Unlocking Superior Protection and Performance with Silicon Carbide Coatings

Share

In the ever-evolving landscape of industrial technology, the demand for materials that can withstand extreme conditions while delivering enhanced performance is paramount. Among the advanced solutions available, silicon carbide (SiC) coatings have emerged as a cornerstone for protecting and augmenting components across a multitude of high-stakes sectors. These coatings are not merely superficial layers; they are engineered enhancements that significantly extend the lifespan and improve the efficiency of critical parts. For engineers, procurement managers, and technical buyers in industries like semiconductors, aerospace, and high-temperature manufacturing, understanding the value of custom SiC coating solutions is key to maintaining a competitive edge. The quest for superior material properties often leads to technical ceramic coatings, and SiC stands out for its remarkable combination of hardness, thermal stability, and chemical inertness.

The importance of SiC technology is underscored by dedicated industrial hubs, such as Weifang City in China, which has become a global center for silicon carbide customizable parts manufacturing. This region hosts over 40 SiC production enterprises, accounting for a significant majority of China’s national output. Within this vibrant ecosystem, Sicarb Tech has played a pivotal role since 2015, introducing and implementing advanced SiC production technology. As an entity belonging to the Chinese Academy of Sciences (Weifang) Innovation Park and collaborating closely with the National Technology Transfer Center of the Chinese Academy of Sciences , SicSino leverages the robust scientific and technological capabilities of Chinese Academy of Sciences. This allows us to not only witness but actively contribute to the ongoing development of the local SiC industry, ensuring that our clients benefit from the latest advancements in protective SiC layers and custom component manufacturing.

Core Advantages: Why Opt for Silicon Carbide Coatings?

The decision to utilize silicon carbide coatings stems from a clear set of performance benefits that directly address the challenges faced in demanding industrial environments. These coatings offer a transformative upgrade to substrate materials, providing a shield against wear, corrosion, and high temperatures, ultimately leading to reduced downtime, lower maintenance costs, and improved product quality. When technical buyers and engineers seek high-performance ceramic coatings, SiC consistently ranks as a top choice due to its intrinsic properties.

Let’s delve into the specific advantages:

- Exceptional Wear Resistance: Silicon carbide is one of the hardest commercially available ceramic materials, second only to diamond. When applied as a coating, it imparts outstanding resistance to sliding wear, abrasion, and erosion. This makes wear-resistant SiC coatings ideal for components subjected to friction, particulate matter, or high-velocity flows.

- Superior Corrosion Resistance: SiC exhibits remarkable inertness to a wide spectrum of acids, alkalis, and molten salts, even at elevated temperatures. This makes corrosion-resistant coatings based on SiC invaluable for equipment used in chemical processing, marine environments, and power generation where aggressive media can rapidly degrade unprotected parts.

- High-Temperature Stability and Thermal Barrier Properties: SiC coatings can maintain their structural integrity and protective qualities at temperatures exceeding 1500∘C (2732∘F) in certain formulations. They can also act as effective thermal barrier coatings (TBC) SiC, protecting underlying substrates from excessive heat and thermal shock, which is critical in combustion chambers, exhaust systems, and furnace components.

- Enhanced Hardness and Durability: The inherent hardness of SiC significantly increases the surface hardness of the coated component, protecting it from scratches, dents, and deformation. This leads to a substantial improvement in the overall durability and lifespan of the part.

- Tailorable Electrical Properties: Depending on the purity and specific formulation (e.g., doping), SiC coatings can range from being electrically insulating to semiconducting. This versatility allows for their use in electrical insulation layers or, conversely, in applications requiring controlled conductivity at high temperatures.

- Chemical Inertness and Purity: The low reactivity of SiC ensures that the coatings do not contaminate processes, which is particularly vital in semiconductor manufacturing and pharmaceutical applications where process purity is paramount.

To put these benefits into perspective, consider the following comparison:

| Feature | Silicon Carbide (SiC) Coating | Typical TiN Coating | Typical DLC Coating | Alumina Coating |

|---|---|---|---|---|

| Max. Use Temperature | Very High (e.g., >1500∘C) | Moderate (e.g., ∼600∘C) | Low (e.g., ∼350∘C) | High (e.g., ∼1700∘C) |

| Hardness (HV) | Extremely High (2500-3500) | High (2000-2400) | Very High (1500-9000) | High (1800-2200) |

| Chemical Resistance | Excellent | Good | Good | Very Good |

| Abrasion Resistance | Excellent | Good | Excellent | Good |

| Primary Benefit Example | High-temp wear & corrosion | General wear | Low friction | Electrical insulation |

This table illustrates why industrial SiC coating applications are often chosen when a combination of extreme hardness, high-temperature capability, and robust chemical resistance is required. Sicarb Tech works closely with clients to identify the optimal SiC coating strategy that aligns with their specific operational demands, ensuring that these advantages are fully realized.

Key Industrial Applications: Where Silicon Carbide Coatings Make a Difference

The unique combination of properties offered by silicon carbide coatings makes them indispensable across a diverse range of industries. Procurement professionals and OEMs seeking reliable OEM SiC coating solutions will find that these advanced ceramics enhance performance and longevity in some of the most challenging operational environments. The versatility of SiC allows it to be tailored for specific needs, from protecting delicate semiconductor components to fortifying robust industrial machinery.

