Silicon Carbide Blocks: The Unrivaled Solution for Extreme Industrial Environments

Share

In the demanding landscape of modern industry, the quest for materials that can withstand extreme conditions is perpetual. Engineers, procurement managers, and technical buyers across sectors like semiconductors, high-temperature processing, aerospace, energy, and industrial manufacturing are constantly seeking components that offer superior performance, longevity, and value. Among the advanced technical ceramics, custom silicon carbide (SiC) blocks have emerged as a cornerstone material, delivering exceptional properties where conventional materials falter. Their unique combination of thermal, mechanical, and chemical resistance makes them indispensable for a myriad of high-performance industrial applications.

The significance of SiC blocks lies not just in their inherent material characteristics but also in the ability to customize them to precise specifications. This adaptability ensures optimal performance in specific applications, addressing unique challenges related to wear, temperature, and corrosive environments. As industries push the boundaries of innovation, the demand for reliable, high-quality industrial SiC components continues to surge. This blog post will delve into the world of silicon carbide blocks, exploring their applications, advantages, design considerations, and what to look for in a premier supplier like Sicarb Tech, your trusted partner in the heart of China’s SiC manufacturing hub.

Key Industrial Applications Driving Demand for SiC Blocks

The versatility of silicon carbide blocks allows them to be cornerstone components in a wide array of demanding industrial sectors. Their exceptional properties translate into enhanced efficiency, longevity, and reliability in critical processes. As industries evolve and demand higher performance standards, technical ceramics like SiC are becoming increasingly integral.

In the semiconductor manufacturing industry, SiC blocks are prized for their high thermal conductivity, excellent thermal shock resistance, and dimensional stability at elevated temperatures. They are used in components like wafer chucks, electrostatic chucks, and various furnace parts where maintaining pristine conditions and precise temperature control is paramount. The low coefficient of thermal expansion and high stiffness of SiC ensure minimal warping and distortion, crucial for the intricate processes involved in semiconductor fabrication. The ability to produce large, high-purity SiC blocks for semiconductor equipment is a critical manufacturing capability.

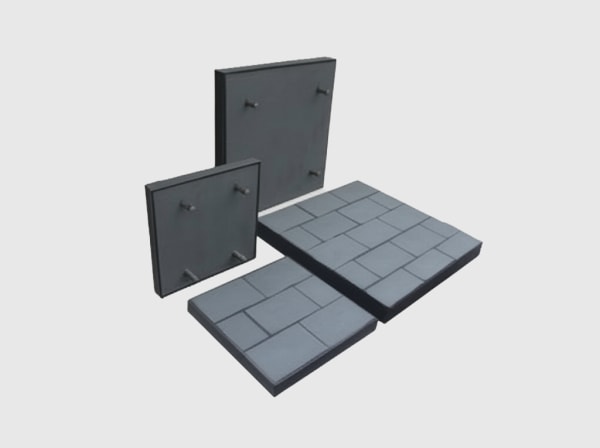

High-temperature furnace applications extensively utilize SiC blocks as refractory materials, kiln furniture (beams, supports, plates), and burner nozzles. Their capacity to withstand extreme temperatures (often exceeding 1600circC), coupled with excellent resistance to oxidation and creep, makes them ideal for environments in ceramics firing, metal heat treatment, and glass manufacturing. Furnace refractory materials made from SiC contribute to energy savings and longer campaign lives due to their durability.

The aerospace and defense sectors leverage SiC blocks for applications requiring lightweight yet highly durable materials capable of performing under severe thermal and mechanical stress. Examples include components for rocket nozzles, armor plating, and high-performance braking systems. The material’s high strength-to-weight ratio and resistance to erosion are particularly beneficial for aerospace ceramic components.

In the energy sector, particularly in power generation and conversion, SiC blocks find use in heat exchangers, recuperators, and components for advanced gas turbines. Their ability to operate efficiently at high temperatures improves energy recovery and overall system performance. SiC for energy applications also extends to components in nuclear power, where its radiation resistance and stability are advantageous.

Industrial manufacturing encompasses a broad range of applications where wear resistance is a primary concern. SiC blocks are fabricated into components like mechanical seals, pump shafts and sleeves, bearings, cyclone liners, and nozzles for abrasive material handling. The exceptional hardness of SiC provides extended service life for industrial wear parts, reducing downtime and maintenance costs in demanding industries such as mining, chemical processing, and paper production. The use of precision SiC components ensures that these parts integrate seamlessly into complex machinery.

