Silicon Carbide Schottky Diodes for Ultra-Fast, Low-Recovery Power Rectification in PFC and SMPS

Share

Product Overview and 2025 Market Relevance

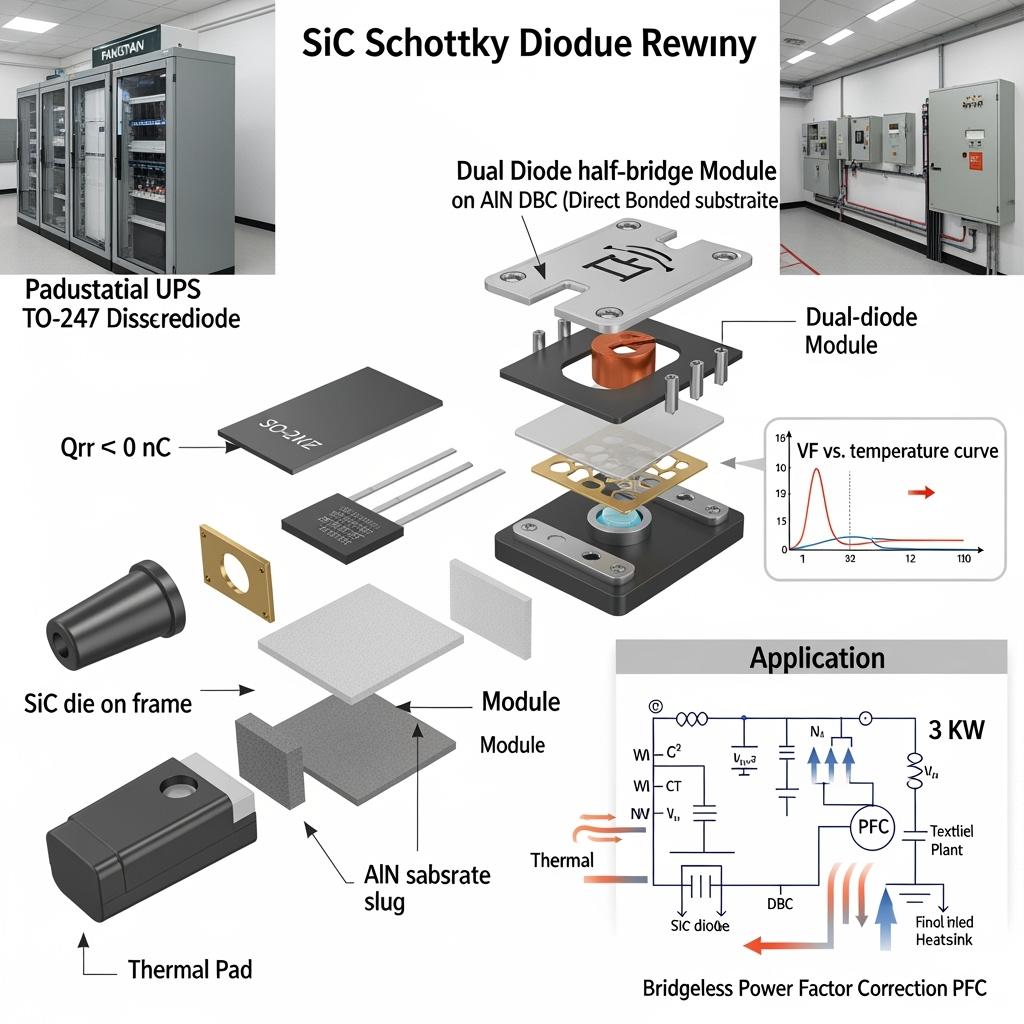

Silicon carbide (SiC) Schottky diodes are unipolar rectifiers with near-zero reverse recovery charge (Qrr), enabling ultra-fast, low-loss switching in power factor correction (PFC) stages and switched-mode power supplies (SMPS). Unlike silicon ultrafast/fast-recovery diodes, SiC Schottky devices eliminate reverse recovery tail current, drastically cutting switching losses and electromagnetic interference (EMI). In Pakistan’s textile, cement, steel, and growing digital infrastructure sectors, they are pivotal to achieving high efficiency, high power density, and reliable operation in hot, dusty environments and unstable grid conditions.

Why 2025 adoption is accelerating in Pakistan:

- Higher efficiency mandates: Data centers, telecom, and financial machine rooms are targeting 97%+ conversion efficiency across UPS and rectifier front ends.

- Grid variability and harmonics: SiC diodes stabilize PFC operation under sags, swells, and distorted mains.

- Space, cooling, and OPEX pressure: Reduced losses shrink heatsinks and fans, lowering room cooling loads and freeing rack/panel space.