Here are some of the primary sectors and applications benefiting from SiC coatings:

- Semiconductor Manufacturing: This industry demands ultra-high purity and resistance to aggressive plasma environments.

- Applications: Protecting plasma etch chamber components (showerheads, electrostatic chucks, liners), wafer handling systems (end effectors, chucks), and CVD equipment parts like SiC coating for graphite susceptors and injector tubes.

- Benefits: Reduced particle generation, extended component lifetime, improved process stability, and prevention of metallic contamination. SicSino, through its network in Weifang, supports manufacturers in sourcing high-purity CVD SiC coating for these critical applications.

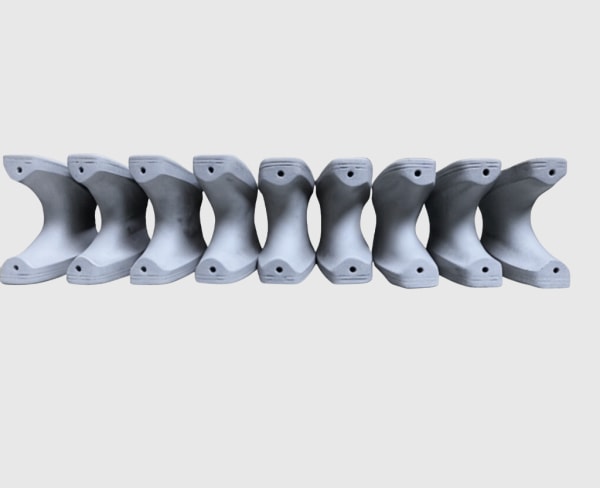

- High-Temperature Furnaces & Kilns: Components in these environments face extreme heat, thermal cycling, and potentially corrosive atmospheres.

- Applications: Coating for heating elements (SiC or metallic), furnace linings, thermocouple protection tubes, crucibles, and kiln furniture (beams, rollers, plates).

- Benefits: Enhanced oxidation resistance, prevention of sagging or warping at high temperatures, improved energy efficiency, and longer service life of furnace internals.

- Aerospace & Defense: The demand for lightweight materials that can withstand extreme temperatures, erosion, and corrosive jet fuels is critical.

- Applications: Protective coatings for turbine engine components (blades, vanes, combustors), rocket nozzles, missile leading edges, and components for hypersonic vehicles.

- Benefits: Increased engine efficiency through higher operating temperatures, protection against hot gas erosion and oxidation, and reduced wear on critical parts.

- Energy Sector: This sector requires materials resistant to high temperatures, pressures, wear, and corrosion in power generation and resource extraction.

- Applications: Components in gas and steam turbines, heat exchangers, solar power tower receivers, fuel cells, and downhole equipment in oil and gas. Corrosion-resistant SiC coatings are vital for nuclear applications, protecting components from harsh coolants and radiation.

- Benefits: Improved thermal efficiency, extended operational periods between maintenance, and enhanced safety in aggressive environments.

- Industrial Manufacturing & Machinery: Many general industrial processes involve abrasive materials, corrosive chemicals, or high mechanical loads.

