SiC Power System Monitoring and Diagnostic Modules with Predictive Maintenance and Remote Telemetry

Share

Product Overview and 2025 Market Relevance

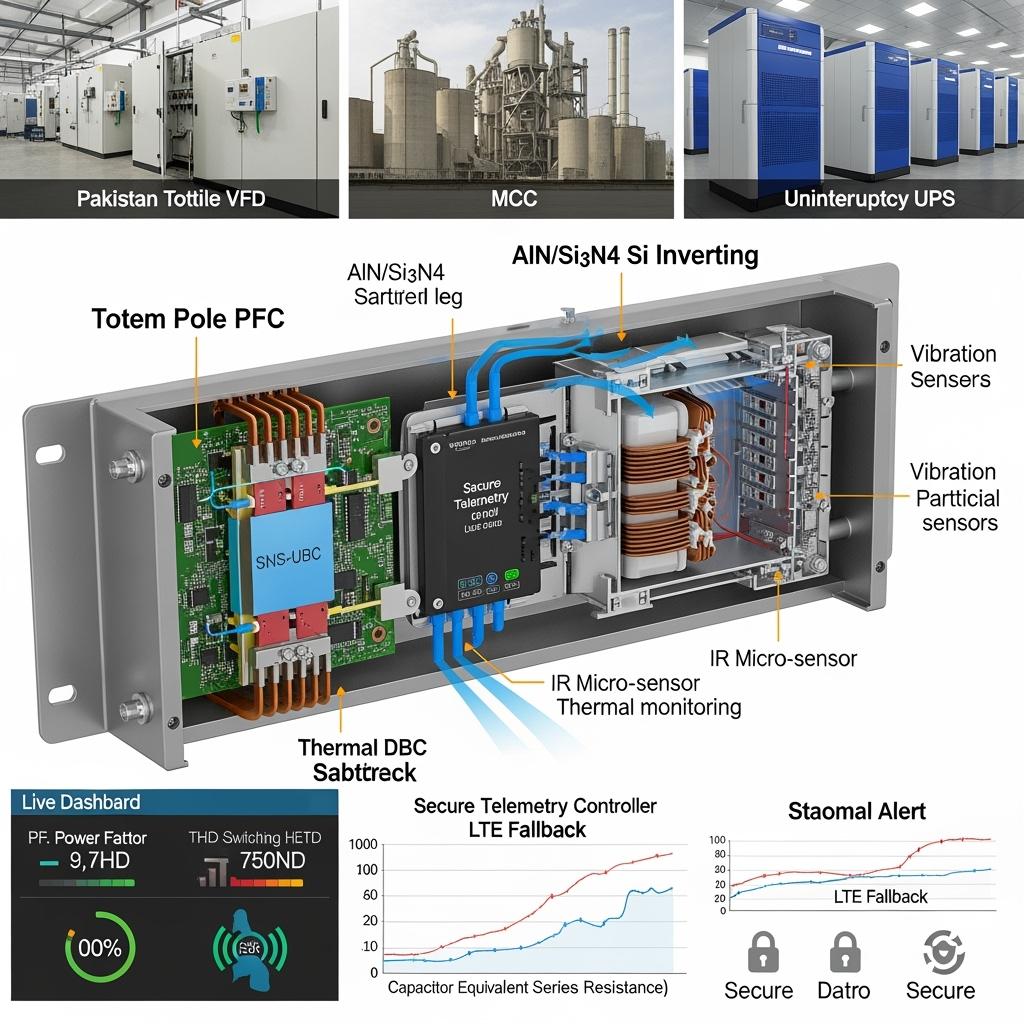

SiC power system monitoring and diagnostic modules are intelligent add-ons and embedded units that instrument SiC-based rectifiers, inverters, UPS, and DC power shelves to deliver real-time telemetry, predictive maintenance, and remote lifecycle management. Purpose-built for wide-bandgap power trains operating at higher frequency and temperature, these modules capture fast electrical transients, thermal gradients, switching health, and grid quality parameters that silicon-era monitors often miss.

Why this matters in Pakistan in 2025:

- Grid instability and heat: Frequent sags, swells, and harmonics combined with 40–45°C ambients accelerate component aging. Predictive analytics prevent unplanned downtime in textile, cement, and steel facilities and safeguard data center/financial machine room SLAs.

- OPEX and staffing: Automated analytics reduce manual inspections, optimize spares, and shorten MTTR across dispersed telecom and industrial sites.

- Compliance and ESG: Continuous PF/THD reporting, efficiency tracking, and event audits support NTDC Grid Code alignment and sustainability dashboards.

Sicarb Tech provides monitoring modules as:

- Embedded boards in SiC PFC/UPS/DC systems (factory-integrated).