The following table outlines key applications and the specific SiC properties that make them suitable:

| Industry Sector | Common Applications for SiC Blocks | Key SiC Properties Leveraged | Targeted Keywords for B2B Buyers |

|---|---|---|---|

| Semiconductor | Wafer chucks, electrostatic chucks, furnace components, CMP rings | High thermal conductivity, high purity, stiffness, thermal shock resistance, low CTE | SiC semiconductor components, custom SiC chucks, high-purity SiC |

| High-Temperature Furnaces | Kiln furniture (beams, supports), burner nozzles, refractory linings | High-temperature strength, oxidation resistance, creep resistance, thermal shock resistance | SiC kiln furniture, refractory SiC blocks, high-temp SiC parts |

| Aerospace & Defense | Rocket nozzles, armor, brake components, mirror substrates | High strength-to-weight ratio, hardness, thermal stability, low density, wear resistance | aerospace SiC, lightweight ceramic armor, SiC mirror blanks |

| Energy | Heat exchangers, recuperators, turbine components, nuclear parts | High thermal conductivity, corrosion resistance, high-temperature stability, radiation resistance | SiC heat exchanger tubes, energy sector ceramics, SiC power gen |

| Industrial Manufacturing | Mechanical seals, bearings, nozzles, pump parts, cyclone liners | Extreme hardness, wear resistance, corrosion resistance, chemical inertness | SiC wear parts, ceramic mechanical seals, custom SiC nozzles |

The growing reliance on custom silicon carbide blocks across these diverse and critical industries underscores the material’s indispensable role in advancing technology and improving operational efficiencies. As a leader in custom SiC solutions, Sicarb Tech is well-positioned to meet these evolving demands with high-quality, tailored components.

The Unmatched Advantages of Custom Silicon Carbide Blocks

Choosing custom silicon carbide blocks for demanding industrial applications is a strategic decision rooted in the material’s exceptional combination of properties. Unlike many traditional materials or even other technical ceramics, SiC offers a unique profile that translates into tangible benefits for performance, longevity, and operational efficiency. Customization further amplifies these advantages, allowing engineers to specify dimensions, shapes, and even microstructural characteristics to precisely match application requirements.

Key benefits of utilizing custom SiC blocks include:

- Exceptional Thermal Properties:

- High Thermal Conductivity: Silicon carbide exhibits excellent thermal conductivity, often comparable to or exceeding that of many metals. This allows for rapid and uniform heat dissipation, crucial for applications like heat sinks, heat exchangers, and components in semiconductor processing equipment. For instance, Reaction Bonded Silicon Carbide (RBSiC or SiSiC) can have thermal conductivity in the range of 80−150,W/mcdotK, while Sintered Silicon Carbide (SSiC) can reach up to 120−200,W/mcdotK.

- Excellent Thermal Shock Resistance: SiC can withstand rapid temperature changes without cracking or significant degradation. This is due to its high thermal conductivity, relatively low coefficient of thermal expansion (typically 4−5times10−6/circC), and high strength. This makes thermal shock resistant ceramics like SiC ideal for furnace components, burner nozzles, and applications involving thermal cycling.

- High-Temperature Stability: SiC maintains its mechanical strength and structural integrity at very high temperatures, often up to 1400−1650circC in air, depending on the grade. This makes it superior to most metals and many other ceramics for high-temperature structural applications.

- Superior Mechanical Properties:

- Extreme Hardness and Wear Resistance: With a Mohs hardness of around 9.0-9.5 (Knoop hardness typically 2500−2900,kg/mm2), SiC is one of the hardest commercially available ceramic materials, second only to diamond. This translates to outstanding abrasion resistant SiC components, perfect for wear parts such as mechanical seals, bearings, nozzles handling abrasive slurries, and cyclone liners. This significantly extends component lifetime and reduces maintenance intervals.

- High Strength and Stiffness: Silicon carbide possesses high flexural strength (typically 300−550,MPa for RBSiC and 400−600,MPa for SSiC) and a high Young’s modulus (around 350−450,GPa). This means high strength SiC blocks can withstand significant loads without deforming or fracturing, making them suitable for structural supports and components subjected to mechanical stresses.

- Outstanding Chemical Inertness and Corrosion Resistance:

- Resistance to Acids and Alkalis: SiC is highly resistant to a wide range of corrosive chemicals, including strong acids and alkalis, even at elevated temperatures. This makes chemically inert ceramics like SiC invaluable for components in chemical processing equipment, pumps, and valves handling aggressive media.

- Oxidation Resistance: While SiC can oxidize at very high temperatures (typically above 1200circC), it forms a protective layer of silicon dioxide (SiO_2) on its surface. This passive layer significantly slows down further oxidation, allowing SiC components to operate for extended periods in oxidizing atmospheres.