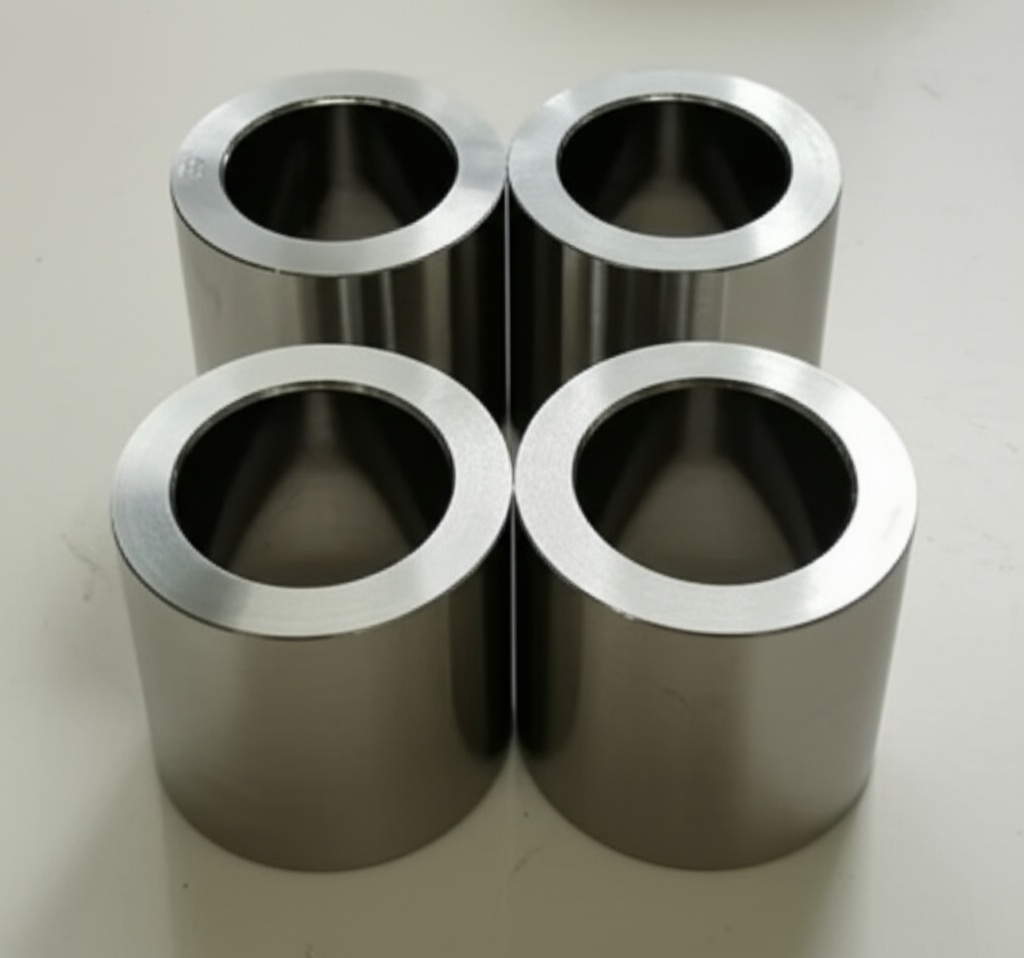

- Applications: Coating for pump components (impellers, casings, shafts), mechanical seals, bearings, valves (balls, seats), cutting tools, nozzles for abrasive blasting or fluid jetting, and various other wear-resistant SiC coatings for wear parts.

- Benefits: Dramatically increased lifespan of wear components, reduced need for lubrication in some cases, improved reliability of machinery, and lower overall maintenance expenditure.

- Chemical Processing Industry (CPI): Equipment in CPI often handles highly corrosive acids, bases, and solvents at various temperatures.

- Applications: Protective linings for reactors, pipes, valves, agitators, and sensors.

- Benefits: Superior protection against a wide range of chemical attacks, prevention of product contamination, and extended equipment life, leading to safer and more efficient chemical production.

Sicarb Tech understands the nuances of these diverse applications. Leveraging our deep expertise and the comprehensive capabilities of the SiC manufacturing hub in Weifang, we assist clients in developing custom SiC coating strategies tailored to their specific operational contexts, ensuring optimal performance and value. Whether it’s for wholesale SiC coating requirements or highly specialized OEM components, our access to a broad range of production technologies facilitates solutions that meet the rigorous demands of modern industry.

Understanding SiC Coating Deposition Techniques

Applying a silicon carbide coating effectively requires sophisticated deposition techniques that ensure optimal adhesion, desired thickness, and the correct microstructure for the intended application. Each method offers unique advantages and is suited to different substrate materials, component geometries, and performance requirements. Understanding these techniques is crucial for technical buyers and engineers when specifying protective SiC layers.

Below are some of the prominent SiC coating deposition techniques:

- Chemical Vapor Deposition (CVD):

- Process: CVD involves introducing volatile precursor gases (containing silicon and carbon, e.g., methyltrichlorosilane – MTS, or silane and a hydrocarbon) into a reaction chamber heated to high temperatures (typically 900∘C to 1400∘C, but can be higher for specific SiC phases). The gases decompose and react on the heated substrate surface, forming a dense, highly pure, and conformal SiC film.

- Advantages: Produces coatings of very high purity and density, excellent conformity to complex shapes, superior adhesion, and ability to form crystalline (often cubic β-SiC) or amorphous SiC. CVD SiC coating is a preferred method for semiconductor components and applications requiring extreme corrosion resistance.

- Typical Applications: Coating graphite susceptors for semiconductor epitaxy, components for MOCVD reactors, rocket nozzles, heat exchanger tubes, and high-purity SiC components.

- Physical Vapor Deposition (PVD):

- Process: PVD encompasses several vacuum deposition methods, including sputtering and evaporation.

- Sputtering: High-energy ions bombard a SiC target, ejecting SiC atoms or molecules that then deposit onto the substrate.

- Evaporation: SiC material is heated in a vacuum until it evaporates; the vapor then condenses on the cooler substrate.

- Advantages: Generally lower deposition temperatures compared to CVD (can be 100∘C to 500∘C), allowing coating of temperature-sensitive substrates. Offers good control over coating thickness and structure. Line-of-sight process, so complex geometries may require substrate manipulation.

- Typical Applications: Wear-resistant coatings on cutting tools, decorative coatings, optical coatings, and protective layers on metallic or plastic components.

- Process: PVD encompasses several vacuum deposition methods, including sputtering and evaporation.

- Plasma Spraying (Atmospheric Plasma Spray – APS / Vacuum Plasma Spray – VPS):

- Process: SiC powder is injected into a high-temperature plasma jet, where it melts and is propelled at high velocity onto the substrate. The molten droplets flatten upon impact, rapidly solidify, and form a coating. APS is done in air, while VPS occurs in a controlled low-pressure environment for higher purity and density.

- Advantages: Ability to apply thick coatings (millimeters if needed), suitable for a wide range of substrate materials (metals, ceramics, composites), relatively high deposition rates, and can coat large surface areas. Often used for thermal barrier coatings (TBC) SiC and wear-resistant applications.

- Typical Applications: Wear-resistant coatings on boiler tubes, pump casings; thermal barrier coatings on engine components; corrosion protection in aggressive industrial environments.

