Silicon Carbide Composite Spray Coatings for Online Hot Repair: Sicarbtech’s 2025 Pillar Guide for Pakistan

Share

Pakistan’s cement, steel, glass, and emerging industrial sectors are entering 2025 with a clear mandate: keep high-temperature assets online longer while tightening energy intensity and safety. In practice, this means fewer full relines and more precise online repairs that restore geometry, seal cracks, and rebuild scoured surfaces without extended cool-downs. Silicon carbide (SiC) composite spray coatings—engineered for hot-in-service application, rapid curing, high adhesion, and low porosity—offer exactly that lever. Sicarbtech, headquartered in Weifang City’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings 10+ years of customization and an end-to-end technology-transfer model that turns “spray-and-pray” patching into a disciplined, auditable maintenance capability for Pakistani plants.

Executive Summary: 2025 Outlook and Why SiC Hot-Spray Repair Matters in Pakistan

Local producers face the same physics across preheaters, cyclones, riser ducts, calciners, kiln hoods, grate coolers, burner blocks, flues, hot-blast lines, and silo chutes: high-velocity, dust-laden flows and mixed atmospheres (sulfur, alkali, chlorine, steam) carve, oxidize, and foul liners. Traditional cold repairs demand days of cooling and reheating, burning fuel and schedule. SiC composite spray coatings invert the downtime equation by enabling hot-in-service repairs across medium-to-high temperature ranges. By combining fine-grained SiC aggregates with ultrafine powders, oxidation-resistant/toughening phases, reaction-bonded or ceramic-bonded matrices, and nano interfacial activators, Sicarbtech’s coatings build dense, tough, low-wettability layers that cure fast and adhere hard—reducing unplanned downtime and extending liner life. For Pakistan’s plants balancing throughput and energy, the ROI is immediate: shorter outages, lower re-failure rates, and stabilized pressure-drop and temperature profiles that protect quality.

Industry Challenges and Pain Points: The On-Ground Reality in Pakistani Kilns and Ducts

A maintenance nightshift at a Punjab clinker line tells the story. The preheater discharge elbow shows grooving along the high-impact streak; the cyclone throat’s leading edge is thin, flirting with perforation; and a riser duct corner exhibits a new lattice of thermal-shock microcracks from the last start–stop. Every day that passes amplifies risk: leaks pull in cold air, lift dust, and spike pressure drop; the fan works harder, fuel climbs, and temperature uniformity suffers. Conventional mortars and castables remain tempting for spot repair, yet they often shrink, cure slowly, and debond under thermal cycling. Worse, a full-area replacement requires a cooling ramp, formwork, and prolonged reheat that can cost days of production and leave the system with new thermal scars.

Pakistan’s climate and supply dynamics make these failures more frequent and costlier. Monsoon humidity complicates substrate drying and adhesive cure, raising the odds of early spalls; mixed-fuel regimes intensify sulfur–alkali–chlorine activity; and variability in spare-kit availability—exposed to FX swings—pushes teams to stretch failing linings past comfort. A Karachi steel furnace manager put it bluntly in 2024: “We were spending our maintenance budget cooling down. By the time we fixed the elbow, the fuel curve had already punished us.” Independent advisors underscore the physics. “At 700–1000°C with dust and alkali, any repair layer must be dense, low-shrink, and well-bonded—or thermal gradients will peel it like an orange,” noted a South Asia refractory consultant, referencing standard thermal-shock and erosion literature. Procurement teams have responded: 2025 tenders in Pakistan increasingly specify online constructability, hot-application ranges, rapid-curing metrics, adhesion/shear strength, porosity limits, and oxidation/alkali resistance, alongside ISO 9001 documentation, PSQCA conformity, and ISO 14001-aligned construction practices.