- Favorable Electrical Properties (Tunable):

- While often used as an electrical insulator, SiC is inherently a semiconductor. Its electrical conductivity can be tailored through doping and processing, making it suitable for specific electrical applications such as heating elements, igniters, and components in power electronics where high power density and high-temperature operation are required.

- Benefits of Customization:

- Tailored Geometries: The ability to produce custom SiC blocks in complex shapes and precise dimensions allows for optimized designs that are not possible with off-the-shelf components. This is crucial for OEMs and technical buyers needing parts that integrate perfectly into their systems.

- Application-Specific Grades: Different manufacturing processes (e.g., reaction-bonded, sintered) yield SiC with varying microstructures and property profiles. Customization allows for the selection of the most appropriate grade for a specific application, balancing performance requirements with cost considerations.

- Integration with Other Materials: SiC blocks can be designed for assembly with other components, and their surfaces can be prepared for various joining techniques.

Sicarb Tech leverages its deep understanding of SiC material science and advanced manufacturing processes to deliver custom silicon carbide blocks that fully exploit these advantages. Our expertise ensures that clients receive components optimized for their unique operational challenges, leading to improved system performance and reduced total cost of ownership. For procurement professionals seeking wholesale SiC blocks or customized technical ceramics, the benefits of tailored SiC solutions are compelling.

Understanding Silicon Carbide Grades for Block Manufacturing

Silicon carbide is not a monolithic material; rather, it encompasses a family of materials produced through different manufacturing routes, each resulting in distinct microstructures and, consequently, varying properties. When specifying silicon carbide blocks, it is crucial for engineers and technical buyers to understand these grades to select the most appropriate type for their application. The choice significantly impacts performance, manufacturability, and cost.

The primary grades of silicon carbide relevant to block manufacturing include:

- Reaction-Bonded Silicon Carbide (RBSiC or SiSiC – Silicon Infiltrated Silicon Carbide):

- Manufacturing Process: RBSiC is produced by infiltrating a porous preform, typically made of SiC grains and carbon, with molten silicon. The silicon reacts with the carbon to form additional SiC in-situ, which bonds the initial SiC grains. The resulting material usually contains a small percentage (typically 8-20%) of free, unreacted silicon within the SiC matrix.

- Key Properties of RBSiC Blocks:

- Excellent thermal conductivity (due to the presence of free silicon).

- High strength and good wear resistance.

- Good thermal shock resistance.

- Relatively low manufacturing cost compared to SSiC.

- Near-net-shape manufacturing capability, minimizing the need for extensive machining.

- Maximum operating temperature is typically limited by the melting point of silicon (around 1410circC). It’s generally recommended for use up to 1350−1380circC.

- Common Applications: Kiln furniture (beams, rollers, setters), burner nozzles, wear liners, mechanical seals, pump components. RBSiC blocks are often preferred for their cost-effectiveness in applications where the presence of some free silicon is acceptable.

- Sintered Silicon Carbide (SSiC):

- Manufacturing Process: SSiC is produced from fine, high-purity SiC powder, often with non-oxide sintering aids (like boron and carbon). The powder is compacted into the desired shape and then sintered at very high temperatures (typically 2000−2200circC) in an inert atmosphere. This process results in a dense, single-phase SiC material with minimal or no free silicon.

- Key Properties of SSiC Blocks:

- Superior high-temperature strength and creep resistance (can often be used up to 1600−1650circC).

- Excellent corrosion resistance, even against highly aggressive chemicals.

- Very high hardness and outstanding wear resistance.

- Good thermal conductivity, though generally slightly lower than high-silicon RBSiC.

- Higher manufacturing cost compared to RBSiC due to higher purity raw materials and more complex processing.

- Common Applications: Chemical pump components (bearings, seals, shafts), valve parts, high-performance bearings, semiconductor processing equipment (chucks, rings), armor. SSiC properties make it the material of choice for the most demanding applications involving extreme temperatures, corrosive media, and severe wear.

- Nitride-Bonded Silicon Carbide (NBSiC):

- Manufacturing Process: NBSiC is produced by mixing SiC grains with silicon metal powder and other additives. The mixture is formed into shape and then fired in a nitrogen-rich atmosphere. During firing, the silicon reacts with nitrogen to form silicon nitride (Si_3N_4), which acts as the bonding phase for the SiC grains.

- Key Properties of NBSiC Blocks:

- Good thermal shock resistance.

- Good resistance to molten non-ferrous metals (e.g., aluminum, zinc).

- Moderate strength and wear resistance.

- Generally lower cost than RBSiC and SSiC.

- Common Applications: Furnace linings, components for handling molten aluminum (e.g., thermocouple protection tubes, riser stalks), kiln furniture for less demanding applications.