- Other Notable Methods:

- Pack Cementation: A diffusion coating process where the part is buried in a powder mixture containing SiC and activators, then heated. Silicon and carbon diffuse into the substrate surface. Often used for SiC coating for graphite.

- Sol-Gel Process: Involves the application of a liquid precursor solution (sol) which is then converted into a glassy or ceramic coating (gel) through heat treatment. Can produce thin, uniform coatings at relatively low temperatures.

- Slurry Coating (Painting/Dipping): A SiC-containing slurry is applied to the substrate by painting, dipping, or spraying, followed by drying and often a high-temperature sintering or reaction bonding step to consolidate the coating.

The selection of the most appropriate deposition technique is a critical decision that depends on factors such as the substrate material, the service conditions of the component, the desired coating properties, and economic considerations.

| Deposition Technique | Typical Temperature | Coating Thickness Range | Adhesion | Purity | Cost Factor | Key Advantage |

|---|---|---|---|---|---|---|

| CVD SiC Coating | High (900−1400∘C+) | Microns to millimeters | Excellent | Very High | High | High purity, conformal, dense |

| PVD SiC Coating | Low-Moderate (100−500∘C) | Sub-micron to microns | Good | High | Moderate | Lower temperature, versatile |

| Plasma Spray SiC Coating | N/A (Substrate low) | Tens of microns to mm | Good | Moderate | Moderate-High | Thick coatings, wide substrate range |

| Pack Cementation | Very High | Tens to hundreds of μm | Excellent | Good | Moderate | Good for graphite, diffusion bonding |

Sicarb Tech, benefiting from the advanced technological landscape of Weifang and the expertise of the Chinese Academy of Sciences, has access to a network of partners proficient in these varied deposition methods. This enables us to guide clients towards the most effective industrial SiC coating applications and provide comprehensive solutions from material selection to finished product.

Substrate Compatibility and Preparation for SiC Coating

The success of a silicon carbide coating is not solely dependent on the coating material or deposition technique; it is also critically linked to the substrate material and its preparation. Achieving optimal adhesion and performance from protective SiC layers requires careful consideration of substrate compatibility and meticulous surface treatment. Engineers and procurement managers should be aware of these factors when specifying custom SiC coating projects.

Common Substrate Materials for SiC Coatings:

Silicon carbide coatings can be applied to a diverse range of substrate materials, each with its own set of characteristics and preparation requirements:

- Metals and Alloys:

- Examples: Stainless steels, tool steels, nickel-based superalloys (e.g., Inconel), titanium alloys, molybdenum, tungsten.

- Considerations: Thermal expansion mismatch between the metal and SiC can be significant, potentially requiring bond coats or functionally graded layers to mitigate stress. Oxidation or reaction of the metal surface at high deposition temperatures (especially in CVD) must be controlled.

- Ceramics:

- Examples: Alumina (Al2O3), zirconia (ZrO2), other silicon carbide components (SiC-on-SiC), silicon nitride (Si3N4).

- Considerations: Generally good thermal expansion compatibility with SiC coatings. Surface chemistry and porosity of the ceramic substrate influence adhesion.

- Graphite:

- Examples: Isotropic graphite, pyrolytic graphite.

- Considerations: SiC coating for graphite is very common, especially using CVD, to prevent oxidation and particle shedding at high temperatures, particularly in semiconductor and furnace applications. The porosity of graphite requires careful infiltration or sealing by the coating.

- Composites:

- Examples: Carbon-Carbon (C/C) composites, Ceramic Matrix Composites (CMCs).

- Considerations: Coatings protect the composite fibers and matrix from oxidation and erosion, especially in aerospace applications.

Importance of Substrate Surface Preparation:

The interface between the substrate and the SiC coating is critical for adhesion and long-term performance. Inadequate surface preparation is a common cause of coating failure. Key preparation steps include:

- Cleaning: Removal of all contaminants such as oils, greases, rust, scale, and dirt. This may involve solvent cleaning, ultrasonic cleaning, or chemical etching.

- Roughening: Creating a specific surface topography (roughness) can enhance mechanical interlocking between the coating and substrate. Techniques include grit blasting, grinding, or chemical etching. The optimal roughness depends on the coating process and thickness.

- Activation: For some substrate-coating combinations, surface activation (e.g., plasma treatment) may be necessary to improve chemical bonding.

- Outgassing: For porous substrates or those intended for vacuum applications, an outgassing step (heating in vacuum) may be needed prior to coating to remove trapped volatiles.

Design Considerations for Parts to be Coated:

The geometry of a component can significantly impact the feasibility and quality of the SiC coating:

- Sharp Edges and Corners: These can lead to thinner coating coverage or stress concentrations. Radiusing sharp edges is generally recommended.

- Internal Corners and Small Bores: Line-of-sight processes like PVD may struggle to coat these areas uniformly. CVD, being a gas-phase process, offers better conformality in such features.

- Aspect Ratios: Deep, narrow holes or channels can be challenging to coat uniformly.

- Masking: Areas that do not require coating may need to be masked, and the masking strategy must be compatible with the deposition process and temperature.

Managing Differential Thermal Expansion:

A significant challenge, particularly when coating metallic substrates with ceramic SiC, is the difference in coefficients of thermal expansion (CTE). As the coated part heats and cools during deposition or in service, this CTE mismatch can induce stresses at the interface, potentially leading to cracking or delamination. Strategies to manage this include:

- Using metallic bond coats with intermediate CTE.