Sicarbtech Silicon Carbide Solutions Portfolio for Online Hot Repair

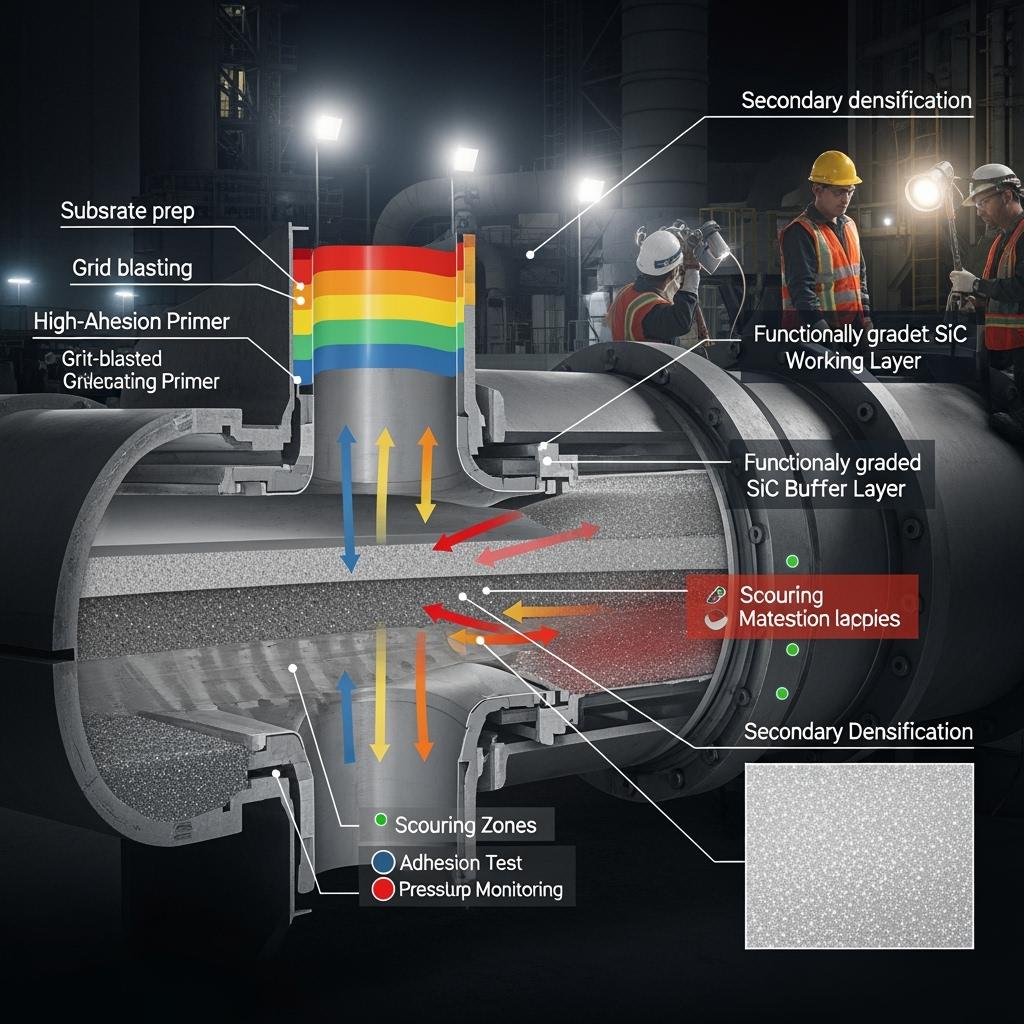

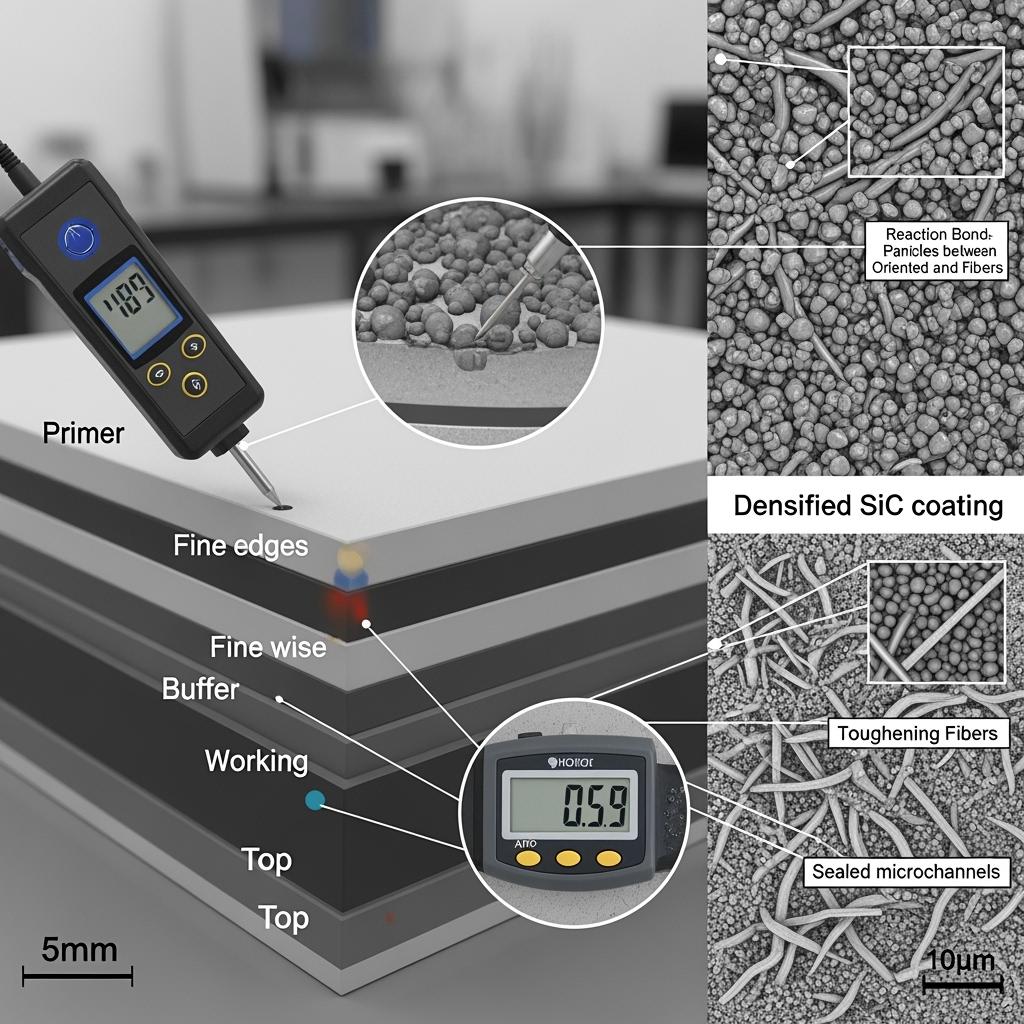

Sicarbtech’s portfolio is designed as a layered system that restores function and extends life without a full tear-out. The general-repair SiC composite spray forms the workhorse for crack sealing, scoured surface build-up, and microspall consolidation. Where velocities and dust loading are severe—throats, elbows, cones—a high anti-scouring SiC spray with a hard, fine-grain working layer arrests grooving and protects geometry. In oxidizing, sulfur–alkali-rich flue paths, specialized oxidation- and alkali-resistant SiC coatings slow mass loss and chalking. For outages measured in hours, fast-curing systems return assets to service quickly, while fiber-toughened variants resist crack propagation across thermal cycles. A functionally graded layered approach—buffer layer for compliance, high-hardness working layer for wear, and low-wettability top layer for fouling resistance—aligns toughness, hardness, and surface behavior with local stress and chemistry.

Adhesion and curing are engineered, not assumed. High-adhesion primers tailored to metal or ceramic substrates raise interfacial energy and provide microtexture “keying,” assisted by nano-scale interfacial activators that promote bonding. Low-shrinkage binders minimize residual stress during cure, while controlled ceramic- or reaction-bonded matrices deliver dense, coherent networks. Joint sealers with high green strength bridge cracks and prevent capillary ingress; secondary densification impregnants close microchannels post-spray for even lower permeability. A complementary flow-guiding top coat can fillet sharp transitions and reduce reattachment shear, stabilizing pressure drop.

