SiC: Strengthening Capabilities in the Defense Industry

Share

SiC: Strengthening Capabilities in the Defense Industry

Introduction: The Strategic Imperative of Silicon Carbide in Modern Defense

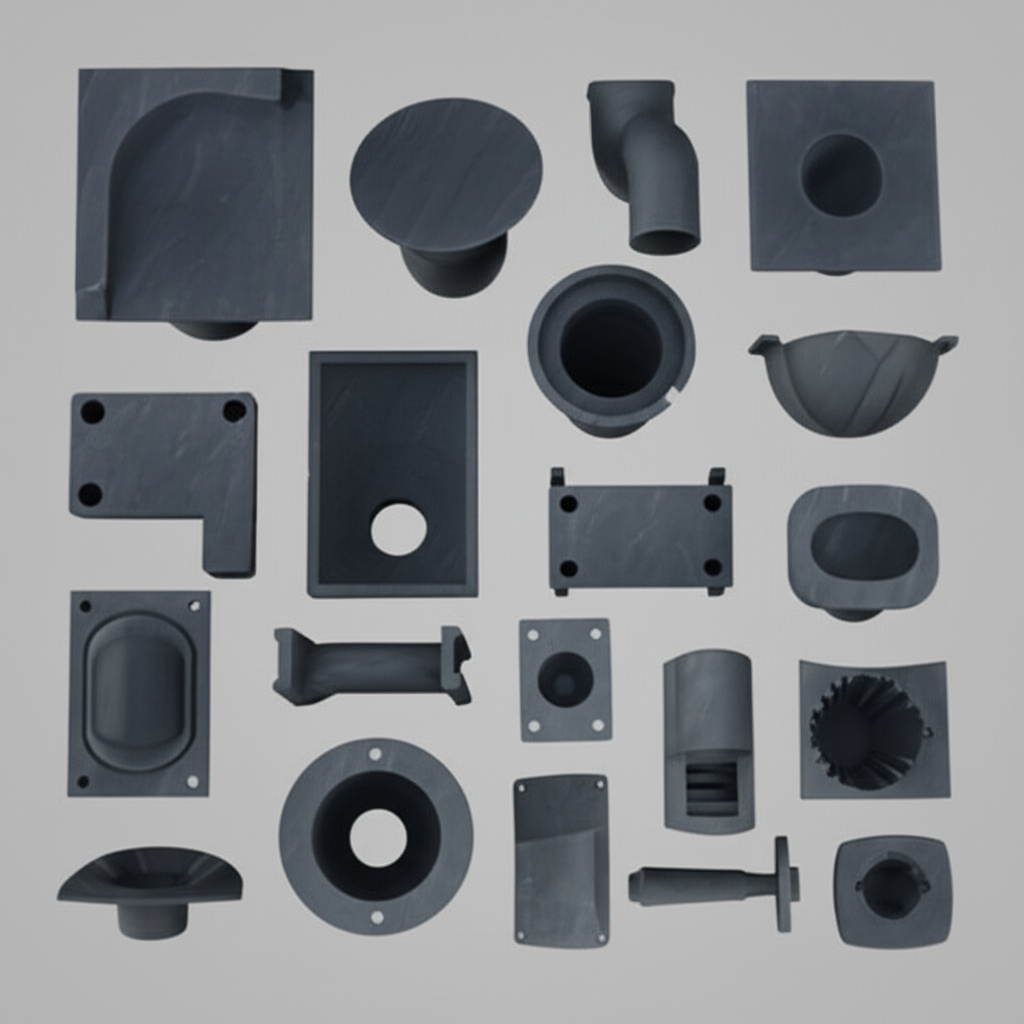

In an era where technological superiority dictates defense capabilities, advanced materials play a pivotal role. Among these, custom silicon carbide (SiC) products have emerged as a cornerstone for high-performance industrial and defense applications. Silicon carbide, a synthetic compound of silicon and carbon, is not merely another material; it’s a strategic enabler. Its exceptional combination of hardness, thermal resistance, chemical inertness, and lightweight properties makes it essential for mission-critical components that operate under extreme conditions. For engineers, procurement managers, and technical buyers in the defense sector, understanding the multifaceted advantages of SiC is crucial for developing next-generation systems that offer enhanced protection, improved performance, and greater operational reliability. As defense technologies evolve, the demand for materials that can withstand severe mechanical stresses, ultra-high temperatures, and aggressive chemical environments is ever-increasing. Custom silicon carbide ceramics are uniquely positioned to meet these challenges, offering solutions where traditional metals and other ceramics fall short. From personnel and vehicle armor to sophisticated sensor systems and power electronics, SiC is helping to redefine the boundaries of what’s possible in defense technology, ensuring that armed forces maintain a decisive edge.