- Developing functionally graded material (FGM) interlayers where the composition gradually changes from the substrate material to SiC.

- Optimizing coating thickness and deposition parameters.

Sicarb Tech, with its strong foundation in material science and process technology through its association with the Chinese Academy of Sciences, provides crucial expertise in advising on design for manufacturability. We assist our clients in selecting appropriate substrate materials and defining optimal preparation protocols to ensure the success and reliability of their custom SiC coating applications. Our experience within Weifang’s SiC hub allows us to connect with specialized factories capable of handling complex preparation and coating tasks for OEM SiC coating solutions.

Quality Control, Testing, and Characterization of SiC Coatings

Ensuring that silicon carbide coatings meet the stringent performance requirements of industrial applications necessitates a robust framework for quality control, testing, and characterization. For technical buyers and OEMs, understanding these processes is vital for verifying the integrity and functionality of protective SiC layers. High-quality advanced ceramic coatings demand meticulous attention to detail from raw material input to final inspection.

The characterization of SiC coatings typically involves evaluating several key properties:

- Thickness Measurement:

- Importance: Coating thickness directly impacts performance aspects like wear life, thermal insulation, and corrosion protection. It must be uniform and within specified tolerances.

- Techniques:

- Scanning Electron Microscopy (SEM): Cross-sectional imaging provides direct and accurate thickness measurement.

- X-Ray Fluorescence (XRF): A non-destructive technique that can determine thickness by analyzing emitted X-rays.

- Profilometry: A stylus is dragged across a step edge (from coated to uncoated area) to measure height difference.

- Eddy Current/Magnetic Induction: Non-destructive methods suitable for conductive coatings on non-conductive substrates, or vice-versa.

- Adhesion Testing:

- Importance: The bond strength between the SiC coating and the substrate is critical for durability. Poor adhesion leads to premature failure through spallation or delamination.

- Techniques:

- Tape Test (ASTM D3359): A simple qualitative test where pressure-sensitive tape is applied and removed; the amount of coating removed is assessed.

- Scratch Test (ASTM C1624, D7027): A stylus with increasing load is drawn across the surface until the coating fails (critical load).

- Pull-Off Test (ASTM D4541, C633): A stud is glued to the coating surface and pulled perpendicularly; the force required to detach the coating measures adhesion strength.

- Hardness and Wear Resistance Testing:

- Importance: Key for applications involving abrasion, erosion, or sliding contact.

- Techniques:

- Microhardness Testing (Vickers, Knoop – ASTM E384): An indenter is pressed into the coating surface with a known load, and the size of the indentation is measured to calculate hardness.

- Rockwell Hardness Test: Less common for thin coatings but can be used for thicker layers.

- Taber Abrasion Test (ASTM D4060): Measures wear resistance by subjecting the coated surface to rubbing action from abrasive wheels.

- Pin-on-Disk or Ball-on-Disk Wear Tests (ASTM G99, G133): Quantify wear rates and friction coefficients under controlled sliding conditions.

- Corrosion Testing:

- Importance: Essential for components exposed to corrosive chemicals, moisture, or high-temperature gases.

- Techniques:

- Salt Spray Test (ASTM B117): Assesses resistance to corrosion in a saline environment.

- Electrochemical Testing (e.g., Potentiodynamic Polarization – ASTM G5, G61): Measures corrosion current and potential to evaluate corrosion rate and passivation behavior.

- Immersion Testing (ASTM G31): Submerging coated samples in specific corrosive media at controlled temperatures.

- Microstructural Analysis:

- Importance: The microstructure (grain size, porosity, phase composition, presence of defects) significantly influences the coating’s properties.

- Techniques:

- Scanning Electron Microscopy (SEM): Provides high-magnification images of the surface morphology and cross-section, revealing details about density, grain structure, and defects.

- X-Ray Diffraction (XRD): Identifies the crystalline phases present in the coating (e.g., α-SiC, β-SiC) and can assess crystallinity and residual stress.

- Energy Dispersive X-ray Spectroscopy (EDS/EDX): Often coupled with SEM, provides elemental composition analysis.

For OEM SiC coating solutions to be truly effective, they must consistently meet stringent quality benchmarks. Sicarb Tech, by capitalizing on the advanced measurement and evaluation technologies available through the Chinese Academy of Sciences, ensures that the SiC coatings provided by our partner network meet the highest quality standards. Our domestic top-tier professional team specializes in customized production, and this includes rigorous quality assurance protocols implemented throughout the integrated process, from materials to final coated products. This commitment ensures reliable and high-performing industrial SiC coating applications for our global clientele.

Choosing Your Silicon Carbide Coating Partner: Key Considerations

Selecting the right supplier for your silicon carbide coating services is a critical decision that can significantly impact the performance, reliability, and cost-effectiveness of your components. For procurement professionals, engineers, and OEMs, evaluating potential vendors requires looking beyond just price to assess their technical prowess, customization capabilities, and overall commitment to quality. The goal is to find a partner who can deliver consistent, high-quality custom SiC coating solutions tailored to your specific industrial needs.

Here are key considerations when choosing a SiC coating partner:

- Technical Expertise and Experience:

- Importance: A deep understanding of SiC material science, various SiC grades (e.g., reaction-bonded, sintered, CVD-SiC), and different deposition methods is crucial.

