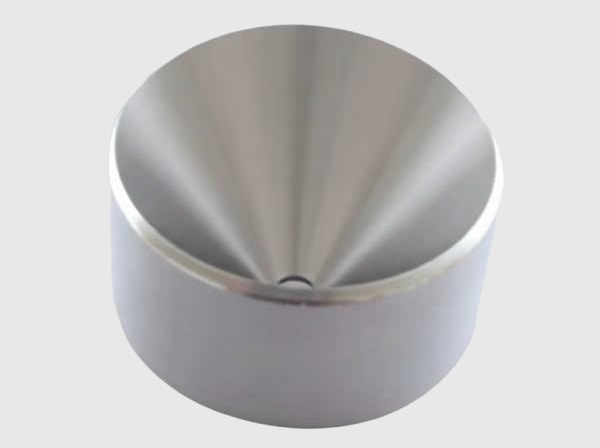

SiC Rings: Key Consumables for Effective Sealing

Share

SiC Rings: Key Consumables for Effective Sealing

In demanding industrial environments, where extreme temperatures, abrasive media, and corrosive chemicals are the norm, the integrity of sealing components is paramount. Engineers, procurement managers, and technical buyers across industries like semiconductors, aerospace, power electronics, and industrial manufacturing are constantly seeking advanced materials that can deliver superior performance and reliability. Among these, silicon carbide (SiC) rings have emerged as critical consumables, providing unparalleled sealing effectiveness and extending operational lifespans. This blog post delves into the world of SiC rings, exploring their unique properties, diverse applications, and the benefits of custom solutions.

The Unmatched Versatility of Silicon Carbide Rings

Silicon carbide, a compound of silicon and carbon, is celebrated for its exceptional material properties. As a leading technical ceramic, SiC offers a combination of characteristics that make it ideal for high-performance sealing applications. Its extraordinary hardness, ranking just below diamond, provides superior wear resistance, crucial for dynamic sealing environments. Furthermore, SiC exhibits excellent thermal conductivity, aiding in heat dissipation, and remarkable chemical inertness, making it resistant to a wide range of corrosive substances. These attributes collectively contribute to the extended service life and reliable performance of SiC rings in the most challenging conditions.

Applications Across Core Industries

The demand for high-performance sealing solutions spans a vast array of industrial sectors. SiC rings, as custom silicon carbide products, are at the forefront of this demand, proving indispensable in critical applications:

- Semiconductor Manufacturing: In highly sensitive processes, SiC rings are vital for vacuum pumps, wafer processing equipment, and chemical mechanical planarization (CMP) tools, where their purity and resistance to aggressive chemicals are essential.

- Automotive Companies: With the rise of electric vehicles (EVs) and hybrid powertrains, SiC rings are increasingly used in electric motor bearings, mechanical seals for cooling systems, and high-temperature pumps due to their excellent wear resistance and thermal stability.

- Aerospace Companies: In aircraft engines, hydraulic systems, and spacecraft components, SiC rings provide reliable sealing under extreme temperatures and pressures, contributing to enhanced safety and efficiency.

- Power Electronics Manufacturers: As SiC-based power devices gain traction, SiC rings are employed in high-power converters, inverters, and charging stations, where their thermal management capabilities are critical.

- Renewable Energy Companies: From wind turbines to solar panel manufacturing, SiC rings are used in gearbox seals, pump components, and processing equipment, ensuring durability and efficiency in harsh outdoor environments.

- Metallurgical Companies: In furnaces, kilns, and metal processing equipment, SiC rings withstand high temperatures and abrasive molten metals, extending the lifespan of critical components.

- Defense Contractors: For military vehicles, marine vessels, and advanced weapon systems, SiC rings offer robust sealing solutions, capable of performing under extreme operational demands.

- Chemical Processing Companies: Resistance to highly corrosive acids, bases, and solvents makes SiC rings ideal for pumps, valves, and reactors in chemical processing plants.

- LED Manufacturers: In the production of LED chips, SiC rings are utilized in high-temperature reactors and gas delivery systems, ensuring precision and purity.

- Industrial Equipment Manufacturers: General industrial pumps, compressors, and mixing equipment benefit from the enhanced durability and reliability offered by SiC seals.

- Telecommunications Companies: SiC components are found in high-frequency, high-power telecommunication equipment, contributing to improved performance and longevity.