SiC’s Expanding Role: Key Applications in the Defense Sector

The versatility and superior properties of silicon carbide have led to its adoption across a wide spectrum of defense applications. Its ability to perform reliably in harsh environments makes it invaluable for systems where failure is not an option. Procurement professionals and engineers are increasingly specifying SiC for components that demand exceptional durability and performance. Key applications include:

- Ballistic Protection: Custom silicon carbide armor plates are a primary application. SiC ceramic tiles, often integrated into composite armor systems, offer superior protection against a wide range of projectile threats for personnel, vehicles, aircraft, and naval vessels. Their high hardness and relatively low density contribute to lightweight armor solutions that enhance mobility and survivability.

- Aerospace and Hypersonic Components: The extreme temperatures and thermal shock experienced by hypersonic vehicles and advanced aerospace platforms necessitate materials like SiC. Applications include leading edges, rocket nozzles, thruster components, and thermal protection systems. Its ability to maintain structural integrity at temperatures exceeding 1500°C is critical.

- Naval Defense Systems: SiC is used in various naval applications due to its wear resistance and corrosion resistance in saline environments. Components such as pump seals, bearings, and valve parts in seawater systems, as well as protective elements for sonar domes, benefit from SiC’s robustness.

- Advanced Optical and Sensor Systems: For reconnaissance, surveillance, and targeting systems, SiC’s thermal stability, high stiffness, and polishability make it an excellent material for mirrors, optical benches, and sensor windows, especially in space-based and airborne applications. CVD (Chemical Vapor Deposition) SiC is particularly favored for high-precision optical components.

- Defense Electronics and Power Modules: SiC-based semiconductors are revolutionizing power electronics in defense systems. Their ability to operate at higher temperatures, voltages, and frequencies allows for smaller, lighter, and more efficient power conversion and management systems in radar, electronic warfare (EW) suites, and directed energy weapons.

- Directed Energy Weapon (DEW) Components: The development of DEWs, such as high-energy lasers and microwave weapons, requires materials that can withstand intense energy fluxes and manage significant thermal loads. SiC’s thermal conductivity and stability are crucial for mirrors, beam steering optics, and cooling systems in these advanced weapons.

- Wear-Resistant Components: In various defense machinery and equipment, SiC parts like nozzles, bearings, seals, and flow control components offer extended service life and reduced maintenance due to their exceptional wear and erosion resistance, even when handling abrasive materials or high-velocity fluids.

The integration of SiC into these diverse applications underscores its strategic importance, offering tangible improvements in performance, resilience, and operational readiness for modern defense forces.

The Unmatched Advantages: Why Custom SiC is a Force Multiplier for Defense

The decision to specify custom silicon carbide in defense applications stems from a clear understanding of its inherent benefits, which directly translate into enhanced operational capabilities and strategic advantages. For technical buyers and engineers, recognizing these advantages is key to leveraging SiC as a true force multiplier. The benefits of customization further amplify these strengths, allowing for components tailored to specific, demanding defense scenarios.

- Exceptional Hardness and Ballistic Performance: SiC is one of the hardest commercially available materials, surpassed only by diamond and boron carbide. This extreme hardness, coupled with its relatively low density, makes it an ideal candidate for lightweight armor systems. Custom-designed SiC ceramic tiles can defeat advanced ballistic threats, providing superior protection for personnel and vehicles while minimizing added weight, thereby improving mobility and fuel efficiency.

- Superior High-Temperature Stability and Thermal Shock Resistance: Defense systems often operate in extreme thermal environments. SiC maintains its strength and structural integrity at very high temperatures (up to 1650°C or higher for some grades in inert atmospheres). Its excellent thermal shock resistance allows it to withstand rapid temperature fluctuations without cracking or failing, crucial for applications like rocket nozzles, hypersonic vehicle components, and brake systems.

