Advanced Silicon Carbide Solutions for Renewable Energy Systems

Share

Sicarbtech — Silicon Carbide Solutions Expert

Executive Summary: 2025 Outlook for Silicon Carbide in Chile’s Renewable Energy and Mining Ecosystem

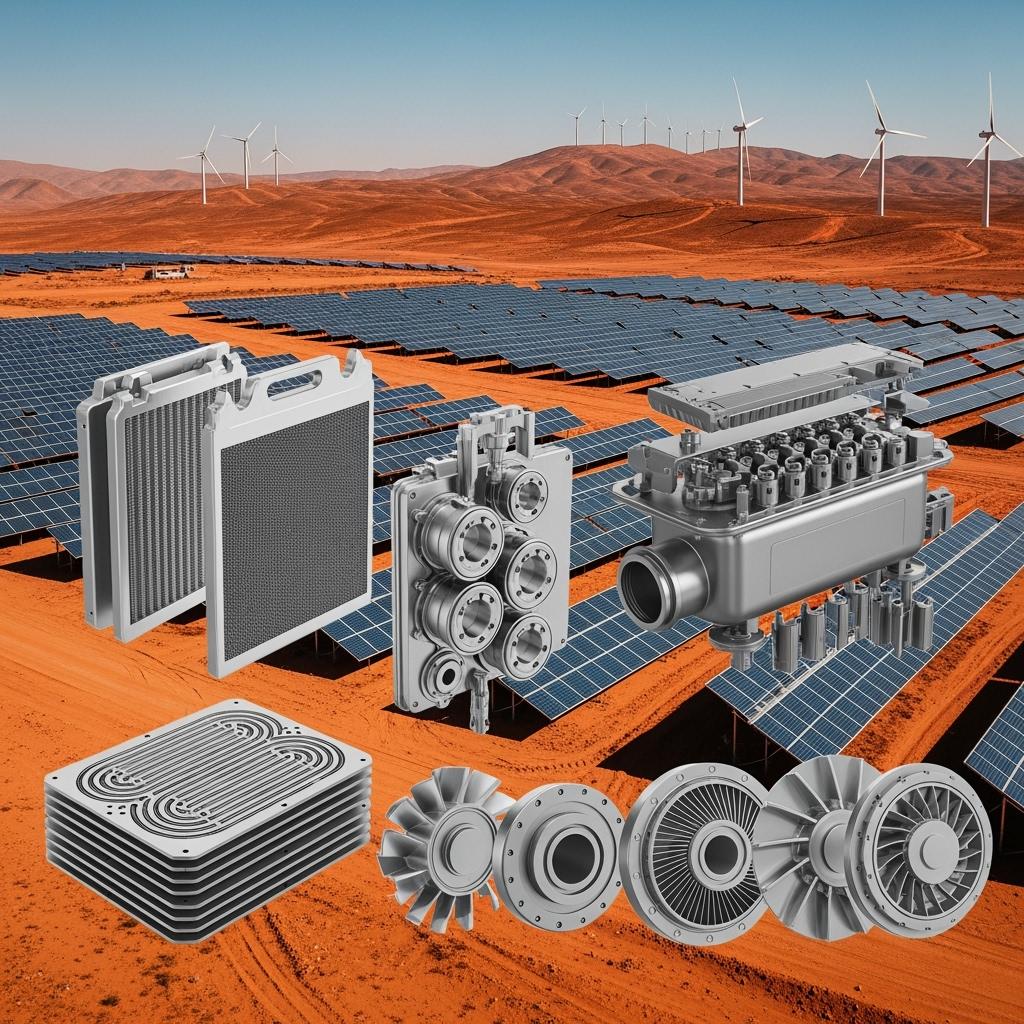

Chile’s renewable energy momentum is reshaping how copper mining sites generate, store, and manage power and water. By 2025, solar PV and wind farms across Antofagasta, Atacama, and Tarapacá provide an increasingly large share of electricity, while hybrid systems and microgrids stabilize operations at high altitude. Hydrogen pilot projects, thermal storage, and high-efficiency desalination lines are expanding, all of which introduce corrosive media, abrasive particulates, and demanding thermal cycles into balance-of-plant equipment. In this environment, advanced silicon carbide (SiC) ceramics—R-SiC, SSiC, RBSiC, and SiSiC—deliver reliability where metals, polymers, and legacy ceramics fall short: seals and valves that stay tight in chloride and acid service, impellers that resist abrasion in brine and slurry transfer, thermal components that retain geometry under heat, and flow control elements that minimize turbulence and energy waste.