- Oil and Gas Companies: In drilling equipment, pumps, and valves exposed to abrasive slurries and corrosive hydrocarbons, SiC rings provide robust sealing solutions.

- Medical Device Manufacturers: For precision pumps and fluid handling systems in medical equipment, the inertness and biocompatibility of SiC are highly valued.

- Rail Transportation Companies: In high-speed rail systems, SiC rings contribute to the longevity and reliability of various mechanical components, including bearings and braking systems.

- Nuclear Energy Companies: Due to their exceptional radiation resistance and high-temperature stability, SiC rings are increasingly considered for critical sealing applications in nuclear power plants.

Advantages of Custom Silicon Carbide Rings

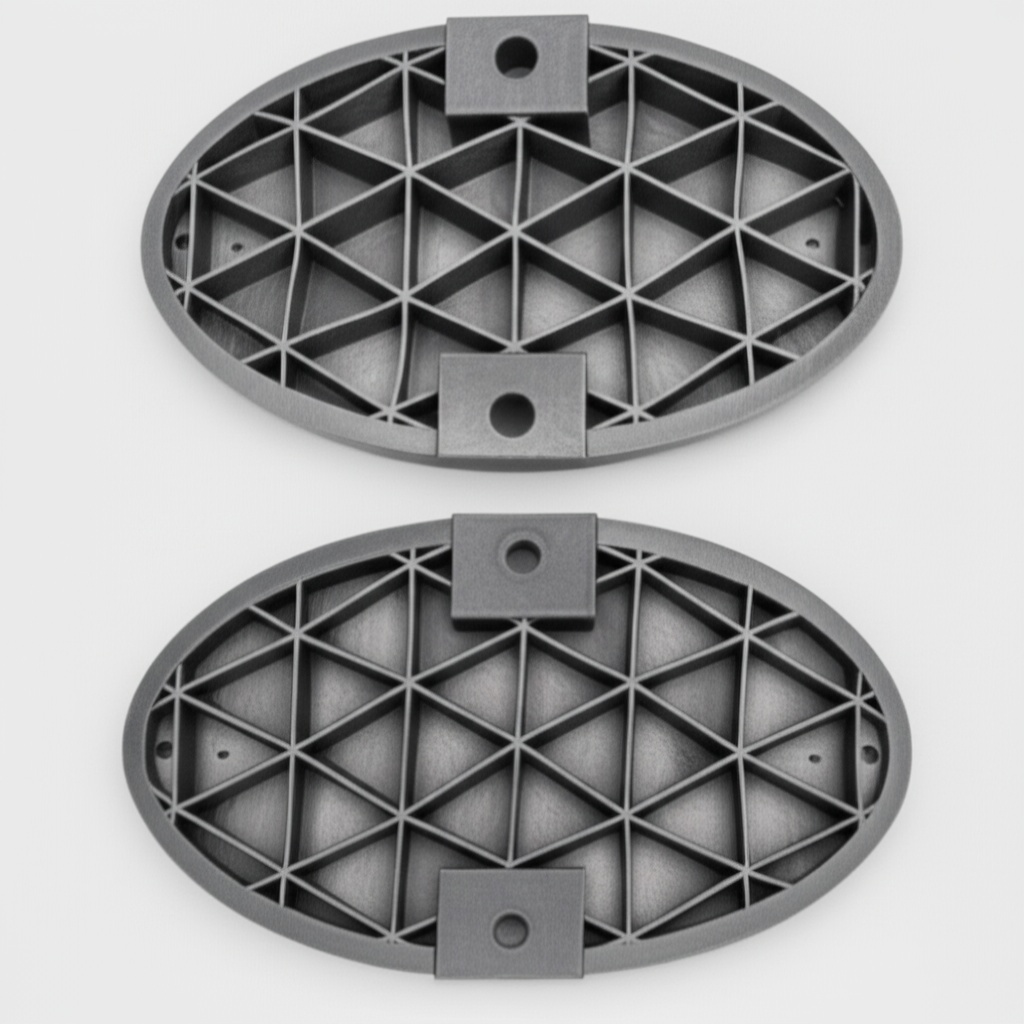

While standard SiC rings offer significant benefits, custom silicon carbide solutions unlock even greater potential. Tailoring the design, dimensions, and material composition to specific application requirements ensures optimal performance and extends the lifespan of the sealing component. This customization allows for:

- Optimized Fit and Performance: Precision-engineered rings ensure a perfect fit, minimizing leakage and maximizing sealing effectiveness.

