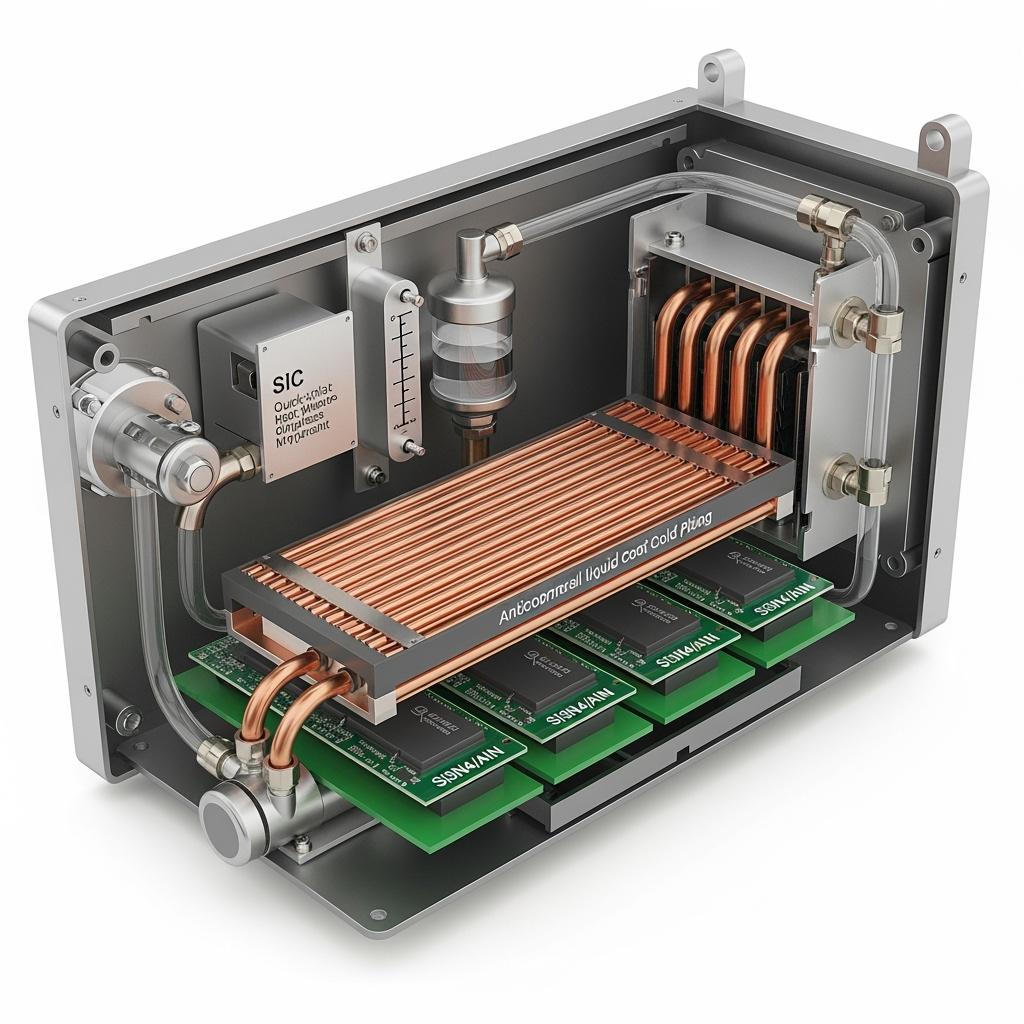

Modular Cooling Assemblies (Liquid/Air) for SiC Power Modules with Cold Plates and Dust-Resistant Heat Exchangers

Share

Product Overview and 2025 Market Relevance

Modular cooling assemblies purpose-built for silicon carbide (SiC) power modules combine high-performance cold plates, dust-resistant heat exchangers, and configurable pumps/fans to keep junction temperatures stable in harsh environments. For Pakistan’s textile, cement, and steel industries—where ambient conditions can exceed 45°C and airborne particulates are common—cooling is mission-critical to achieve ≥98.5% inverter efficiency, up to 2× power density, and MTBF targets of 200,000 hours.