The following table provides a comparative overview of these common SiC grades:

| Property | Reaction-Bonded SiC (RBSiC/SiSiC) | Sintered SiC (SSiC) | Nitride-Bonded SiC (NBSiC) |

|---|---|---|---|

| Main Constituents | SiC, Free Silicon (8-20%) | SiC (typically >98%) | SiC, Silicon Nitride (Si_3N_4) |

| Typical Density (g/cm3) | 3.02−3.15 | 3.10−3.20 | 2.5−2.7 |

| Max. Use Temperature (circC) | 1350−1380 | 1600−1650 (and higher for specific grades) | 1300−1400 |

| Flexural Strength (MPa) | 250−550 (RT) | 400−600 (RT) | 100−200 (RT) |

| Thermal Conductivity (W/mK) | 80−150 | 80−200 (depending on purity/density) | 15−25 |

| Hardness (Knoop, kg/mm2) | 2200−2900 | 2500−2900 | 1200−1500 |

| Corrosion Resistance | Good | Excellent | Moderate to Good |

| Relative Cost | Medium | High | Low to Medium |

Selecting the right technical ceramic grade requires a thorough understanding of the application’s operating conditions, performance requirements, and economic considerations. Sicarb Tech, with its extensive experience in custom SiC design and manufacturing, assists clients in choosing the optimal SiC grade. Our facility in Weifang City, the hub of China’s silicon carbide customizable parts manufacturing, is supported by the robust scientific capabilities of the Chinese Academy of Sciences . This unique backing allows us to offer not just standard grades but also tailored material compositions to meet highly specific needs for OEM SiC components and other specialized block applications.

Critical Design and Manufacturing Considerations for Custom SiC Blocks

The successful implementation of custom silicon carbide blocks relies heavily on meticulous design and a comprehensive understanding of the manufacturing process. While SiC offers exceptional properties, its inherent hardness and brittleness present unique challenges that must be addressed during the design phase to ensure manufacturability, performance, and cost-effectiveness. Collaborating with an experienced custom SiC manufacturer like SicSino from the outset is crucial.

Designing for Manufacturability (DfM):

- Geometric Complexity: While advanced forming techniques allow for relatively complex shapes, overly intricate designs can significantly increase manufacturing difficulty and cost.

- Recommendation: Simplify geometries where possible. Avoid sharp internal corners and opt for generous radii to reduce stress concentrations and facilitate demolding or machining. Discuss complex features with the manufacturer early in the design process.

- Wall Thickness and Aspect Ratios:

- Minimum Wall Thickness: Extremely thin walls can be difficult to manufacture reliably and may be prone to damage during handling or operation. The minimum achievable thickness depends on the overall size of the block and the manufacturing method (e.g., pressing, slip casting, extrusion).

- Uniformity: Strive for uniform wall thicknesses to prevent distortion or cracking during drying and sintering. Abrupt changes in thickness can lead to differential shrinkage and internal stresses.

- Aspect Ratios: Very high aspect ratios (length-to-width or length-to-thickness) can also pose challenges in maintaining dimensional stability and straightness during firing.

- Internal Features: Creating complex internal cavities, channels, or undercuts in SiC blocks requires specialized techniques.

- Considerations: Assess the necessity of such features. Alternative designs or assembly of simpler SiC parts might be more cost-effective. If internal features are essential, discuss the manufacturing feasibility (e.g., using fugitive phases, green machining, or additive manufacturing approaches) with your supplier.

- Tolerances: While SiC can be machined to tight tolerances, this typically involves diamond grinding, which is a slow and expensive process.

- Recommendation: Specify only the critical tolerances necessary for functionality. Over-tolerancing non-critical features significantly increases cost. “As-sintered” tolerances are generally wider but more economical.

Material-Specific Design Considerations:

- Brittleness and Stress Concentration: SiC is a brittle material, meaning it has low fracture toughness compared to metals. Designs must carefully manage stress concentrations.

- Mitigation:

- Use fillets and radii instead of sharp corners.

- Avoid notches, small holes, or abrupt section changes in highly stressed areas.

- Consider the direction of applied loads and potential impact forces.

- Incorporate features for controlled fracture if unavoidable (e.g., score lines for designed breakage points in certain applications).

- Mitigation:

- Joining and Assembly: If the SiC block is part of a larger assembly or needs to be joined to other materials (ceramic or metallic):

- Design for Attachment: Incorporate features like flanges, tapped holes (often with metallic inserts), or specific surface finishes to facilitate brazing, mechanical clamping, or adhesive bonding.