- Enhanced Durability: Customization allows for the selection of specific SiC grades and processing techniques that are best suited to withstand the unique stresses of a given application.

- Cost-Effectiveness: By designing a ring that precisely meets needs, unnecessary material usage and premature failures are avoided, leading to long-term cost savings.

- Problem Solving: Custom SiC products can address unique sealing challenges that off-the-shelf solutions cannot, such as extreme pressure differentials or highly aggressive chemical environments.

Recommended SiC Grades and Compositions

The performance of SiC rings is highly dependent on the specific grade and composition of the silicon carbide used. Here’s a brief overview of common types:

| SiC Grade | Description | Key Properties | Typical Applications for Sealing |

|---|---|---|---|

| Reaction-Bonded SiC (RBSC) | Formed by infiltrating a compact of silicon carbide and carbon with molten silicon. | Good strength, high thermal conductivity, excellent resistance to thermal shock, relatively porous. | Mechanical seals, pump components, furnace parts. |

| Sintered Alpha SiC (SSiC) | Produced by sintering fine alpha-SiC powder with sintering aids at very high temperatures. | High purity, superior hardness, excellent wear resistance, good corrosion resistance, fine grain structure. | High-performance mechanical seals, bearings, nozzles, semiconductor equipment. |

| Nitride-Bonded SiC (NBSC) | Silicon carbide particles bonded with silicon nitride. | Good thermal shock resistance, moderate strength, high refractoriness. | Kiln furniture, larger structural components, some sealing applications where cost is a factor. |

| Siliconized SiC (Si-SiC) | Similar to RBSC, but with higher free silicon content. | Excellent corrosion resistance, good thermal shock resistance, high strength. | Chemical pump seals, wear plates, components in aggressive environments. |

Choosing the right grade is crucial for optimal performance, and an experienced supplier can provide invaluable guidance in this selection process.

Design Considerations for SiC Rings

Designing custom SiC rings requires a deep understanding of both material science and application specifics. Key considerations include:

- Geometry and Dimensions: Precise outer diameter (OD), inner diameter (ID), and thickness are critical for proper fit and function within the sealing assembly.

- Tolerances: Tight tolerances are often required for effective sealing, especially in dynamic applications.

- Surface Finish: The surface roughness impacts friction, wear, and sealing effectiveness. Lapped and polished surfaces are common for high-performance seals.

- Wall Thickness: Adequate wall thickness is necessary to ensure mechanical integrity and prevent breakage, especially during installation or under pressure.

- Stress Points: Identifying and mitigating stress concentrations through proper design can prevent premature failure.

- Integration with Mating Materials: Consideration must be given to the compatibility of the SiC ring with its mating surface (e.g., carbon graphite, ceramics, or metals) to optimize performance and minimize wear on both components.

- Grooves and Features: Incorporating specific grooves, chamfers, or other features can enhance sealing performance, accommodate O-rings, or facilitate installation.

Tolerances, Surface Finish & Dimensional Accuracy

Achieving superior sealing performance with SiC rings relies heavily on precise manufacturing and strict adherence to dimensional accuracy. The capabilities of the manufacturing process directly influence the achievable tolerances and surface finishes. For critical sealing applications, extremely tight tolerances are often required, typically in the range of microns. Surface finishes, measured in Ra (arithmetic average roughness), can range from a few micrometers for general applications to sub-micrometer levels for high-pressure or high-speed seals. Lapping and polishing are common post-processing steps to achieve the desired surface quality, which is crucial for minimizing friction, reducing wear, and ensuring a leak-proof seal. A reputable custom SiC manufacturer will have the advanced machining and finishing capabilities to meet these exacting specifications.

Post-Processing Needs for Enhanced Performance

While the initial fabrication of SiC rings provides their fundamental properties, post-processing steps can further enhance their performance, durability, and specific functionalities:

- Grinding and Lapping: These abrasive machining processes are essential for achieving tight dimensional tolerances and superior surface finishes, crucial for optimal sealing.

- Polishing: For the most demanding applications, polishing can achieve mirror-like surfaces, significantly reducing friction and wear.