- Outstanding Wear and Abrasion Resistance: Components in defense systems are frequently subjected to harsh conditions, including abrasive particles, high-velocity flows, and mechanical wear. Custom SiC parts, such as seals, nozzles, bearings, and liners, exhibit exceptional resistance to wear and abrasion, leading to significantly longer service life, reduced maintenance downtime, and lower lifecycle costs.

- Chemical Inertness and Corrosion Resistance: SiC is highly resistant to corrosion and attack by a wide range of chemicals, including strong acids and bases, even at elevated temperatures. This makes it suitable for components in chemical processing environments within defense operations or for parts exposed to corrosive propellants, sea water, or decontaminating agents.

- High Thermal Conductivity: Certain grades of SiC possess high thermal conductivity, which is vital for thermal management applications. In defense electronics, SiC substrates and heat sinks help dissipate heat efficiently, enabling higher power densities and improved reliability for critical systems. This is also beneficial in applications like heat exchanger tubes for advanced power systems.

- Design Flexibility with Customization: The ability to produce custom silicon carbide components allows engineers to optimize designs for specific defense applications. Complex geometries, intricate features, and integration with other materials can be achieved, ensuring that the SiC part delivers maximum performance within the system. This tailoring capability is essential for pushing the boundaries of defense technology.

- Electrical Properties Tailoring: While often an electrical insulator, SiC can also be engineered as a semiconductor. This duality is exploited in power electronics for higher efficiency and in specialized applications requiring controlled electrical resistivity.

- Long-Term Durability and Reliability: The combination of these properties results in components that are extremely durable and reliable, even under the most demanding operational conditions. This reliability is paramount in defense, where system failure can have critical consequences.

By capitalizing on these advantages, the defense industry can develop systems that are lighter, stronger, more resilient, and more efficient, ultimately enhancing the capabilities and safety of its personnel.

Selecting the Shield: Recommended SiC Grades for Demanding Defense Scenarios

Choosing the appropriate grade of silicon carbide is critical for optimizing performance, cost, and manufacturability in defense applications. Different manufacturing processes yield SiC materials with varying microstructures and property profiles. Technical procurement professionals should be aware of these distinctions to make informed decisions.

| SiC Grade | Key Characteristics | Common Defense Applications | Considerations |

|---|---|---|---|

| Reaction-Bonded Silicon Carbide (RBSiC / SiSiC) | High strength, excellent wear and corrosion resistance, good thermal shock resistance, complex shapes possible, contains some free silicon (typically 8-15%). | Armor tiles, wear components (nozzles, liners), kiln furniture, heat exchangers, structural components. | Presence of free silicon limits maximum operating temperature (around 1350°C) and resistance to certain aggressive chemicals. Generally cost-effective for complex shapes. |

| Sintered Silicon Carbide (SSiC) | Very high purity (typically >98% SiC), extreme hardness, excellent chemical resistance, high-temperature strength (up to 1650°C+), good thermal conductivity. | High-performance armor, ballistic missile components, chemical processing equipment parts, mechanical seals, bearings, semiconductor processing components. | Can be more challenging and costly to produce complex shapes compared to RBSiC. Shrinkage during sintering needs careful design consideration. |

| Nitride-Bonded Silicon Carbide (NBSC) | Good thermal shock resistance, high strength, good wear resistance, resistant to molten non-ferrous metals. | Furnace components, components for molten metal handling, some wear parts. | Properties can be tailored by adjusting the SiC grain to silicon nitride binder ratio. May not offer the same peak performance as SSiC in all aspects. |

| Chemical Vapor Deposited Silicon Carbide (CVD SiC) | Ultra-high purity (99.999%+), theoretically dense, exceptional thermal conductivity, excellent oxidation and corrosion resistance, highly polishable surfaces. | Optical mirrors for space and laser systems, semiconductor wafer processing equipment (etch rings, showerheads), protective coatings, nuclear applications. | Typically the most expensive SiC grade due to complex manufacturing. Often used for applications where extreme purity and specific surface characteristics are paramount. Can be deposited as a coating or grown as a bulk material. |

| Recrystallized Silicon Carbide (RSiC) | High porosity, excellent thermal shock resistance, good for high temperatures in oxidizing atmospheres. | Kiln furniture, setters, crucibles, heating elements. | Lower mechanical strength compared to dense SiC grades due to porosity. Not typically used for direct ballistic protection but can serve in supporting high-temperature roles. |

The selection process involves a thorough analysis of the operational environment (temperature, chemical exposure, mechanical loads), desired performance characteristics (hardness, thermal conductivity, purity), component geometry, and budget constraints. Collaborating with an experienced SiC manufacturer is crucial to identify the optimal grade and ensure the design is compatible with the chosen material’s fabrication capabilities. For instance, applications requiring intricate internal cooling channels for thermal management in hypersonic systems might favor RBSiC for its near-net-shaping capabilities, while ultra-pure optical mirrors for satellite surveillance would demand CVD SiC.