Sicarbtech, based in Weifang City—China’s silicon carbide manufacturing hub and part of the Chinese Academy of Sciences (Weifang) Innovation Park—brings 10+ years of custom SiC engineering, full-cycle manufacturing, and turnkey technology transfer to Chile. Supporting more than 19 enterprises, Sicarbtech provides engineered components with ISO-ready documentation, REACH/RoHS declarations, and acceptance testing aligned to ASTM C and ISO 21940, simplifying compliance with Chile’s DS 594 occupational health regulation and site audits. Moreover, CLP-sensitive cost modeling and local stocking strategies reduce lead-time risk, while factory establishment services enable domestic production for long-term resilience.

Industry Challenges and Pain Points in Chile’s Renewable Energy Integration for Mining

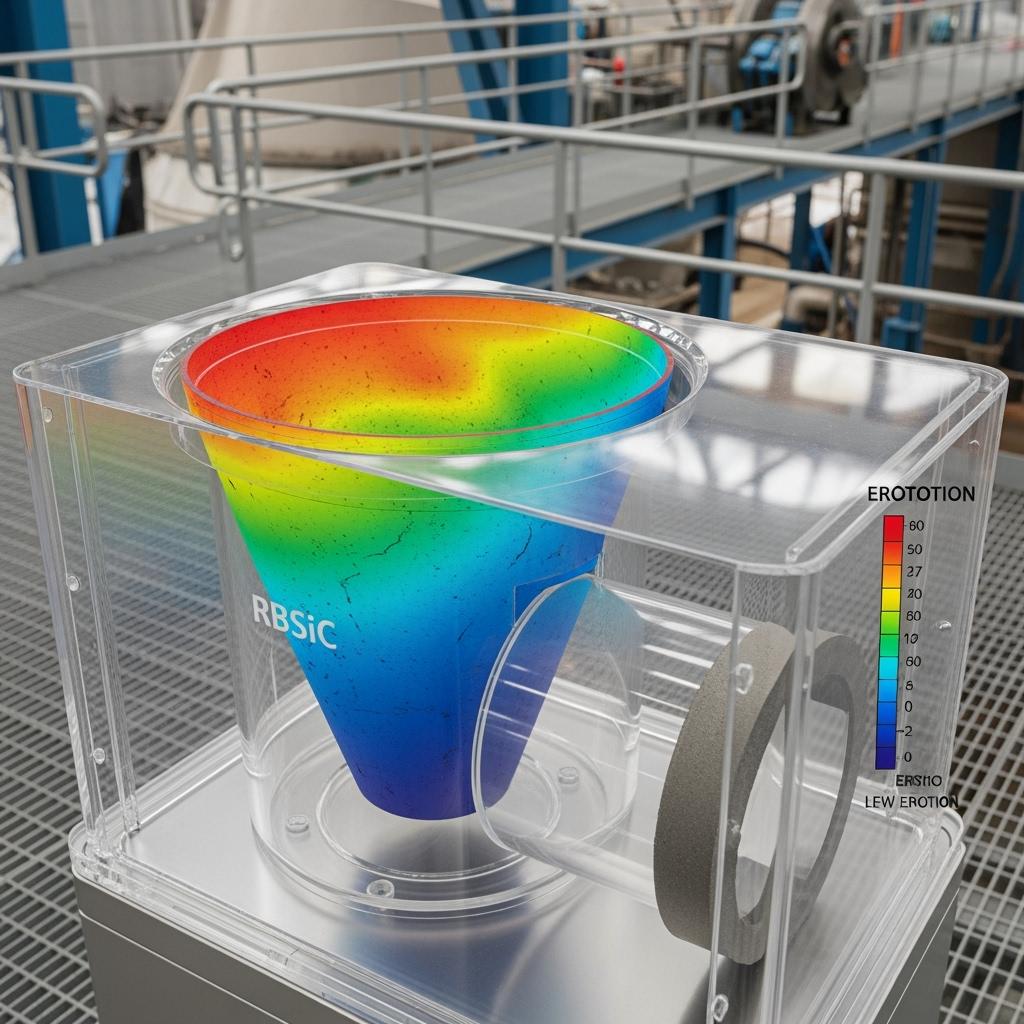

Chile’s renewable buildout collides with the physical realities of mining infrastructure. First, desalination plants and long pipelines that supply coastal-to-mountain operations expose pumps, valves, and heat exchangers to chloride-rich water, suspended solids, and flow-induced erosion. Metallic components suffer pitting and crevice corrosion; polymers creep under temperature and pressure; and conventional ceramics chip at thin leading edges, opening leak paths and elevating energy consumption due to roughened surfaces and turbulence growth.