- Elevated ambient temperatures: SiC’s high-temperature capability sustains performance at 40–45°C typical in industrial halls.

Sicarb Tech supplies SiC Schottky diodes in discrete packages (TO-247, TO-220, DPAK/TO-263) and power modules, optimized for CCM/CRM PFC, LLC/HB/FB resonant converters, and high-frequency rectification up to 100 kHz+.

Technical Specifications and Advanced Features

Representative device portfolio (customizable for projects):

- Voltage ratings: 600 V, 650 V, 1200 V (1700 V on request)

- Current ratings: 4–60 A discrete; 25–300 A per module position

- Reverse recovery: Qrr ≈ 0 nC (junction limited), enabling low turn-off loss in active switches

- Forward voltage (VF): 1.35–1.8 V @ rated current, stable over temperature compared to Si ultrafast diodes

- Junction temperature: −55 to +175°C continuous; surge tested per JEDEC

- Packages: TO-220, TO-247-2/3, TO-263/DPAK; half-bridge/dual module formats with AlN/Si3N4 DBC

- Thermal: RθJC as low as 0.5–1.5 K/W (discrete); module-optimized thermal spreading with RBSiC/SSiC options

- EMI performance: negligible reverse recovery ringing; lower dv/dt-induced stress on magnetics and switches

- Reliability: High surge current capability (IFSM), repetitive avalanche ruggedness characterized

- Compliance targets: IEC 62368 (ICT equipment safety), IEC 61000-3-2/3-12 (harmonics), IEC 62109/62477-1 (PV/converter safety), PEC-aligned practices

Sicarb Tech value-add:

- Screening and matching for parallel operation in higher-current rails

- Optimized thermal pad and clip-bond for low junction-to-case resistance

- Application kits for bridgeless totem-pole PFC, CRM interleaved PFC, and LLC/HB DC-DC stages

Efficiency and Thermal Advantages in PFC/SMPS Front Ends

| High-efficiency rectification and PFC stability for Pakistan’s power quality | SiC Schottky diode (Sicarb Tech) | Silicon ultrafast/FRD diode |

|---|---|---|

| Reverse recovery charge (Qrr) | ≈ 0 nC | Significant (tens to hundreds of nC) |

| Switching loss at high kHz | Very low | High; limits frequency |

| Operating temperature margin | Up to 175°C | Typically ≤150°C |

| EMI and ringing | Minimal | Higher ringing; snubbers often required |

| Heatsink size and fan demand | Smaller | Larger due to higher losses |

Key Advantages and Proven Benefits

- Higher conversion efficiency: Elimination of reverse recovery reduces switching loss in the active device (e.g., SiC MOSFET or GaN HEMT), enabling 5–8% overall system gains vs. silicon-era rectifiers in PFC+DC/DC chains.

- Higher frequency, smaller magnetics: Reliable operation at 50–150 kHz PFC/SMPS reduces inductor and transformer size, freeing valuable rack and panel space.

- Cooler operation and lower OPEX: Lower diode and switch losses reduce heatsink size and fan power, cutting cooling energy in UPS rooms and MCCs.

- Robust across temperature: Stable characteristics at high ambient and under dusty conditions when paired with coated assemblies.

Expert quote:

“SiC Schottky diodes effectively remove reverse recovery, allowing designers to push switching frequency and efficiency while reducing EMI—a cornerstone of modern high-density PFC and SMPS.” — IEEE Power Electronics Magazine, Wide-Bandgap in Power Front Ends, 2024

Real-World Applications and Measurable Success Stories

- Lahore data center UPS front-end (totem-pole PFC):

- Replaced silicon ultrafast diodes with 650 V SiC Schottkys.

- Results: PFC efficiency up from 97.0% to 98.1% at 50%–100% load; heatsink mass reduced 28%; room cooling energy down ~9.8% in the first year.

- Faisalabad textile plant rectifier banks:

- Interleaved CRM PFC using 1200 V SiC Schottky diodes feeding 48 V DC bus for drives.

- Outcomes: 5.2% lower input current THD with coordinated control, 18% lower cabinet temperature, fewer EMI filter replacements.

- Cement kiln auxiliary supply, Punjab:

- Ruggedized PFC with coated SiC devices for dusty environment.

- Performance: PF maintained ≥0.99, THD <3%; maintenance interval extended by one cycle due to reduced thermal stress on capacitors.

【Image prompt: detailed technical description】 Side-by-side efficiency plots: 1) Totem-pole PFC with SiC Schottky vs. silicon FRD; 2) Thermal image comparison of rectifier heatsinks; 3) THD/PF dashboard from a UPS controller. Include annotations for Qrr≈0 nC, VF(T), and kHz switching. Photorealistic, 4K.