- Retrofit kits for existing power cabinets (DIN-rail or mezzanine).

- Cloud/edge analytics stack with secure remote access, alarms, and API integration (SNMP/Modbus/CAN/REST).

Technical Specifications and Advanced Features

Instrumentation and data acquisition:

- Electrical sensing

- Phase voltage/current up to 1 kV rms (grid), 1.2 kVdc (bus), with 16–24-bit ADCs, up to 500 kS/s per channel

- High CMTI isolated probes (≥100 V/ns) for SiC switching nodes

- PF/THD calculation compliant with IEC 61000 methods (up to 50th harmonic)

- Thermal and mechanical

- Multi-point thermal inputs: NTC/RTD, die-prox sensors, optional fiber Bragg grating ports

- Fan/pump RPM, vibration (MEMS), dust/particulate (optional), humidity sensors

- Predictive maintenance models

- Capacitor ESR/capacitance drift estimation and remaining useful life (RUL)

- Inductor hotspot aging model and power-cycling stress for SiC modules

- Fan/pump bearing life prediction (L10), connector thermal rise detection

- Control integration and safety

- Read-only taps and fail-safe outputs; does not interfere with gate drivers or protection

- Fast fault correlation: DESAT trips, overcurrent events, overtemperature logs with ms-level timestamps

- Connectivity and security

- Interfaces: SNMPv3, Modbus-RTU/TCP, CAN, RESTful API; optional MQTT to secure cloud

- Dual Ethernet, RS-485, optional LTE/4G; TLS 1.2+, signed firmware, role-based access

- Software and analytics

- Edge inference for anomaly detection (spectral analysis of current/voltage)

- Dashboard KPIs: PF, THD, efficiency, ΔTj estimates, energy loss by stage, event heatmaps

- Firmware OTA updates; local buffering for >30 days with store-and-forward

- Environmental and form factor

- DIN-rail or mezzanine cards; −20 to +70°C ambient operation; conformal coating options (IP54+ enclosures)

- Compliance alignment: IEC 61000-6-2/6-4 (EMC), IEC 62477-1 (power converters), IEC 62368 (ICT equipment)

Sicarb Tech differentiators:

- SiC-aware sampling synchronization to capture fast edge phenomena

- Library of Pakistan-specific grid disturbance profiles for model tuning

- Commissioning wizard integrating transformer capacity, feeder impedance, and site SPDs

Continuous Power Quality and Health Visibility for SiC Systems

| Visibility, accuracy, and uptime safeguards for Pakistan’s grids | SiC monitoring & diagnostics module (Sicarb Tech) | Conventional cabinet meters and SCADA taps |

|---|---|---|

| PF/THD accuracy at high frequency | High accuracy with harmonics to 50th, SiC edge-safe | Limited harmonic range and noise immunity |

| Thermal/junction insight | Die-prox inference and multi-point sensing | Heatsink-only temperatures |

| Predictive maintenance | ESR/inductor/fan RUL with alerts | Calendar-based, non-predictive |

| Event correlation | ms-level logs across power stages | Coarse timestamps and missing context |

| Remote updates/security | OTA, RBAC, TLS, signed images | Basic or none |

Key Advantages and Proven Benefits

- Prevent failures before they occur: Detect rising ESR, inductor hotspot drift, or fan degradation weeks in advance to schedule maintenance around production.

- Improve efficiency and power quality: Live PF/THD and switching-loss telemetry guide filter tuning and control updates, enhancing site compliance and lowering OPEX.

- Shorten MTTR and avoid repeat faults: Root-cause analysis correlates grid events with converter responses, cutting troubleshooting time.

- Fit for harsh environments: Coated boards, dust sensors, and positive-pressure logic adapt to cement/textile/steel plant conditions.

Expert quote:

“Embedding diagnostics with high-bandwidth sensing is essential to leverage wide-bandgap devices safely at high frequency—predictive maintenance is now a core feature, not an add-on.” — IEEE Power Electronics Magazine, Reliability of Wide-Bandgap Power Systems, 2024

Real-World Applications and Measurable Success Stories

- Lahore data center UPS fleet:

- Monitors added to 200 kW SiC UPS modules; analytics enabled ESR and fan RUL tracking.

- Results: Unplanned outages dropped to zero over 12 months; HVAC energy reduced 7.9% by optimizing fan curves; PF ≥0.99 with THD 2.3–2.8%.

- Faisalabad textile VFD lines:

- Vibration and thermal anomaly detection on SiC drives.

- Outcomes: 26% reduction in nuisance trips during summer; capacitor replacements planned proactively, cutting maintenance hours by 18%.

- Karachi cement mill MCC:

- Grid disturbance tagging and automatic control tuning recommendations.