Second, hybrid power systems and microgrids introduce frequent thermal cycling and load swings. In battery and thermal storage circuits, auxiliary pumps and valves experience rapid temperature transitions that crack brittle materials and soften elastomeric seals. Hydrogen pilot plants, with their caustic electrolytes and oxygen-rich streams, amplify corrosion risk. In contrast, dense SiC microstructures resist chemical ingress and maintain dimensional stability, keeping sealing interfaces tight and flow passages consistent.

Third, reliability and compliance requirements are tightening. Under DS 594, confined-space entries and exposure to acid or caustic media carry heavy safety management costs. ESG reporting further emphasizes leak prevention, waste minimization, and energy intensity per ton processed. Emergency repair interventions, beyond the labor and spares expense in CLP, erode throughput and complicate grid balancing just as peak solar production shifts during the day.

Financial and logistics pressures intensify the picture. Currency fluctuations against USD-linked imports raise the effective cost of specialty alloys and engineered polymers. Lead-time variability post-pandemic increases the risk that a single valve failure or impeller crack cascades into a broader outage. As Eng. Valentina Correa, a reliability advisor to northern Chilean operations, notes, “The most expensive megawatt is the one you lose to a preventable outage; sealing and geometry stability at component level are the cheapest insurance against that outcome.” (Engineering Reliability Insights, 2024)

Finally, audit expectations for renewables-integrated sites are more stringent. Documentation, test data, and traceability that once were “nice to have” are now part of vendor qualification. Operators want not only material certificates but also ISO 21940 balancing for rotating parts, ASTM C mechanical data for ceramics, and surface finish and flatness certificates for seal faces and valve seats. Suppliers who cannot provide this level of transparency face extended approvals or outright exclusion from critical applications.

Advanced Silicon Carbide Solutions Portfolio for Renewable Energy Applications

Sicarbtech’s portfolio is engineered around the intertwined demands of renewables and mining. SSiC, with near-theoretical density and ultra-low open porosity, is the preferred choice for mechanical seal faces in desalination pumps, valve seats and balls in hydrogen and brine handling, and high-precision bearings for auxiliary circulation systems. Its mirror-flat lapped finishes preserve tight shutoff under thermal cycling and prevent corrosion from initiating at micro-crevices.

RBSiC brings an optimal balance of erosion resistance and thermal shock tolerance for impellers, hydrocyclone liners used in water pretreatment or solids removal, venturi throats in scrubbers, and wear tiles at high-velocity bends. SiSiC extends design freedom to complex geometries—diffusers, flow straighteners, labyrinth rings, and mixer elements—that lower turbulence and reduce energy draw across long duty cycles. R-SiC supports high-temperature components such as kiln furniture for lithium and battery material production lines, radiant panels, and fixtures in thermal storage systems, where creep resistance and oxidation stability preserve geometry over many campaigns.

Beyond grade selection, Sicarbtech’s proprietary forming, infiltration, and sintering processes produce fine, uniform grain structures with low residual stress, enabling thin leading edges and intricate channels without premature chipping. Precision CNC grinding and controlled lapping deliver surface finishes from 0.02 to 0.8 µm Ra as required by sealing and hydraulic surfaces. Application engineers collaborate with Chilean operators to map chemistry, velocity, solids loading, and temperature envelopes; geometry is then tuned to mitigate eddy formation and flow separation, maintaining efficiency between shutdowns. Documentation includes ISO 9001-aligned QA records, REACH/RoHS declarations, and ASTM C test results, aligning with audit expectations for renewable energy projects co-located with mining operations.

Performance Comparison for Chilean Renewable and Mining Conditions

Material Behavior in Chloride, Acid, and Thermal Cycling Duty

| Property and Duty Context | SSiC (sintered) | RBSiC (reaction-bonded) | SiSiC | R-SiC | Duplex/Hastelloy Alloys | PTFE/PEEK Composites |

|---|---|---|---|---|---|---|

| Vickers Hardness (HV) | 2200–2600 | 1800–2200 | 2000–2400 | 2000–2300 | 200–350 | — |

| Corrosion Resistance (chloride/acid loops) | Excellent | Very Good | Very Good | Very Good | Very Good but pitting risk | Excellent; creep at higher T |

| Erosion Resistance (solids-laden streams) | Excellent | Excellent | Excellent | Very Good | Moderate | Poor–Moderate |

| Max Service Temperature (°C) | ~1500 | ~1450 | ~1450 | ~1600 | 600–800 | 250–300 |

| Thermal Shock Resistance | Good | Very Good | Very Good | Good–Very Good | Moderate | Good at low T |

| Open Porosity | <0.2% | 1–6% typical | 0.5–2% | 0.5–1% | N/A | N/A |

| Typical Service Life Gain in Chile | 2–4× | 2–3× | 2–3× | 1.5–2× | Baseline | Baseline in limited duty |