- Look for: A proven track record with similar applications, knowledgeable engineering staff who can provide technical consultation, and experience in problem-solving complex coating challenges.

- Customization Capabilities:

- Importance: Off-the-shelf solutions rarely suffice for specialized industrial applications. The ability to tailor coating properties – such as thickness, density, morphology, hardness, and composition – is paramount.

- Look for: Suppliers who offer engineering support to develop custom SiC coating formulations and processes specific to your requirements.

- Material Quality and Sourcing:

- Importance: The quality of the raw SiC powders, precursors (for CVD), and other consumables directly impacts the final coating’s properties and purity.

- Look for: Transparency in material sourcing, use of high-purity materials, and quality control measures for incoming raw materials.

- Range of Coating Services and Deposition Techniques:

- Importance: Different applications and substrates benefit from different coating methods (CVD, PVD, plasma spray, etc.). A supplier offering a broader range of techniques is more likely to provide the optimal solution.

- Look for: Access to various deposition technologies and the expertise to recommend the most suitable one for your component’s geometry, substrate material, and performance goals.

- Quality Management Systems and Certifications:

- Importance: Robust quality control processes ensure consistency and reliability of the coatings.

- Look for: Certifications like ISO 9001, well-documented QC procedures, investment in advanced testing and characterization equipment, and traceability of materials and processes.

- Capacity, Lead Times, and Scalability:

- Importance: The supplier must be able to meet your volume requirements, from prototypes to wholesale SiC coating orders, within acceptable lead times.

- Look for: Adequate production capacity, efficient scheduling, and the ability to scale operations to meet fluctuating demands.

- Cost-Effectiveness:

- Importance: While performance is key, cost is always a factor. The ideal partner offers a balance between superior coating quality and competitive pricing.

- Look for: Clear pricing structures, value engineering insights to optimize costs without compromising performance, and long-term cost benefits through extended component life.

Why Sicarb Tech is Your Trusted Partner:

Sicarb Tech stands out as a premier partner for your custom silicon carbide needs, including specialized coatings. Our unique position within Weifang City, the hub of China’s SiC customizable parts factories, and our direct affiliation with the Chinese Academy of Sciences provide unparalleled advantages:

- Unmatched Expertise: We leverage the formidable scientific, technological capabilities, and talent pool of Chinese Academy of Sciences. Our domestic top-tier professional team specializes in the customized production of silicon carbide products, including advanced coatings. We possess a wide array of technologies covering material, process, design, and measurement & evaluation.

- Reliable Quality and Supply Assurance: We have assisted over 10 local enterprises in Weifang with our technologies, fostering an ecosystem of high-quality SiC manufacturing. Our integrated process, from materials to products, allows us to meet diverse customization needs and offer higher-quality, cost-competitive customized silicon carbide components and coatings within China.

- Technology Transfer and Turnkey Solutions: Beyond supplying components, SicSino is committed to advancing the global SiC industry. If you aim to establish a professional silicon carbide products manufacturing plant in your country, we offer technology transfer for professional SiC production. This includes a full-range of turnkey project services: factory design, procurement of specialized equipment, installation and commissioning, and trial production, ensuring a reliable technology transformation and a guaranteed input-output ratio.

- Comprehensive Support: As a bridge facilitating the integration and collaboration in technology transfer, we have established a comprehensive service ecosystem. This commitment to innovation and quality makes us a reliable choice for businesses seeking OEM SiC coating solutions and other advanced SiC products.

Choosing Sicarb Tech means partnering with an organization that is deeply embedded in the heart of SiC production and innovation, backed by one of the world’s leading scientific institutions.

Common Challenges in Silicon Carbide Coating and Mitigation Strategies

While silicon carbide coatings offer exceptional benefits, their application is not without challenges. Understanding these potential hurdles and the strategies to mitigate them is crucial for engineers and technical buyers aiming to successfully implement protective SiC layers. Effective problem-solving often involves a combination of material science expertise, process control, and careful design considerations.

Here are some common challenges associated with SiC coatings and how they can be addressed:

- Adhesion Issues (Delamination/Spallation):

- Challenge: The coating fails to bond adequately to the substrate, leading to peeling or flaking, especially under thermal cycling or mechanical stress.

- Causes: Improper substrate cleaning or preparation, significant thermal expansion mismatch (CTE) between coating and substrate, high residual stresses in the coating, or an inappropriate deposition process for the substrate.

- Mitigation Strategies:

- Thorough Substrate Cleaning & Roughening: Ensure an atomically clean and appropriately textured surface for good mechanical keying and chemical bonding.

- Bond Coats/Interlayers: Use intermediate layers (e.g., metallic bond coats, functionally graded materials) to gradually transition CTE and improve chemical compatibility.

- Process Parameter Optimization: Adjust deposition temperature, pressure, and gas flow rates to minimize residual stress.

- Post-Coating Annealing: Controlled heat treatment can relieve stress and improve adhesion.

- Selecting a deposition technique known for good adhesion on the specific substrate (e.g., CVD often offers excellent adhesion).

- Cracking of the Coating:

- Challenge: Cracks can develop in the SiC coating during deposition, cooling, or in service, compromising its protective function.