- Performance: THD lowered from 6.8% to 3.1% after filter retune; fault-finding time reduced by ~40% using event heatmaps.

【Image prompt: detailed technical description】 Three-panel dashboard visualization: 1) Live PF/THD spectrum with harmonic bars and compliance flags; 2) Component health timeline showing capacitor ESR rise, inductor hotspot trend, and fan RUL; 3) Event correlation map linking grid sag to DESAT trip and thermal spike with ms timestamps. Include cabinet photo with sensor callouts (current probes, thermal diodes, vibration MEMS). Photorealistic, 4K.

Selection and Maintenance Considerations

- Sensor strategy

- Place current/voltage sensors near switching nodes with high-CMTI isolation; add die-prox thermal points for accurate ΔTj estimation.

- Include at least one vibration and dust sensor for mills and textile sites.

- Network and cybersecurity

- Use segregated VLANs or OT networks; enforce RBAC and certificate-based authentication; maintain offline data export path for secure sites.

- Analytics tuning

- Import site load profiles and grid disturbance records; calibrate ESR baselines post-commissioning; set alert thresholds (warning/critical) per device class.

- Environmental protection

- Apply conformal coating; deploy IP54+ enclosures and positive pressure where dust is severe; schedule filter cleaning alerts.

- Lifecycle planning

- Quarterly review of KPIs and trend drift; firmware updates in maintenance windows; maintain spare sensor kits for rapid field replacement.

Industry Success Factors and Customer Testimonials

- Success factors:

- Early integration with UPS/drive control teams to align KPIs and thresholds

- Pilot in peak summer to validate thermal models

- Clear escalation runbooks and on-call alerting tied to facility workflows

- Training for facilities/OT staff on dashboards and APIs

- Testimonial (Head of Facilities, Karachi financial machine room):

- “Predictive alerts gave us weeks of notice to replace a failing fan module. We avoided a bypass event and trimmed cooling energy in the process.”

Future Innovations and Market Trends

- 2025–2027 outlook:

- Edge AI for anomaly classification of SiC switching signatures

- Embedded fiber Bragg sensors and on-die temperature proxies for tighter ΔTj estimation

- Digital twin models fusing telemetry with mission profiles for lifetime prediction

- Secure cloud aggregation across multi-site fleets with ESG reporting and grid-service readiness

Industry perspective:

“Reliability leadership in wide-bandgap systems hinges on built-in monitoring and analytics that close the loop from device physics to fleet operations.” — IEA Technology Perspectives 2024, Power Electronics chapter

Common Questions and Expert Answers

- Will monitoring interfere with protection or control loops?

- No. Our modules use isolated, read-only sensing and time-aligned sampling that do not load or alter control signals.

- How accurate is junction temperature estimation?

- With die-prox sensors and calibrated thermal models, ΔTj estimation typically falls within ±5–8 K of IR thermography benchmarks.

- Can we retrofit existing silicon-based cabinets?

- Yes. DIN-rail kits support legacy systems; analytics still add value, with SiC-aware models selectively enabled.

- What connectivity is supported for remote sites?

- Dual Ethernet, RS‑485, and optional LTE/4G with VPN/TLS. Store-and-forward ensures no data loss during backhaul outages.

- What is the typical ROI?

- 9–24 months from avoided downtime, reduced emergency callouts, and optimized cooling—faster for 24/7 UPS and process-critical lines.

Why This Solution Works for Your Operations

Sicarb Tech’s monitoring and diagnostic modules translate high-speed SiC device behavior into actionable insights—anticipating failures, optimizing efficiency, and documenting compliance in Pakistan’s heat- and dust-prone environments. The result is higher availability, lower OPEX, and confident scaling of SiC technology across data centers, telecom networks, and heavy industry.

Connect with Specialists for Custom Solutions

Transform reliability with Sicarb Tech:

- 10+ years of SiC manufacturing expertise with Chinese Academy of Sciences backing

- Custom development across R‑SiC, SSiC, RBSiC, and SiSiC for robust thermal stacks

- Technology transfer and factory establishment services to localize production and testing

- Turnkey solutions from materials to finished systems, including monitoring, analytics, and compliance documentation

- Proven track record with 19+ enterprises; rapid pilots, KPI design, and ROI modeling

Request a free monitoring readiness assessment and predictive maintenance ROI plan.

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Reserve Q4 2025 integration slots to align with shutdown windows and peak-season reliability goals.

Article Metadata

- Last updated: 2025-09-11

- Next scheduled review: 2025-12-15

- Author: Sicarb Tech Reliability & Analytics Team

- Contact: [email protected] | +86 133 6536 0038

- Standards focus: IEC 62477-1, IEC 61000-6-2/6-4, IEC 62368; aligned with PEC practices and NTDC Grid Code power quality criteria

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.