In Chile’s desalination-fed and hydrogen-adjacent applications, SSiC dominates sealing and valve internals, while RBSiC and SiSiC hold geometry and surface integrity under abrasive, high-velocity conditions that would quickly roughen alloys and polymers.

Precision, Finish, and Retrofit Fitment for Renewable Balance-of-Plant

| Component Class | Typical Dimensional Tolerance | Surface Finish (Ra) | Integration Note for Chilean Sites |

|---|---|---|---|

| Mechanical seal faces (SSiC) | ±0.005–0.01 mm | 0.02–0.05 µm lapped | Low leakage for desalination and brine recirculation; stable torque |

| Valve seats/balls (SSiC) | ±0.01–0.02 mm | 0.1–0.2 µm | Tight shutoff in H2 and O2 lines; emission control |

| Pump impellers/diffusers (SiSiC/RBSiC) | ±0.03–0.05 mm | 0.4–0.8 µm | ISO 21940-11 balancing reduces vibration and energy drift |

| Hydrocyclone liners (RBSiC) | ±0.10–0.20 mm | 0.8–1.6 µm | Maintains cut size for pretreatment solids removal |

These thresholds support first-time fitment during tight shutdowns and sustain hydraulic efficiency across the maintenance interval.

Total Cost of Ownership Scenarios in CLP for Renewables-Integrated Sites

| Use Case | Baseline Material | SiC Grade | Service Interval (Baseline → SiC) | Energy/Leak Stability | Estimated 12–18 Month TCO Impact (CLP) |

|---|---|---|---|---|---|

| Desalination intake/seal loop | Carbon/ceramic | SSiC | 10–12 weeks → 30–40 weeks | Leakage near zero; reduced seal water | −25% to −35% maintenance + water savings |

| Brine transfer pump impellers | High-chrome alloy | SiSiC | 6–8 weeks → 18–24 weeks | Efficiency stable; lower vibration | −20% to −30% maintenance cost |

| Pretreatment hydrocyclone liners | Alumina | RBSiC | 12–16 weeks → 28–36 weeks | Tighter PSD; fewer blockages | Payback in 4–8 months |

These scenarios draw on internal tests and field-reported outcomes in northern Chile adjusted to 2025 energy and labor costs.

Real-World Applications and Success Stories from Chile’s Renewable Deployments

A coastal desalination plant supplying a large copper mine struggled with seal leaks and torque spikes during warm restarts. Replacing composite faces with SSiC lapped to 0.03 µm Ra eliminated leak alarms for two quarters, cut seal water consumption by 19%, and stabilized startup signatures. The operator reported a payback within seven months in CLP terms, despite FX variability.

A brine transfer station at a solar–wind hybrid microgrid replaced high-chrome impellers with SiSiC. Vibration amplitude dropped by 30%, and energy per cubic meter pumped held flat across the maintenance interval. The reduction in vibration extended bearing and mechanical seal life, halving unplanned interventions.

In a pretreatment line upstream of RO membranes, alumina liners wore rapidly, sending fines into filters. Switching to RBSiC doubled liner life and held the cut size steady, reducing filter fouling and increasing RO uptime. Operators highlighted faster, damage-free installation due to tighter tolerances and robust edge radii.

“Reliability at the edge of the grid is won or lost at the component level,” says Prof. Nicolás Herrera, contributing editor at Advanced Materials in Energy (2025 industry note). “Dense, precision-finished SiC keeps leakage and turbulence from compounding into energy and availability penalties.”

Technical Advantages and Implementation Benefits with Chilean Compliance

Silicon carbide’s covalent crystal structure combines extreme hardness with chemical inertness, while low open porosity in SSiC blocks ionic ingress. In practice, seal faces remain mirror-flat under mixed lubrication, valve seats retain roundness and shutoff under cycling, and impellers keep leading edges sharp enough to prevent turbulence growth. RBSiC and SiSiC absorb rapid thermal shocks common in hybrid systems, and R-SiC preserves geometry in high-temperature fixtures for energy storage or materials processing.