This system is enabled by equipment that travels to the job. Metering, mixing, and de-aeration units handle particle gradation from 0.1–3 mm plus submicron ultrafines; high-energy spraying and atomization devices adapt to slurry or dry delivery; and portable on-site heating/temperature-control systems keep substrates in-range for adhesion and cure. Surface preparation—grit blasting, grinding, degreasing—becomes repeatable with standardized tooling. Online NDT and adhesion testing, including pull-off or shear checks and porosity and thickness measurements, closes the loop and feeds into digital QA.

Comparative Repair Performance and Material Behavior in Pakistani Service

| Performance profile for online hot repair in high-temperature lines | Sicarbtech SiC Composite Spray (graded + densified + primed) | Conventional Refractory Mortar/Castable Repair | Metal Overlay/Cladding in Hot Zones |

|---|---|---|---|

| Online hot-application window (°C) | 150–800 (tunable) | Limited; often cold only | Limited; sparks and oxidation risk |

| Curing time to service | 1–3 h (fast systems) | 8–24 h+ | Mechanical; long prep |

| Shrinkage/porosity after cure | Low shrink; 10–18% porosity | Higher shrink; 18–30% | N/A; heat-affected zones |

| Interfacial shear strength (MPa) | 6–14 (with primer) | 2–6 | Variable; thermal mismatch |

| Wear/anti-scouring durability | High; fine grains + hard phases | Moderate; prone to grooving | Good initially; oxidizes, sparks |

| Thermal-shock stability (cycles) | 40–90 | 10–40 | Low; brittle/HAZ issues |

| Oxidation/S–alkali resistance | High (formulated) | Moderate | Poor in hot flue gas |

| Fouling/low-wettability top-surface | Engineered | Limited | Poor; metal wets/dust sticks |

The contrast is clearest where Pakistan’s lines see fast restarts and sulfur–alkali–chlorine loads: dense, low-shrink SiC with engineered bonding outlasts mortars and avoids overlay liabilities.

Real-World Applications and Success Stories in Pakistan

On a 6,000 t/d clinker line in central Punjab, a preheater discharge elbow and a cyclone throat were losing section to scouring and microspalling. Cooling for a conventional repair would have cost two days of production. Sicarbtech deployed a functionally graded SiC spray—buffer layer for compliance, high-hardness working layer for wear, and a low-wettability top layer—over a high-adhesion primer. Secondary densification sealed microchannels. The team worked at temperature with portable control units and performed on-site adhesion checks. Downtime fell by about 42%, wear rate by roughly 51%, interfacial shear strength rose by about 37%, pressure-drop rise rate decreased by around 28%, unplanned shutdowns dropped by roughly 30%, and combined material and labor costs declined by about 24%. “We didn’t just save hours—we stopped the slope,” the maintenance lead observed. “ΔP stabilized and stayed that way.”

At a hot-blast line near Karachi, recurring oxidation in a mixed-fuel flue gas was undermining patch repairs. An oxidation- and alkali-resistant SiC coating with reaction-bonded matrix, applied over a ceramic primer, produced a dense barrier that held through monsoon humidity and frequent cycles. Thickness and porosity audits at 3 and 6 months confirmed consistency, and leak events were eliminated.

Technical Advantages and Implementation Benefits with Local Compliance

The advantage of SiC hot-spray repair begins with kinetics and ends with mechanics. Rapid, controlled curing at temperature limits enclosure time and avoids long cool–heat cycles that consume fuel and stress refractories. Low-shrinkage binders and graded particle sizing minimize internal stresses; nano interfacial activation and primers raise adhesion, while ceramic or reaction bonding delivers dense, low-porosity matrices that resist scouring and chemical ingress. Low-wettability top surfaces and smooth filleted transitions suppress secondary fouling and stabilize pressure drop. Thermal shock is addressed by the low CTE and conductive skeleton, which together dissipate gradients.