- Thermal Expansion Mismatch: When joining SiC to materials with different coefficients of thermal expansion (CTE), carefully consider the stresses that will arise during thermal cycling. Flexible interlayers or specific joint designs might be necessary.

Manufacturing Process Impact:

The chosen manufacturing route (e.g., uniaxial pressing, isostatic pressing, slip casting, extrusion for green body formation, followed by reaction bonding or sintering) will influence design possibilities.

- Pressing: Generally suitable for simpler shapes and high-volume production. Tooling design is critical.

- Slip Casting/Extrusion: Allows for more complex shapes and hollow sections.

- Green Machining: Machining the SiC component in its “green” (unfired) state can be a cost-effective way to achieve certain features before the material becomes extremely hard after sintering. Design should allow for access for green machining tools.

- Sintering Shrinkage: Significant shrinkage (typically 15-20% linearly for SSiC) occurs during sintering. This must be accurately accounted for in the initial (“green”) design of the mold and part. Non-uniform shrinkage can lead to warping or cracking.

Key Engineering Tips for Designing SiC Blocks:

- Engage Early with Your Supplier: Discuss your design concepts with SicSino’s technical team at the earliest stage. Our experts, backed by the Chinese Academy of Sciences technology transfer platform, can provide invaluable input on DfM, material selection, and potential cost-saving modifications.

- Provide Comprehensive Application Details: The more information you provide about the operating environment (temperature, chemical exposure, mechanical loads, thermal cycling), the better your supplier can assist in optimizing the design and material grade.

- Iterative Prototyping: For complex or critical components, consider an iterative prototyping approach to validate the design and manufacturing process before committing to large-scale production of precision SiC components.

By addressing these critical design and manufacturing considerations, companies can harness the full potential of custom SiC blocks, leading to robust, reliable, and cost-effective solutions for their most challenging industrial applications. SicSino’s commitment to an integrated process from materials to finished products ensures that these considerations are expertly managed.

Achievable Tolerances, Surface Finishes, and Quality Assurance for SiC Blocks

Once a silicon carbide block is designed and the appropriate SiC grade is selected, achieving the required dimensional accuracy and surface finish becomes paramount, especially for precision SiC components used in high-tech industries. Furthermore, robust quality assurance (QA) processes are essential to guarantee that every block meets the specified standards. Silicon carbide’s extreme hardness necessitates specialized machining techniques and meticulous quality control.

Dimensional Tolerances:

The achievable tolerances for SiC blocks depend on several factors, including the manufacturing method (as-sintered vs. machined), the size and complexity of the block, and the specific SiC grade.

- As-Sintered Tolerances:

- Components produced without post-sintering machining typically have wider tolerances. This is due to the inherent variability in shrinkage during the sintering process.

- For Reaction-Bonded Silicon Carbide (RBSiC/SiSiC), which experiences less shrinkage than SSiC, as-sintered tolerances are generally tighter. Typical linear tolerances might be around pm0.5 to pm1.5 of the dimension.

- For Sintered Silicon Carbide (SSiC), which undergoes significant shrinkage (15-20%), as-sintered tolerances are usually wider, potentially in the range of pm1 to pm2, or even more for very large or complex parts.

- Opting for as-sintered tolerances where feasible is more cost-effective as it avoids expensive grinding operations.

- Machined Tolerances (Post-Sintering):

- To achieve tighter tolerances, SiC blocks must be machined after sintering, primarily using diamond grinding techniques.

- Precision Grinding: Can achieve tolerances as tight as pm0.005,mm to pm0.025,mm ($ \pm 5 , \mu m$ to pm25,mum) for critical dimensions on smaller, simpler geometries.

- Standard Grinding: More commonly, tolerances of pm0.05,mm to pm0.1,mm are achievable for general features.

- Achieving very tight tolerances across large surface areas or complex geometries significantly increases machining time and cost. It is crucial to specify tight tolerances only where functionally necessary.

Surface Finishes:

The surface finish of a SiC block can be critical for applications involving sealing, wear, optics, or fluid dynamics.

- As-Sintered Surface: The surface finish of an as-sintered block depends on the mold surface and the SiC grade. It is generally rougher than a machined surface. Typical R_a (average roughness) values might range from 1,mum to 5,mum or more.

- Ground Surfaces: Standard grinding can achieve surface finishes with R_a values typically between 0.4,mum and 0.8,mum.

- Lapping and Polishing: For applications requiring exceptionally smooth surfaces (e.g., mechanical seals, optical mirrors, semiconductor wafer chucks), lapping and polishing processes are employed.

- Lapped Surfaces: Can achieve R_a values down to 0.1,mum to 0.4,mum.