- Causes: High tensile residual stresses due to CTE mismatch, coating thickness exceeding a critical limit for the stress level, thermal shock, or mechanical impact.

- Mitigation Strategies:

- CTE Management: As with adhesion, use bond coats or select substrate/coating combinations with closer CTE values.

- Control Coating Thickness: Avoid excessively thick coatings unless specifically designed and validated.

- Optimize Deposition Parameters: Minimize intrinsic stresses.

- Gradual Heating/Cooling Rates: Reduce thermal shock during processing and in service.

- Toughening Mechanisms: For some applications, incorporating secondary phases or designing microstructures that arrest crack propagation can be considered, although this is more common in bulk SiC than typical thin coatings.

- Porosity in the Coating:

- Challenge: The presence of pores can reduce the coating’s density, hardness, and effectiveness as a barrier against corrosion or gas penetration.

- Causes: Sub-optimal deposition parameters (e.g., too low temperature, incorrect pressure), shadowing effects in PVD, or outgassing from the substrate during coating.

- Mitigation Strategies:

- Optimize Deposition Process: Fine-tune parameters to achieve dense coatings (e.g., higher temperature in CVD, ion bombardment assistance in PVD, higher particle velocity/temperature in plasma spray).

- Substrate Outgassing: Perform a vacuum bake-out of the substrate before coating if necessary.

- Post-Coating Sealing: For some applications, a sealant can be applied to fill porosity, though this may compromise high-temperature performance or purity.

- Uniformity of Coating Thickness:

- Challenge: Achieving a consistent coating thickness across complex geometries or large surfaces can be difficult.

- Causes: Line-of-sight limitations in PVD or some spray techniques, gas flow dynamics in CVD, or uneven heating of the substrate.

- Mitigation Strategies:

- Substrate Manipulation: Rotating or moving the substrate during PVD or spraying.

- Reactor Design & Gas Flow Control: Optimizing CVD reactor geometry and precursor delivery for uniform deposition.

- Multiple Sources/Nozzles: Using multiple deposition sources in PVD or plasma spray.

- Conformal Techniques: Employing CVD for complex shapes where uniformity is critical.

- Cost of Coating Process:

- Challenge: Some SiC coating processes, particularly high-purity CVD, can be expensive due to equipment costs, long cycle times, and precursor material expenses.

- Mitigation Strategies:

- Process Selection: Choose the most cost-effective deposition technique that meets the performance requirements. Not all applications need the highest-purity CVD SiC.

- Optimize Batch Sizes: Maximize the number of parts per coating run where possible.

- Evaluate Total Cost of Ownership: Consider the extended lifespan and reduced maintenance of coated parts, which can offset higher initial coating costs. For wholesale SiC coating, economies of scale can be leveraged.

Sicarb Tech and its network partners in Weifang are experienced in navigating these challenges. By leveraging the deep technical expertise derived from the Chinese Academy of Sciences and practical manufacturing know-how, we help clients optimize their custom SiC coating designs and processes to achieve reliable, high-performance results while managing costs effectively. Our focus on material, process, design, and measurement technologies provides a holistic approach to overcoming the complexities of SiC coating applications.

Frequently Asked Questions (FAQ) about Silicon Carbide Coatings

As a leading authority in custom silicon carbide products and technology, Sicarb Tech often addresses inquiries from engineers, procurement managers, and technical buyers. Here are some frequently asked questions regarding silicon carbide coatings:

- What is the typical thickness range for SiC coatings, and how is it determined?

- The typical thickness for SiC coatings can vary widely, from a few micrometers (μm) to several millimeters (mm), depending on the deposition method and the application.

- Thin films (e.g., 1-50 μm): Often produced by CVD or PVD, suitable for semiconductor components, optical applications, or where dimensional changes must be minimal.

- Medium thickness (e.g., 50-500 μm): Common for general wear and corrosion resistance, often applied by plasma spray or thicker CVD.

- Thick coatings (e.g., >500 μm to several mm): Typically achieved by plasma spray techniques for severe wear, erosion, or thermal barrier applications.

- The optimal thickness is determined by factors such as the severity of the wear or corrosive environment, thermal insulation requirements, stress considerations (thicker coatings can have higher residual stress), cost, and the specific performance goals for the protective SiC layer. Sicarb Tech works with clients to specify the ideal thickness for their custom SiC coating needs.

- The typical thickness for SiC coatings can vary widely, from a few micrometers (μm) to several millimeters (mm), depending on the deposition method and the application.

- Can SiC coatings be applied to complex geometries and internal surfaces?

- Yes, but the feasibility and uniformity depend heavily on the chosen deposition technique.

- Chemical Vapor Deposition (CVD): Is excellent for coating complex geometries, including internal surfaces, narrow bores, and intricate shapes, due to its gas-phase nature which allows precursors to reach all exposed surfaces. This makes CVD SiC coating highly suitable for parts like intricately designed showerheads or internal channels.

- Physical Vapor Deposition (PVD): Is generally a line-of-sight process. While substrate rotation and manipulation can help, coating highly complex internal surfaces uniformly can be challenging.

- Plasma Spraying: Also largely line-of-sight, best suited for external surfaces or accessible internal areas. Specialized gun extensions can sometimes be used for internal diameters.

- Other methods like pack cementation or slurry coating can also be adapted for certain complex shapes.