SiC devices operate efficiently at higher switching frequencies (50–150 kHz), allowing smaller magnetic components and cabinets. However, higher power density elevates thermal flux, making liquid-cooled cold plates or ruggedized air-cooling essential. In 2025, as Pakistan scales distribution-level PV interconnections (11–33 kV) and modernizes industrial drives, operators need compact, maintainable cooling subsystems that sustain performance in dusty electrical rooms and rooftop inverters. Modular assemblies with field-replaceable filters, corrosion-resistant materials, and smart controls directly reduce derating, HVAC load, and maintenance time.

Technical Specifications and Advanced Features

- Thermal performance:

- Cold plate thermal resistance: as low as 0.02–0.05 K/W per module footprint (application-dependent)

- Liquid loop ΔT (supply–return): typically 3–8 K with variable-speed pumping

- Air-side heat exchanger optimized for high-dust environments with wide-fin spacing to reduce clogging

- Mechanical and materials:

- Cold plate materials: copper (nickel-plated) or aluminum (hard-anodized) for corrosion control

- Seals and hoses: FKM/EPDM and reinforced hoses rated for industrial coolants and temperature cycling

- Quick-service architecture: tool-less filter access, dripless couplings for field service

- Fluids and environment:

- Coolants: deionized water with inhibitors, glycol–water mixes for temperature extremes

- Operating temperature: -20°C to +60°C ambient for cooling assembly; supports junction operation to +175°C

- Sensing and control:

- Flow, pressure, and temperature sensors with alarms for low flow, high ΔP (filter clog), high temp

- Optional CAN/Modbus interface for inverter controller integration and predictive maintenance

- Reliability and safety:

- Redundant pump/fan options for critical loads

- Leak detection trays and conductivity sensors

- IP55–IP65 enclosures for outdoor/rooftop inverters

- Compliance support:

- Designed to help meet THD and efficiency targets by stabilizing junction temperatures under high-frequency operation

Descriptive Comparison: Liquid vs Air Modular Cooling for SiC Inverters and Drives

| Criterion | Liquid-cooled cold plate with dust-resistant heat exchanger | Ruggedized air-cooled heatsink with dust-resistant fins |

|---|---|---|

| Power density support | Highest; best for compact MV cabinets | Moderate; larger heatsinks needed |

| Thermal resistance | Lowest; tight junction control | Higher; may require derating at 45°C+ |

| Maintenance | Filter wash/replace; coolant checks | Filter cleaning; fewer wetted parts |

| Dust handling | Plate HX outside cabinet with wide fins minimizes clogging | Wide-fin heatsinks mitigate but need frequent cleaning in heavy dust |

| Noise and HVAC load | Lower cabinet airflow demand | Higher airflow, potentially louder |

| Typical use cases | 500 kW+ PV inverters, steel/cement heavy drives | Rooftop inverters, sites with limited access to liquid loops |

Key Advantages and Proven Benefits with Expert Quote

- Higher efficiency and uptime: Stable junction temperatures minimize conduction and switching loss drift, sustaining ≥98.5% system efficiency.

- Compact installation: Efficient heat removal supports up to 2× power density and about 40% reduction in cooling volume compared to legacy silicon-based systems.

- Dust resilience: Wide-fin, pre-filtered exchangers and sealed loops reduce fouling and extend maintenance intervals in harsh environments.

- Predictive maintenance: Sensor-rich modules flag clogged filters, low flow, or rising ΔT early, protecting modules and extending service life.

Expert perspective:

“Thermal management remains a decisive factor for realizing the benefits of wide bandgap power electronics. Robust, maintainable cooling systems are essential to unlock higher switching frequencies and power density while preserving reliability.” — IEEE Power Electronics Society technical viewpoints (ieee.org)

Real-World Applications and Measurable Success Stories

- MV PV inverter pilot (Balochistan): Transition to liquid-cooled cold plates with dust-resistant plate heat exchangers contributed to 98.7% operating efficiency and ~40% reduction in equipment volume, enabling rooftop deployment in constrained spaces.

- Textile VFD racks (Punjab): Dust-resistant air-cooled assemblies with washable pre-filters reduced thermal trips during summer peaks and cut filter maintenance by an estimated 30%.

- Cement plant ID/FD fan drives: Redundant pump loops maintained thermal stability during process upsets, improving uptime and reducing unplanned stoppages.

- Steel re-rolling lines: Stabilized junction temperatures reduced drift in gate-drive settings and improved long-term device parameter consistency under frequent load transients.