- Polished Surfaces: Can achieve mirror-like finishes with R_a values below 0.05,mum (even down to nanometer-scale roughness for specialized optics). Polished SiC surfaces are essential for high-performance seals and low-friction applications.

Sicarb Tech offers comprehensive SiC grinding services and polishing capabilities to meet diverse customer requirements for high precision ceramic blocks.

Quality Assurance (QA) and Inspection:

A rigorous QA system is vital to ensure the consistency and reliability of custom SiC blocks. This involves inspections at various stages, from raw material qualification to final product verification.

- Raw Material Inspection: Verifying the purity, particle size, and morphology of SiC powders and any additives.

- In-Process Inspection:

- Monitoring green body formation (dimensions, density, integrity).

- Controlling sintering parameters (temperature profiles, atmosphere).

- Dimensional checks after sintering but before final machining.

- Final Inspection: This typically includes:

- Dimensional Verification: Using precision measurement tools such as Coordinate Measuring Machines (CMMs), micrometers, calipers, and profilometers.

- Surface Finish Measurement: Using surface profilometers or optical non-contact methods.

- Visual Inspection: Checking for cracks, chips, porosity, or other surface defects.

- Non-Destructive Testing (NDT):

- Dye Penetrant Inspection (DPI): To detect surface-breaking cracks.

- Ultrasonic Testing (UT): To detect internal flaws like voids or large cracks.

- X-ray Radiography: For detecting internal defects in critical components.

- Material Property Verification (on a sample basis or if required by customer): Density, hardness, and sometimes flexural strength or thermal conductivity tests.

The following table summarizes typical achievable tolerances and surface finishes:

| Feature | As-Sintered (Typical) | Standard Grinding (Typical) | Precision Grinding / Lapping / Polishing |

|---|---|---|---|

| Linear Tolerance | pm0.5 to pm2.0 | pm0.05,mm to pm0.1,mm | pm0.005,mm to pm0.025,mm |

| Surface Roughness (R_a) | 1.0,mum – 5.0,mum (or higher) | 0.4,mum – 0.8,mum | $\< 0.05 , \\mu m$ – 0.4,mum |

At SicSino, our commitment to SiC quality control is unwavering. Leveraging the advanced measurement and evaluation technologies derived from our association with the Chinese Academy of Sciences, we ensure that every custom SiC block we deliver adheres to the strictest quality standards and customer specifications. This rigorous approach provides our B2B clients, including OEMs and technical procurement professionals, with the confidence that they are receiving components of the highest reliability for their critical applications.

Partnering with the Right Supplier for Your Custom SiC Block Needs: Why SicSino Stands Out

Selecting the ideal supplier for custom silicon carbide blocks is a critical decision that extends beyond just comparing quotes. It involves evaluating technical capabilities, material expertise, customization flexibility, quality assurance systems, and overall reliability. For businesses seeking wholesale SiC blocks, OEM SiC components, or highly specialized technical ceramics, the right partner can mean the difference between project success and costly setbacks.Sicarb Tech distinguishes itself as a premier custom SiC manufacturer and a trusted partner in the advanced ceramics industry.

Key Factors to Evaluate in a SiC Supplier:

- Technical Expertise and Material Knowledge:

- Does the supplier have a deep understanding of different SiC grades (RBSiC, SSiC, etc.) and their suitability for various applications?

- Can they provide expert advice on material selection and design optimization?

- Do they have R&D capabilities for developing custom material compositions if needed?

- Customization Capabilities:

- How flexible is the supplier in accommodating unique designs, complex geometries, and specific dimensional tolerances?

- What range of manufacturing processes do they offer (pressing, slip casting, extrusion, green machining, precision grinding, lapping, polishing)?

- Can they handle both prototype development and large-volume production?

- Quality Management Systems and Certifications:

- What quality control procedures are in place (raw material inspection, in-process checks, final inspection, NDT)?

- Are they ISO certified or do they adhere to other relevant industry quality standards?

- Can they provide material certifications and inspection reports?

- Manufacturing Facilities and Location:

- Does the supplier have modern, well-equipped manufacturing facilities?

- What is their production capacity and ability to scale?

- Where are they located, and what are the logistical implications?

- Lead Time and Cost-Effectiveness:

- What are their typical lead times for custom orders?

- Is their pricing competitive, considering the quality and level of customization offered?

- Are they transparent about cost drivers?

- Customer Service and Communication:

- How responsive and communicative is their team?

- Do they provide dedicated technical support throughout the project lifecycle?

- Can they offer references or case studies of similar projects?

Why SicSino is Your Ideal Partner for Custom SiC Blocks:

Sicarb Tech is uniquely positioned to meet and exceed these expectations, offering a compelling value proposition to industrial buyers, engineers, and OEMs.