Blueprint for Protection: Critical Design Considerations for Defense SiC Components

Successfully integrating silicon carbide into defense systems requires more than just selecting the right grade; it demands careful design considerations tailored to SiC’s unique material properties. While SiC offers immense advantages, its inherent ceramic nature—particularly its hardness and brittleness compared to metals—must be accounted for during the design phase to ensure manufacturability, performance, and reliability.

- Managing Brittleness: SiC is a brittle material, meaning it has low fracture toughness compared to metals. Designs should aim to minimize stress concentrations. This involves:

- Using generous radii on internal corners and edges.

- Avoiding sharp notches or sudden changes in cross-section.

- Designing for compressive loads where possible, as ceramics are much stronger in compression than in tension.

- Considering pre-stressing techniques or reinforcement in critical areas.

- Designing for Impact Resistance: For armor applications, the design of SiC tiles and their backing systems is critical.

- Tile Size and Geometry: Smaller, appropriately shaped tiles can sometimes offer better multi-hit performance than large monolithic plates. Hexagonal or square tiles are common.

- Interface and Adhesion: The method of attaching SiC tiles to a backing material (e.g., aramid fiber, UHMWPE, or metal) significantly affects ballistic performance.

- Edge Effects: Proper support and design around tile edges are crucial to prevent premature failure.

- Complexity and Manufacturability: While custom SiC parts can be complex, there are limitations.

- Near-Net Shaping: Design for near-net shape manufacturing (e.g., with RBSiC) to minimize costly and difficult post-sintering machining.

- Wall Thickness and Aspect Ratios: Extremely thin walls or high aspect ratios can be challenging to produce without defects. Consult with manufacturers like Sicarb Tech on achievable limits.

- Internal Features: Internal cavities or channels are possible but add complexity and cost. Their design must be compatible with the chosen manufacturing route (e.g., slip casting, additive manufacturing, or machining green bodies).

- Thermal Management Design: For high-temperature applications or those requiring heat dissipation:

- Incorporate features like cooling channels or fins, considering the manufacturing constraints.

- Ensure good thermal contact with adjacent components if SiC is used as a heat spreader.

- Account for thermal expansion mismatch when SiC is joined to other materials to prevent stress buildup.

- Joining and Integration: SiC components often need to be integrated into larger assemblies.

- Techniques include brazing, diffusion bonding, mechanical fastening, or adhesive bonding. Each method has its own design requirements and service temperature limitations.

- Design interfaces to accommodate differences in thermal expansion coefficients between SiC and the mating material.

- Tolerancing: While precise tolerances are achievable, over-specifying can significantly increase costs. Define critical tolerances based on functional requirements.

Early collaboration between design engineers and SiC manufacturing experts is paramount. This ensures that the design is optimized for SiC’s properties, is manufacturable, and meets the stringent performance demands of defense applications. Iterative design and prototyping are often essential steps in developing robust SiC components for the defense industry.

Precision Under Fire: Tolerance, Surface Finish, and Dimensional Accuracy in Defense SiC

In the demanding realm of defense applications, precision is often non-negotiable. Silicon carbide components, whether used in optical systems, high-speed machinery, or tightly integrated armor arrays, frequently require exacting tolerances, specific surface finishes, and high dimensional accuracy to ensure optimal performance and interchangeability. Achieving these specifications with a material as hard as SiC necessitates specialized manufacturing and finishing processes.

Achievable Tolerances:

- As-Sintered Tolerances: The initial dimensional accuracy of SiC parts depends on the manufacturing process (e.g., pressing, slip casting, sintering). As-sintered tolerances are typically in the range of ±0.5% to ±2% of the dimension. For many applications, this level of precision is insufficient.

