiC or RBSC without specific reinforcement strategies) is very hard and strong but can be brittle, meaning it may fracture suddenly under impact or high stress. Silicon carbide composites, such as C/SiC (carbon fiber-reinforced SiC) or SiC/SiC (SiC fiber-reinforced SiC), incorporate a reinforcing phase (fibers, whiskers, or specific microstructural designs) within the SiC matrix. This reinforcement helps to deflect or arrest cracks, significantly increasing fracture toughness and leading to a more damage-tolerant, less catastrophic failure. Essentially, composites are engineered to be tougher and more reliable under demanding mechanical and thermal conditions.

Q2: Are silicon carbide composites significantly more expensive than traditional SiC or high-performance alloys? A2: Generally, custom silicon carbide composites, particularly advanced CMCs like SiC/SiC, can have a higher initial cost compared to monolithic SiC grades or many high-performance metal alloys. This is due to the cost of specialized raw materials (e.g., high-purity SiC fibers), complex and often lengthy manufacturing processes (like CVI or PIP), and the challenging nature of machining these hard materials. However, the higher upfront cost can often be justified by: * Superior performance: Enabling operation at higher temperatures or in more corrosive environments where metals would fail. * Longer service life: Due to better wear resistance, corrosion resistance, and thermal stability. * Reduced downtime and maintenance: Leading to lower lifecycle costs. * Weight savings: Especially in aerospace, leading to fuel efficiency. For applications where standard SiC or alloys meet requirements, composites might not be cost-effective. But for extreme environments where performance is paramount, SiC composites offer value that outweighs the initial investment. Companies like Sicarb Tech are working to provide more cost-competitive custom silicon carbide components by leveraging industrial hubs and advanced technologies.

Q3: What are the typical lead times for custom silicon carbide composite components? A3: Lead times for custom SiC composite components can vary widely, ranging from several weeks to many months, depending on several factors: * Complexity of the part: Simple geometries will generally have shorter lead times than intricate designs. * Type of SiC composite: Some manufacturing processes (e.g., CVI for dense SiC/SiC) are inherently slow. RBSC or sintered parts might be quicker. * Availability of raw materials: Specialized fibers or powders may have their own lead times. * Tooling requirements: If new molds or custom tooling are needed, this will add to the initial lead time. * Production volume: Small, one-off prototypes might take longer on a per-unit basis than larger production runs once the process is established. * Post-processing requirements: Extensive machining, grinding, or coating will extend the lead time. * Supplier’s current capacity: Backlogs at the manufacturer can also impact delivery. It is always best to discuss specific lead time requirements with the supplier, such as Sicarb Tech, early in the project. They can provide more accurate estimates based on your component design, material choice, and their production schedule. Providing detailed specifications and drawings upfront will help in getting a quicker and more precise quotation and lead time estimate.

Conclusion: Embracing the Power of Custom Silicon Carbide Composites

Silicon carbide composites stand at the forefront of materials science, offering an extraordinary combination of properties that unlock new levels of performance in the most challenging industrial environments. From the scorching heat of aerospace engines and industrial furnaces to the aggressive chemical environments of semiconductor processing and the demanding wear conditions in manufacturing, custom SiC composites provide solutions where conventional materials falter. Their enhanced fracture toughness, exceptional high-temperature stability, superior wear resistance, and tailorable properties make them indispensable for innovation and efficiency.

The journey to successfully implementing these advanced materials involves careful consideration of design, material grades, manufacturing processes, and post-processing requirements. Navigating potential challenges such as cost, machining complexity, and integration requires expertise and close collaboration with knowledgeable suppliers.

Organizations like Sicarb Tech are pivotal in this landscape. Situated in Weifang City, the heart of China’s SiC industry, and backed by the formidable research capabilities of the Chinese Academy of Sciences, SicSino not only provides access to high-quality, cost-competitive custom silicon carbide components but also offers a unique pathway for technology transfer and the establishment of specialized production facilities. This commitment to both supplying advanced materials and empowering clients with manufacturing knowledge underscores a forward-thinking approach to advancing the global adoption of SiC technology.

For engineers, procurement managers, and technical buyers, embracing silicon carbide composites means investing in durability, reliability, and the future of high-performance applications. By partnering with experienced and technologically advanced suppliers, industries can harness the full potential of these remarkable materials, driving progress and achieving unparalleled operational excellence.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.