- Unparalleled Expertise from the Heart of China’s SiC Hub: SicSino is strategically located in Weifang City, the epicenter of China’s silicon carbide customizable parts manufacturing. This region hosts over 40 SiC production enterprises, accounting for more than 80% of the nation’s total output. Since 2015, SicSino has been instrumental in introducing and implementing advanced SiC production technology, fostering large-scale production and technological advancements within this industrial cluster. We haven’t just supplied materials; we’ve witnessed and actively contributed to the growth and development of China’s SiC industry.

- Backed by the Prestigious Chinese Academy of Sciences : SicSino operates under the umbrella of the Chinese Academy of Sciences (Weifang) Innovation Park and collaborates closely with the National Technology Transfer Center of the Chinese Academy of Sciences. This provides us with unparalleled access to the robust scientific and technological capabilities and talent pool of the Chinese Academy of Sciences. This backing ensures that our material science, process technologies, design methodologies, and measurement & evaluation techniques are at the forefront of the industry.

- Comprehensive Customization and Integrated Solutions: We possess a domestic top-tier professional team specializing in the customized production of silicon carbide products. Our expertise spans the entire integrated process, from raw materials to finished precision SiC components. This allows us to meet diverse customization needs with higher quality and cost-competitiveness. More than 10 local enterprises have directly benefited from our technologies.

- Reliable Quality and Supply Assurance: Our deep involvement in the local SiC ecosystem and our advanced technological base translate into more reliable quality and supply assurance for our clients within China and globally. We offer higher-quality, cost-competitive customized silicon carbide components.

- Technology Transfer and Turnkey Project Capabilities: Beyond supplying components, SicSino is committed to global collaboration. If you are considering establishing a specialized SiC products manufacturing plant in your own country, we offer comprehensive technology transfer for professional silicon carbide production. This includes a full range of “turnkey project” services: factory design, procurement of specialized equipment, installation and commissioning, and trial production. This unique offering enables clients to own a professional SiC manufacturing plant with ensured effective investment, reliable technology transformation, and a guaranteed input-output ratio.

Choosing SicSino means partnering with a technical ceramics expert that combines deep industry roots, cutting-edge scientific backing, and a commitment to customer success. We are more than just a silicon carbide supplier China; we are a strategic partner dedicated to providing innovative and reliable SiC solutions for the most demanding industrial environments.

Frequently Asked Questions (FAQ) about Silicon Carbide Blocks

Engineers, procurement managers, and technical buyers often have specific questions when considering custom silicon carbide blocks for their applications. Here are answers to some common queries:

1. What is the typical lead time for custom silicon carbide blocks?

The lead time for custom SiC blocks can vary significantly based on several factors: * Complexity of the Design: Simpler blocks with standard geometries will generally have shorter lead times than highly complex parts with intricate features or very tight tolerances. * SiC Grade: Some SiC grades, like Sintered Silicon Carbide (SSiC), involve longer processing times (e.g., higher sintering temperatures, longer cycles) compared to Reaction-Bonded Silicon Carbide (RBSiC). * Tooling Requirements: If custom tooling (molds, dies) is required, the time to design and fabricate this tooling will add to the overall lead time. This is usually a one-time factor for a new part. * Quantity Ordered: Small prototype orders might be processed faster than large production runs, although economies of scale in manufacturing can sometimes influence this. * Post-Processing Needs: Extensive machining (grinding, lapping, polishing) to achieve tight tolerances or specific surface finishes will extend the lead time. * Current Supplier Capacity: The supplier’s current workload and production schedule will also play a role.

Generally, for custom orders, lead times can range from **4 to 12 weeks** after design approval and order confirmation. Simple, existing designs might be quicker, while highly complex or large-volume orders requiring new tooling could take longer. It's always best to discuss specific lead time requirements with your supplier, like SicSino, early in the project planning phase. We strive to provide accurate lead time estimates based on your unique project parameters.

2. What information is typically required to get an accurate quote for custom SiC blocks?

To provide an accurate and timely quotation for custom SiC blocks, suppliers need comprehensive information about your requirements. Key details include:

- Detailed Engineering Drawings or CAD Models: These should clearly specify all dimensions, geometric features, and required tolerances for each feature. 2D drawings (e.g., PDF) and 3D models (e.g., STEP, IGES) are ideal.

- Material Grade Specification: Indicate the desired type of silicon carbide (e.g., RBSiC/SiSiC, SSiC, or specific property requirements if the exact grade is unknown). If unsure, describe the application environment.

- Surface Finish Requirements: Specify the desired surface roughness (R_a or other parameters) for all relevant surfaces. Indicate if any surfaces require lapping or polishing.