- Machined Tolerances: To achieve tighter tolerances, SiC components are typically machined in their densified state using diamond grinding techniques. With precision grinding, lapping, and polishing, it’s possible to achieve dimensional tolerances as tight as ±0.001 mm (1 micron) or even better for critical features, though this significantly impacts cost.

Surface Finish Options:

- Standard Finishes: As-fired or as-sintered surfaces can be relatively rough. Standard grinding operations can achieve surface roughness (Ra) values typically in the range of 0.4 to 0.8 µm.

- Fine Grinding and Lapping: For applications requiring smoother surfaces, such as seals, bearings, or some aerodynamic surfaces, fine grinding and lapping processes are employed. These can achieve Ra values down to 0.1 µm or lower.

- Polishing (Optical Finishes): For optical components like mirrors or windows, extremely smooth, low-scatter surfaces are required. Specialized polishing techniques using diamond slurries can achieve surface roughness values below 1 nm (Ra) and angstrom-level finishes for CVD SiC. This is crucial for laser systems and high-resolution imaging.

- Control of Flatness, Parallelism, and Roundness: Beyond surface roughness, other geometric tolerances like flatness, parallelism, cylindricity, and roundness are critical for many defense components. These are also controlled through precision machining and metrology. For example, SiC seal faces may require flatness tolerances in the helium light band range.

Dimensional Accuracy and Stability:

- SiC exhibits excellent dimensional stability over a wide range of temperatures and does not typically suffer from creep at operational stresses relevant to many defense applications, ensuring that precision, once achieved, is maintained in service.

- Metrology is a key aspect of ensuring dimensional accuracy. Advanced measurement techniques, including CMMs (Coordinate Measuring Machines), optical profilometers, and interferometers, are used to verify that components meet stringent defense specifications.

Procurement managers and technical buyers should clearly define the required tolerances and surface finishes in their specifications, understanding that tighter requirements will generally lead to increased manufacturing time and cost. It’s advisable to specify the tightest tolerances only where functionally necessary. Engaging with a supplier experienced in precision machining of technical ceramics is vital to ensure that the specified dimensional accuracy and surface quality can be consistently achieved for demanding defense SiC components.

Beyond the Blank: Post-Processing for Optimized SiC Defense Performance

While the inherent properties of silicon carbide are impressive, various post-processing treatments can further enhance its performance, durability, and suitability for specific defense applications. These steps go “beyond the blank” SiC component, tailoring it to meet the nuanced demands of military systems, from improved wear resistance to enhanced optical or stealth characteristics.

Common post-processing techniques for SiC in defense include:

- Precision Grinding and Lapping:

- Purpose: To achieve tight dimensional tolerances, specific geometric forms (flatness, parallelism, roundness), and desired surface finishes. As SiC is extremely hard, diamond abrasives are exclusively used.

- Defense Relevance: Essential for components like high-performance bearings, precision seals in hydraulic or fuel systems, mating surfaces in armor assemblies, and substrates for electronic devices.

- Polishing:

- Purpose: To create ultra-smooth, low-scatter surfaces, often to optical quality.

- Defense Relevance: Critical for SiC mirrors in satellite imaging systems, laser guidance systems, reconnaissance windows, and other optical applications where surface perfection dictates performance. CVD SiC is often polished to angstrom-level finishes.

- Edge Chamfering and Radiusing:

- Purpose: To remove sharp edges which can be stress concentrators and sources of chipping or cracking in brittle materials like SiC.

- Defense Relevance: Improves the handling safety and mechanical integrity of SiC armor tiles, structural components, and parts that might experience impact or vibration.

- Cleaning and Surface Preparation:

- Purpose: To remove any contaminants, machining residues, or loose particles from the SiC surface. This is crucial before subsequent coating, joining, or assembly.

- Defense Relevance: Ensures proper adhesion of coatings, integrity of brazed joints, and cleanliness for sensitive optical or electronic applications.

- Coatings:

- Purpose: To impart additional functionalities or improve certain properties. Common coatings include:

- Diamond-Like Carbon (DLC): Enhances surface hardness and reduces friction for wear components.

- Metallic Coatings (e.g., Nickel, Gold): For brazing, electrical conductivity, or optical reflectivity.

- Specialized Dielectric Coatings: For optical filters or anti-reflective surfaces on SiC windows.

- Stealth Coatings: Materials designed to absorb or scatter radar signals can be applied to SiC components used in low-observable platforms.