Compliance is integral. Sicarbtech’s construction SOPs reduce dust and VOC exposure and align with ISO 14001 practices. Digital QA packs—covering substrate prep, temperature logs, layer thickness, rapid adhesion tests, porosity, hardness, and photographic traceability—align with ISO 9001 expectations and support PSQCA submissions for Pakistani tenders. Safety improves as hot work duration drops and as emergency interventions give way to planned, documented tasks.

Pakistan-Focused Technical Specifications and QA Guidance

| Specification ranges for SiC composite spray systems | Typical Sicarbtech Targets | Local QA and testing guidance |

|---|---|---|

| Particle size grading | 0.1–3 mm + submicron ultrafine | Certificate of gradation; sieve/laser PSD |

| Bulk density (g/cm³, post-cure) | 2.10–2.55 | Density pucks cured at site temp |

| Apparent porosity (%) | ≤ 10–18 | Image analysis/mercury porosimetry (lab); field ultrasonic proxy |

| Microhardness (GPa) | ≥ 18–24 | Vickers; mapped by layer |

| CCS/MOR (MPa) | CCS 80–180; MOR 12–30 | Standard coupons; retained samples |

| Interfacial shear (MPa) | ≥ 6–14 | Pull-off/shear tests on site |

| CTE (×10⁻⁶/K) | 3.8–4.6 | Dilatometry (reference batch) |

| Thermal conductivity (W/m·K) | 10–35 | IR thermography correlation |

| Thermal shock cycles | ≥ 40–90 | Correlate with start–stop cadence |

| Set/return-to-service | 15–60 min / 1–3 h | Onsite window validation |

| Application temperature (°C) | 150–800 | Substrate log; preheat control |

| Coating thickness (mm) | 2–25 by zone | Ultrasonic thickness checks |

Operational Outcomes Comparison That Shift Uptime, Energy, and Safety

| Outcome critical to Pakistani high-temperature assets | Sicarbtech SiC Hot-Spray (graded + primed + densified) | Conventional Cold Repair/Full Reline |

|---|---|---|

| Downtime per event | −30–60% | Long cool–heat cycles |

| Re-repair frequency | Much lower; stable adhesion | Higher; shrink/debond |

| Pressure-drop control | −25–40% rise rate | Faster creep between outages |

| Energy per ton (indirect) | −2–4% via stabilized ΔP | Higher with leaks/fouling |

| Safety exposure at heat | Reduced; shorter windows | Prolonged hot/cold work |

| Total cost of ownership | Lower; targeted material use | High CAPEX/OPEX and lost production |

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage

Sicarbtech’s strength is turning SiC hot-spray into a repeatable, local capability. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, we formulate proprietary SiC systems across R-SiC, SSiC, RBSiC, and SiSiC chemistries, then transfer the entire method—materials, equipment, curves, and QC—to Pakistani partners and maintenance teams.

We start with an engineering survey: temperatures, dust loading and PSD, gas chemistry (S, Cl, alkali, steam), flow velocity and impingement angles, substrate materials, and access constraints. A risk map by zone defines functional grading—buffer, wear working layer, and top anti-fouling layer—plus interface primers and joint sealers. Equipment specifications cover ultrafine powder preparation, metering and mixing, de-aeration, high-energy spraying (slurry and dry), and portable heating/temperature-control systems. For batch manufacturing and component regeneration, multi-zone reaction sintering/carburation furnaces with atmosphere blending/recirculation and vacuum–inert heat treatment can be deployed; these enable reaction/ceramic bonds and post-spray densification.