- It’s crucial to discuss the component’s geometry with your coating provider. SicSino can advise on the best approach by leveraging the diverse technological capabilities within the Weifang SiC manufacturing cluster.

- Yes, but the feasibility and uniformity depend heavily on the chosen deposition technique.

- How does the cost of SiC coating compare to other protective coatings, and what are the main cost drivers?

- SiC coatings are generally considered a premium performance solution, and their cost can be higher than some conventional coatings like hard chrome plating or basic polymer coatings. However, they often provide significantly better performance and longer life in demanding applications, leading to a lower total cost of ownership.

- Comparison:

- More expensive than many paints, basic polymer coatings, or simple electroplating.

- Comparable to or sometimes more expensive than other advanced ceramic coatings (e.g., alumina, zirconia, TiN, DLC), depending on the specific SiC type, deposition method, and thickness. High-purity CVD SiC coating is typically among the more expensive options.

- Main Cost Drivers:

- Deposition Method: CVD processes are often more capital-intensive and have higher operational costs than PVD or some spray techniques.

- Coating Thickness: Thicker coatings require longer processing times and more material.

- Purity Requirements: Higher purity demands more expensive precursors and stricter process controls.

- Component Complexity and Size: Affects handling, masking, and batch size.

- Volume of Parts: Wholesale SiC coating generally offers better per-unit pricing due to economies of scale.

- Pre- and Post-Processing: Cleaning, surface preparation, masking, and any required finishing steps add to the cost.

- Sicarb Tech strives to provide cost-competitive customized silicon carbide components and coatings by optimizing processes and leveraging the efficient manufacturing ecosystem in Weifang.

- What is the maximum operating temperature for SiC coatings?

- Silicon carbide is renowned for its excellent high-temperature stability. The maximum operating temperature of a SiC coating depends on several factors:

- Type of SiC: Pure, dense SiC can withstand very high temperatures. For instance, CVD SiC can often operate above 1600∘C (2912∘F) in inert or controlled atmospheres.

- Atmosphere: In oxidizing atmospheres (like air), SiC forms a passive silica (SiO2) layer that protects it up to around 1600−1700∘C. Above this, active oxidation can occur.

- Substrate Material: The substrate’s temperature limit might be lower than the SiC coating itself.

- Presence of Impurities or Binders: Some SiC coatings (especially certain sprayed or sintered types) might contain binders or have porosity that can limit their maximum use temperature.

- Generally, SiC coatings offer reliable performance in the range of 1200∘C to 1600∘C for many industrial applications, and significantly higher in non-oxidizing environments. It’s a key reason they are chosen for thermal barrier coatings (TBC) SiC applications.

- Silicon carbide is renowned for its excellent high-temperature stability. The maximum operating temperature of a SiC coating depends on several factors:

- Can existing or worn parts be refurbished with SiC coatings?

- Yes, in many cases, existing or worn parts can be refurbished with SiC coatings, offering a cost-effective way to extend their service life. The process typically involves:

- Assessment: Evaluating the condition of the worn part to determine if it’s a suitable candidate for recoating.

- Stripping (if necessary): Removing any old coating or damaged surface layers.

- Repair/Machining: Re-machining critical dimensions if wear is significant.

- Surface Preparation: Thorough cleaning and preparation as for new parts.

- Coating Application: Applying the new SiC coating.

- Finishing: Any required post-coating grinding or polishing.

- Refurbishment with wear-resistant SiC coatings is common for components like pump shafts, seals, and rollers, significantly reducing replacement costs and material waste. Sicarb Tech can help assess the feasibility of refurbishing your components.

- Yes, in many cases, existing or worn parts can be refurbished with SiC coatings, offering a cost-effective way to extend their service life. The process typically involves:

Conclusion: The Enduring Value of Custom Silicon Carbide Coatings

In the relentless pursuit of industrial excellence, silicon carbide coatings stand out as a transformative technology, offering unparalleled protection and performance enhancement for components operating in the most demanding environments. From the intricate world of semiconductor manufacturing to the extreme conditions of aerospace and high-temperature furnaces, the benefits of wear resistance, corrosion resistance, and thermal stability provided by SiC are undeniable. The ability to tailor these coatings through various deposition techniques to suit specific substrates and operational needs further underscores their versatility and value.

Choosing the right partner for your custom SiC coating requirements is paramount to realizing these benefits., deeply rooted in Weifang City – the heartland of China’s silicon carbide innovation – and backed by the formidable scientific prowess of the Chinese Academy of Sciences , offers a unique and compelling proposition. We provide not only access to high-quality, cost-competitive OEM SiC coating solutions and customized components but also a wealth of technical expertise spanning material science, process technology, and application engineering. Our commitment extends to fostering industry growth through technology transfer, empowering businesses worldwide to establish their own specialized SiC production capabilities.

Whether you are seeking to enhance the durability of critical machinery, improve process purity in sensitive applications, or push the boundaries of high-temperature operations, silicon carbide coatings delivered by a knowledgeable and reliable supplier like Sicarb Tech represent a strategic investment in efficiency, longevity, and innovation. We invite engineers, procurement managers, and technical buyers to engage with us to explore how our advanced SiC solutions can address your specific challenges and elevate your industrial applications to new levels of performance. Sources and related content

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.