- Quantity: State the required number of blocks for the initial order and, if applicable, estimated annual usage or future order quantities, as this can impact pricing.

- Application Details: A brief description of how and where the SiC block will be used (e.g., operating temperature, chemical environment, mechanical loads, thermal cycling) helps the supplier confirm material suitability and understand critical performance aspects.

- Testing and Certification Requirements: Specify if any particular tests (e.g., NDT, material property tests) or certifications (e.g., certificate of conformity, material data sheets) are needed.

- Target Price (Optional but helpful): If you have a target price or budget, sharing this can help the supplier propose the most cost-effective solutions that still meet your technical needs.

- Delivery Requirements: Desired delivery date or project timeline.

Providing as much detailed information as possible allows suppliers like SicSino to offer a precise quotation and reduces the need for back-and-forth clarifications, streamlining the procurement process for industrial SiC components.

3. Can silicon carbide blocks be effectively joined or bonded to other materials, including metals or other ceramics?

Yes, silicon carbide blocks can be joined or bonded to other materials, but the methods and success depend on the specific materials involved and the application requirements (e.g., operating temperature, mechanical stress, hermeticity). SiC’s low coefficient of thermal expansion (CTE) compared to many metals can pose challenges due to stress buildup during thermal cycling.

Common joining techniques include:

- Brazing: This is a common method for joining SiC to metals or other ceramics. Active metal brazing is often used, where the braze alloy contains an active element (like titanium) that reacts with the SiC surface to promote wetting and bonding. The choice of braze alloy depends on the operating temperature and environment.

- Adhesive Bonding: For lower temperature applications (typically below 200−300circC), high-performance epoxy or other structural adhesives can be used. Surface preparation is critical for good adhesion.

- Mechanical Fastening: SiC blocks can be designed with features like holes or threads (often using metallic inserts due to SiC’s brittleness) to allow for mechanical clamping or bolting to other components. This method can accommodate some CTE mismatch.

- Diffusion Bonding: This solid-state joining process involves pressing materials together at elevated temperatures below their melting points. It can create strong, hermetic seals but often requires precise surface finishes and controlled atmospheres.

- Glass or Glass-Ceramic Sealants: For certain applications, especially those requiring hermetic seals at high temperatures, specialized glass or glass-ceramic compositions can be used as an intermediary bonding layer.

When designing custom SiC blocks that need to be joined, it’s crucial to consider the joining method early in the design phase. Factors like joint geometry, surface preparation, and managing CTE mismatch are critical. SicSino’s technical team can provide guidance on designing SiC blocks for effective integration into larger assemblies and discuss suitable joining strategies based on your specific application.

Conclusion: The Enduring Value of Custom Silicon Carbide Blocks in Demanding Industries

The journey through the intricacies of custom silicon carbide blocks reveals a material of exceptional capability, uniquely suited to conquer the most demanding industrial environments. From the ultra-clean rooms of semiconductor fabrication to the searing heat of industrial furnaces and the abrasive conditions of heavy manufacturing, SiC blocks consistently deliver unparalleled performance in terms of thermal management, wear resistance, chemical inertness, and high-temperature strength. The ability to tailor these components—from selecting specific technical ceramic grades like RBSiC or SSiC to defining precise geometries and surface finishes—amplifies their value, enabling engineers to optimize their systems for peak efficiency and longevity.

The decision to incorporate custom SiC components is an investment in reliability and reduced operational costs. While the initial outlay for these advanced ceramics may be higher than for conventional materials, the extended service life, reduced downtime, and improved process yields offered by industrial wear parts and high-performance SiC blocks translate into a significantly lower total cost of ownership.

Choosing the right partner is paramount to unlocking the full potential of silicon carbide. Sicarb Tech, with its deep roots in Weifang City – the heart of China’s SiC manufacturing – and its powerful backing from the Chinese Academy of Sciences, stands as a beacon of expertise and reliability. Our comprehensive understanding of material science, coupled with advanced manufacturing and customization capabilities, ensures that our clients receive high-quality, cost-competitive customized silicon carbide blocks tailored to their exact specifications. Beyond component supply, SicSino’s commitment extends to fostering technological advancement through technology transfer and turnkey project support, empowering businesses globally.

For procurement professionals, engineers, and OEMs seeking not just a supplier but a strategic partner in the realm of advanced ceramics, SicSino offers an integrated solution from material innovation to precision-engineered components. We invite you to engage with our technical team to explore how custom silicon carbide blocks can elevate your applications and provide a decisive competitive edge in your industry. The future of high-performance materials is here, and it is forged in silicon carbide.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.