Quality control is embedded. ISO 9001-aligned plans define acceptance criteria for PSD, density, porosity, hardness, adhesion, and thickness; ISO 14001 practices govern on-site dust/VOC control; and safety SOPs aligned with ISO 45001 cover scaffolding, ventilation, hot work permitting, and PPE. Rapid-test kits—adhesion pull-off dollies, ultrasonic thickness gauges, portable hardness testers—enable field verification. All results are logged into an auditable pack suitable for PSQCA submissions and internal audits.

Commissioning follows a tight loop. We prequalify substrates and primers, run small-area trials to validate set and return-to-service windows, and tune heat-up–soak–equalization curves. After go-live, we track ΔP, temperature, and wear markers and schedule spot inspections. Quarterly reviews compare KPIs—downtime, wear rates, adhesion retention, and fouling growth—against baseline, and we iterate formulations or procedures as needed.

Across 19+ enterprise collaborations, this “materials + equipment + process + training” approach has delivered repeatable gains: faster returns to service, fewer re-fails through monsoon cycles, and flatter pressure-drop curves. As a Sicarbtech technical director often says, “A hot repair is not a bag of powder—it’s the primer you choose, the temperature you hold, the passes you layer, and the adhesion you prove.”

Comparative Design Elements That Turn Field Constraints into Lasting Repairs

| Design and execution element | Sicarbtech SiC Hot-Spray System | Conventional Repair Approach |

|---|---|---|

| Layer architecture | Functionally graded (buffer + working + top) | Single layer; generic |

| Bonding mechanism | Reaction/ceramic bonds selectable | Hydraulic set; shrink-prone |

| Interface control | Nano-activated primers; microtexture | Limited priming; weak keying |

| Porosity/permeation | Low porosity; densified microchannels | Higher porosity; ingress paths |

| Surface behavior | Low-wettability anti-fouling | Untreated; fouling-prone |

| Construction window | Hot-in-service; fast return | Cold-only; long outage |

| Digital QC | Onsite adhesion, thickness, porosity logs | Visual checks; delayed testing |

Innovation That Matters: Graded Layers, Activated Interfaces, and Post-Spray Densification

Three levers deliver the bulk of lifecycle benefit. First, functional grading places a compliant buffer under a hard, fine-grained working layer, topped with a low-wettability surface—balancing toughness, wear resistance, and fouling control. Second, nano interfacial activation and primers lift the interfacial energy and provide mechanical micro-keying, driving higher shear strength under cycling. Third, secondary densification seals microchannels after spray, which lowers permeability and slows chemical ingress and oxidation. Together, these innovations reset the re-failure curve and make “online hot repair” a reliable plant standard rather than a last resort.

Future Market Opportunities and 2025+ Trends in Pakistan

Three trends will pull SiC hot-spray forward. O&M models centered on fewer shutdowns will prioritize materials that cure fast at temperature and hold adhesion through cycling. Mixed fuels and more aggressive atmospheres will raise the bar for oxidation and alkali resistance in repair layers. And localization pressures—FX volatility and lead-time risk—will favor providers who transfer not only materials but also method and metrology, enabling in-country execution with audit-ready documentation.

Scale-wise, a 3,000–7,000 t/d clinker line or a mid-to-large furnace typically consumes 3–20 tons of hot-spray materials annually at known hotspots. Nationally, new builds and revamps point to several hundred tons per year; services—construction crews, testing, O&M programs—extend the addressable market into the tens to hundreds of millions of Pakistani Rupees. For operators, the business case is straightforward: stabilize ΔP and temperature uniformity, compress downtime, and prove the improvement with data. Sicarbtech’s integrated platform is designed to deliver precisely that.

As one regional reliability engineer commented in a 2025 workshop, “When your elbow patch survives the monsoon and your ΔP trend flattens, you know you’ve changed the physics, not just the calendar.”

Frequently Asked Questions

Which SiC spray system should we start with for the most severe scour zones?

Begin with a functionally graded system: apply a compliant buffer for stress relief, then a high-hardness working layer optimized for wear, capped with a low-wettability top coat to suppress fouling. Use high-adhesion primer matched to your substrate and add post-spray densification for permeability control.

How much downtime and energy can we realistically save?