Selection and Maintenance Considerations

- Thermal sizing:

- Calculate worst-case heat dissipation at target switching frequency (50–150 kHz) and ambient 45–50°C.

- Choose cold plate geometry (microchannel vs pin-fin) based on pressure drop and coolant quality.

- Environmental fit:

- High-dust sites: prefer liquid loops with external, wide-fin exchangers; add differential pressure sensing across filters.

- Water-limited sites: rugged air-cooling with high-IP fans and easily serviceable pre-filters.

- Materials and fluids:

- Match coolant chemistry to materials to prevent corrosion; maintain resistivity for deionized loops.

- Use plated or anodized surfaces for longevity.

- Controls and monitoring:

- Integrate pump/fan control with inverter logic for load-based modulation.

- Implement alarms for flow, ΔP, and temperature thresholds; log data for SPC and predictive maintenance.

- Service planning:

- Establish cleaning cadence based on dust load (visual inspection and ΔP trend).

- Stock critical spares: filters, hoses, pumps/fans, and seal kits for rapid turnaround.

Industry Success Factors and Customer Testimonials

- Co-design with power module packaging and layout teams ensures even thermal spreading and minimal thermal interface resistance.

- Early CFD and FEA thermal simulations de-risk cabinet integration and accelerate commissioning.

Customer feedback:

“Our MV inverter cooling upgrade stabilized junction temperatures through heatwaves. The washable pre-filters and flow alarms cut maintenance calls and kept production on track.” — Operations manager, industrial park in southern Pakistan

Future Innovations and Market Trends

- Integrated cold plates with embedded temperature sensors and microchannel topologies for lower thermal resistance

- Corrosion-tolerant coatings and smart inhibitors tailored for long-life DI loops

- Predictive maintenance via machine learning on flow/temperature/ΔP signals to prevent fouling-related derating

- Localized manufacturing and assembly of modular cooling skids to support Pakistan’s >5 GW MV PV expansion and USD 500 million inverter market

Common Questions and Expert Answers

- How do I choose between liquid and air cooling?

Use liquid cooling for high power density, MV cabinets, and enclosed rooms with dust; use rugged air cooling when water infrastructure is limited and power density is moderate. - What is the impact on efficiency?

Maintaining lower junction temperatures reduces conduction and switching losses, helping achieve ≥98.5% system efficiency with SiC-based designs. - How are dust-resistant exchangers different?

They use wide-fin spacing, removable pre-filters, and fan control to resist clogging and maintain airflow in dusty environments. - What maintenance is required?

Regular filter cleaning/replacement, coolant quality checks (conductivity, inhibitor concentration), and inspection of hoses/seals. Sensor alarms guide service intervals. - Can the system operate reliably above 45°C ambient?

Yes. Properly sized cold plates and heat exchangers, combined with variable-speed pumps/fans, maintain thermal margins up to 50°C ambient and support +175°C junction operation.

Why This Solution Works for Your Operations

Modular cooling assemblies engineered for SiC enable compact, efficient, and reliable power conversion across Pakistan’s industrial landscape. By pairing low-resistance cold plates with dust-resistant heat exchangers and intelligent controls, operators reduce derating, shrink cabinet size, and extend equipment life—delivering measurable gains in uptime, LCOE reduction, and maintenance efficiency for 11–33 kV PV inverters and mission-critical drives in textile, cement, and steel facilities.

Connect with Specialists for Custom Solutions

Partner with a team that delivers end-to-end thermal solutions for SiC:

- 10+ years of SiC manufacturing expertise with deep thermal design experience

- Backing from a leading research ecosystem for rapid innovation and validation

- Custom product development across R-SiC, SSiC, RBSiC, and SiSiC thermal and structural components

- Technology transfer and factory establishment services for local cooling assembly production

- Turnkey delivery from materials and modules to cooling, testing, and integration

- Proven track record with 19+ enterprises achieving higher efficiency and reliability

Get a free consultation and a tailored cooling architecture proposal:

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Act now to secure design slots for upcoming 2025–2026 MV inverter and industrial drive programs. Early engagement accelerates thermal validation and de-risks commissioning.

Article Metadata

Last updated: 2025-09-10

Next scheduled update: 2026-01-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.