- Defense Relevance: Coatings can significantly enhance the survivability of optical elements, reduce the wear rate of moving parts, enable hermetic sealing, or contribute to the stealth characteristics of a defense platform.

- Purpose: To impart additional functionalities or improve certain properties. Common coatings include:

- Joining and Assembly:

- Purpose: To integrate SiC components with other parts made of SiC, other ceramics, metals, or composites. Techniques include brazing, diffusion bonding, adhesive bonding, and mechanical fastening.

- Defense Relevance: Essential for creating complex assemblies like sensor packages, cooled mirror systems, armor arrays, and integrated electronic modules. The choice of joining method depends on the operating temperature, stresses, and environmental conditions.

- Sealing (for Porous Grades):

- Purpose: Some SiC grades, like certain types of RBSiC or NBSC, may have residual porosity. Sealing treatments (e.g., glass infiltration or polymer impregnation) can be applied to make them impervious to gases or liquids if required.

- Defense Relevance: Important for applications like heat exchanger tubes or components requiring gas-tightness where a porous grade might otherwise be suitable for its other properties.

Each post-processing step adds value but also cost and complexity. Therefore, it’s crucial for defense contractors and engineers to work closely with their SiC suppliers to determine which treatments are necessary and optimal for their specific application, ensuring the final component delivers the desired performance and reliability in the field.

Navigating the Gauntlet: Common Challenges with SiC in Defense and Mitigation Strategies

While silicon carbide offers a compelling suite of properties for defense applications, its adoption is not without challenges. Understanding these potential hurdles and the strategies to mitigate them is crucial for successful implementation. Engineers and procurement specialists must be aware of these factors to make informed decisions and manage project risks.

Common Challenges:

- Brittleness and Fracture Toughness:

- Challenge: SiC, like most advanced ceramics, is inherently brittle. This means it has a lower resistance to fracture from impact or high tensile stress compared to metals. Unexpected failures can occur if not properly designed for.

- Mitigation Strategies:

- Employ design principles that minimize stress concentrations (e.g., fillets, radii).

- Design for compressive loading where possible.

- Incorporate SiC into composite systems (e.g., ceramic-matrix composites or backed armor tiles) to improve toughness and manage crack propagation.

- Utilize proof testing or non-destructive evaluation (NDE) techniques like ultrasonic testing or X-ray inspection to screen for flaws.

- Consider tougher SiC grades or microstructurally engineered variants if available for the application.

- Machining Complexity and Cost:

- Challenge: The extreme hardness of SiC makes it very difficult and time-consuming to machine. This typically requires diamond tooling and specialized equipment, leading to higher machining costs compared to metals or softer ceramics.

- Mitigation Strategies:

- Design for near-net-shape manufacturing wherever feasible to minimize the amount of material removal needed in the densified state.

- Work with suppliers who have extensive experience and advanced capabilities in SiC machining.

- Clearly define and justify tight tolerances; avoid over-specifying.

- Explore alternative shaping methods for green or partially sintered bodies if the final properties allow.

- Cost of Raw Materials and Processing:

- Challenge: High-purity SiC powders and the energy-intensive processes required for densification (e.g., sintering at high temperatures) contribute to a higher material cost compared to many conventional materials. Custom or complex components further add to this.

- Mitigation Strategies:

- Perform a thorough cost-benefit analysis, considering the lifecycle cost advantages (e.g., longer life, reduced maintenance) that SiC can offer.

- Optimize component design for material efficiency.

- Explore different SiC grades; for example, RBSiC can be more cost-effective for complex shapes than SSiC if its properties meet requirements.

- Engage with suppliers early in the design process to get accurate cost estimates and explore design-for-manufacturing options. For instance, organizations like Sicarb Tech leverage their position in Weifang, China’s SiC hub, to offer cost-competitive customized silicon carbide components.

- Joining SiC to Other Materials:

- Challenge: Differences in thermal expansion coefficients, wettability, and chemical compatibility can make it challenging to create strong, reliable joints between SiC and metals or other ceramics, especially for high-temperature applications.

- Mitigation Strategies:

- Select appropriate joining techniques (e.g., active metal brazing, diffusion bonding, specialized adhesives) based on the application’s thermal and mechanical demands.

- Design joints to accommodate thermal stresses, possibly using compliant interlayers.

- Work with specialists in ceramic-to-metal joining.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.