- Chamfering and Deburring: Removing sharp edges prevents chipping and facilitates easier installation, reducing the risk of damage.

- Coating: In some cases, specialized coatings (e.g., DLC – Diamond-like Carbon) can be applied to further enhance wear resistance, reduce friction, or provide additional chemical inertness, though SiC itself offers excellent properties.

- Annealing: Heat treatments can sometimes be employed to relieve internal stresses introduced during manufacturing, improving the overall integrity of the component.

- Inspection and Quality Control: Thorough inspection, including dimensional checks, surface finish analysis, and non-destructive testing (NDT), is paramount to ensure the rings meet all specifications and are free from defects.

Common Challenges and How to Overcome Them

Despite their numerous advantages, working with silicon carbide presents certain challenges:

| Challenge | Description | Mitigation Strategy |

|---|---|---|

| Brittleness | SiC is a hard, but inherently brittle material, susceptible to chipping or cracking under impact or improper handling. | Careful design to avoid sharp corners, proper handling procedures, and appropriate packaging during transport. |

| Machining Complexity | Its extreme hardness makes SiC difficult and costly to machine, requiring specialized tools and techniques. | Collaborate with manufacturers possessing advanced diamond grinding and lapping capabilities. Design for manufacturability to minimize complex machining. |

| Thermal Shock | While generally resistant, extreme and rapid temperature changes can induce thermal shock in certain SiC grades. | Select SiC grades with high thermal shock resistance (e.g., Reaction-Bonded SiC) for applications with rapid temperature fluctuations. Ensure proper thermal design of the overall system. |

| Cost | Compared to conventional materials, custom SiC products can have a higher upfront cost. | Focus on the long-term cost savings through extended lifespan, reduced downtime, and improved performance. Optimize design to minimize material waste. |

Partnering with an experienced custom silicon carbide manufacturer is key to effectively addressing these challenges and realizing the full potential of SiC rings.

Choosing the Right SiC Supplier

Selecting a reliable supplier for custom silicon carbide rings is a critical decision. A competent partner can significantly impact the quality, cost, and lead time of your components. Consider the following factors:

- Technical Expertise: Does the supplier have a deep understanding of SiC material science, manufacturing processes, and application engineering? Look for a team that can provide design assistance and material recommendations.

- Material Options: Can they offer a range of SiC grades (e.g., SSiC, RBSC, NBSC) to meet diverse application requirements?

- Manufacturing Capabilities: Do they possess advanced machining, grinding, lapping, and polishing capabilities for precise custom components?

- Quality Control: What quality assurance processes and certifications (e.g., ISO 9001) are in place to ensure consistent quality and dimensional accuracy?

- Customization Support: Do they offer comprehensive support for customizing support from initial design to final production?

- Industry Experience: Do they have a proven track record of supplying SiC components to your specific industry?

- Global Reach and Supply Chain: Can they reliably deliver products to your location and ensure a stable supply chain?

Speaking of reliable suppliers, it’s worth noting the significant role that Weifang City, China, plays in the global silicon carbide industry. Weifang is recognized as the hub of China’s silicon carbide customizable parts factories. This region has been home to over 40 silicon carbide production enterprises of various sizes, collectively accounting for more than 80% of the nation’s total silicon carbide output. This concentration of expertise and manufacturing capacity ensures a robust supply chain and competitive pricing for custom SiC products.

One company that stands out in this regard is Sicarb Tech. Sicarb Tech has been actively introducing and implementing silicon carbide production technology since 2015, assisting local enterprises in achieving large-scale production and technological advancements in product processes. They have been a witness to the emergence and ongoing development of the local silicon carbide industry. Based on the platform of the national technology transfer center of the Chinese Academy of Sciences , Sicarb Tech belongs to Chinese Academy of Sciences (Weifang) Innovation Park, a national-level innovation and entrepreneurship service platform integrating innovation, entrepreneurship, technology transfer, venture capital, incubation, acceleration, and scientific and technological services.

Sicarb Tech capitalizes on the robust scientific, technological capabilities and talent pool of the Chinese Academy of Sciences . Backed by the Chinese Academy of Sciences National Technology Transfer Center, they serve as a bridge, facilitating the integration and collaboration of crucial elements in the transfer and commercialization of scientific and technological achievements. Moreover, they have established a comprehensive service ecosystem that spans the entire spectrum of the technology transfer and transformation process. This translates to more reliable quality and supply assurance within China.