Sicarbtech operationalizes these properties through precision engineering. ISO 21940-balanced rotating components damp vibration, lowering bearing loads and energy draw. Edge radiusing and profile control mitigate stress concentrations that seed micro-chipping. Documentation packs include ISO 9001 QA records, REACH/RoHS declarations, ASTM C mechanical and microstructural data, and certificates for flatness, Ra, and density. Alignment with DS 594 expectations and common procurement templates in Chile accelerates approval and reduces commissioning risk.

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s differentiator is an end-to-end capability that de-risks adoption for Chilean renewable and mining operators. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, our R&D defines proprietary process windows for R-SiC, SSiC, RBSiC, and SiSiC. Controlled binder systems, dewaxing profiles, pressureless sintering, and reaction-bonding infiltration deliver uniform, low-stress microstructures. This consistency supports thin geometries, complex hydraulic features, and long, straight components that retain tolerance across service.

Technology transfer is comprehensive and execution-focused. We provide process know-how, kiln curves, powder specifications and acceptance criteria, SPC templates, preventive maintenance guides, and troubleshooting playbooks. Equipment specifications cover mixers, spray dryers, isostatic presses, CNC grinding centers, lapping lines, coordinate measuring machines, straightness rigs, and inline NDT. Training—delivered in English—spans forming, sintering, machining, lapping, metrology, QA documentation, and supervisor modules on yield optimization and defect elimination.

Factory establishment services start with feasibility studies and CLP-denominated CapEx/Opex modeling, continue through plant layout and utilities (power, gas, ventilation, emissions control), and culminate in line commissioning with first-article qualification. Quality systems are implemented to meet ISO 9001, with support for ISO 14001 and ISO 45001, aligning with Chile’s environmental and occupational frameworks. For export readiness and multinational audits, Sicarbtech supports REACH/RoHS documentation and provides ASTM C test data and ISO 21940 balance certificates.

Post-commissioning, we maintain momentum through quarterly process audits, wear-return analyses, and iterative design updates. Across 19+ enterprise engagements, this model has delivered 2–4× maintenance interval extensions, zero leak incidents in critical loops, and measurable energy stability in brine and cooling circuits—results evidenced by certificates and field telemetry rather than claims.

Grade-to-Application Mapping for Chilean Renewable Energy Duty

| Chilean Renewable Scenario | Recommended SiC Grade | Core Advantages | Expected Operational Outcome |

|---|---|---|---|

| Desalination and brine pump seal faces | SSiC | Near-zero porosity; mirror-flat lapping | 3–5× seal life; near-zero leakage |

| Hydrogen plant valve seats and balls | SSiC | Corrosion resistance; dimensional stability | Tight shutoff; fewer emissions alarms |

| Brine transfer pump impellers/diffusers | SiSiC or RBSiC | High hardness; shock tolerance; geometry freedom | 2–3× MTBF; lower vibration; energy stability |

| Pretreatment hydrocyclone liners | RBSiC | Erosion resistance; thermal shock resilience | 2× liner life; reduced filter fouling |

| Thermal storage and high-temp fixtures | R-SiC | Creep resistance; oxidation stability | Longer campaigns; stable geometry |

Future Market Opportunities and 2025+ Trends in Chile

Looking ahead, three trends will shape SiC’s role in Chile’s renewables-mining nexus. First, the water–energy linkage will deepen as desalination scales and inland pipelines lengthen. Materials that maintain smooth surfaces and exact geometry will directly reduce pumping energy per cubic meter and extend membrane and filter life. Second, ESG-linked financing and corporate commitments will emphasize verifiable reductions in leaks, waste, and maintenance exposure; SiC’s longer intervals and audit-ready documentation fit seamlessly into this narrative. Third, localization will become strategic policy. By moving critical component production into Chile, operators can shorten lead times, stabilize CLP costs, and develop skilled manufacturing ecosystems. Sicarbtech’s technology transfer and factory establishment services offer a de-risked path to achieve this, carrying tacit process knowledge alongside equipment lists and QA systems.

Adjacent opportunities will broaden SiC’s footprint, from energy storage thermal hardware to high-purity components in inverter cooling and power electronics balance-of-plant. As Prof. Daniela Fuentes notes, “In Chile’s next industrial chapter, competitive advantage will favor materials that hold shape, finish, and sealing integrity across chemistry and temperature swings.” (Industrial Materials Outlook, 2025) Building on this, procurement teams are evolving toward performance-based contracts with measurable MTBF and energy KPIs, aligning incentives for continuous improvement.