Plants typically cut per-event downtime by 30–60% compared to cold repairs and trim 2–4% from energy per ton indirectly by stabilizing pressure-drop and sealing leaks. Gains depend on baseline variability, ΔP trajectory, and adherence to construction SOPs.

Can we apply SiC hot-spray during monsoon season?

Yes, with controls. We enforce substrate temperature and moisture checks, use moisture-tolerant primers where needed, deploy localized heating and dehumidification, and verify adhesion with onsite pull tests. Edge sealing and top-surface anti-wetting further protect against transient humidity.

How do SiC coatings resist sulfur–alkali–chlorine attack?

Formulations incorporate oxidation-resistant phases and ceramic/reaction bonds; low porosity and post-spray densification minimize pathways for corrosives. For the most aggressive zones, we add tailored barrier chemistries and schedule inspection intervals by trend rather than fixed calendar.

What preparation is essential for reliable adhesion?

Remove scale and contamination, grit-blast or grind to specified roughness, warm the substrate into the target window, and apply the correct primer. Control interpass times and total thickness to limit residual stresses. Verify with rapid adhesion and thickness checks.

Are metal substrates suitable for SiC hot-spray?

Yes, with appropriate primers and thermal expansion management. We match CTE and layer stiffness to mitigate differential strain, and we avoid geometries that trap stress. For mixed ceramic–metal interfaces, we often use a compliant buffer before the wear layer.

What KPIs should we track post-repair?

Track pressure-drop trend, temperature profiles, wear thickness at marker points, adhesion retention (periodic pulls on sacrificial tabs), fouling growth rate, and unplanned repair frequency. Correlate these with batch QA (porosity, hardness) and construction logs.

Can Sicarbtech localize materials and equipment in Pakistan?

Yes. We provide formulations, equipment specs for spraying and temperature control, and—where relevant—sintering/carburation and heat-treatment capabilities for reaction/ceramic bonds. Training covers surface prep, spraying technique, curing, and rapid QA; documentation aligns with ISO 9001/14001 and supports PSQCA.

What are safe return-to-service practices?

Follow the validated set and cure window, execute a staged heat-up/soak/equalization curve, and avoid immediate high-velocity impact at newly coated zones. Confirm layer thickness and adhesion before ramping to full duty.

How do we budget for a full-year program?

Baseline your hotspots and ΔP slope, then model repair frequency under graded SiC with fast returns. Include training, rapid-test kits, and periodic audits. Most sites see payback within the first cycle by avoided downtime and stabilized energy.

Making the Right Choice for Your Operations

If grooved throats, creeping pressure drops, and emergency cleanouts are setting your schedule, the repair method is managing your plant. SiC composite hot-spray—graded for toughness and wear, primed for adhesion, and densified for durability—hands control back to your team. The payoff is visible in flatter ΔP trends, steadier temperatures, shorter outages, and audit-ready records that satisfy procurement, QA, and HSE alike.

Get Expert Consultation and Custom Solutions

Share your operating envelope—zone temperatures, dust/PSD, gas chemistry, velocities and impingement angles, substrate materials, access constraints, and ΔP/temperature histories—and Sicarbtech will engineer a tailored hot-spray program. We will specify layer architecture, binders and bonding mechanism, primer and activators, cure and ramp profiles, QA checkpoints, and post-spray densification. If localization is your goal, we will map a phased technology-transfer plan—from field construction kits to in-country production—aligned with your CAPEX and maintenance strategy.

Sicarbtech – Silicon Carbide Solutions Expert

Weifang City, China’s silicon carbide manufacturing hub

Member of Chinese Academy of Sciences (Weifang) Innovation Park

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Article Metadata

Last updated: 2025-09-19

Next scheduled update: 2026-01-15

Content freshness indicators: 2025 Pakistan cement/steel/glass outlook validated; SiC hot-spray technical ranges aligned with current field deployments; ISO/PSQCA alignment reviewed; contact details verified for Pakistan engagements.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.