Sicarb Tech possesses a domestic top-tier professional team specializing in customized production of silicon carbide products. Under their support, 345+ local enterprises have benefited from their technologies. They possess a wide array of technologies, such as material, process, design, measurement & evaluation technologies, along with the integrated process from materials to products. This enables them to meet diverse customization needs and offer higher-quality, cost-competitive customized silicon carbide components in China. Furthermore, if you are considering establishing a professional silicon carbide products manufacturing plant in your country, Sicarb Tech can provide you with the technology transfer for professional silicon carbide production, along with a full range of services (turnkey project) including factory design, procurement of specialized equipment, installation and commissioning, and trial production. This enables you to own a professional silicon carbide products manufacturing plant while ensuring a more effective investment, reliable technology transformation, and guaranteed input-output ratio. You can explore their capabilities further by checking out their technology transfer services and case studies.

Cost Drivers and Lead Time Considerations

The cost and lead time for custom SiC rings are influenced by several factors:

- Material Grade: Higher purity and specialized SiC grades (e.g., SSiC) are typically more expensive than standard grades.

- Design Complexity: Intricate geometries, tight tolerances, and special features require more advanced machining and contribute to higher costs.

- Size and Volume: Larger rings and smaller batch sizes generally have a higher per-unit cost. Economies of scale apply to larger production runs.

- Surface Finish Requirements: Extensive grinding, lapping, and polishing for very fine finishes increase production time and cost.

- Supplier Capabilities: A supplier with optimized processes and efficient manufacturing can offer more competitive pricing and shorter lead times.

- Tooling Costs: For highly customized designs, initial tooling costs may be a factor, amortized over the production run.

- Shipping and Logistics: International shipping and specific logistical requirements can impact the overall cost and lead time.

Frequently Asked Questions (FAQ)

Here are some common questions regarding silicon carbide rings:

- What is the primary advantage of SiC rings over other ceramic or metal sealing materials?

The primary advantage of SiC rings lies in their unique combination of extreme hardness, superior wear resistance, excellent chemical inertness, and high thermal conductivity. This allows them to perform reliably in environments where other materials would quickly fail due to abrasion, corrosion, or high temperatures. - Are SiC rings resistant to all chemicals?

While SiC rings exhibit exceptional chemical inertness to a wide range of acids, bases, and solvents, there are a few exceptions, such as highly concentrated hydrofluoric acid at elevated temperatures. It’s always best to consult with the supplier regarding specific chemical compatibility for your application. - How do I determine the right SiC grade for my application?

Determining the right SiC grade depends on several factors, including operating temperature, pressure, chemical environment, required wear resistance, and cost. It’s highly recommended to consult with an experienced SiC manufacturer who can analyze your specific application requirements and recommend the most suitable grade. - What is the typical lifespan of a SiC ring?

The lifespan of a SiC ring varies significantly depending on the operating conditions (temperature, pressure, media, speed), the specific SiC grade, and the quality of the installation. However, properly designed and installed SiC rings are known for their exceptionally long service life, often outperforming traditional sealing materials by many times. - Can SiC rings be repaired or refurbished?

While minor surface damage or wear on SiC rings can sometimes be addressed through re-lapping or re-polishing, significant damage (cracks, chips) usually necessitates replacement. The cost-effectiveness of repair versus replacement depends on the extent of the damage and the complexity of the ring.

Conclusion

SiC rings are more than just components; they are critical consumables that enable industries to achieve higher levels of performance, reliability, and efficiency in the most challenging operating environments. Their unparalleled properties, combined with the flexibility of custom silicon carbide manufacturing, make them an indispensable solution for effective sealing across diverse sectors, from semiconductors to nuclear energy.

By understanding the nuances of SiC grades, design considerations, and the importance of partnering with a knowledgeable supplier like Sicarb Tech, engineers and procurement managers can make informed decisions that lead to significant long-term benefits. Investing in high-quality, custom SiC rings is an investment in enhanced operational longevity, reduced downtime, and ultimately, greater profitability for your industrial applications. For further inquiries or to discuss your specific custom silicon carbide needs, feel free to contact us.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.