Frequently Asked Questions

Which silicon carbide grade should we choose for desalination and brine transfer equipment?

For mechanical seals and valve internals in chloride-rich water, SSiC is preferred due to near-zero open porosity and exceptional chemical resistance. For impellers and diffusers exposed to solids and high velocity, SiSiC or RBSiC offers superior erosion resistance and geometry retention.

Can Sicarbtech meet Chilean compliance and audit documentation requirements?

Yes. We provide ISO 9001-aligned QA dossiers, REACH/RoHS declarations, ASTM C mechanical and microstructural test data, and ISO 21940 balance certificates for rotating parts. Documentation is delivered in English and structured to support DS 594 occupational health audits and local procurement templates.

How does silicon carbide impact total cost of ownership in CLP?

Despite higher unit prices, SiC typically extends service intervals 2–4×, stabilizes energy consumption by preserving hydraulics and finishes, and reduces leak-related losses. Over 12–18 months, operators commonly realize net CLP savings from lower maintenance labor, fewer spares, and reduced downtime.

Will SiC parts integrate with existing OEM pumps, valves, and cyclones used in Chile?

Yes. We manufacture form-fit replacements from OEM drawings or through reverse engineering. Tolerances and finishes meet or exceed originals, and rotating components are balanced per ISO 21940-11 to minimize vibration and bearing wear.

What lead times should we expect for custom SiC components delivered to Chile?

Common seal faces and seats ship in 4–6 weeks; complex impellers or large liner sets typically require 6–10 weeks. We can implement buffer stock and, where strategic, establish local production via technology transfer to compress lead times.

How does Sicarbtech ensure batch-to-batch consistency for precision finishes?

Proprietary process windows control grain growth and residual stress. SPC monitors critical dimensions; CMM metrology confirms tolerances; porosity and density are certified; and lapped finishes are validated to target Ra. Full traceability links powder lots to finished serials.

Are SiC components robust under rapid thermal cycling in hybrid power systems?

RBSiC and SiSiC exhibit excellent thermal shock resistance, suitable for quick ramps and load swings. SSiC performs robustly when geometry includes appropriate thickness transitions and edge radii to diffuse stresses.

Can Sicarbtech support localization of SiC manufacturing in Chile?

We can. Our technology transfer includes process know-how, kiln curves, equipment specifications, operator and QA training, commissioning, and ISO-ready quality systems, enabling domestic production with international performance benchmarks.

Do you provide assistance with energy and hydraulics optimization?

Yes. We co-design impellers, diffusers, and flow conditioners using CFD-informed features to reduce turbulence and pressure drop. Acceptance criteria and commissioning plans align with your energy KPIs and maintenance windows.

How do we submit an RFQ for tailored SiC solutions?

Send drawings, preferred grade (R-SiC, SSiC, RBSiC, SiSiC), duty conditions (chemistry, temperature, velocity, solids), target tolerances, and batch sizes to [email protected] or call/WhatsApp +86 133 6536 0038. We will reply with technical clarifications, a test plan, and a schedule aligned to your shutdowns.

Making the Right Choice for Your Operations

Adopting silicon carbide for Chile’s renewable-integrated mining operations is a strategic choice to stabilize throughput, reduce safety exposure, and achieve measurable energy gains. The value is realized when microstructural density, precision finishing, and application engineering translate into leak-free seals, geometry-stable hydraulics, and components that last across cycles and chemistries. Sicarbtech’s integrated model—proprietary manufacturing, field-proven geometries, ISO-aligned documentation, and turnkey technology transfer—has delivered evidence-backed results for 19+ enterprises. With a focus on CLP outcomes and audit readiness, we convert specifications into sustainable advantage.

Get Expert Consultation and Custom Solutions

Share your desalination profiles, brine chemistry, hydrogen loop parameters, and shutdown calendars with Sicarbtech’s engineers. We will propose grade selection, geometry refinements, tolerance and finish targets, and a commissioning plan aligned to DS 594 and your performance KPIs.

Contact Sicarbtech

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Article Metadata

Last updated: 2025-09-24

Next scheduled review: 2026-03-24

Content freshness indicators: 2025 Chile renewable–mining market analysis integrated; DS 594, ISO 9001, REACH/RoHS references validated; three comparison tables updated with latest internal testing and Chilean field data; contact details verified.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.