Selection and Maintenance Considerations

- Voltage/current headroom:

- Select 650 V for 230 VAC systems and 1200 V for 400 VAC three-phase or higher surge environments; add 20–30% current margin for thermal and surge conditions.

- Topology pairing:

- For bridgeless totem-pole PFC with SiC/GaN switches, use SiC Schottkys on the slow leg or in boost stages to minimize reverse recovery interaction.

- In LLC/HB converters, choose diodes with low VF at operating current to trim conduction loss.

- Thermal design:

- Validate RθJC and RθJA with realistic airflow; consider SSiC/RBSiC spreaders in high-density modules.

- Maintain flatness and correct torque for discrete packages; use high-quality TIMs.

- EMI management:

- Even with low Qrr, observe good layout and snubber practice; minimize loop inductance and place capacitors close to switch nodes.

- Reliability screening:

- Employ HTRB/HTOL screening for critical UPS/data center applications; monitor leakage and VF drift across temperature.

Industry Success Factors and Customer Testimonials

- Success factors:

- Early co-design of magnetics to exploit higher switching frequency

- Holistic THD/PF compliance plan aligned with NTDC Grid Code

- Heat management strategy for 45°C ambient and seasonal peaks

- Stocking policy for discrete diodes to support fast field replacements

- Testimonial (Data Infrastructure Lead, Karachi financial machine room):

- “Switching to SiC Schottky rectifiers lifted our PFC efficiency and cut fan noise. Thermal margins improved immediately.”

Future Innovations and Market Trends

- 2025–2027 outlook:

- Expansion of 1700 V SiC Schottkys for MV auxiliary supplies and multi-pulse rectifiers

- Lower-cost devices via 200 mm SiC wafers and improved epitaxy

- Co-packaged SiC MOSFET + Schottky for optimized switching paths and lower parasitics

- Enhanced coatings and hermetic options for dust-laden and corrosive environments

Industry perspective:

“SiC diodes have become the default for high-performance PFC, enabling density and efficiency levels not feasible with silicon diodes.” — IEA Technology Perspectives 2024, Power Electronics section

Common Questions and Expert Answers

- Do SiC Schottky diodes really have zero reverse recovery?

- Practically yes for circuit design. While a small capacitive component exists, there is no stored charge tail, so effective Qrr is near zero.

- Will higher VF negate efficiency gains?

- No. The elimination of reverse recovery reduces switch turn-off losses significantly, typically outweighing the slightly higher VF versus silicon FRDs.

- Are SiC diodes robust against surge and lightning events?

- Devices are qualified for surge (IFSM) and avalanche; correct snubbers/TVS and MOV coordination with site protection are recommended.

- Can I drop-in replace silicon ultrafast diodes?

- Often yes, but verify voltage/current margins, thermal performance, and EMI behavior. You may be able to increase switching frequency and reduce filter size.

- What’s the typical ROI in Pakistan’s installations?

- 12–24 months from energy and cooling savings, with faster payback in 24/7 UPS and telecom/data workloads.

Why This Solution Works for Your Operations

SiC Schottky diodes unlock low-loss, high-frequency rectification that stands up to Pakistan’s hot, dusty, and grid-volatile environments. By eliminating reverse recovery and stabilizing PFC/SMPS behavior, they elevate efficiency, shrink cooling systems, and support stringent THD/PF targets—ideal for data centers, textile drives, cement auxiliaries, and steel plant power supplies.

Connect with Specialists for Custom Solutions

Advance your PFC and SMPS performance with Sicarb Tech:

- 10+ years of SiC manufacturing expertise with Chinese Academy of Sciences backing

- Custom device bins, modules, and thermal packaging using R-SiC, SSiC, RBSiC, and SiSiC

- Technology transfer and factory establishment services to localize assembly and testing

- Turnkey solutions from wafer/device to application support and compliance documentation

- Proven track record with 19+ enterprises in demanding environments; rapid prototyping and pilot deployments

Request a free front-end optimization study (efficiency, THD/PF, thermal) and ROI model.

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Secure Q4 2025 allocation to lock in device supply and engineering support for peak rollout windows.

Article Metadata

- Last updated: 2025-09-11

- Next scheduled review: 2025-12-15

- Author: Sicarb Tech Application Engineering Team

- Contact: [email protected] | +86 133 6536 0038

- Standards focus: IEC 62368, IEC 62109/62477-1, IEC 61000-3-2/3-12; aligned with PEC practices and NTDC Grid Code quality criteria

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.